Summary of Contents for dunphy TD

- Page 1 _________________________________________________________________________________________ DUAL FUEL BURNERS TD/TAD4 GENERAL INFORMATION OPERATING MANUAL 1 of 165...

- Page 2 Operating Instructions For TD/TAD4 Dual Fuel Burner Revision Table Rev No. Description Date Emergency stop information added - section 5.9 6.6.13 Exploded drawings revised – section 11 June 13 2 of 165 TD/TAD4 Manual Rev 4...

- Page 3 The Company strongly advises that the commissioning of the burners is carried out by Dunphy trained engineers and points out that it may be impossible to impart all the necessary information to enable others to do so.

-

Page 4: Table Of Contents

Operating Instructions For TD/TAD4 Dual Fuel Burner Contents General Information ............................7 General ................................7 Working parameters ........................... 7 Fuels ................................. 7 1.3.1 Fuel Tanks .............................. 8 1.3.2 Filtration ..............................8 1.3.3 Ring Main Pumps ..........................8 1.3.4 Pipe Runs ..............................8 1.3.5... - Page 5 Operating Instructions For TD/TAD4 Dual Fuel Burner Modulation ..............................55 Normal mode ............................... 55 Local mode ..............................55 Non-volatile lockout ..........................55 Ratiotronic 6000 Inverter interface additional information ............56 Post Purge Operation..........................56 Emergency Stop ............................57 Component Setup Parameters ....................... 58 Ratiotronic 6000 ............................

- Page 6 Operating Instructions For TD/TAD4 Dual Fuel Burner 12.2 RWF 40 Burner temperature controller ................... 123 12.3 Unibloc ................................. 128 12.3.1 Unibloc General Arrangements ....................128 12.3.2 65mm Ratiotronic Unibloc exploded diagram and parts list........... 130 12.3.3 65mm Ratiotronic Unibloc with pilot exploded diagrams and parts list ...... 131 12.3.4 80mm Ratiotronic Unibloc exploded diagrams and parts list .........

-

Page 7: General Information

Dunphy technical department. Fuels 'TD / TAD' Series of burner must only be used with the fuels specified on the burner data plate and in the case of gas, the pressure must not, under any circumstances, drop below the stated minimum operating level. -

Page 8: Fuel Tanks

Operating Instructions For TD/TAD4 Dual Fuel Burner 1.3.1 Fuel Tanks Fuel storage tanks must be positioned to maintain a positive head to burners or ring main pumps, regardless of the oil level in the tank. Vertical and horizontal storage tanks should be mounted on concrete plinths in accordance with local, national or any environmental standards that may apply. -

Page 9: Oil Line Connections

Operating Instructions For TD/TAD4 Dual Fuel Burner 1.3.8 Oil Line Connections It is essential that the final connections between the main oil supply lines and the burner fuel pump are made with flexible oil lines that are long enough to allow the burner to be swung open on its hinges without having to be disconnected. - Page 10 Operating Instructions For TD/TAD4 Dual Fuel Burner On burners which have air inlet silencers as standard a 0-10 scale is fitted to indicate the opening of the air shutter (not the firing rate) and nylon support bearings ensure that the travel is as smooth as possible.

- Page 11 Operating Instructions For TD/TAD4 Dual Fuel Burner Control desks are available in ‘wardrobe’ type style (figure 3) or ‘desk’ type style (figure 4). These can vary in complexity and are able to house a whole host of burner/boiler controllers, water levels controls, inverters, plc etc...

-

Page 12: Burner Details And Power Curve

Burner details and power curve BURNER Firing Rate kW VOLUME FIRING MODE OPTIONS (m3/HR)*1 Pump Running Starting Motor Motor Voltage Electronic Current Current High / TYPE Modulation High / Low Oil TD410Z 4500 380-420 23 Amp 48 Amp ... -

Page 13: General Arrangement Details

General arrangement details 1.6.1 High low/modulating burners on gas, high low on oil High Low and Pneumatic Modulation burners both use air/gas ratio valves (details can be found in the component section of this manual). They have built-in governors thus not requiring an external governor for gas pressures up to 350mbar. -

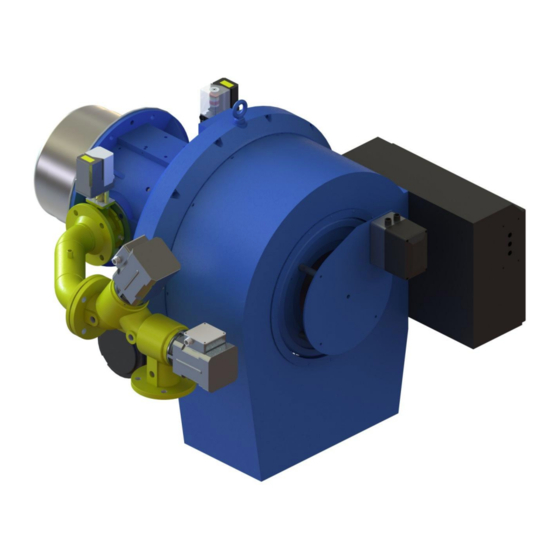

Page 14: Electronic Modulation Burners (M Rt)

Operating Instructions For TD/TAD4 Dual Fuel Burner 1.6.2 Electronic modulation burners (M RT) Electronic modulation burners are fitted with on/off gas valves and electronically controlled butterfly valves for the gas regulation. The gas valve is generally a Unibloc (see component section for details) however other valves can also be used depending on site details or customer preference. - Page 15 Operating Instructions For TD/TAD4 Dual Fuel Burner TD420 Burners with Unibloc Gas Valve June 13 15 of 165 TD/TAD4 Manual Rev 4...

