Advertisement

Electronic copies of the most current TSM issue can be found on the Viking Pump website at www.vikingpump.com

INTRODUCTION

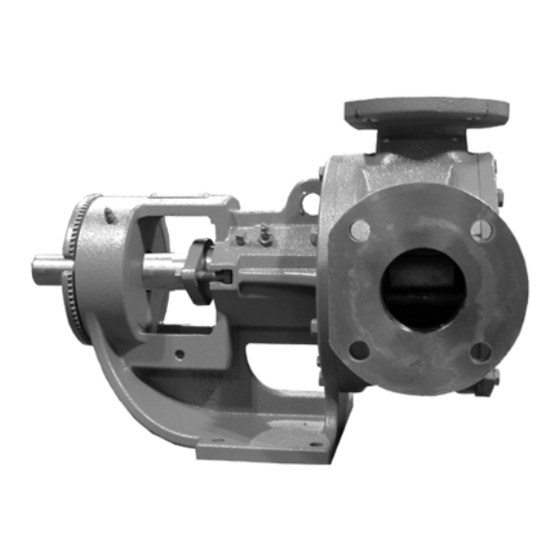

This bulletin deals exclusively with the Model LV3900 Heavy

Duty Pump. The illustrations used are to help you identify

pump parts by name and to assist in the maintenance and

repair of your pump.

When ordering repair parts, secure a parts list from your

Viking representative and be sure to give the complete part

name and material as well as the pump model and serial

number.

CONTENTS

Maintenance .......................................................................

Repair .................................................................................

Thrust Bearing Adjustment .................................................

DANGER !

Before opening any Viking pump liquid cham-

ber (pumping chamber, reservoir, relief valve

adjusting cap fitting etc.) Be sure:

1. That any pressure in the chamber has been

completely vented through the suction or

discharge lines or other appropriate openings

or connections.

2. That the driving means (motor, power takeoff,

turbine, engine, etc.) has been "locked out"

or made non- operational so that it cannot be

started while work is being done on pump.

3. That you know what liquid the pump has been

handling and the precautions necessary to

safely handle the liquid. Obtain a material

safety data sheet (MSDS) for the liquid to be

sure these precautions are understood.

Failure to follow above listed precaution-

ary measures may result in serious injury or

death.

VIKING PUMP, INC.

TECHNICAL SERVICE MANUAL

HEAVY-DUTY BRACKET MOUNTED PUMPS

MAINTENANCE AND REPAIR INSTRUCTIONS

•

A Unit of IDEX Corporation

MODEL LV3900

2

3

4

MODEL LV3900

To extend the life of the LV3900, it is recommended that

the pump be operated within the catalog ratings whenever

possible.

Catalog Ratings

Nominal Flow

GPM

M 3/hr

Pressure Range

PSI

Bar

Temp. Range

(°F)

(°C)

Viscosity Range

•

Cedar Falls, IA 50613 USA

SECTION

TSM 110.2

PAGE

1 OF 6

ISSUE

C

FIGURE 1

140

32

200 PSI: 100 SSU and

above. (Contact factory

for pressures greater than

200 PSI)

14 Bar: 20 cSt and above

7 Bar: below 20 cSt

+ 225

+ 120

Up to 750 SSU

Advertisement

Table of Contents

Summary of Contents for Viking pump LV3900

- Page 1 Electronic copies of the most current TSM issue can be found on the Viking Pump website at www.vikingpump.com TECHNICAL SERVICE MANUAL SECTION TSM 110.2 PAGE 1 OF 6 HEAVY-DUTY BRACKET MOUNTED PUMPS MODEL LV3900 ISSUE MAINTENANCE AND REPAIR INSTRUCTIONS INTRODUCTION This bulletin deals exclusively with the Model LV3900 Heavy Duty Pump.

-

Page 2: Safety Information And Instructions

● You know what material the pump has been For weight of the pump alone (which does not include handling, have obtained a material safety data the drive and/or base plate) refer to the Viking Pump sheet (MSDS) for the material, and understand product catalog. -

Page 3: Maintenance

The points listed below will help provide long service life. SUGGESTED REPAIR TOOLS: The following tools must be available to properly repair Model LV3900 pumps. These LUBRICATION: Before each use, external lubrication should tools are in addition to standard mechanics’ tools such as be applied slowly with a handgun at all 4 lubrication fittings open end wrenches, pliers, screw drivers, etc. - Page 4 EXPLODED VIEW - MODEL LV3900 (FOR PARTS IDENTIFICATION) 〇 〇 〇 〇 〇 〇 〇 〇 〇 〇 〇 23 24 30 31 〇 〇 〇 〇 〇 〇 〇 〇 〇 〇 〇 〇 〇 〇 〇〇 〇 〇 〇...

-

Page 5: Thrust Bearing Adjustment

BUSHING DANGER LIPSEAL BEFORE STARTING PUMP, BE SURE ALL DRIVE EQUIPMENT GUARDS ARE IN PLACE. IDLER DISC FAILURE TO PROPERLY MOUNT GUARDS MAY IDLER RESULT IN SERIOUS INJURY OR DEATH. FIGURE 3 THRUST BEARING ADJUSTMENT See Fig. 5 Loosen the two set screws “A” in the outer face of the BALL BEARING BEARING HOUSING bearing housing “B”... -

Page 6: Maintenance And Repair Instructions

Viking’s website (www.vikingpump.com/warranty/warranty-info). A complete copy of the warranty may also be obtained by contacting Viking through regular mail at Viking Pump, Inc., 406 State Street, Cedar Falls, Iowa 50613, USA. THIS WARRANTY IS AND SHALL BE VIKING’S SOLE...

Need help?

Do you have a question about the LV3900 and is the answer not in the manual?

Questions and answers