Summary of Contents for SHAN DONG HUA YUAN LAI DONG ENGNE CO..LTD KM385BT Series

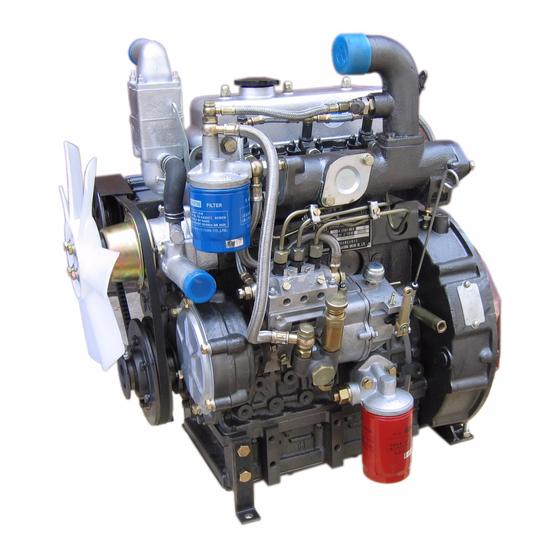

- Page 1 KM385BT DIESEL ENGINE MODEL KM385BT SERIES OPERATION MANUAL SHAN DONG HUA YUAN LAI DONG ENGNE CO..LTD...

- Page 2 PREFACE Please read the manual of operation carefully before opefrate the engine ,and the operator should maintain it strictly as required. The engine is improved from time to time ,so the manual of operation may be different from the engine ,please draw attentions to it .The engine NO.is engraved in the central position of cylinder-block upper end by the side of the fly wheel.

-

Page 3: Table Of Contents

CONTENTS CHAPTER I engine ntroduction……………………………………………….. 1 1. Main specifications 2. Main accessories specifications 3. Fitting clearances and wearing limits of the main moving parts 4. Main bolts tightening torque CHAPTER engine operation and precautions…………………………….5 1. Engine operation 2. Precautions when operating 3. -

Page 4: Main Specifications

CHAPTER I ENGINE INTRODUCTION 1. MAIN SPECIFICATIONS Dynamic Norm of the Engine(the power of each type is show on the nameplate) KM385BT Diesel Engine order Rated Power/Speed(KW/rpm) Max Torque/Speed(N m/rpm) 18.4/2350 86 / 1762 17.8/2400 81.5/ 1800 17.6/2350 82.3/ 1762 18.3/2350 85.5/ 1762 18.4/2400... -

Page 5: Main Accessories Specifications

Valve sinkage Intake valve(mm) 0.7~0.9 Exhaust valve(mm) 0.7~0.9 Steady speed adjusting ratio at rated conditon Oil sump capacity(L) Temperature( ) Water outlet 75~85 85~95 Exhaust pipe Starting method Electric starting Lubricating method Pressure & splash Cooling method Water cooling Overall dimension (L×W×H) (mm) 569×525×604 Net weight (kg) Tractor, engineering... - Page 6 STANDARD NEW ENGINE L1MIT NAME FITTING SIZE FITTING CLEARANCE ALLOWANCE Shaft 58h6 Main journal and Clearance –0.019 0.07~0. 138 0.25 main bearing hole +0.119 Hole 58 +0.07 -0.075 Axial clearance of Clearance -0.165 0.075~0. 265 0.50 crankshaft +0.10 Crankshaft journal Shaft 50h6 Clearance...

-

Page 7: Main Bolts Tightening Torque

No NAME STANDARD FITTING NEW ENGINE LIMIT SIZE FITTING CLEARANCE ALLOWANCE 12 Camshaft journal Clearance -0.050 Shaft 44c7 –0.075 and its bushing 0.08~0.130 0.20 +0.055 Hole 44 +0.03 13 Camshaft axial Clearance -0.070 5C11 -0.145 0.07~0.245 0.60 clearance +0.10 14 Valve tappet Clearance -0.016... -

Page 8: Chapter Engine Operation And Precautions

CHAPTER ENGINE OPERATION AND PRECAUTIONS 1. ENGINE OPERATION Fuel, oil and cooling water 1) Fuel and oil: Fuel and oil selected subject to local ambient temprature. 2) Cooling water: Water of rain or clear river water is always preferably selected as cooling water. You are always suggested to fill some anti-frozen liquid in cooling system in cold winter. -

Page 9: Precautions When Operating

Engine running 1) Engine is only a11owed working with 1oad when the coo1ing water temperature is up to 50ºC. Running at rated power when the coo1ing water temperature is about 80ºC. 2) Increasing or decreasing the 1oad and speed should be smoothly and gradually carried out Normally is not a11owed to increase or decrease the 1oad suddenly. -

Page 10: Chapter Engine Maintenance

CHAPTER ENGINE MAINTENANCE To ensure a longer service life, the engine should be maintained according to the following procedure. 1. DAILY MAINTENANCE Check the oil level in oil sump, to ensure the oil level be between the two marks on the oil dipstick. -

