Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for MAN Diesel & Turbo L28/32H

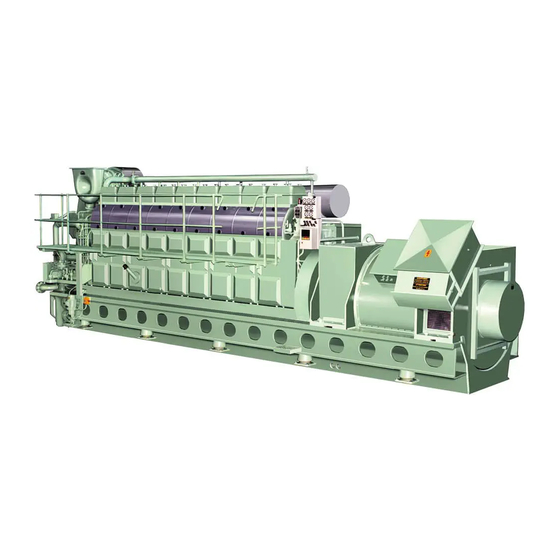

- Page 1 L28/32H Instruction Manual - Marine Four-stroke GenSet compliant with IMO Tier II...

- Page 2 MAN Diesel GenSet Index L28-2 Text Index Drawing No. Engine data 500/600 Preface Description A6000 Warning Description A6001 Questionnaire Description A6002 Main particulars Description 600.00 (07H) Introduction Description 600.01 (08H) Safety Description 600.02 (06H) Cross section Description 600.05 (07H) Key for engine designation Description 600.10 (02H) Designation of cylinders...

- Page 3 MAN Diesel Index GenSet L28-2 Text Index Drawing No. Quality requirem. for lube oil (SAE30) for operation with gas oil, diesel Description 604.01 (26H) oil (MGO/MDO) and biofuel Treatment and maintenance of lubricating oil Description 604.03 (11H) Criteria for cleaning/exchange of lubricating oil Description 604.04 (17H) Lubricating points...

-

Page 4: Table Of Contents

MAN Diesel GenSet Index L28-2 Text Index Drawing No. Camshaft 507/607 Camshaft and camshaft drive Description 607.01 (05H) Camshaft and camshaft drive Working card 607-01.00 (01H) Inspection and replacement of camshaft bearing Working card 607-01.05 (01H) Adjustment of camshaft for valve and injection timing Working card 607-01.20 (04H) Intermediate wheel... - Page 5 MAN Diesel Index GenSet L28-2 Text Index Drawing No. Inspection of main bearing shells Working card 610-01.05 (05H) Inspection of guide bearing shells Working card 610-01.10 (08H) Vibration damper Working card 610-04.00 (01H) Crankshaft Plate 61001-15H Crankshaft Plate 61001-21H Resilient gear wheel Plate 61002-07H Coupling for central drive lub.

- Page 6 MAN Diesel GenSet Index L28-2 Text Index Drawing No. Exhaust pipe arrangement with welded compensator Plate 61202-28H Exhaust pipe arrangement Plate 61202-27H Exhaust pipe arrangement with welded compensator Plate 61202-42H Water washing of compressor side Plate 61205-02H Steam trap Plate 61208-01H Blowgun for dry cleaning of turbocharger Plate...

- Page 7 MAN Diesel Index GenSet L28-2 Text Index Drawing No. Lubricating oil, thermostatic valve Working card 615-01.20 (01H) Check of lubricating oil piping system Working card 615-01.90 (01H) Lubricating oil cooler Working card 615-06.00 (02H) Centrifugal by-pass filter Working card 615-15.00 (01H) Lubricating oil pump (central driven) Plate 61501-12H...

- Page 8 MAN Diesel GenSet Index L28-2 Text Index Drawing No. Tool combinations for tightening of connecting rod screws Working card 620-01.20 (01H) Max. pressure indicator Working card 620-01.25 (02H) Tools for cylinder head Plate 62005-03H Tools for piston, connecting rod and cylinder liner Plate 62006-11H Tools for operating gear for inlet valves, exhaust valves and fuel...

-

Page 9: Engine Data

Engine data 500/600... - Page 10 MAN Diesel & Turbo Instruction Manual for: MAN Diesel & Turbo Identification No. for Instruction Manual. 000 . 00 Identification No. for Description: Function Section No. 000 - 00 . 00 Identification No. for Working Card: Sub-function Function Section No. 00000 - 00 H Identification No.

- Page 11 MAN Diesel & Turbo MAN Diesel & Turbo | PrimeServ The MAN Diesel & Turbo Group offers worldwide round-the-clock service, 365 days a year. Apart from the MAN Diesel & Turbo service headquarters in Augsburg, Copenhagen, Frederikshavn, Holeby, Stockport, St. Nazaire, Tur- bocharger and service centres on all continents provide comprehensive and continuous support.

- Page 12 MAN Diesel & Turbo Description Warning Page 1 (1) General Warning ! (Marine engines only) It is important that all MAN Diesel & Turbo engines are operated within the given specifications and performance tolerances specified in the engines' Technical Files and are maintained according to the MAN Diesel &...

- Page 13 MAN Diesel & Turbo Questionnaire – Technical Documentation Your opinion counts! Your opinion is valuable to us as it helps us to evaluate our services and to continuously improve the quality of our Technical Documentation. May we ask you for a few minutes of your time to complete and then return this questionnaire to TechDoc@mandieselturbo.com: Your company: Very...

- Page 14 MAN Diesel & Turbo 600.00 Description Main Particulars Page 1 (1) Edition 07H L28/32H Cycle 4-stroke Configuration In-line Cyl. Nos. available 5-6-7-8-9 Power range 1050-1980 kW Speed 720/750 rpm Bore 280 mm Stroke 320 mm Stroke/bore ratio 1.14:1 Piston area per cyl. 616 cm Swept volume per cyl. 19.7 ltr. Compression ratio 13.9:1 Max. combustion pressure 130 bar Turbocharging principle Constant pressure system and inter c ool i ng Fuel quality acceptance HFO (up to 700 cSt/50° C, RMK700)

- Page 15 MAN Diesel & Turbo 600.01 Description Introduction Page 1 (1) Edition 08H General Introduction Description This instruction book provides general information The book is a basic instruction manual for the particu- on the engine design, operation and maintenance. lar engine supplied, with plant-adapted infor mation It can also be used as a reference when ordering such as basic media-system drawings, electrical spare parts.

-

Page 16: Cylinder Head

MAN Diesel 600.02 Description Safety Page 1 (2) Edition 06H General Spares General Large spare parts should, as far as possible, be pla- Proper maintenance, which is the aim of this book, ced well strapped near the area of application and constitutes the crucial point in obtaining optimum accessible by crane. - Page 17 MAN Diesel 600.02 Description Safety Page 2 (2) Edition 06H General Feeling over Turning with air Whenever repairs or alterations have been made to After prolonged out-of-service periods or overhaul the running gear, apply the "Feel-over sequence" work which may involve a risk of accumulation of until ensured that there is no undue heating, oil- liquid in the combustion spaces, turning with open mist formation, blow-by, or failure of cooling water...

- Page 18 MAN Diesel & Turbo 600.05 Description Cross Section Page 1 (1) Edition 07H L28/32H 10.36 - ES1...

- Page 19 MAN Diesel 600.10 Description Key for Engine Designation Page 1 (1) Edition 02H General Engine Type Identifi cation The engine types of the MAN B&W programme are identifi ed by the following fi gures: 28/32 No of cylinders 5, 6, 7, 8, 9 12, 16, 18 Engine Type In-line...

- Page 20 MAN Diesel 600.11 Description Designation of Cylinders Page 1 (1) Edition 01H L28/32H Flywheel end Front End Exhaust Side / Right Side Control Side / Camshaft Side / Left Side 89.17 - ES1S-L...

- Page 21 MAN Diesel & Turbo 600.12 Description Engine Rotation Clockwise Page 1 (1) Edition 02H General Direction of rotation seen from flywheel end “Clockwise” Engine Alternator 10.39 - ES1...

- Page 22 MAN Diesel & Turbo 600.20 Description Code Identification for Instruments Page 1 (2) Edition 03H General Explanation of Symbols Measuring device Local reading Temperature Indicator No. 40 * Measuring device Sensor mounted on engine/unit Reading/identification mounted in a panel on the engine/unit Pressure Indicator No.

- Page 23 MAN Diesel & Turbo 600.20 Code Identification for Instruments Description Page 2 (2) Edition 03H General Standard Text for Instruments Diesel Engine/Alternator LT Water System 01 inlet to air cooler 04 inlet to alternator 07 inlet to lub. oil cooler 02 outlet from air cooler 05 outlet from alternator 08 inlet to fresh water cooler (SW)

- Page 24 MAN Diesel 600.24 Description Introduction to Planned Maintenance Programme Page 1 (1) Edition 02H General General Related procedures - indicates other works, depending on this work - or works which would be The overhaul intervals are based on operation on expedient to carry out.

- Page 25 MAN Diesel 600.25 Description Planned Maintenance Program Page 1 (4) Edition 33H L28/32H Time Between Overhaul Working = Overhaul to be carried out Description ● Card = Check the condition ■ Operating of Engine: Readings of data for Engine and Generator, with refe- rence to "Engine Performance Data", section 602-1 ..

- Page 26 MAN Diesel 600.25 Description Planned Maintenance Program Page 2 (4) Edition 33H L28/32H Time Between Overhaul Working = Overhaul to be carried out Description ● Card = Check the condition ■ Operating Gear for Inlet Valves, Exhaust Valves and Fuel Injection Pumps: Roller guide for valve gear ..........

- Page 27 MAN Diesel 600.25 Description Planned Maintenance Program Page 3 (4) Edition 33H L28/32H Time Between Overhaul Working Description = Overhaul to be carried out ● Card = Check the condition ■ Engine Frame and Bedplate: Holding down bolts - Retightening, see page 600.40 ..

- Page 28 MAN Diesel 600.25 Description Planned Maintenance Program Page 4 (4) Edition 33H L28/32H Time Between Overhaul Working = Overhaul to be carried out Description ● Card = Check the condition ■ Fuel Oil System and Injection Equipment: Fuel oil filter - Dismantling and cleaning ......

- Page 29 MAN Diesel & Turbo 600.30 Description Operation Data & Set Points Page 1 (2) Edition 50H L28/32H Acceptable Normal Value at Full load value at shop Alarm Set point Autostop of engine at ISO conditions test or after repair Lubricating Oil System Temp.