-

Page 16: Td10-415 Multi - Fuel Low Nox Burner General Arrangement

Operating Instructions For TD/TAD4 Dual Fuel Burner 1.6.3 TD10-415 Multi – Fuel Low Nox Burner General Arrangement June 13 16 of 165 TD/TAD4 Manual Rev 4... -

Page 17: Td420 Multi - Fuel Low Nox Burner General Arrangement

Operating Instructions For TD/TAD4 Dual Fuel Burner 1.6.4 TD420 Multi – Fuel Low Nox Burner General Arrangement June 13 17 of 165 TD/TAD4 Manual Rev 4... -

Page 18: Tad420 Multi - Fuel Low Nox Burner General Arrangement

Operating Instructions For TD/TAD4 Dual Fuel Burner 1.6.5 TAD420 Multi – Fuel Low Nox Burner General Arrangement June 13 18 of 165 TD/TAD4 Manual Rev 4... -

Page 19: Installation

It is important to check that the burner draught tube projection into the combustion chamber conforms to the appliance manufacturers instructions. Non standard draught tube projections are available on request; - please consult the Dunphy sales dept. In general, for reverse flame boilers the draught tube projection into the combustion chamber should be between 50 and 100mm. -

Page 20: Gas Valve Mounting

Operating Instructions For TD/TAD4 Dual Fuel Burner Gas Valve mounting 2.2.1 Burner fitted with Unibloc The Unibloc gas valve is a heavy item and will require two persons to lift it into position and secure in place using bolts provided. - Page 21 Operating Instructions For TD/TAD4 Dual Fuel Burner VGD Gas Valve Orientation Unibloc Orientation Governor Orientation Fit governor in accordance with manufactures instructions. June 13 21 of 165 TD/TAD4 Manual Rev 4...

-

Page 22: Burner Fitted With Siemens Vgd40 Gas Valve

Operating Instructions For TD/TAD4 Dual Fuel Burner With the gas isolation valve next to the burner closed, a pressure test should be carried out on the main gas supply pipe work and all connections checked with a suitable, non corrosive leak detection fluid. -

Page 23: Fuel Oil Installations

Operating Instructions For TD/TAD4 Dual Fuel Burner Fuel oil installations Fuel oil installations must comply with the following British Standards or equivalent local, national or international standards. BS799 Oil burning equipment BS5410 Code of practice for oil firing BS2869 Fuel oils for non marine use Installations must conform to local Bye-laws and regulations which should be identified by application to the local planning authority. -

Page 24: Gas Installation

Operating Instructions For TD/TAD4 Dual Fuel Burner 5. Turn pump slow until all air has been vented both from the pump itself and the burner pipework, and the system is fully flooded. 6. The pump can now be put into operation. - Page 25 Operating Instructions For TD/TAD4 Dual Fuel Burner Provision must be made for an adequate supply of combustion and ventilating air to be available when all access doors, fire doors and windows are closed. Air supply fans or flue dilution systems must be interlocked to prevent operation of the burner(s) in the event of fan failure or shutdown.

-

Page 26: Combustion Head Settings

Operating Instructions For TD/TAD4 Dual Fuel Burner 3 Combustion Head Settings On burners fitted with standard 'Z' and 'Y' type nose cones, the dimension 'A' between the end of the burner nose cone and the front face of the flame plate, can be altered by releasing the three, M6 locking nuts inside the draught tube, and sliding the cone forwards / backwards, along its adjustment slots until the required setting is obtained. -

Page 27: High / Low Burners

Operating Instructions For TD/TAD4 Dual Fuel Burner High / Low Burners June 13 27 of 165 TD/TAD4 Manual Rev 4... -

Page 28: Modulating Burners

Operating Instructions For TD/TAD4 Dual Fuel Burner Modulating Burners June 13 28 of 165 TD/TAD4 Manual Rev 4... -

Page 29: Modulating Td410 Burners Fitted With Low Nox Multi-Pipe Gas Head

Operating Instructions For TD/TAD4 Dual Fuel Burner Modulating TD410 Burners Fitted With Low NOx Multi-Pipe Gas Head June 13 29 of 165 TD/TAD4 Manual Rev 4... - Page 30 Operating Instructions For TD/TAD4 Dual Fuel Burner June 13 30 of 165 TD/TAD4 Manual Rev 4...

-

Page 31: Modulating Td415-420 Burners Fitted With Low Nox Multi-Pipe Gas Head

Operating Instructions For TD/TAD4 Dual Fuel Burner Modulating TD415-420 Burners Fitted With Low NOx Multi-Pipe Gas Head June 13 31 of 165 TD/TAD4 Manual Rev 4... - Page 32 Operating Instructions For TD/TAD4 Dual Fuel Burner June 13 32 of 165 TD/TAD4 Manual Rev 4...

-

Page 33: Modulating Td410 Burners Fitted With Low Nox Multi-Pipe Gas Head & Multi-Oil

Operating Instructions For TD/TAD4 Dual Fuel Burner Modulating TD410 Burners Fitted With Low NOx Multi-Pipe Gas Head & Multi-Oil June 13 33 of 165 TD/TAD4 Manual Rev 4... - Page 34 Operating Instructions For TD/TAD4 Dual Fuel Burner June 13 34 of 165 TD/TAD4 Manual Rev 4...

-

Page 35: Modulating Td415-420 Burners Fitted With Low Nox Multi-Pipe Gas Head & Multi-Oil

Operating Instructions For TD/TAD4 Dual Fuel Burner Modulating TD415-420 Burners Fitted With Low NOx Multi-Pipe Gas Head & Multi- June 13 35 of 165 TD/TAD4 Manual Rev 4... - Page 36 Operating Instructions For TD/TAD4 Dual Fuel Burner June 13 36 of 165 TD/TAD4 Manual Rev 4...