Page 11: Engine Preservation Storage

Carry out the follow procedure besides item 2. Check full injection pressure and atomization quality. Clean and adjust when necessary. Check injection advance angle and adjust when necessary. Dismount cylinder head; Remove carbon deposit; Check valve sealing and lap when necessary. Check connecting rod bolts, main bearing bolts and flywheel bolts for tightness. -

Page 12: The Structure Of Engine

Engine should be stored in place of dry, clean and good ventilation. Chemical medicine is strictly prohibited nearby. The above preservation method could store the engine for 3 months, if the preservation is overdue, the engine should be preserved as above again. CHAPTER IV THE STRUCTURE OF ENGINE CY L I NDE R B L O CK AS S E MB L Y . -

Page 13: Crankshaft And Flywheel Assembly

CRA NK S H AFT AN D FL Y W H E E L AS S E M B L Y Crankshaft is made of QT900-2 nodular cast iron. Main bearing is made of steel back 20% alloy with high tin and aluminum which can't adhere oil while mounting to avoid affecting its radiating efficiency and damaging bearings. -

Page 14: Driving Mechanism

The connecting rod is made of 35CrMoA. There is coupling mark on the body and cap. You must install according to the mark; wrong installing should be avoided. The tightening torque of the connecting rod bolts is50 – 60N.m. The connecting rod bearing is made of steel back alloy with aluminum, tin, silicon and cuprum. -

Page 15: Fuel Suppl Y System

Valve clearance adjustment: Valve clearance shall affect engine performance. It should be checked and adjusted according to technical maintaining stipulation. The intake valve cooling clearance is of 0.20-0.25mm,the exhaust valve cooling clearance is of 0.25-0.30mm. The adjusting procedure as following: Make the first cylinder piston stop at T.D.C. -

Page 16: Lubrication System

the engine shall exhaust black smoke, lower power and speed, raise exhaust temperature or knock the cylinder. To check the trouble injector, loosen injection pipes one by one, stop injection, and inspect the color of exhaust smoke. Only the trouble injector stop injection can make the engine no smoke, crank the crankshaft slowly to check injection sound of each injector, the trouble injector shall be no sound injection. -

Page 17: Electric Systsem

in cylinder block and head are very small, so care must be taken not to block them especially those holes between cylinder bores and the triangle area where injection nozzle located to prevent trouble caused by overheating. Water pump is centrifugal type. If there is trouble in water seal, water may leak out from overflowing hole, repair it in time. -

Page 18: Engine Can Not Be Started

CHAPTER V ENGINE TROUBLES AND REMEDY A: ENGINE CAN NOT BE STARTED Trouble Cause Remedy 1. Fuel System 1) No fuel in fuel tank or fuel cock not opens. 1) Fill in fuel or open fuel cock. 2) Air in fuel system 2) Discharge air by manual delivery pump. -

Page 19: Engine Stops Suddenly

3. Insufficient fuel supply. 1) Delivery pipe & fuel filter blocked. 1) Clean it. 2) Nozzle tip worn out. 2) Replace nozzle tip or injector. 4. Water in fuel 4. Replace fuel. 5. Incorrect fuel supply advance angle. 5. Adjust 6. -

Page 20: Engine Over Heat

7. Too large clearance between main bearing and 7. Check and replace when necessary. connecting rod bearing. 8. Improper adjustment of pressure adjusting valve on 8. Readjust it oil filter. 9. Oil pressure gauge damaged 9. Replace it 10. Wrong assembling of oil filter seat packing 10. - Page 21 3. Exhaust black smoke (bad combustion) 1) Reduce the load. 1) Engine overloaded 2) Adjust or replace the nozzle. 2) Nozzle with bad atomization or leak fuel 3) Adjust the fuel delivery advance angle. 3) Fuel delivery too late 4) Clean air filters and air intake pipe or 4) Air filter blocked replace filter cartridge.

-

Page 22: Starter Is Out Of Order

8. Engine unsteady in low speed. 1) Idle speed screw not correct. 1) Adjust it. 2) Uneven fuel supply in low speed. 2) Adjust it, I. STARTER IS OUT OF ORDER Trouble cause Remedy I. The starter can't work. 1). Connecting wire is broken or bad connection. l). -

Page 23: Alternator Is Out Of Order

J. ALTERNATOR IS OUT OF ORDER Trouble cause Remedy 1. The alternator can not generating power. 1). The wire is broken or wrong connection. 1). Check and repair it. 2). The stator and rotor coil is broken or short circuit. 2). - Page 24 Add : 40,Wulong North Road, Laiyang City ,Shandong , China FAX:0086-535-7215149 E--mail : ldworks@ec . com . cn KM385BT-35500-1...

Need help?

Do you have a question about the KM385BT Series and is the answer not in the manual?

Questions and answers