- Page 30 MAN Diesel & Turbo 600.30 Descriptoin Operation Data & Set Points Page 2 (2) Edition 50H L28/32H Acceptable Normal Value at Full load value at shop Alarm Set point Autostop of engine at ISO conditions test or after repair Speed Control System...

- Page 31 MAN Diesel & Turbo 600.33 Description "Green Passport" Page 1 (1) Edition 02H General In 2009 IMO adopted the „Hong Kong International Convention for the Safe and Environmentally Sound Recycling of Ships, 2009“ Until this convention enters into force the recommen- datory guidelines “Resolution A.962(23)”...

-

Page 32: Camshaft

MAN Diesel & Turbo 600.35 Description Data for Pressure and Tolerance Page 1 (2) Edition 16H L28/32H Section Description mm. / bar Safety valve to be adjusted to 170 bar Maximum inner diameter, valve guide 18.35 mm. For grinding of valve spindle and valve seat ring (see also working card 605-01.10) - Page 33 MAN Diesel & Turbo 600.35 Data for Pressure and Tolerance Description Page 1 (2) Edition 16H L28/32H Section Description mm. / bar Maximum combustion pressure at full load Max 133 bar Individual cylinders; admissible deviation from average ± 3 bar A change of the height of the thrust piece spacer ring of 0.10 mm.

- Page 34 Main bearing stud (in frame) Stud M 56 Loctite 243 Molykote Nut for main bearing stud M 52 x 3 (Unimol gl 82) Main bearing side screw - L28/32H Screw M 24 – Main bearing side screw - V28/32H Screw M 30 –...

- Page 35 Gear wheel on lub. oil pump M 30 x 2 (Unimol gl 82) Impeller and gear wheel on fresh- water cooling pump - L28/32H M 24 x 1.5 – Impeller and gear wheel on fresh- water cooling pump - V28/32H M 33 x 2 –...

- Page 36 MAN Diesel & Turbo 600.45 Description Declaration of Weight Page 1 (1) Edition 01H L28/32H Section Component Plate No. Item No. Weight in Kg. Cylinder Head, incl. rocker arms 60501-60502 60508-60510 Piston, complete 60601 Piston Pin 60601 Connecting Rod, complete...

- Page 37 MAN Diesel & Turbo 600.50 Description Ordering of Spare Parts Page 1 (2) Edition 06H General Spare parts can be ordered from MAN Diesel & Note: Turbo, PrimeServ. • Components from different engine builders When spare parts are ordered or inquired, the fol- cannot be considered as interchangeable.

- Page 38 MAN Diesel & Turbo 500.50 600.50 Description Ordering of Spare Parts Page 2 (2) Edition 03 Edition 06H General Name of customer Name of Plant/Vessel IMO No Engine type Engine No Engine Builder Plate No Edition No Item No Designation of the Item No Qty.

- Page 39 MAN Diesel & Turbo 600.51 Description How to Return Spare Parts and/or Tools Page 1 (1) Edition 05H General How to return spare parts and/or tools If you return to Holeby instead of Frederikshavn, If the unfortunate situation occurs that your spare you will have to pay freight charges of minimum parts do not fit or is damaged in any way, you need EUR 70,-...

- Page 40 MAN Diesel 600.55 Description Service Letters Page 1 (1) Edition 01H General Description Since new service letters might be of great impor- In order to ensure the most effi cient, economical and tance to the operation of the plant, we recommend up-to-date operation of our engines, we regularly send that engine staff fi...

- Page 41 MAN Diesel 600.60 Description Conversion Table Page 1 (3) Edition 01 General Basic Sl Units Velocity, Speed (m/s) (3.6 km/h = 1 m/s) Quantity Name Symbol 1 kn (knot) = 1 nautical mile/h 1.852 km/h = 0.5144 m/s Cincerning other conversions, see table for length length metre mass kilogram...

- Page 42 MAN Diesel 600.60 Description Conversion Table Edition 01 Page 2 (3) General Power (1 kg m = 1 N m/s = 1 J/s = 1 W) Specifi c heat capacity (J/(kg K)) 1 kpm/s 9.807 1 kcal /(kg x °C) 4.187 x 10 J/(kg K) I.T.

- Page 43 MAN Diesel 600.60 Description Conversion Table Page 3 (3) Edition 01 General Volume (1 m = 1000 l) 1 cub. in (cubic inch) 16.39 x 10 1 cub. ft (cubic foot) 28.32 x 10 = 28.32 l 1 gallon* (imperial, UK) 4.546 x 10 = 4.546 l 1 gallon* (US)

- Page 44 MAN Diesel 600.65 Description Basic Symbols for Piping Page 1 (3) Edition 01H General Symbol Symbol designation Symbol Symbol designation 2.14 Spectacle fl ange 1. GENERAL CONVENTIONAL SYMBOLS Pipe 2.15 Orifi ce Pipe with indication of direction of fl ow 2.16 Orifi...

- Page 45 MAN Diesel 600.65 Description Basic Symbols for Piping Page 2 (3) Edition 01H General Symbol Symbol designation Symbol Symbol designation 3.17 Double-seated changeover valve 4. CONTROL AND REGULATION PARTS Suction valve chest 3.18 Fan-operated 3.19 Suction valve chest with non-return valves Remote control 3.20 Double-seated changeover valve, straight...

- Page 46 MAN Diesel 600.65 Description Basic Symbols for Piping Page 3 (3) Edition 01H General Symbol Symbol designation Symbol Symbol designation Gear or screw pump 6. FITTINGS Funnel / waste tray Hand pump (bucket) Drain Ejector Waste tray 5.10 Various accessories (text to be added) Waste tray with plug 5.11 Piston pump...

- Page 47 Operation of engine 501/601...

- Page 48 MAN Diesel 601.01 Description Operating Page 1 (3) Edition 21H L+V28/32H Preparations for Starting The following describes what to do before starting, Open the fuel oil supply to the feed pump. when the engine has been out of service for a lon- ger period of time, or if major overhauls has been Starting on HFO: circulate preheated fuel through made.

- Page 49 MAN Diesel 601.01 Description Operating Page 2 (3) Edition 21H L+V28/32H Starting The exhaust gases should be free from smoke at all loads. For normal exhaust temperatures, see Start the engine, by activating the start but- the test sheet from shop and sea trials. tom.

- Page 50 MAN Diesel 601.01 Description Operating Page 3 (3) Edition 21H L+V28/32H Starting on MDO For starting on MDO there are no restrictions except lubricating oil viscosity may not be higher than 1500 cSt (5° C SAE 30, or 10° C SAE 40). Initial ignition may be diffi...

- Page 51 MAN Diesel 601.05 Description Out-of Service Page 1 (2) Edition 17H General Stand-by Engines 4.3. Open up all fi lters to check that fi lter elements are intact. Filter cartridges in the lub. oil fi lter is to be During engine standstill in stand-by position, the replaced before start after repair or due to excessive media cooling water, fuel oil and nozzle oil should differential pressure.

- Page 52 MAN Diesel 601.05 Description Out-of Service Page 2 (2) Edition 17H General The differential pressure across the lub. oil fi lter b) Adjustment speed: Switch-in generator on must be watched very carefully after cleaning and the switchboard and set the load to about 40%. On star ting-up the engine.

- Page 53 MAN Diesel 601.10 Description Starting-up after Out of Service Periods Page 1 (1) Edition 17H L+V28/32H The following enumerates checks are to be made After the last feel-over, repeat check 4 page 601.05, im mediately after starting, during load increase, and see also Ignition in Crankcase page 603.04 in sec- during normal running.

- Page 54 MAN Diesel & turbo 601.15 Description Guidelines for Longterm Low-Load Operation on HFO Page 1 (1) Edition 03H General Part load/low load operation and turbocharger. HFO-operation at loads lower than 20% MCR should therefore only take place within certain time limitations according to the curves. In certain ship and power station operation modes the diesel generating sets are exposed to part load/low After a certain period of HFO-operation at loads lower...

- Page 55 MAN Diesel & Turbo Guidelines Regarding MAN Diesel & Turbo GenSets 601.16 Description Operating on Low Sulphur Fuel Oil Page 1 (1) Edition 02H General Low sulphur distillates Exhaust emissions from marine diesel engines have been the focus of recent legislation. Apart from nitrous oxides (NOx), sulphur oxides (SOx) are considered In general our GenSet is developed for continuous to be the most important pollution factor.

- Page 56 Performance and condition 502/602...

- Page 57 MAN Diesel & Turbo 602.01 Description Engine Performance and Condition Page 1 (3) Edition 12H L+V28/32H Performance Data and Engine Condition An increase in charge air temperature involves a cor- responding increase in the exhaust gas temperature level by a ratio of about 1:1.5, i.e. 1°C higher charge During operation small changes in the engine condi- air temperature causes about 1.5°C higher exhaust tion take place continuously as a result of combustion,...

- Page 58 MAN Diesel & Turbo 602.01 Engine Performance and Condition Description Page 2 (3) Edition 12H L+V28/32H When evaluating operational results, a distinction is If, for any reason, the surface temperature of the fuel to be made between changes which affect the whole valve nozzle is lower than the condensation tempera- engine (all cylinder units) and changes which occur ture of sulphuric acid, sulphuric acid condensate...

- Page 59 MAN Diesel & Turbo 602.01 Description Engine Performance and Condition Page 3 (3) Edition 12H L+V28/32H Air Inlet Valves Engine Room Ventilation, Exhaust System The operational conditions of the air inlet valves are Good ventilation of the engine room and suitable loca- not altered substantially when using residual fuel.

- Page 60 MAN Diesel & Turbo Evaluation of Readings Regarding 602.02 Description Combustion Condition Page 1 (1) Edition 11H General PRESSURE DROP INCREASING (limit 50%) Air filters fouled. PRESSURE DROP INCREASING (limit 50%) Air side of cooler fouled. ALL CYLINDERS Exhaust temp. increa- sing: TEMP.

- Page 61 MAN Diesel 602.05 Description Condensate Amount Page 1 (2) Edition 08H General Ambient air temperature (1 bar) 0.10 0.08 0.06 Max. water content of atmosphere 0.04 0.02 Relative air humidity Charge air temperature after cooler. Air temperature in tank. Fig. 1. Nomogram for calculation of condensate amount. General Condensation of water in the engine's charge air receiver is consequently dependent on the humidity...