-

Page 37: Modulating Burners Fitted With Bio - Gas Head

Operating Instructions For TD/TAD4 Dual Fuel Burner Modulating Burners Fitted With Bio - Gas Head June 13 37 of 165 TD/TAD4 Manual Rev 4... -

Page 38: Nozzle Adjustment

Operating Instructions For TD/TAD4 Dual Fuel Burner Nozzle Adjustment 3.3.1 Gas Head The Combustion head is attached to the gas inlet on the body. The gas flows through the gas annulus and through the 4 holes in the gas nozzle. -

Page 39: Adjustments And Operating Principles

Operating Instructions For TD/TAD4 Dual Fuel Burner 4 Adjustments and Operating Principles High/Low burners (HL) 4.1.1 High / Low Gas High low control is classed as the simplest form of control for a burner of this size. It relies on a high/low thermostat monitoring either the temperature or pressure of an appliance which in turn via the control box will drive the air damper servo between the high fire position and low fire position. -

Page 40: High / Low Oil

Operating Instructions For TD/TAD4 Dual Fuel Burner 4.1.2 High / Low Oil Atomisation of the fuel is by two separate nozzles, one for low fire and the second for high fire. The oil supply to each nozzle passes through one of twin solenoid shut-off valves and the burner output is determined by the size of nozzle and the pressure setting of the fuel pump regulator. - Page 41 Operating Instructions For TD/TAD4 Dual Fuel Burner HIGH/LOW BURNERS NOZZLE PRESSURE/OIL THROUGHPUT TABLES U.S. GALLONS PER HOUR LITRES PER HOUR Rated Flow at 100 P.S.I. PRESSURE P.S.I. PRESSURE BAR G.P.H. L/hr 1.00 3.78 1.12 1.22 1.32 1.41 1.58 1.73 1.87 4.56...

-

Page 42: Pneumatic Modulating Burners (M And M-Sc) On Gas, High / Low On Oil

The control system however does differ in that the position of the air damper can be done in incremental steps via a 3-stage switched input. This is generally performed using a temperature or pressure controller, Dunphy use an RWF40 controller to perform this function – see component section for more details, however any suitable controller with a 3-stage output would suffice. -

Page 43: Oil Operating System Modulating Burners Art 114 And Art 1400 Nozzles

Operating Instructions For TD/TAD4 Dual Fuel Burner 4.3.1 Oil Operating System Modulating Burners ART 114 and ART 1400 Nozzles Atomisation of the oil is by means of a single nozzle which works on the spill-back principle. The nozzle fits into a hydraulic nozzle line assembly that allows oil from the pump outlet to circulate through the nozzle and back through the metering valve to the pump return when the burner is ready to fire, N.C. -

Page 44: Art114 Burner Gun

Operating Instructions For TD/TAD4 Dual Fuel Burner 4.3.2 ART114 Burner Gun To set the spring tension of the piston, the spring tension screw is set 20mm from the back chamber as shown above. The piston stroke is setup using the piston limit screw. The screw is first fully screwed in so that the piston cannot move;... - Page 45 Operating Instructions For TD/TAD4 Dual Fuel Burner CAPACITY TABLES FOR TYPE ART114/1400 RETURN FLOW NOZZLES Supply pressure - 30 bar Viscosity - 5cSt (35 secs Redwood) Maximum output with return closed. ATOMIZER RETURN PRESSURES IN BAR RECOMMENDED NUMBER OUTPUTS IN KILOGRAMS/hr...

-

Page 46: Oil Operating System Modulating Burners Art 106 Nozzle

Operating Instructions For TD/TAD4 Dual Fuel Burner 4.3.4 Oil Operating System Modulating Burners ART 106 Nozzle Atomisation of the oil is by means of a single nozzle which works on the spill-back principle. From the schematic diagram below it can be seen that when the oil supply is admitted to the nozzle by the two main oil valves, the flow can either pass through the nozzle into the furnace or can return down the spill line to the pump return. - Page 47 Operating Instructions For TD/TAD4 Dual Fuel Burner CAPACITY TABLES FOR TYPE ART 106 RETURN FLOW NOZZLES Supply pressure - 20 bar Viscosity - 5 cSt ( 35 secs Redwood ) NOZZLE OUTPUT Kg/hr NOZZLE TURN-DOWN NUMBER RETURN PRESSURE CLOSED RATIO...

-

Page 48: Oil Operating System Modulating Burners Multi-Oil Nozzles

Operating Instructions For TD/TAD4 Dual Fuel Burner 4.3.5 Oil Operating System Modulating Burners Multi-Oil Nozzles Atomisation of the oil is by means of three nozzles which work on the spill-back principle. The nozzle fits into the hydraulic nozzle line assemblies that allow oil from the pump outlet to circulate through the nozzles and back through the metering valves to the pump return when the burner is ready to fire, two PDV N/C solenoid valves open allowing oil to flow through the nozzles. -

Page 49: Oil Operating System High/Low Burners Multi-Oil Nozzles

Operating Instructions For TD/TAD4 Dual Fuel Burner 4.3.6 Oil Operating System High/Low Burners Multi-Oil Nozzles Atomisation of the oil is by mean of three outer nozzles and one central nozzle. The pump pressure is set at 25 Bar, the two pressure regulators controlling the pressure to all four nozzles are set at 10 Bar. -

Page 50: Oil Operating System Air / Steam Atomising

Operating Instructions For TD/TAD4 Dual Fuel Burner 4.3.7 Oil Operating System Air / Steam Atomising The ‘TA’ principle of operation is that oil, carrying both heat and hydraulic energy, enters a mixing chamber in the nozzle where it is mixed with the streams of the atomising fluid (compressed air or steam), carrying kinetic energy and in the case of steam, heat energy. -

