Advertisement

Advertisement

Table of Contents

Summary of Contents for Tevo TORNADO

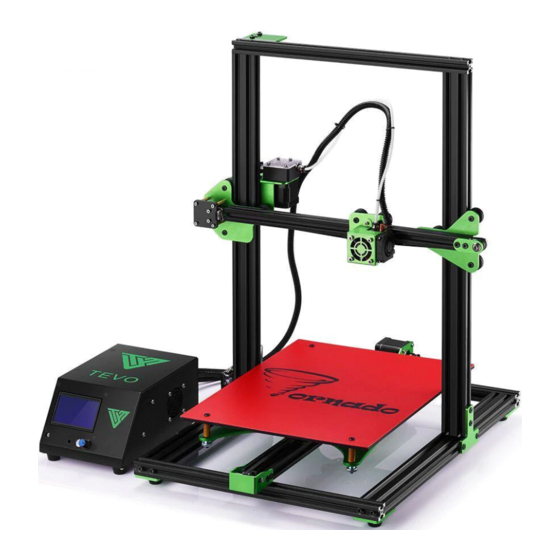

- Page 1 TEVO TORNADO ASSEMBLY MANUAL TEVO TEVO 3D Electronic Technology Co., Ltd.

-

Page 3: Read Me First

READ THIS MANUAL COMPLETELY BEFORE ASSEMBLING AND POWERING UP YOUR PRINTER! Hazards and Warnings The TEVO Tarantula 3D printer has motorized and heated parts. When the printer is in operation always be aware of possible hazards. Electric Shock Hazard Never open the electronics bay of the printer while the printer is powered on. Before removing the access door, always power down the printer and unplug the AC line cord. -

Page 4: Table Of Contents

Table of Contents READ ME FIRST Table of Contents Letter from TEVO Assembly Fine-Tuning Leveling the Build Plate Preparaing Slicing Software How to Slice 3D Object for SD Print How to Flash Firmware TEVO After-Sales... -

Page 5: Letter From Tevo

Letter from TEVO Dear Customer, Thank you for purchasing the TEVO Tarantula 3D printer. This guide will step you through the assembly and the first run of the printer. If you have any problems during assembly, please go to our Facebook group: https://www.facebook.com/groups/TEVO.3dprinter.owners/... -

Page 6: Assembly

Assembly 1. Remove the parts from the box and remove any tape and padding from the parts. Inspect the parts to make sure they were not damaged in shipment. 2. Install the gantry frame (A) to the base frame (B). •... - Page 7 3. Install the two T-shaped frame reinforcement plates. The plate with the limit switch goes on the Z stepper motor side. • Loosen the T-nuts by hand and turn them so they will fit inside the grooves on the frames. Keep the nuts loose so that when you tighten the bolts, the nuts will rotate 90 degress and grab onto the inside of the groove.

- Page 8 4. Connect all electrical cables. • Put the control box on the lead screw side of the printer with the screen facing forward. • Connect the heater cables to the control box. The cable for the build pates has four pins. The cable for the nozzle heater has eight pins.

- Page 9 5. Make sure the PTFE tube is all the way down in the hotend, it may come loose during transportation. Push it down all the way into the hotend. Gaps between PTFE tube and nozzle will cause clogging.

-

Page 10: Fine-Tuning

Fine-Tuning 1. Adjust the tension of the build plate wheels on the Y-axis on the base frame. • Check the tension of the build plate wheels. Try to turn the wheels under the build plate without forcing it. If the wheel turns freely or without much effort, then it is too loose. •... - Page 11 3. Adjust the tension of the X-carriage wheels on the X-axis on the gantry frame. • Check the tension of the X-carriage wheels. Try to turn the wheels under the build plate without forcing it. If the wheel turns freely or without much effort, then it is too loose. •...

- Page 12 5. Check the tension of the belt driving the X-carriage. The belt should be taut, with no slack or slop. • If the belt is loose: • Loosen the two bolts at the right side of the gantry holding the belt pulley. •...

-

Page 13: Leveling The Build Plate

Leveling the Build Plate To build good parts, the build plate needs to be level, and the nozzle needs to be about 0.1mm from the build plate in all locations. This is about the thickness of a single piece of A4 paper. You want to adjust the height of the build plate so thate you can barely slide the paper between the nozzle and the build plate with only a little resistance. -

Page 14: Preparaing Slicing Software

Preparaing Slicing Software This printer works with most slicing/printing software like Simplify3D, Cura, Repetier-Host, etc. But we will go in details for Repetier-Host software and tell you how to set it up so that you can make your first print. First we recommend you to download the software from the official website: https://www.repetier.com After installation is done and you start the software, you should get the following screen: Now we have to set up our printer in the settings so that Repetier-Host can connect to it and will... - Page 15 Click on Printer Shape tab, change the following values: X Max - 320 Y Max - 320 Print Area Width - 300 Print Area Depth - 300 Print Area Height - 400...

- Page 16 Go to Printer tab, change the value according to the picture on the left. Go to Slicer tab, select Slic3r as slicer and click on Configuration.

- Page 17 On Slic3r window, go to File -> Load Config. (Loaded setting is for general PLA filament printing). Select and load Tornado.ini from SD card. Rename print setting, filament, printer to Tornado and save.

-

Page 18: How To Slice 3D Object For Sd Print

How to Slice 3D Object for SD Print Click on Load, browse to location of the file, then choose Open. After the file is open up in 3D view, click on Slicer tab to go into slicing page. - Page 19 Select the correct Print Setting, Printer Settings, and Extruder type, then click on Slice with Slic3r. After slicing, click on Save for SD Print to save the G-code file to the SD card with file name of your choice. Then you can insert the card to your printer and choose Print from SD to start printing.

-

Page 20: How To Flash Firmware

How to Flash Firmware To install firmware on your printer, you'll need to download the following: 1. Arduino IDE (http://www.arduino.cc) 2. Firmware Source Code (You can get it from many ways, e.g. our Facebook Page Files section, our Customer Service, or from Marlin and Repetier directly.) In this chapter, we're going to use Marlin for demonstration. -

Page 21: Tevo After-Sales

TEVO After-Sales Dear Customer, Thank you for purchasing TEVO 3D printer. We are dedicated to producing low price, high quality 3D printers and hope you have as much fun using it as we did creating it! If you have any issue/questions regarding the contents in the kit, please fill out a Service Ticket on our Support page. - Page 22 If the part is the LCD Panel, Power Supply or Mainboard, the customer shall ship the part back to TEVO and TEVO will send a new part. 2.5. For parts damaged by the customer, refer to section 1.3, submit a Service Ticket (Report a Problem / Customer Damaged Parts.)

Need help?

Do you have a question about the TORNADO and is the answer not in the manual?

Questions and answers