- Page 62 MAN Diesel 602.05 Description Condensate Amount Page 2 (2) Edition 08H General Solution according to diagram: Amount of Condensate Water in Air Tanks. Water content of air (l) 0.033 kg/kg The volume of condensate in the air tank is determin- Max.

- Page 63 MAN Diesel & Turbo 602-01.00 Working Card Engine Performance Data Edition 03H Page 1 (4) L28/32H Safety precautions: Special tools: Stopped engine Plate no. Item no. Note. Shut-off starting air Shut-off cooling water 62005 Max. pressure Shut-off fuel oil indicator Shut-off cooling oil Stopped lub.

- Page 64 MAN Diesel & Turbo 602-01.00 Engine Performance Data Working Card Page 2 (4) Edition 03H L28/32H Engine Performance Data Engine Type Engine No. Date/Year Hour Total Engine running Hours Engine RPM Fuel Type Turbocharger Turbocharger Visc. Density Type Serial No.

- Page 65 602-01.00 Engine Performance Data Working Card Page 3 (4) Edition 03H L28/32H The Instruction for Filling in the Diagram "Engine Cylinder Data. Performance Data". Cylinder no. - can be read on engine plate. The numbers in the instruction are commensurate A/B is used for V-engines.

- Page 66 Working Card Engine Performance Data Page 4 (4) Edition 03H L28/32H Temperature of the exhaust gas after TC (°C) Temperature of the low temperature (LT) cool- - Thermometer TI 61. ing water (sea, raw or fresh) at inlet lub. oil cooler (°C)

- Page 67 Trouble shooting 503/603...

- Page 68 MAN Diesel 603.01 Description Starting Failures Page 1 (1) Edition 08H General Trouble Possible cause Trouble shooting Engine turns as soon as shut-off Faults in electrical system Check electrical parts valve is opened, without start but-ton being activated Engine does not turn when start Air pressure in starting air recei- Start compressors, re-charge air button is activated...

- Page 69 MAN Diesel 603.02 Description Faults in Fuel Oil System Page 1 (3) Edition 09H L+V28/32H Trouble Possible cause Trouble shooting Engine turns on starting air, but Sluggish movement of Lubricate and mobilize rod con- ignition fails. Fuel pumps are not manoeuvring gear nections in manoeuvring gear actuated...

- Page 70 MAN Diesel 603.02 Description Faults in Fuel Oil System Page 2 (3) Edition 09H L+V28/32H Trouble Possible cause Trouble shooting Compression during start too low (5) Check intake and exhaust valve for tight closing. Check cyl. wear and piston rings Incorrect timing of camshaft (6) Check fuel pump timing advance, and fuel valve opening pressure...

- Page 71 MAN Diesel 603.02 Description Faults in Fuel Oil System Page 3 (3) Edition 09H L+V28/32H Oil on the piston crown will in most cases have leaked down from a defective fuel valve. As these oil accumulations are dangerous, the lea-kage should be found and remedied before the engine is started again.

- Page 72 MAN Diesel 603.03 Description Disturbances during Running Page 1 (3) Edition 08H L+V28/32H Trouble Possible cause Trouble shooting Exhaust temperature(s) (All cyls.) Increased charging air See Working Card 612-01.00. increase(s) temperature due to ineffective air coolers (All cyls.) Fouling or air and gas Reduce load and water-wash tur- passages bine.

- Page 73 MAN Diesel 603.03 Description Disturbances during Running Page 2 (3) Edition 08H L+V28/32H Trouble Possible cause Trouble shooting Engine stops Shut-down Check pressure and temperatu- res. If OK, check for faults in shut- down devices. See also Starting Failures Smoky exhaust Turbine RPM lagging behind en- Reasonably smoke is normal when RPM increases;...

- Page 74 MAN Diesel 603.03 Description Disturbances during Running Page 3 (3) Edition 08H L+V28/32H If this happens the fuel pump barrel and plun- If the cooling of the atomizers fails (if arranged ger must be changed, and if, to obtain full for oil cooling) while running, carbon de posits load of the respective cylinder, it is necessary will build up round the nozzle holes, some times...

- Page 75 MAN Diesel 603.04 Description Ignition in Crankcase Page 1 (1) Edition 09H L+V28/32H Cause Stop the engine During running, the atmosphere in the crankcase Leave the engine room. Shut doors and keep contains the same gases (N2-O2-CO2) in the same away from them.

- Page 76 MAN Diesel 603.05 Description Trouble Shooting Guide for Centrifugal By-pass Filter Page 1 (1) Edition 08H L+V28/32H Tabulated below are the corresponding remedial actions to be taken if the following faults are obser- ved: Trouble Possible cause Trouble shooting Oil leakage through cover nut Missing or damaged O-ring (see Replace O-ring Item 29, Plate 61515)

- Page 77 MAN Diesel 603.06 Description Trouble Shooting Guide for Turbine Starter Page 1 (2) Edition 09H L+V28/32H Trouble Possible cause Trouble shooting Motor will not run. No air supply. Check for blockage or damage to air supply lines or tank. Damaged motor assembly (12). Inspect motor assembly and power train and repair power train or re- place motor assembly if necessary.

- Page 78 MAN Diesel 603.06 Description Trouble Shooting Guide for Turbine Starter Page 2 (2) Edition 09H L+V28/32H Trouble Possible cause Trouble shooting Low air pressure. Check air supply. Wrong drive pinion. Replace with proper drive pinion. Oil in air supply line. Inspect air line and remove source Oil blowing out of exhaust.

- Page 79 MAN Diesel 603.09 Description Trouble Shooting for Cooling Water System Page 1 (1) Edition 08H General Description The pump bearings are lubricated automatically with oil from the lubricating oil system of the engine. The built-on fresh water pump in the high tempera- ture (HT) circuit is of the centrifugal type and is If the pump leaks and the shaft sealing rings are mounted on the front cover of the engine and is...

- Page 80 MAN Diesel 603.10 Description Trouble Shooting for Lubricating Oil Cooler Page 1 (2) Edition 01H General In case of fatigue fracture, this will normally neces- Trouble Shooting. sitate a replacement of all plates and gaskets - as In case of damage to plates or gaskets, it will often there may be a risk of fatigue fracture in all the be necessary to replace them.

- Page 81 MAN Diesel 603.10 Description Trouble Shooting for Lubricating Oil Cooler Edition 01H Page 2 (2) General Non-Visible Leakage Trouble Possible cause Trouble shooting Reduced heat transmission and/or Fouled plates or choked plate chan- Separate the plate heat exchanger and increasing pressure drop. nels.

- Page 82 Media specification 504/604...

- Page 83 604.01 Description heavy fuel oil operation (HFO) Page 1 (5) Edition 27H L28/32H V28/32H The specific output achieved by modern diesel en- Only lubricating oils that have been approved by gines combined with the use of fuels that satisfy MAN Diesel & Turbo may be used. These are listed the quality requirements more and more frequently in the table entitled "Lubricating oils approved for...

- Page 84 604.01 Description heavy fuel oil operation (HFO) Page 2 (5) Edition 27H L28/32H V28/32H Medium-alkaline lubricating oil For tips on selecting the base number, refer to the table entitled “Base number to be used for various The prepared oil (base oil with additives) must have operating conditions".

- Page 85 604.01 Description heavy fuel oil operation (HFO) Page 3 (5) Edition 27H L28/32H V28/32H approx. BN of fresh Engines / Operating conditions oil (mg KOH/g oil) Marine diesel oil (MDO) with a lower quality (ISO-F-DMC) or heavy fuel oil with a sulphur content of less than 0.5 %...

- Page 86 604.01 Description heavy fuel oil operation (HFO) Page 4 (5) Edition 27H L28/32H V28/32H Oil during operation If the engine is operated provisionally with low-sul- phur diesel fuel for more than 1000 h and is sub- sequently operated once again with HFO, a lubri- There are no prescribed oil change intervals for MAN Diesel &...

- Page 87 Specification for lubricating oils (SAE30) for 604.01 Description heavy fuel oil operation (HFO) Page 5 (5) Edition 27H L28/32H V28/32H Examinations Note! No liability when using these oils We can analyse heavy fuel oil for customers at our laboratory. A 0.5 l sample is required for the test.

- Page 88 Description tion with Gas Oil, Diesel Oil (MGO/MDO) and Biofuel Page 1 (5) Edition 26H L28/32H V28/32H The specific output achieved by modern diesel en- Only lubricating oils approved by MAN Diesel may gines combined with the use of fuels that satisfy be used.

- Page 89 604.01 Description tion with Gas Oil, Diesel Oil (MGO/MDO) and Biofuel Page 2 (5) Edition 26H L28/32H V28/32H Doped lubricating oils (HD-oils) Additional requirements The base oil to which the additives have been add- The lubricating oil must not contain viscosity index ed (doped lubricating oil) must have the following improver.

- Page 90 604.01 Description tion with Gas Oil, Diesel Oil (MGO/MDO) and Biofuel Page 3 (5) Edition 26H L28/32H V28/32H Speed controller Temporary operation with gas oil Multigrade oil 5W40 should ideally be used in me- Due to current and future emission regulations, chanical-hydraulic controllers with a separate oil heavy fuel oil cannot be used in designated regions.

- Page 91 Quality Requirements for Lube Oil (SAE30) for Opera- 604.01 Description tion with Gas Oil, Diesel Oil (MGO/MDO) and Biofuel Page 4 (5) Edition 26H L28/32H V28/32H Tests Approved lubricating oils SAE 30 Base Number We can analyse heavy fuel oil for customers at our...

- Page 92 Quality Requirements for Lube Oil (SAE30) for Opera- 604.01 Description tion with Gas Oil, Diesel Oil (MGO/MDO) and Biofuel Page 5 (5) Edition 26H L28/32H V28/32H Limit value Procedure Viscosity at 40 °C 75-160 mm ISO 3104 or ASTM D445...

- Page 93 604.03 Description Treatment and maintenance of lubricating oil Page 1 (4) Edition 11H L32/40, L28/32H, V28/32H General Operation on Heavy Fuel Oil (HFO) During operation of trunk engines the lubricating oil HFO-operated engines require effective lubricating will gradually be contaminated by small particles oil cleaning.

- Page 94 Description Treatment and maintenance of lubricating oil Page 2 (4) Edition 11H L32/40, L28/32H, V28/32H The most appropriate type of equipment for a par- Lubricating oil preheating ticular application depends on the engine output, The installed heater on the separator unit ensures...