Page 51: Fuel Pumps And Motors

Operating Instructions For TD/TAD4 Dual Fuel Burner 4.3.8 Fuel Pumps and Motors All `TD` series burners are supplied with a separate, directly coupled fuel pump and drive motor. Details of the various sizes of pumps and motors are given in the table below. -

Page 52: Operation & User Interface

Operating Instructions For TD/TAD4 Dual Fuel Burner Operation & User Interface The Display / Keypad The display is a 2 line, 20 characters per line, dot matrix vacuum fluorescent type allowing the use of plain text messages for display parameters. The keypad is a membrane construction with tactile keys to give a positive feedback of the actuation. -

Page 53: Start -Up Sequence

Operating Instructions For TD/TAD4 Dual Fuel Burner Start -up Sequence When a fuel selection is made and the ‘burner select’ signal is given to start up the burner, the controller performs the sequence described below. If a gas profile is selected and the safety valve proving function is selected, the controller will perform safety valve pressure proving concurrently with the start-up sequence. - Page 54 Operating Instructions For TD/TAD4 Dual Fuel Burner State State name Description Pre-purge Once the servo motors are at their purge positions the controller starts the pre-purge (t2) timer. Move to ignition When t2 has elapsed, the fuel and the air motors are moved to positions the ignition position for the selected profile.

-

Page 55: Modulation

Operating Instructions For TD/TAD4 Dual Fuel Burner State State name Description Modulation When t8 has elapsed the fuel and air motors are modulated according to the demand placed on the burner. If the fuel selection is changed or the ‘burner on’ signal (PE9) is removed, the main valve output(s) are turned off. -

Page 56: Ratiotronic 6000 Inverter Interface Additional Information

Operating Instructions For TD/TAD4 Dual Fuel Burner If any step of the gas proving sequence fails In stages 1-9 (inclusive) if a flame is detected In stages 11-16 (inclusive) if a flame is not detected In stage 4 if the air pressure switch goes high (air pressure present) ... -

Page 57: Emergency Stop

Operating Instructions For TD/TAD4 Dual Fuel Burner Emergency Stop The emergency stop or e-stop is a safety mechanism used to shut off the burner in an emergency situation in which it cannot be shut down in the usual manner. Unlike a normal shut-down... -

Page 58: Component Setup Parameters

Operating Instructions For TD/TAD4 Dual Fuel Burner 6 Component Setup Parameters Before the commissioning process of the burner can take place, there are certain components like the Ratiotronic 6000, inverter (when fitted), etc, which will need to be setup. The burner should be factory set;... - Page 59 Operating Instructions For TD/TAD4 Dual Fuel Burner Drive 5 profile assignment Drive 6 profile assignment Drive 7 profile assignment Drive 8 profile assignment Drive 9 profile assignment Drive 0 rotation 0 = anti-clockwise / 1 = clockwise Drive 1 rotation...

- Page 60 Operating Instructions For TD/TAD4 Dual Fuel Burner 10.6 Maximum permissible leakage rate 10.7 Vent valve select 1 – VPS enabled, DO NOT DISABLE 10.8 Valve proving select 10.9 VPS Power Time 12.0 Photocell / IR flame detection select 12.1 Pilot flame threshold photocell 12.2...

- Page 61 Operating Instructions For TD/TAD4 Dual Fuel Burner 18.7 LV input 7 function PB14-PB17 18.8 LV input 8 function PB5-PB6 18.9 LV input 9 function PB5-PB7 19.1 LV input 1 message PB9-PB10 19.2 LV input 2 message PB9-PB11 19.3 LV input 3 message PB9-PB12 19.4...

- Page 62 Operating Instructions For TD/TAD4 Dual Fuel Burner 24.7 Lag on delay 24.8 Lag off rate 24.9 Lag off delay 29.0 Analogue output 1 function VSD1 overrides if selected 29.1 Analogue output 1 zero (4mA) value 29.2 Analogue output 1 span (20mA) value 29.3...

- Page 63 Operating Instructions For TD/TAD4 Dual Fuel Burner 42.1 Second oxygen probe calibration offset 42.2 Second oxygen probe calibration gain 42.4 Maximum oxygen variation 42.5 Maximum flue temp variation 42.6 Second oxygen probe calibration enable 44.0 Set real time clock 44.1 Set year 44.2...

-

Page 64: Danfoss Vlt Fc 102

Operating Instructions For TD/TAD4 Dual Fuel Burner Danfoss VLT FC 102 NAME FACTORY DEFAULT DCL SETTING 0-20 DISPLAY LINE 1.1 REF % ANALOG INPUT 53 0-21 DISPLAY LINE 1.2 MOTOR AMPS 0-22 DISPLAY LINE 1.2 POWER KW 0-23 DISPLAY LINE 2... - Page 65 Operating Instructions For TD/TAD4 Dual Fuel Burner 5-42 RELAY 1 OFF DELAY 0.01 SEC 5-40 RELAY 2 FUNCTION RUNNING ALARM 5-41 RELAY 2 ON DELAY 0.01 SEC 5-42 RELAY 2 OFF DELAY 0.01 SEC 6-12 TERMINAL 53 MIN SCALING 4.00 mA...