- Page 95 Description Treatment and maintenance of lubricating oil Page 3 (4) Edition 11H L32/40, L28/32H, V28/32H Example 1 Three 1000 kW engines operating on HFO connec- For multi-engine plants, one separator per engine in ted to a common self-cleaning separator with a operation is recommended.

- Page 96 Description Treatment and maintenance of lubricating oil Page 4 (4) Edition 11H L32/40, L28/32H, V28/32H rous particles and rust are active. Furthermore, the lacquer and varnish oxidation products of the oil Deterioration of oil itself have an accelerating effect. Continuous clean- Oil seldomly loses its ability to lubricate, i.e.

- Page 97 MAN Diesel & turbo 604.04 Description Criteria for Cleaning/Exchange of Lubricating Oil Page 1 (2) Edition 17H General Replacement of Lubricating Oil Unit : cSt (mm Possible test The expected lubricating oil lifetime in operation is methods : ASTM D-445, DIN 51562/53018, difficult to determine.

- Page 98 MAN Diesel & turbo 604.04 Description Criteria for Cleaning/Exchange of Lubricating Oil Edition 17H Page 2 (2) General The neutralization capacity must secure that the acidic Unit : Weight % combustion products, mainly sulphur originate from the fuel oil, are neutralized at the lube oil consumption Possible test level for the specific engine type.

- Page 99 MAN Diesel 604.05 Description Lubricating Points Page 1 (1) Edition 01H General Lubricating Oil Types used in the Engine. Description Lub. Oil Type Engine system lubricating oil. SAE 30 oil according to lubricating oil specifi cation on page 604.01. Turbocharger Engine system lubricating oil.

- Page 100 MAN Diesel 604.05 Description Lubricating Points Edition 02H Page 1 (1) General Lubricating Oil Types used in the Engine. Description Lub. Oil Type Engine system lubricating oil. SAE 40 oil according to lubricating oil specifi cation on page 604.01. Turbocharger Engine system lubricating oil.

- Page 101 MAN Diesel 604.06 Description Lubricating Oil in Base Frame Page 1 (1) Edition 16H L28/32H Type L28/32H 5 cyl. 6 cyl. 7 cyl. 8 cyl. 9 cyl. Min. level H2 (mm) Max. level H3 (mm) 1078 1220 1362 Min. litre H2...

- Page 102 L16/24 1000/1200 0.4 - 0.8 L21/31 900/1000 0.4 - 0.8 L23/30H 720/750/900 0.6 - 1.0 L27/38 720/750 0.4 - 0.8 L28/32H 720/750 0.6 - 1.0 V28/32H 720/750 0.6 - 1.0 V28/32S 720/750 0.4 - 0.8 L32/40 720/750 0.7 - 1.1...

- Page 103 MAN Diesel 604.07 Description Specifi c Lubricating Oil Consumption - SLOC Page 2 (2) Edition 02H General 04.46 - ES0...

- Page 104 3.3.3 MAN Diesel & Turbo Heavy fuel oil (HFO) specification Prerequisites MAN four-stroke diesel engines can be operated with any heavy fuel oil obtained from crude oil that also satisfies the requirements in Table 1, pro- viding the engine and fuel processing system have been designed accord- ingly.

- Page 105 3.3.3 MAN Diesel & Turbo (polymers or chemical waste) is not permitted. Some of the reasons for this are as follows: abrasive and corrosive effects, unfavourable combustion characteristics, poor compatibility with mineral oils and, last but not least, adverse effects on the environment. The order for the fuel must expressly state what is not permitted as the fuel specifications that generally apply do not include this limitation.

- Page 106 3.3.3 MAN Diesel & Turbo Asphaltene content Weight % 2/3 of coke residue Combustion properties (according to Conradson) Sodium content mg/kg Sodium < 1/3 Vanadium, Heavy fuel oil processing Sodium<100 The fuel must be free of admixtures that cannot be obtained from mineral oils, such as vegetable or coal-tar oils. It must also be free of tar oil and lubricating oil (old oil), and also chemical waste products such as solvents or polymers.

- Page 107 3.3.3 MAN Diesel & Turbo Figure 1: ISO 8217-2010 specification for heavy fuel oil 4 (12) 6680 3.3.3-01 EN...

- Page 108 3.3.3 MAN Diesel & Turbo Figure 2: ISO 8217-2010 specification for heavy fuel oil (continued) 6680 3.3.3-01 EN 5 (12)

- Page 109 3.3.3 MAN Diesel & Turbo Additional information The purpose of the following information is to show the relationship between the quality of heavy fuel oil, heavy fuel oil processing, the engine operation and operating results more clearly. Selection of heavy fuel oil Economic operation with heavy fuel oil within the limit values specified in the "The fuel specification and corresponding properties for heavy table entitled...

- Page 110 3.3.3 MAN Diesel & Turbo "Achievable proportion of foreign matter and water (following separa- Table tion)" shows the prerequisites that must be met by the separator. These limit values are used by manufacturers as the basis for dimensioning the separa- tor and ensure compliance.

- Page 111 3.3.3 MAN Diesel & Turbo Water-containing sludge must be removed from the settling tank before the separation process starts, and must also be removed from the service tank at regular intervals. The tank's ventilation system must be designed in such a way that condensate cannot flow back into the tank.

- Page 112 3.3.3 MAN Diesel & Turbo system is higher. These problems can also occur when using unstable heavy fuel oils, or if incompatible heavy fuel oils are mixed. This would lead to an increased deposition of asphalt (see "Compatibility”). Ignition quality Nowadays, to achieve the prescribed reference viscosity, cracking-process products are used as the low viscosity ingredients of heavy fuel oils although the ignition characteristics of these oils may also be poor.

- Page 113 3.3.3 MAN Diesel & Turbo V Viscosity in mm /s (cSt) at 50° C A Normal operating conditions D Density [in kg/m B The ignition characteristics can ] at 15° C be poor and require adapting the engine or the operating condi- tions.

- Page 114 3.3.3 MAN Diesel & Turbo Compatibility The supplier must guarantee that the heavy fuel oil is homogeneous and remains stable, even after the standard storage period. If different bunker oils are mixed, this can lead to separation and the associated sludge formation in the fuel system during which large quantities of sludge accumulate in the separator that block filters, prevent atomisation and a large amount of resi- due as a result of combustion.

- Page 115 3.3.3 MAN Diesel & Turbo Tests Sampling To check whether the specification provided and/or the necessary delivery conditions are complied with, we recommend you retain at least one sample of every bunker oil (at least for the duration of the engine's warranty period). To ensure that the samples taken are representative of the bunker oil, a sam- ple should be taken from the transfer line when starting up, halfway through the operating period and at the end of the bunker period.

- Page 116 3.3.2 MAN Diesel & Turbo Diesel oil (MDO) specification Marine diesel oil Other designations Marine diesel oil, marine diesel fuel. Origin Marine diesel oil (MDO) is supplied as heavy distillate (designation ISO-F- DMB) exclusively for marine applications. MDO is manufactured from crude oil and must be free of organic acids and non-mineral oil products.

- Page 117 3.3.2 MAN Diesel & Turbo Additional information During transshipment and transfer, MDO is handled in the same manner as residual oil. This means that it is possible for the oil to be mixed with high- viscosity fuel or heavy fuel oil – with the remnants of these types of fuels in the bunker ship, for example –...

- Page 118 3.3.1 MAN Diesel & Turbo Gas oil / diesel oil (MGO) specification Diesel oil Other designations Gas oil, marine gas oil (MGO), diesel oil Gas oil is a crude oil medium distillate and therefore must not contain any residual materials. Military specification Diesel oils that satisfy specification F-75 or F-76 may be used.

- Page 119 3.3.1 MAN Diesel & Turbo * The process for determining the filterability in accordance with DIN EN 116 is similar to the process for determining the cloud point in accordance with ISO 3015 Additional information Use of diesel oil If distillate intended for use as heating oil is used with stationary engines instead of diesel oil (EL heating oil according to DIN 51603 or Fuel No.

- Page 120 3.3.1 MAN Diesel & Turbo Bio fuel specification Biofuel Other designations Biodiesel, FAME, vegetable oil, rapeseed oil, palm oil, frying fat Origin Biofuel is derived from oil plants or old cooking oil. Provision Transesterified and non-transesterified vegetable oils can be used. Transesterified biofuels (biodiesel, FAME) must comply with the standard EN 14214.

- Page 121 3.3.1 MAN Diesel & Turbo Improper handling of operating fluids If operating fluids are improperly handled, this can pose a danger to health, safety and the environment. The relevant safety information by the supplier of operating fluids must be observed. Analyses We can analyse fuel for customers at our laboratory.

- Page 122 3.3.4 MAN Diesel & Turbo Viscosity-temperature diagram (VT diagram) Explanations of viscosity-temperature diagram Figure 1: Viscosity-temperature diagram (VT diagram) In the diagram, the fuel temperatures are shown on the horizontal axis and the viscosity is shown on the vertical axis. The diagonal lines correspond to viscosity-temperature curves of fuels with different reference viscosities.

- Page 123 3.3.4 MAN Diesel & Turbo * With these figures, the temperature drop between the last preheating device and the fuel injection pump is not taken into account. A heavy fuel oil with a viscosity of 180 mm /s at 50 °C can reach a viscosity of 1000 mm /s at 24 °C (line e) –...

- Page 124 MAN Diesel 604.30 Description Fuel Oil Cleaning Page 1 (2) Edition 01H General Purifi cation Recommendations. Especially for fuels above 180 cST/50°C (1500 sec. RW/100°F) the highest possible temperature 98°C (208°F) should be maintained in the centrifuge oil Fuel oils are always contaminated and should there- preheater.

- Page 125 MAN Diesel 604.30 Description Fuel Oil Cleaning Edition 01H Page 2 (2) General Flow Rate For the determination of centrifuging capacity, we generally advise to follow the recommendations of Related to Rated Capacity of Centrifuge the centrifuge maker, but the curves on fi g. 1, can be used as a guidance.

- Page 126 3.3.7 MAN Diesel & Turbo Engine cooling water specifications Preliminary remarks As is also the case with the fuel and lubricating oil, the engine cooling water must be carefully selected, handled and checked. If this is not the case, cor- rosion, erosion and cavitation may occur at the walls of the cooling system in contact with water and deposits may form.