-

Page 66: Rwf 40.000A97 Default Burner Settings

Operating Instructions For TD/TAD4 Dual Fuel Burner 6.2.1 RWF 40.000A97 Default Burner Settings SETTING FACTORY DCL SETTING REMARKS DEFAULT C111 9030 F000 PRESSURE 0000 TEMP C112 0010 0000 0110 0110 C113 100.0 16.0 PRESSURE TEMP SCL2 100.0 100.0 SCH2 16.0 PRESSURE 100.0... -

Page 67: Commissioning

Operating Instructions For TD/TAD4 Dual Fuel Burner Commissioning Basic settings It is essential that heat output of the appliance is known in order that the correct fuel input can be calculated and set. If there is any doubt at all with regard to the appliance rating, the manufacturer should be consulted before the burner is fired. -

Page 68: Start Gas Heat Input

Operating Instructions For TD/TAD4 Dual Fuel Burner adjustments described below, there are no pre-determined positions applicable to a particular burner. The scale reading only represents the air damper opening and not the firing rate! Adjustments to the burner combustion head (for example the position of the flame ring in the nose cone) may be necessary during the `setting up` of a burner. -

Page 69: Pre-Commissioning

Operating Instructions For TD/TAD4 Dual Fuel Burner is the safety time in seconds (s): is the maximum start gas heat input expressed as a percentage of the main gas rate This approximates to an ignition rate of less than one third of the maximum firing rate. -

Page 70: Commissioning - High Low And Pneumatic Modulation Burners - Firing On Gas

Operating Instructions For TD/TAD4 Dual Fuel Burner Commissioning – High Low and Pneumatic Modulation burners - Firing on Gas 7.4.1 Dry run Note: Gas leak checks must be carried out using a suitable non-corrosive leak detection fluid. Check for gas leaks on meters, governors and all mains gas supply pipe work. -

Page 71: Firing The Burner

Operating Instructions For TD/TAD4 Dual Fuel Burner 7.4.5 Firing the burner Ensure that the heat demand will allow an extended run, otherwise the burner may not continue to fire throughout the time required for throughput measurement or commissioning procedure. -

Page 72: Adjustment Of Gas Proving Pressure Switch

Operating Instructions For TD/TAD4 Dual Fuel Burner 7.4.7 Adjustment of Gas Proving Pressure Switch Loosen the screw in the gas inlet measuring point, connect a manometer and remove the clear plastic cover from the gas pressure detector. Switch on the burner and allow to fire. - Page 73 Operating Instructions For TD/TAD4 Dual Fuel Burner over two pluses on the pump motor. Do not swap the mains electrical feed as this will also reverse the burner fan motor rotation. Start the burner and allow to go through pre-purge cycle. When the burner reaches its ignition position, the ignition transformer is switched on, followed by the fuel pump motor, and then the two solenoid valves, which should result in the burner lighting.

- Page 74 Operating Instructions For TD/TAD4 Dual Fuel Burner relation to the gap through which the air is passing, causing poor flame shape and impingement on the furnace structure. 4. Where divergent ( expanded ) nose cones are used, the cone itself should be positioned...

-

Page 75: Electronic Modulating Burners

Operating Instructions For TD/TAD4 Dual Fuel Burner Electronic Modulating Burners IMPORTANT! When commissioning burners fitted with Electronic Modulating Control Systems, the respective operating manuals must be followed. Only competent and trained personnel are permitted to commission burners fitted with these controls. -

Page 76: Ratiotronic Programming

Operating Instructions For TD/TAD4 Dual Fuel Burner 7.6.4 Ratiotronic programming The Ratiotronic 6000 burner control system is generally pre-programmed in the factory prior to despatch. However it is important that the parameters are checked against the lists supplied with the test data supplied with the burner. -

Page 77: Burner Maintenance Schedule

Operating Instructions For TD/TAD4 Dual Fuel Burner 8 Burner Maintenance Schedule REMEMBER! ELECTRICAL AND FUEL SUPPLIES MUST BE ISOLATED BEFORE ANY MAINTENANCE WORK IS CARRIED OUT ON THE BURNER. The following schedules are only to be taken as a guide to those persons responsible for day to day maintenance of the burners. -

Page 78: Minor Maintenance

Operating Instructions For TD/TAD4 Dual Fuel Burner Minor Maintenance (a) Check the operation of the flame failure system daily by deliberately locking out the burner. This can be achieved by either removing the UV cell, or on burners fitted with ionisation probes isolating the gas supply to the burner. -

Page 79: Dismantling And Re-Assembly Of Burners

Operating Instructions For TD/TAD4 Dual Fuel Burner Dismantling and Re-assembly of Burners Combustion Head Removal The combustion head can be removed, as a unit, for maintenance purposes. Before commencing refer to the combustion head drawings in the exploded diagram section at rear of this manual for relevant positions of the various components. - Page 80 Gas Valve Actuator -Removal/Replacement Removal of gas valve actuators must only be carried out by suitably qualified personnel. Full details of removal/replacement procedures for all standard actuators fitted by Dunphy Combustion are given in the 'Unibloc' section of this manual.

-

Page 81: Faults And Fault Finding

Operating Instructions For TD/TAD4 Dual Fuel Burner 9 Faults and fault finding Ratiotronic 6000/6006 Faults relating to electronic modulation burners must refer to the Ratiotronic 6000 controller manual – Section 9. June 13 81 of 165 TD/TAD4 Manual Rev 4... -

Page 82: Useful Information

Operating Instructions For TD/TAD4 Dual Fuel Burner 10 Useful Information Common Conversion Tables To Convert Into Multiply by Bars kg/m 1.020 x 10 Bars p.s.i. 14.5 Bars kg/cm 1.01972 1054.8 kg.cal 0.2520 Btu/hr 2.928 x 10 Btu/lb MJ/Kg 2.326 x 10 ºC. - Page 83 Operating Instructions For TD/TAD4 Dual Fuel Burner RECORD OF COMMISSIONING VALUES SITE: ADDRESS: BURNER TYPE: SERIAL NUMBER: BOILER TYPE: SERIAL NUMBER: BOILER OUTPUT: OPERATING TEMP/PRESS: DATE OF COMMISSIONING: ENGINEERS NAME: FUEL: PUMPED RING MAIN/GRAVITY SUPPLY? NOZZLE TYPE & SIZE OIL PUMP...