- Page 127 3.3.7 MAN Diesel & Turbo Hardness The total hardness of the water is the combined effect of the temporary and permanent hardness. The proportion of calcium and magnesium salts is of overriding importance. The temporary hardness is determined by the carbo- nate content of the calcium and magnesium salts.

- Page 128 3.3.7 MAN Diesel & Turbo Additives for cooling water Only the additives approved by MAN Diesel and listed in the tables under the "Approved cooling water additives“ may be used. section entitled Required approval A cooling water additive may only be permitted for use if tested and approved as per the latest directives of the ICE Research Association (FVV) "Suitability test of internal combustion engine cooling fluid additives.”...

- Page 129 3.3.7 MAN Diesel & Turbo and the required concentrations, contact the manufacturer. As regards the „Nitrite-Containing Chemical Addi- chemical additives indicated in the table tives“ , their compatibility with ethylene glycol-based antifreezes has been proved. Anti-freeze solutions may only be mixed with one another with the consent of the manufacturer, even if these solutions have the same composi- tion.

- Page 130 3.3.7 MAN Diesel & Turbo Regular checks of the cooling water condition and cooling water system Treated cooling water may become contaminated when the engine is in operation, which causes the additive to loose some of its effectiveness. It is therefore advisable to regularly check the cooling system and the cooling water condition.

- Page 131 3.3.7 MAN Diesel & Turbo Protective measures Anticorrosive agents contain chemical compounds that can pose a risk to health or the environment if incorrectly used. Comply with the directions in the manufacturer's material safety data sheets. Avoid prolonged direct contact with the skin. Wash hands thoroughly after use.

- Page 132 3.3.7 MAN Diesel & Turbo Manufacturer Product designation Initial dosing for Minimum concentration ppm 1,000 litres Product Nitrite Na-Nitrite (NaNO Uniservice N.C.L.T. 12 l 12,000 2,000 3,000 Via al Santuario di N.S. della Guardia 58/A Colorcooling 24 l 24,000 2,000 3,000 16162 Genova, Italy Marichem –...

- Page 133 3.3.7 MAN Diesel & Turbo Anti-freeze solutions with slushing properties Manufacturer Product designation Minimum concentration BASF Glysantin G 48 Carl-Bosch-Str. Glysantin 9313 67063 Ludwigshafen, Glysantin G 05 Rhein Deutschland Castrol Int. Antifreeze NF, SF Pipers Way Swindon SN3 1RE, UK BP, Britannic Tower Anti-frost X2270A Moor Lane,...

- Page 134 000.07 MAN Diesel & Turbo Cooling water inspecting Summary Acquire and check typical values of the operating media to prevent or limit damage. The fresh water used to fill the cooling water circuits must satisfy the specifi- cations. The cooling water in the system must be checked regularly in accordance with the maintenance schedule.

- Page 135 000.07 MAN Diesel & Turbo Testing the concentration of anticorrosive agents Short specification Anticorrosive agent Concentration Chemical additives according to the quality specification in Volume 010.005 Engine - Operating Instructions, Chapter 3, Sheet 3.3.7 Anti-freeze agents according to the quality specification in Volume 010.005 Engine - Operating Instructions, Chapter 3, Sheet 3.3.7 Table 2: Concentration of the cooling water additive Testing the concentration of...

- Page 136 000.08 MAN Diesel & Turbo Cooling water system Cleaning Summary Remove contamination/residue from operating fluid systems, ensure/re- establish operating reliability. Cooling water systems containing deposits or contamination prevent effec- tive cooling of parts. Contamination and deposits must be regularly elimina- ted.

- Page 137 000.08 MAN Diesel & Turbo other manufacturers can be used providing they have similar properties. The manufacturer's instructions for use must be strictly observed. Prior to clean- ing, check whether the cleaning agent is suitable for the materials to be "Cleaning agents for remov- cleaned.

- Page 138 000.08 MAN Diesel & Turbo Cleaning products can cause damage The products to be used can endanger health and may be harmful to the environment. Follow the manufacturer's handling instructions without fail. The applicable regulations governing the disposal of cleaning agents or acids must be observed.

- Page 139 3.3.10 MAN Diesel & Turbo Water specification for fuel-water emulsions Prerequisites The water used for the fuel-water emulsion is an operating fluid that must be carefully selected, processed (if necessary) and monitored. If this is not done, deposits, corrosion, erosion and cavitation may occur on the fuel system components that come into contact with the fuel-water emulsion.

- Page 140 3.3.11 MAN Diesel & Turbo Specifications for intake air (combustion air) General The quality and condition of intake air (combustion air) have a significant effect on the power output, wear and emissions of the engine. In this regard, not only are the atmospheric conditions extremely important, but also con- tamination by solid and gaseous foreign matter.

- Page 141 Cylinder head 505/605...

- Page 142 Description Cylinder head Page 1 (1) Edition 14H L28/32H, V28/32H and is encased by the seating collar (5) which over- General laps it. The assembled valve rotator is held The cylinder head is made of cast iron and is tight- together, when removed, by the retaining ring (6).

- Page 143 MAN Diesel & Turbo 605-01.00 Working Card Dismantling of Cylinder Head Page 1 (2) Edition 01H L/V28/32H Safety precautions: Special tools: Stopped engine Plate no. Item no. Note. Shut-off starting air Shut-off cooling water 62021 Shut-off fuel oil 62021 Oil injector, Shut-off cooling oil (complete) Stopped lub.

- Page 144 Attach the hook to the lifting tool and lift the Disconnect the cooling oil pipes, (inlet and cylinder head away. outlet. Disconnect the rocker arm lubricating oil pi- V28/32H L28/32H Remove the thermometer attachment bran- (cooling water outlet pipe). Fig. 2 Fig. 1 91.45 - ES0S...

- Page 145 MAN Diesel & Turbo Inspection of Inlet Valve, Exhaust Valve and 605-01.05 Working Card Valve Guide Edition 06H Page 1 (3) L+V28/32H Safety precautions Special tools Stopped engine Plate no Item no Note Shut-off starting air Shut-off cooling water 62005 Shut-off fuel oil 62005 Shut-off cooling oil...

- Page 146 Or as an Alternative: Place wooden blocks under the valve spindle heads. V28/32H L28/32H Fig 2 Now compress the valve springs by tigh ten- ing the nut (B), after which the cone rings can be re-moved, see fig 3.

- Page 147 MAN Diesel & Turbo 605-01.05 Inspection of Inlet Valve, Exhaust Valve and Working Card Valve Guide Edition 06H Page 3 (3) L+V28/32H Release the springs again. Remove the nut Inspection of valve guide (B) and the traverse (C). Now valve rotator and springs can be removed.

- Page 148 MAN Diesel & Turbo Reconditioning of Valve Spindle Seat 605-01.10 Working Card and Valve Seat Ring Page 1 (3) Edition 01H L/V28/32H Safety precautions: Special tools: Stopped engine Plate no. Item no. Note. Shut-off starting air Shut-off cooling water 62005 Grinding machine Shut-off fuel oil for valve spindle.

- Page 149 MAN Diesel & Turbo Reconditioning of Valve Spindle Seat 605-01.10 Working Card and Valve Seat Ring Page 2 (3) Edition 01H L/V28/32H Reconditioning of Valve Seat Ring. However when the seat "S" has been ground to such an extent, that the recess "R" disappears, the valve Reconditioning of valve seat rings by machining is seat ring has to be scrapped and a new one to must carried out by means of a grinding machine, the...

- Page 150 MAN Diesel & Turbo Reconditioning of Valve Spindle Seat 605-01.10 Working Card and Valve Seat Ring Page 3 (3) Edition 01H L/V28/32H After assembling the valves, check - on account of the valve motion - that distance "H"2 between the upper edge of the cylinder head and the upper edge of the valve spindle does not exceed the maximum value, see page 600.35.

- Page 151 MAN Diesel & Turbo 605-01.15 Working Card Valve Rotator Page 1 (2) Edition 01H L/V28/32H Safety precautions: Special tools: Stopped engine Plate no. Item no. Note. Shut-off starting air Shut-off cooling water 62005 Shut-off fuel oil Shut-off cooling oil Stopped lub. oil circul. Description: Dismantling, inspection and mounting of valve rotator.

- Page 152 MAN Diesel & Turbo 605-01.15 Working Card Valve Rotator Page 2 (2) Edition 01H L/V28/32H Inspection of Rotocap. When inserting the balls and the tangential springs, note that all balls on the inclined races of the ball Dirt especially in the ball pockets due to residues in pockets point in the same direction, see fig.

- Page 153 MAN Diesel & Turbo 605-01.20 Working Card Replacement of Valve Guide Page1 (2) Edition 05H L+V28/32H Safety precautions Special tools Stopped engine Plate no. Item no. Note. Shut-off starting air Shut-off cooling water 62005 Lytra tools Shut-off fuel oil Shut-off cooling oil Stopped lub.

- Page 154 MAN Diesel & Turbo 605-01.20 Working Card Replacement of Valve Guide Page 2 (2) Edition 05H L+V28/32H If the clearance exceeds the shown max. limit, (see Before mounting the new valve guide, it has to page 600.35), the valve guide must be replaced. be cooled down to approx.

- Page 155 MAN Diesel & Turbo 605-01.25 Working Card Safety Valve Page 1 (3) Edition 04H L+V28/32H Safety precautions: Special tools: Stopped engine Plate no Item no Note Shut-off starting air Shut-off cooling water 62014 Pressure test Shut-off fuel oil pump. Shut-off cooling oil 62014 Pipe for fuel Stopped lub.

- Page 156 MAN Diesel & Turbo 605-01.25 Working Card Safety Valve Page 2 (3) Edition 04H L+V28/32H Maintenance and Checking. 2. Reassembling. During extended periods of standstill and at general Lubricate the threads on valve housing (2) engine overhauls, the safety valves should be tho- with copaslip or similar.

- Page 157 MAN Diesel & Turbo 605-01.25 Working Card Safety Valve Page 3 (3) Edition 04H L+V28/32H Test of Opening Pressure 4. Adjustment of Opening Pressure Increase the pressure to the opening pres- Increase the pressure to the opening pres- sure. sure. Turn the cap nut (1) to the correct opening pressure.

- Page 158 MAN Diesel & Turbo 605-01.26 Working Card Indicator Valve Page 1 (2) Edition 02H L+V28/32H Safety precautions: Special tools: Stopped engine Plate No Item No Note Shut-off starting air Shut-off cooling water Shut-off fuel oil Shut-off cooling oil Stopped lub. oil circul. Description: Dismounting, inspection and mounting of indi- cator valve.

- Page 159 MAN Diesel & Turbo 605-01.26 Working Card Indicator Valve Page 2 (2) Edition 02H L+V28/32H Maintenance By normal working conditions the indicator valve require very little maintenance except an inspec- tion in connection with the normal cylinder cover overhaul. Inspection of the Indicator Valve: Disassemble the indicator valve.

- Page 160 MAN Diesel & Turbo 605-01.30 Working Card Replacement of Sleeve for Fuel Injector Page 1 (2) Edition 04H L+V28/32H Safety precautions Special tools Stopped engine Plate no. Item no. Note. Shut-off starting air Shut-off cooling water Shut-off fuel oil Shut-off cooling oil Stopped lub.

- Page 161 MAN Diesel & Turbo 605-01.30 Working Card Replacement of Sleeve for Fuel Injector Page 2 (2) Edition 04H L+V28/32H Dismounting of Sleeve for Fuel Injector Coat the sealing ring zone in the bore with grea se or lub. oil. Remove the snap ring by means of two screw drivers.

- Page 162 MAN Diesel & Turbo 605-01.35 Working Card Replacement of Valve Seat Ring Page 1 (4) Edition 06H L+V28/32H Safety precautions Special tools Stopped engine Plate no. Item no. Note. Shut-off starting air Shut-off cooling water 62021 Shut-off fuel oil 62021 1 piece Shut-off cooling oil 62005...

- Page 163 MAN Diesel & Turbo 605-01.35 Working Card Replacement of Valve Seat Ring Page 2 (4) Edition 06H L+V28/32H Procedure for Dismounting a Valve Seat Dismounting of Valve Seat Rings Ring When reconditioning of a valve seat ring no longer is By means of the guide pin (7) the guide disc possible due to dimensions exceeding the scrapping criteria, the seat ring has to be replaced.

- Page 164 MAN Diesel & Turbo 605-01.35 Working Card Replacement of Valve Seat Ring Edition 06H Page 3 (4) L+V28/32H By pumping up the pack, see working card To facilitate mounting of the valve seat ring it is 620-01.05 for the use of hydraulic tools, the cooled down, however to no more than -25°C valve seat is pressed out max.

- Page 165 MAN Diesel & Turbo 605-01.35 Working Card Replacement of Valve Seat Ring Page 4 (4) Edition 06H L+V28/32H By knocking on the handle and at the same time tightening the nut (4), the valve seat ring slides in place in the bore and it is felt on the knocks when it bears in the bore.

- Page 166 MAN Diesel & Turbo 605-01.40 Working Card Mounting of Cylinder Head Page 1 (2) Edition 06H L+V28/32H Safety precautions Special tools Stopped engine Plate no. Item no. Note. Shut-off starting air Shut-off cooling water 62021 Shut-off fuel oil 62021 Shut-off cooling oil 62021 6 Pieces Stopped lub.

- Page 167 Attach the lifting tool to the cylinder head that has been made ready for installation, and position it carefully on the cylinder liner. V28/32H L28/32H Fig 2 If new studs or nuts have been fitted, the nuts must be tightened and loosened three times,...

- Page 168 MAN Diesel & Turbo 605-01.45 Working Card Inspection of Cylinder Head Cooling Water Space Page 1 (2) Edition 01H L/V28/32H Safety precautions: Special tools: Stopped engine Plate no. Item no. Note. Shut-off starting air Shut-off cooling water Shut-off fuel oil Shut-off cooling oil Stopped lub.

- Page 169 MAN Diesel & Turbo 605-01.45 Working Card Inspection of Cylinder Head Cooling Water Space Page 2 (2) Edition 01H L/V28/32H Inspection of Cylinder Head Cool. Water Space. Inspect the cooling water inlet at the bottom and the cooling water outlet in the top of the cylinder Cooling water, head, see fig.

- Page 170 MAN Diesel Plate Cylinder Head 60501-19H Page 1 (2) L+V28/32H 03.44 - ES0...

- Page 171 MAN Diesel Plate 60501-19H Cylinder Head Page 2 (2) L+V28/32H Item Item Qty. Designation Benævnelse Qty. Designation Benævnelse Cylinder head (as 294) O-ring O-ring Cylinderdæksel (som with brackets and 294) monteret med buk- rockerarms installed Valve guide, inlet and Ventilstyr, indstr. og ke og vippearne.

- Page 172 MAN Diesel Plate Valve Spindles and Valve Gear 60502-31H Page 1 (2) L+V28/32H 22/23 08.28 - ES0...

- Page 173 MAN Diesel Plate 60502-31H Valve Spindles and Valve Gear Page 2 (2) L+V28/32H Item Item Qty. Designation Benævnelse Designation Benævnelse Qty. Thrust piece Trykstykke Rocker arm Vippearm Møtrik Thrust screw Trykskrue Plug screw Propskrue Bearing bush Lejebøsning Valve bridge, Ventilbro, Thrust pin Trykskrue inlet...

- Page 174 MAN Diesel Plate Safety Valve and Indicator Valve 60508-11H Page 1 (2) L+V28/32H 94.25 - ES0S...

- Page 175 MAN Diesel Plate Safety Valve and Indicator Valve 60508-11H Page 2 (2) L+V28/32H Item Item Qty. Designation Benævnelse Designation Benævnelse Qty. Valve cone Ventilkugle Pressure spring Trykfjeder Safety valve, com- Sikkerhedsventil, plete incl. item 03, komplet inkl. item 03, 06, 25, 26, 27, 28 06, 25, 26, 27, 28 Gasket Pakning...

- Page 176 MAN Diesel Plate Cylinder Head, Top Cover 60510-12H Page 1 (2) L+V28/32H 05, 16 06.32 - ES0S...

- Page 177 MAN Diesel Plate 60510-12H Cylinder Head, Top Cover Page 2 (2) L+V28/32H Item Item Qty. Designation Benævnelse Qty. Designation Benævnelse Handle Håndtag O-ring O-ring Møtrik Top cover Topdæksel Top cover, compl. Topdæksel, kompl. incl. item Nos. inkl. pos. nr. 01, 02, 05, 06 01, 02, 05, 06 Gasket Pakning...

- Page 178 Piston/connecting rod 506/606...

- Page 179 MAN Diesel 606.01 Description Piston, Connecting Rod and Cylinder Liner Page 1 (1) Edition 10H L/V28/32H Piston The piston, which is oil-cooled and of the monobloc The big-end bearing is of trimetal type, i.e. steel shells type made of nodular cast iron, is equipped with 3 lined with tin-aluminium or lead-bronze coated with compression rings and 1 scraper ring.

- Page 180 MAN Diesel 606-01.00 Working Card Dismounting of Piston and Connecting Rod Page 1 (3) Edition 01H L28/32H Safety precautions: Special tools: Stopped engine Plate no. Item no. Note. Shut-off starting air Shut-off cooling water 62006 Shut-off fuel oil 62006 Shut-off cooling oil...

- Page 181 Dismounting of Piston and Connecting Rod Page 2 (3) Edition 01H L28/32H Clean the upper part of the cylinder, if not, the Turn the piston in top, in order to push the fl ame piston may get stuck during removal in the carbon ring out of the cylinder by means of the tool.

- Page 182 Working Card Dismounting of Piston and Connecting Rod Page 3 (3) Edition 01H L28/32H Fig. 3. Removal of upper big-end bearing shell. If minor adjustment of the crank throw position ap- pears necessary for acces to the connecting rod screws, the wire rope must be slackened before turning of the crankshaft and tightened up again in the new crank throw position.

- Page 183 L/V28/32H Safety precautions: Special tools: Stopped engine Plate no. Item no. Note. Shut-off starting air Shut-off cooling water 62006 L28/32H Shut-off fuel oil 62006 L28/32H Shut-off cooling oil 62006 V28/32H Stopped lub. oil circul. 62006 Description: Separation of piston and connecting rod for in- spection or/and overhaul.

- Page 184 Take out the securing ring, (seeger circlips), push out the piston pin and lift the connecting rod away. Fig. 1. L28/32H The bearing cap should be mounted with the screws tightened only by hand, in order to protect the serrated joint faces during handling of the assembly, see fi...

- Page 185 MAN Diesel 606-01.10 Working Card Piston (with fl ame ring) Page 1 (4) Edition 09H L+V28/32H Safety precautions Special tools Stopped engine Plate no Item no Note. Shut-off starting air Shut-off cooling water 62006 Shut-off fuel oil 62006 Shut-off cooling oil 62006 Stopped lub.

- Page 186 MAN Diesel 606-01.10 Working Card Piston (with fl ame ring) Page 2 (4) Edition 09H L+V28/32H Removal of Piston Ring Inspection of Piston For removal of piston rings, which are to be used Remove the piston and scraper rings. again, and for all mounting of rings, only the special ring opener which prevents local over stressing of Clean and examine the piston rings to determine the rings should be used.

- Page 187 MAN Diesel 606-01.10 Working Card Piston (with fl ame ring) Page 3 (4) Edition 09H L+V28/32H The piston has to be scrapped if: New ring Piston and oil Ring grooves. grooves. scraper ring. The wear limit on the testing mandrel is ex ceed- Max.

- Page 188 MAN Diesel 606-01.10 Working Card Piston (with fl ame ring) Edition 09H Page 4 (4) L+V28/32H Position of Piston and Scraper Rings Piston Ring No 1: marked with ident. no "top 1619394-4" or "1242". Piston Ring No 2: marked with ident. no "top 1619394-4"...

- Page 189 MAN Diesel 606-01.15 Working Card Connecting Rod Page 1 (4) Edition 04H L/V28/32H Safety precautions: Special tools: Stopped engine Plate no. Item no. Note. Shut-off starting air Shut-off cooling water 62006 140-760 Nm Shut-off fuel oil Shut-off cooling oil Stopped lub. oil circul. Description: Cleaning, inspection and test measurement of connecting rod.

- Page 190 MAN Diesel 606-01.15 Working Card Connecting Rod Page 2 (4) Edition 04H L/V28/32H Cleaning and Inspection of Big-end Bore. Screws, which are damaged as mentioned above or cannot be turned into the threaded holes by hand, The connecting rod is cleaned on all machined must be renewed.