- Page 84 Operating Instructions For TD/TAD4 Dual Fuel Burner June 13 84 of 165 TD/TAD4 Manual Rev 4...

-

Page 85: Exploded Diagram & Spare Parts List

Operating Instructions For TD/TAD4 Dual Fuel Burner 11 Exploded Diagram & Spare Parts List 11.1 Modulating Oil Modulating Gas Setup June 13 85 of 165 TD/TAD4 Manual Rev 4... - Page 86 Operating Instructions For TD/TAD4 Dual Fuel Burner June 13 86 of 165 TD/TAD4 Manual Rev 4...

- Page 87 Operating Instructions For TD/TAD4 Dual Fuel Burner ITEM QTY. DESCRIPTION DWG/PART No. TD410 LOW NOx COMBUSTION HEAD ASSEMBLY GA23554 TD415-420 LOW NOx COMBUSTION HEAD ASSEMBLY GA23555 TD410 COMBUSTION HEAD ASSEMBLY GA23556 TD415-420 COMBUSTION HEAD ASSEMBLY GA23558 T4 VANE CASTING GA08715...

- Page 88 Operating Instructions For TD/TAD4 Dual Fuel Burner JACKING SCREW FASHEX00150 OIL ELECTRODE IGELEC00110 OIL TUBE SUPPORT SPIDER GA12370 SPLIT ELECTRODE BUSH GA8264 ART1400 BURNER GUN GA21876 POSITIONAL ELBOW 10-4L 10mm COMPAD00550 1/4"BSP DOWTY 'BONDED' SEAL SEADOW00105 1/4" BSP YORKSHIRE FTG. BRASS PLUG...

- Page 89 Operating Instructions For TD/TAD4 Dual Fuel Burner 1.1kW 2 POLE PUMP MOTOR MOTPUM00120 MOTOR HANGER BRACKET GA10450 BERGER LAHR SERVO MOTOR SERVBLO00100 VARIOTRONIC OIL VALVE MOUNTING BRACKET GA16089 10mm DIAMETER BUNDI TUBE GA23514A 10mm DIAMETER BUNDI TUBE GA23514B 10mm DIAMETER BUNDI TUBE...

-

Page 90: Modulating Oil Modulating Gas With Dh2 Pump (Td420 Only)

Operating Instructions For TD/TAD4 Dual Fuel Burner 11.2 Modulating Oil Modulating Gas with DH2 Pump (TD420 Only) June 13 90 of 165 TD/TAD4 Manual Rev 4... - Page 91 Operating Instructions For TD/TAD4 Dual Fuel Burner June 13 91 of 165 TD/TAD4 Manual Rev 4...

- Page 92 Operating Instructions For TD/TAD4 Dual Fuel Burner ITEM QTY. DESCRIPTION DWG/PART No. TD415-420 LOW NOx COMBUSTION HEAD ASSEMBLY GA23555 TD415-420 COMBUSTION HEAD ASSEMBLY GA23558 T4 VANE CASTING GA08715 T410 FAN IMPELLOR (WHITE) GA8765 T415 FAN IMPELLOR (BLUE) GA8764 T420 FAN IMPELLOR (BLACK...

- Page 93 Operating Instructions For TD/TAD4 Dual Fuel Burner 1/4"BSP DOWTY 'BONDED' SEAL SEADOW00105 1/4" BSP YORKSHIRE BRASS PLUG YORFIT00510 SWIVEL ELBOW 10mm MSE 10-4 L COMPAD00505 MALE STUD COUPLING 12mm MMC 12-4 L COMPAD00430 MALE STUD COUPLING 12mm X 3/8" MMC 12-6 L COMPAD00420 3/8"BSP DOWTY 'BONDED' SEAL...

-

Page 94: High Low Oil High Low Gas Setup (Td410 Only)

Operating Instructions For TD/TAD4 Dual Fuel Burner 11.3 High Low Oil High Low Gas Setup (TD410 Only) June 13 94 of 165 TD/TAD4 Manual Rev 4... - Page 95 Operating Instructions For TD/TAD4 Dual Fuel Burner June 13 95 of 165 TD/TAD4 Manual Rev 4...

- Page 96 Operating Instructions For TD/TAD4 Dual Fuel Burner ITEM QTY. DESCRIPTION DWG/PART No. TD410 LOW NOx COMBUSTION HEAD ASSEMBLY GA23554 TD410 COMBUSTION HEAD ASSEMBLY GA23556 T4 VANE CASTING GA08715 T410 FAN IMPELLOR (WHITE) GA8765 T415 FAN IMPELLOR (BLUE) GA8764 T420 FAN IMPELLOR (BLACK...

- Page 97 Operating Instructions For TD/TAD4 Dual Fuel Burner INNER NYLON ROLLER GA5761A OUTER NYLON ROLLER GA5761B MOUNTING GASKET GA11741 OIL ELECTRODE IGELEC00110 SPLIT ELECTRODE BUSH GA8264 OIL TUBE SUPPORT SPIDER GA12370 HIGH LOW OIL NOZZLE SEE PROD. SHEET TWIN NOZZLE BLOCK GA5406 1/4"BSP DOWTY 'BONDED' SEAL...

- Page 98 Operating Instructions For TD/TAD4 Dual Fuel Burner PUMP COUPLING PUMZCP00665 PUMP COUPLING INSERT PUMZCP00665 1.1kW 2 POLE PUMP MOTOR MOTPUM00120 MOTOR HANGER BRACKET GA10450 MOTOR HANGER BRACKET SPACER GA7961 BRIDGE HANDLE CONTOL02285 10mm BUNDI TUBE GA23517A 10mm BUNDI TUBE GA23517B...