- Page 191 MAN Diesel 606-01.15 Working Card Connecting Rod Page 3 (4) Edition 04H L/V28/32H If the ovalness exceeds this value, reuse must be Please note that squares for statement of information rejected and a new complete connecting rod, in clu- and identifi cation, should also be properly fi lled in. ding new screws and new bearing shells has to be mounted in the engine.

- Page 192 MAN Diesel 606-01.15 Working Card Connecting Rod Edition 04H Page 4 (4) L/V28/32H 97.24 - ES0S...

- Page 193 MAN Diesel Criteria for Replacement of 606-01.16 Working Card Connecting Rod Big-end and Main Bearing Shells Page 1 (8) Edition 02H L+V28/32H Safety precautions: Special tools: Stopped engine Plate no. Item no. Note. Shut-off starting air 62006 Shut-off cooling water Shut-off fuel oil Shut-off cooling oil Stopped lub.

- Page 194 MAN Diesel Criteria for Replacement of 606-01.16 Working Card Connecting Rod Big-end and Main Bearing Shells Page 2 (8) Edition 02H L+V28/32H This paper gives information about the evaluation of Wear of the bearings running surface starts primarily the connecting rod big-end and main bearing shells in the soft overlay, where the overlay in the slots is when wear appears on the run ning surface under re duced ap prox.

- Page 195 MAN Diesel...

- Page 196 MAN Diesel...

- Page 197 MAN Diesel...

- Page 198 MAN Diesel Criteria for Replacement of 606-01.16 Working Card Connecting Rod Big-end and Main Bearing Shells Page 6 (8) Edition 02H L+V28/32H Limit Case - Levelling Valuation: If the limits shown in fi g. 11 and 12 are exceeded the bearing shells must be exchanged. Condition: The slots are locally totally levelled as shown in fi...

- Page 199 MAN Diesel...

- Page 200 MAN Diesel Criteria for Replacement of 606-01.16 Working Card Connecting Rod Big-end and Main Bearing Shells Page 8 (8) Edition 02H L+V28/32H Limit Case - Empty Slots Valuation: If the limits shown in the below fi g. 18 and 19, are ex ceeded, the bearing shells must be Condition: In some areas there is no overlay in the ex chang ed.

- Page 201 MAN Diesel 606-01.20 Working Card Assembling of Piston and Connecting Rod Page 1 (4) Edition 01H L28/32H Safety precautions: Special tools: Stopped engine Plate no. Item no. Note. Shut-off starting air Shut-off cooling water 62006 Shut-off fuel oil 62006 Shut-off cooling oil 62006 Stopped lub.

- Page 202 Working Card Assembling of Piston and Connecting Rod Page 2 (4) Edition 01H L28/32H Mount the lifting device comprising eye screw, A crank throw position of approx 50 degrees before shackle and wire rope on the piston. TDC will ensure this and also be suitable for the further mounting procedure.

- Page 203 Working Card Assembling of Piston and Connecting Rod Page 3 (4) Edition 01H L28/32H Mount the bearing cap with inserted lower shell of the big-end bearing, using the guide pin, see fi g. Lubricate threads and contact face of the con- necting rod screws with copaslip, molycote pasta or similar.

- Page 204 Assembling of Piston and Connecting Rod Page 4 (4) Edition 01H L28/32H If the rings are opened further than necessary there Before fi tting the coil spring loaded scraper ring, the is a risk of overstressing, which means that rings will coil spring is dismantled from the ring by removal of become permanently distorted and will not confi...

- Page 205 MAN Diesel 606-01.25 Working Card Hydraulic Tightening of Connecting Rod Screws Page 1 (2) Edition 04H L+V28/32H Safety Precautions: Special Tools: Stopped engine Plate No Item No Note Shut-off starting air Shut-off cooling water 62021 Shut-off fuel oil Shut-off cooling oil Stopped lub.

- Page 206 MAN Diesel 606-01.25 Working Card Hydraulic Tightening of Connecting Rod Screws Edition 2 (2) Edition 04H L+V28/32H Tighten the screw pos. 3 home to the connecting rod by hand. Mount the lower part pos. 2 and fasten the lower part with the nuts, pos. 4. Tighten the nuts by hand.

- Page 207 MAN Diesel 606-01.30 Working Card In-situ Inspection of Connecting Rod Big-end Bearing Page 1 (3) Edition 01H L28/32H Safety precautions: Special tools: Stopped engine Plate no. Item no. Note. Shut-off starting air Shut-off cooling water 62006 Shut-off fuel oil 62006...

- Page 208 606-01.30 Working Card In-situ Inspection of Connecting Rod Big-end Bearing Page 2 (3) Edition 01H L28/32H The big-end bearing shells can be inspected and/or replaced in-situ i.e. without dismounting the piston and connecting rod assembly from the engine. Dismounting. The crankshaft of the engine is turned into a po si tion allowing the connecting rod screws to be lo- sen ed.

- Page 209 Working Card In-situ Inspection of Connecting Rod Big-end Bearing Page 3 (3) Edition 01H L28/32H While lowering the connecting rod, it must be guided by hand to ensure correct approach and landing on the journal, see fi g. 4. Mount the bearing cap with inserted lower big-end bearing shell, using the guide pin.

- Page 210 MAN Diesel 606-01.35 Working Card Inspection and Honing of Cylinder Liner Page 1 (4) Edition 08H L+V28/32H Special tools: Safety precautions: Plate no. Item no. Note. Stopped engine Shut-off starting air 62006 Extra tools Shut-off cooling water 62006 Extra tools Shut-off fuel oil 62006 Extra tools...

- Page 211 MAN Diesel 606-01.35 Working Card Inspection and Honing of Cylinder Liner Page 2 (4) Edition 08H L+V28/32H Prior to the honing, deposits of coke and possible Measurement of Cylinder Diameter. wear edges in the top of the liner must be removed by scraping.

- Page 212 MAN Diesel 606-01.35 Working Card Inspection and Honing of Cylinder Liner page 3 (4) Edition 08H L+V28/32H In order to achieve the required angle between the honing grooves, see fi g. 2, the vertical speed is ad- justed to about 1 m/sec. which corresponds to about 2 sec.

- Page 213 MAN Diesel 606-01.35 Working Card Inspection and Honing of Cylinder Liner Page 4 (4) Edition 08H L+V28/32H Measurements of Cylinder Liner Plant/ship: Engine Type: Engine No.: Date: Sign.: Cyl. A-side B-side Pos. Running hours: Fuel: Separator: Yes Tem. of cyl. liner 25°C Nom.

- Page 214 MAN Diesel 606-01.40 Working Card Replacement of Cylinder Liner Page 1 (3) Edition 01H L/V28/32H Safety precautions: Special tools: Stopped engine Plate no. Item no. Note. Shut-off starting air Shut-off cooling water 62006 Shut-off fuel oil Shut-off cooling oil Stopped lub. oil circul. Description: Replacement of cylinder liner.

- Page 215 Edition 01H L/V28/32H Dismounting of Cylinder Liner. Dismount the cooling water guide jacket. L28/32H Prior to mounting of the lifting tool and dis moun- V28/32H ting from the frame, it must be ensured that the liner and frame have been marked to match, for the sake of a posible remounting of the liner, see fi...

- Page 216 MAN Diesel 606-01.40 Working Card Replacement of Cylinder Liner Page 3 (3) Edition 01H L/V28/32H Mounting of Cylinder Liner. Mount the cooling water jacket, (for torque mo- ment see page 600.40), piston/connecting rod and Check that the sealing surfaces on engine, cylinder head according to working card 606-01.20 cylinder liner, and sealing rings are perfectly clean.

- Page 217 MAN Diesel Grinding of Seal Face on 606-01.45 Working Card Cylinder Liner and Cylinder Head. Page 1 (2) Edition 01H L/V28/32H Safety precautions: Special tools: Stopped engine Plate no. Item no. Note. Shut-off starting air Shut-off cooling water 62005 Shut-off fuel oil Shut-off cooling oil Stopped lub.

- Page 218 MAN Diesel Grinding of Seal Face on 606-01.45 Working Card Cylinder Liner and Cylinder Head Page 2 (2) Edition 01H L/V28/32H Note: The grinding tool is used for both grinding the groove in the liner fl ange (1) and the seating surface on the cylinder head (2), see fi...

- Page 219 MAN Diesel Dismounting of Piston and Cylinder Liner 606-01.50 Working Card Page 1 (2) Edition 01H at Low Overhaul Heights L+V28/32H Safety precautions: Special tools: Stopped engine Plate no Item no Note Shut-off starting air Shut-off cooling water 62050 Shut-off fuel oil 62006 Shut-off cooling oil 62006...

- Page 220 MAN Diesel 606-01.50 Dismounting of Piston and Cylinder Liner Working Card Page 2 (2) Edition 01H at Low Overhaul Heights L+V28/32H Dismantling of Piston at Low Overhaul Dismantling of Cylinder Liner at Low Overhaul Heights. Heights. Lift up the piston and the connecting rod through Mount normal lifting tool for cylinder liners.

- Page 221 MAN Diesel Plate Piston and Connecting Rod 60601-34H (Hydraulic Tightened) Page 1 (2) L28/32H 07.01 - ES0...

- Page 222 MAN Diesel Plate 60601-34H Piston and Connecting Rod (Hydraulic Tightened) Page 2 (2) L28/32H Item Item Qty. Designation Benævnelse Qty. Designation Benævnelse Piston pin incl. Stempelpind inkl. item No 02 pos. nr. 02 Socket screw Kraterskrue Retaining ring Sikringsring Plug screw...

- Page 223 MAN Diesel & Turbo Plate Cylinder Liner and Water Guide Jacket 60610-09H Page 1 (2) L28/32H 94.07 - ES0S...

- Page 224 MAN Diesel & Turbo Plate 60610-09H Cylinder Liner and Water Guide Jacket Page 2 (2) L28/32H Item Item Qty. Designation Beskrivelse Designation Beskrivelse O-ring O-ring Sleeve Muffe Water guide Kølekappe jacket O-ring O-ring Sealing ring Tætningsring Plug screw Propskrue 12/C...

- Page 225 Camshaft 507/607...

- Page 226 607.01 Description Camshaft and Camshaft Drive Page 1 (1) Edition 05H L28/32H General The lubricating oil pipes for the gear wheels are equipped with nozzles which are adjusted to apply The camshaft which controls the actuation of inlet the oil at the points where the gear wheels are in valves, exhaust valves and fuel injection pumps is mesh.