-

Page 99: Modulating Gas High Low Oil Setup (Td410 Only)

Operating Instructions For TD/TAD4 Dual Fuel Burner 11.3 Modulating Gas High Low Oil Setup (TD410 Only) June 13 99 of 165 TD/TAD4 Manual Rev 4... - Page 100 Operating Instructions For TD/TAD4 Dual Fuel Burner June 13 100 of 165 TD/TAD4 Manual Rev 4...

- Page 101 Operating Instructions For TD/TAD4 Dual Fuel Burner ITEM QTY. DESCRIPTION DWG/PART No. TD410 LOW NOx COMBUSTION HEAD ASSEMBLY GA23554 TD415-420 LOW NOx COMBUSTION HEAD ASSEMBLY GA23555 TD410 COMBUSTION HEAD ASSEMBLY GA23556 TD415-420 COMBUSTION HEAD ASSEMBLY GA23558 T4 VANE CASTING GA08715...

- Page 102 Operating Instructions For TD/TAD4 Dual Fuel Burner OIL ELECTRODE IGELEC00110 SPLIT ELECTRODE BUSH GA8264 OIL TUBE SUPPORT SPIDER GA12370 HIGH LOW OIL NOZZLE SEE PROD. SHEET TWIN NOZZLE BLOCK GA5406 1/4"BSP DOWTY 'BONDED' SEAL SEADOW00105 MALE STUD COUPLING 10mm MMC 10-4 L...

- Page 103 Operating Instructions For TD/TAD4 Dual Fuel Burner MOTOR HANGER BRACKET GA10450 MOTOR HANGER BRACKET SPACER GA7961 BRIDGE HANDLE CONTOL02285 10mm BUNDI TUBE GA23517A 10mm BUNDI TUBE GA23517B 10mm BUNDI TUBE GA23517C 10mm BUNDI TUBE GA23517D 10mm BUNDI TUBE BUNDIT00115 June 13...

-

Page 104: Multi-Oil Multi-Gas Exploded Diagram

Operating Instructions For TD/TAD4 Dual Fuel Burner 11.4 Multi-Oil Multi-Gas Exploded Diagram June 13 104 of 165 TD/TAD4 Manual Rev 4... - Page 105 Operating Instructions For TD/TAD4 Dual Fuel Burner June 13 105 of 165 TD/TAD4 Manual Rev 4...

- Page 106 Operating Instructions For TD/TAD4 Dual Fuel Burner TD410 TD415 TD420 ITEM QTY. DESCRIPTION PART No. PART No. PART No. T4 HINGE CASTING GA8714 GA8714 GA8714 T4 VANE CASTING GA8715 GA8715 GA8715 T4 IMPELLOR GA8765 GA8764 GA8763 T4 FAN MOTOR MOTORF01210...

- Page 107 Operating Instructions For TD/TAD4 Dual Fuel Burner PUMP MOTOR MOUNTING BRACKET GA9562 GA9562 GA9562 PUMP MOTOR MOTPUM00220 MOTPUM00220 MOTPUM00300 PUMP MOTOR HOUSING GA5900 GA5900 GA9740 DH PUMP VALVE BRACKET GA10190 GA10190 GA10228 DH OIL PUMP SERIES PUMDUN01021 PUMDUN01021 PUMDUN02015 No.3 BANJO BOLT...

- Page 108 Operating Instructions For TD/TAD4 Dual Fuel Burner 10mm DIAMETER BUNDI TUBE GA23697C GA23697C GA23697C 10mm DIAMETER BUNDI TUBE GA23697D GA23697D GA23697D 16mm EYEBOLT EYEBLT00100 EYEBLT00100 EYEBLT00100 1/4" COPPER WASHER COPWAS00075 COPWAS00075 COPWAS00075 SWIVEL RUN TEE COMPAD00655 COMPAD00655 COMPAD00655 LOW OIL PRESSURE SWITCH (SAUTER)LOW...

-

Page 109: Td410 Low Nox Combustion Head Assembly

Operating Instructions For TD/TAD4 Dual Fuel Burner 11.5 TD410 Low NOx Combustion Head Assembly 11.6 TD415-420 Low NOx Combustion Head Assembly June 13 109 of 165 TD/TAD4 Manual Rev 4... -

Page 110: Td410 Combustion Head Assembly

Operating Instructions For TD/TAD4 Dual Fuel Burner 11.7 TD410 Combustion Head Assembly 11.8 TD415-420 Combustion Head Assembly June 13 110 of 165 TD/TAD4 Manual Rev 4... -

Page 111: Dn65 Unibloc

Operating Instructions For TD/TAD4 Dual Fuel Burner 11.9 DN65 Unibloc 11.10 DN80 Unibloc 11.11 DN100 Unibloc June 13 111 of 165 TD/TAD4 Manual Rev 4... -

Page 112: Vgd40.65 Assembly For Pneumatic Modulating And High Low Burners

Operating Instructions For TD/TAD4 Dual Fuel Burner 11.12 VGD40.65 Assembly for Pneumatic Modulating and High Low Burners 11.13 VGD40.80 Assembly for Pneumatic Modulating and High Low Burners June 13 112 of 165 TD/TAD4 Manual Rev 4... -

Page 113: Vgd40.100 Assembly For Pneumatic Modulating And High Low Burners

Operating Instructions For TD/TAD4 Dual Fuel Burner 11.14 VGD40.100 Assembly for Pneumatic Modulating and High Low Burners 11.15 VGD40.65 Assembly for Electronic Modulating Burners June 13 113 of 165 TD/TAD4 Manual Rev 4... -

Page 114: Vgd40.80 Assembly For Electronic Modulating Burners

Operating Instructions For TD/TAD4 Dual Fuel Burner 11.16 VGD40.80 Assembly for Electronic Modulating Burners 11.17 VGD40.100 Assembly for Electronic Modulating Burners June 13 114 of 165 TD/TAD4 Manual Rev 4... -

Page 115: Component Information

Operating Instructions For TD/TAD4 Dual Fuel Burner 12 Component Information 12.1 LFL1.333 Burner Control Box To avoid injury to persons, damage to property or the environment, the following warning notes should be observed! Do not open, interfere with or modify the unit! ... - Page 116 Operating Instructions For TD/TAD4 Dual Fuel Burner Flame supervision with ionisation probe Voltage at the ionization probe: Operation: AC 330 V ±10 % Test: AC 380 V ±10 % Short-circuit current max: 0.5 mA Required ionization current min: 6 µA...