- Page 227 MAN Diesel 607-01.00 Working Card Camshaft and Camshaft Drive Page 1 (2) Edition 01H L/V28/32H Safety precautions: Special tools: Stopped engine Plate no. Item no. Note. Shut-off starting air Shut-off cooling water 62006 20 - 120 Nm. Shut-off fuel oil Shut-off cooling oil Stopped lub.

- Page 228 MAN Diesel 607-01.00 Working Card Camshaft and Camshaft Drive Page 2 (2) Edition 01H L/V28/32H Examine all lubricating oil spray pipe nozz- Dismount the covers which give access to the les. gear wheels, camshaft and crankcase. Start the electrical lubricating oil pump and Examine all gear wheels for cracks, wear and de for- check the oil fl...

- Page 229 MAN Diesel 607-01.05 Working Card Inspection and Replacement of Camshaft Bearing Page 1 (2) Edition 01H L+V28/32H Safety precautions Special tools Stopped engine Plate No Item No Note Shut-off starting air Shut-off cooling water 62006 20 - 120 Nm. Shut-off fuel oil Shut-off cooling oil Stopped lub.

- Page 230 MAN Diesel 607-01.05 Working Card Inspection and Replacement of Camshaft Bearing Page 2 (2) Edition 01H L+V28/32H To Check Roller Path of Cams. While turning the engine, examine the cam Camshaft bearing discs and in particular, check the roller path of all Hole for lubricating oil cams for cracks, crackles and ruffl...

- Page 231 MAN Diesel & Turbo 607-01.20 Adjustment of Camshaft for Valve and Injection Timing Working Card Page 1 (4) Edition 04H L28/32H Safety precautions Special tools Stopped engine Plate no Item no Note Shut-off starting air Shut-off cooling water 62006 20 - 120 Nm.

- Page 232 Working Card Adjustment of Camshaft for Valve and Injection Timing Page 2 (4) Edition 04H L28/32H Measure of fuel pump lead Insert the dial gauge into the support. Set the dial gauge to "Zero". Dismantle covers for fuel camshaft and fuel...

- Page 233 Working Card Adjustment of Camshaft for Valve and Injection Timing Page 3 (4) Edition 04H L28/32H Compare the calculated value determined with the value mentioned below. If the values exceeds the limits, an adjustment must be done in order to correct the errors, on the X-measure or reset the gear wheel, see following text for changing "X"-measuring.

- Page 234 Adjustment of Camshaft for Valve and Injection Timing Page 4 (4) Edition 04H L28/32H The injection timing can be altered on each cylinders Thicker and/or more shims (reduction of the distance by inserting or removing shims under the thrust piece “X”) results in an advanced injection.

- Page 235 MAN Diesel Plate Intermediate Wheel 60701-06H Page 1 (2) L28/32H 06.28 - ES0...

- Page 236 MAN Diesel Plate 60701-06H Intermediate Wheel Page 2 (2) L28/32H Item Item Qty. Qty. Designation Benævnelse Designation Benævnelse Screw Skrue Lock plate Sikringsplade Gasket Pakning Union Vinkelforskruning Pipe Rør Union Vinkelforskruning Spray pipe Sprøjterør Fitted bolt Pasbolt Self locking Selvlåsende møtrik...

- Page 237 MAN Diesel Plate Camshaft and Camshaft Bearing 60705-22H Page 1 (2) L28/32H 02, 29, 32, 33, 34 5 cyl. 35 20 6 cyl. 26 26 7 cyl. 27 27 8 cyl. 28 28 9 cyl. 06.43 - ES0...

- Page 238 MAN Diesel Plate 60705-22H Camshaft and Camshaft Bearing Page 2 (2) L28/32H Item Item Qty. Qty. Designation Benævnelse Designation Benævnelse Camshaft bearing Styreakselleje Camshaft, Styreaksel, intermediate, mellem Camshaft section Styreakselssektion 7 cyl. engine 7 cyl. motor "aft", 6 cyl. engine "agter", 6 cyl.

- Page 239 Operating gear 508/608...

- Page 240 MAN Diesel 608.01 Description Operating Gear for Valve and Fuel Injection Pumps Page 1(1) Edition 12H L/V28/32H Roller Guides The fuel injection pumps and the rocker arms for inlet and exhaust valves are operated by the cams, on the Valve bridge Rocker arm camshaft through roller guides.

- Page 241 MAN Diesel & Turbo 608-01.00 Working Card Inspection of Valve Roller Guides Page 1 (2) Edition 01H L/V28/32H Safety precautions: Special tools: Stopped engine Plate no. Item no. Note. Shut-off starting air Shut-off cooling water 62006 20 - 120 Nm Shut-off fuel oil Shut-off cooling oil Stopped lub.

- Page 242 MAN Diesel & Turbo 608-01.00 Working Card Inspection of Valve Roller Guides Page 2 (2) Edition 01H L/V28/32H Dismounting of Roller Guide. Dismount the screws (3) which secure the roller guide top cover, take off the cover, and lift out Turn the engine so that the roller, rests on the the roller guide (5).

- Page 243 MAN Diesel & Turbo 608-01.05 Working Card Inspection of Fuel Injection Pump Roller Guide Page 1 (2) Edition 01H L/V28/32H Safety precautions: Special tools: Stopped engine Plate no. Item no. Note. Shut-off starting air Shut-off cooling water Shut-off fuel oil Shut-off cooling oil Stopped lub.

- Page 244 MAN Diesel & Turbo 608-01.05 Working Card Inspection of Fuel Injection Pump Roller Guide Page 2 (2) Edition 01H L/V28/32H Dismounting of Roller Guide. Inspect the spherical stud for deformations (replace as necessary). Remove the support ring (1) and spring (2) and take up the roller guide (3), see fig.

- Page 245 MAN Diesel & Turbo 608-01.10 Working Card Control and Adjusting of Valve Clearance Page 1 (3) Edition 01H L/V28/32H Safety precautions: Special tools: Stopped engine Plate no. Item no. Note. Shut-off starting air Shut-off cooling water 62008 Exhaust Shut-off fuel oil 62008 Inlet Shut-off cooling oil...

- Page 246 MAN Diesel & Turbo 608-01.10 Working Card Control and Adjusting of Valve Clearance Page 2 (3) Edition 01H L/V28/32H Adjusting of Inlet Valve Clearance. Turn the engine so that the roller, rests on the circular part of the cam, i.e. the inlet valves and the exhaust valves are closed.

- Page 247 MAN Diesel & Turbo 608-01.10 Working Card Control and Adjusting of Valve Clearance Page 3 (3) Edition 01H L/V28/32H The feeler gauges for checking the clearance have two gauges which are marked "incorrect" and "correct", the latter to be used when adjusting the valve clearance, see fig.

- Page 248 MAN Diesel & Turbo Plate Roller Guide and Push Rods 60801-17H Page 1 (2) L28/32H 11.36 - ES0...

- Page 249 MAN Diesel & Turbo Plate Roller Guide and Push Rods 60801-17H Page 2 (2) L28/32H Item Item Qty. Designation Benævnelse Qty. Designation Benævnelse Thrust piece Trykstykke Roller guide for fuel Rullestyr for brændsels- injection pump, com- pumpe, komplet inkl. Pipe Rør...

- Page 250 Control/safety 509/609...

- Page 251 MAN Diesel 609.01 Description Control and Safety Systems Page 1 (2) Edition 20H L+V28/32H Governor Should a fuel pump plunger seize in its barrel, thus blocking the regulating guide, governing of the The engine speed is controlled by a hydraulic go- remaining fuel pumps may continue un impaired vernor.

- Page 252 MAN Diesel 609.01 Description Control and Safety Systems Page 2 (2) Edition 20H L+V28/32H The engine can be stopped manually by pressing The overspeed alarm (SAH 81) is activated by means down the button (7), see fi g. 1, which will activate the of the micro switch (9).

- Page 253 609.05 Description Instruments and Automatics Page 1 (3) Edition 11H L28/32H Main instrument panel As standard the engine is equipped with an instru- The instrument panel is mounted fl exibly on rubber ment panel, comprising instruments for visual indi- elements and all manometer connections are con- ca tion of the most essential pressures.

- Page 254 609.05 Description Instruments and Automatics Page 2 (3) Edition 11H L28/32H Instrumentation too high press. drop across lub. oil fi lter too high HT FW temperature - outlet engine As standard the engine is supplied with the following too low starting air pressure - inlet engine...

- Page 255 Description Instruments and Automatics Page 3 (3) Edition 11H L28/32H The alarm unit consist of a box with a fl oat switch Alarm for Prelubricating (LAL 25) for level monitoring, see fi g. 4. Alarm for missing prelubricating, when the engine...

- Page 256 609.10 Description Lambda Controller Page 1 (2) Edition 15H L28/32H Purpose Thus the solenoid valve (4) opens. The jet system is activated, the turbocharger accelerates and increases the charge air pressure, thereby pressing the piston The purpose with the lambda controller is to prevent (3) backwards in the lambda cylinder (5).

- Page 257 MAN Diesel 609.10 Description Lambda Controller Page 2 (2) Edition 15H L28/32H 1. Regulating arm 2. Switch (Pick-up) 3. Piston 4. Solenoid valve 5. Lambda controller 6. Overspeed device (mecanical activated 3/2 valve) Charge air receiver Engine's compression air system Fig 1 Lambda controller incl.

- Page 258 MAN Diesel & Turbo 609.35 Description Starting Box Page 1 (1) Edition 06H L28/32H Description Engine / Turbocharger RPM By activating the "Engine RPM/TC RPM" button, the The starting box is mounted on the engine's control indication is changed. side. On front of the box there are the following in-...

- Page 259 MAN Diesel 609.40 Description Converter for Engine- and Turbocharger RPM Signal Page 1 (1) Edition 01H L+V28/32H Engine RPM signal The "engine run" signals will be given through a relay. One for synchronizing and one for start/stop of pre. For measuring the engine's RPM, a pick-up mounted lub.

- Page 260 MAN Diesel Functional Test and Adjustment of Safety, 609-01.00 Working Card Page 1 (2) Alarm and Monitoring Equipment Edition 01H General Safety precautions Special tools Stopped engine Plate No Item No Note. Shut-off starting air Shut-off cooling water See Related Procedure Shut-off fuel oil Shut-off cooling oil Stopped lub.