- Page 117 Operating Instructions For TD/TAD4 Dual Fuel Burner LFL Technical Data June 13 117 of 165 TD/TAD4 Manual Rev 4...

- Page 118 Operating Instructions For TD/TAD4 Dual Fuel Burner LFL Characteristics AC 230 V –15 / +10 % Mains voltage AC 100 V –15 %...AC 110 V +10 % Mains frequency 50...60 Hz ±6 % Unit fuse (built-in) T6,3H250V to DIN EN 60 127 Primary fuse (external) max.

- Page 119 Operating Instructions For TD/TAD4 Dual Fuel Burner General Detector and extraneous light test are resumed immediately on completion afterburn time «t13». Fuel valves that are not closed, or not fully closed, immediately initiate lockout on completion of the afterburn time «t13». The test terminated when the prepurge time «t1» of the next startup sequence.

- Page 120 Operating Instructions For TD/TAD4 Dual Fuel Burner Shortly after the start of «t1», the air pressure switch must change over from terminal 13 to terminal 14. Otherwise lockout Start of air pressure check At the same time, terminal 14 must be live since the ignition transformer will be powered and the fuel released via this current path.

- Page 121 Operating Instructions For TD/TAD4 Dual Fuel Burner If lockout occurs, the burner control can immediately be reset: - Do not press the lockout reset button for more than 10 seconds The sequence switch always returns to its start position first...

- Page 122 Operating Instructions For TD/TAD4 Dual Fuel Burner LFL Glossary of symbols June 13 122 of 165 TD/TAD4 Manual Rev 4...

-

Page 123: Rwf 40 Burner Temperature Controller

Operating Instructions For TD/TAD4 Dual Fuel Burner 12.2 RWF 40 Burner temperature controller The RWF40 is used to control the boiler temperature. It is configured to modulate the burner up and down when firing on gas and provide high/low thermostat functions when firing on oil. - Page 124 Operating Instructions For TD/TAD4 Dual Fuel Burner June 13 124 of 165 TD/TAD4 Manual Rev 4...

- Page 125 Operating Instructions For TD/TAD4 Dual Fuel Burner June 13 125 of 165 TD/TAD4 Manual Rev 4...

- Page 126 Operating Instructions For TD/TAD4 Dual Fuel Burner June 13 126 of 165 TD/TAD4 Manual Rev 4...

- Page 127 Operating Instructions For TD/TAD4 Dual Fuel Burner June 13 127 of 165 TD/TAD4 Manual Rev 4...

-

Page 128: Unibloc

For other gas applications, e.g. bio or producer gas, the valve seating rings are manufactured out of grade 321 stainless steel, because of the corrosive nature of these gases. Where hydrogen sulphide (H2 S) is present in the gas advice must be sought from Dunphy Technical Department. - Page 129 Operating Instructions For TD/TAD4 Dual Fuel Burner Valve actuators are supplied as standard with plated carbon steel seat assemblies fitted with nitrile rubber seating discs. If valves are required to be used on bio, producer or other corrosive gases, the valve seat assemblies will be manufactured in 321 stainless steel with viton seating discs.

-

Page 130: 65Mm Ratiotronic Unibloc Exploded Diagram And Parts List

Operating Instructions For TD/TAD4 Dual Fuel Burner 12.3.2 65mm Ratiotronic Unibloc exploded diagram and parts list. June 13 130 of 165 TD/TAD4 Manual Rev 4... -

Page 131: 65Mm Ratiotronic Unibloc With Pilot Exploded Diagrams And Parts List

Operating Instructions For TD/TAD4 Dual Fuel Burner 12.3.3 65mm Ratiotronic Unibloc with pilot exploded diagrams and parts list June 13 131 of 165 TD/TAD4 Manual Rev 4... - Page 132 Operating Instructions For TD/TAD4 Dual Fuel Burner June 13 132 of 165 TD/TAD4 Manual Rev 4...

-

Page 133: 80Mm Ratiotronic Unibloc Exploded Diagrams And Parts List

Operating Instructions For TD/TAD4 Dual Fuel Burner 12.3.4 80mm Ratiotronic Unibloc exploded diagrams and parts list June 13 133 of 165 TD/TAD4 Manual Rev 4... -

Page 134: 80Mm Ratiotronic Unibloc With Pilot Exploded Diagrams And Parts List

Operating Instructions For TD/TAD4 Dual Fuel Burner 12.3.5 80mm Ratiotronic Unibloc with pilot exploded diagrams and parts list June 13 134 of 165 TD/TAD4 Manual Rev 4... - Page 135 Operating Instructions For TD/TAD4 Dual Fuel Burner June 13 135 of 165 TD/TAD4 Manual Rev 4...

-

Page 136: 100Mm Ratiotronic Unibloc Exploded Diagrams And Parts List

Operating Instructions For TD/TAD4 Dual Fuel Burner 12.3.6 100mm Ratiotronic Unibloc exploded diagrams and parts list June 13 136 of 165 TD/TAD4 Manual Rev 4... -

Page 137: 100Mm Ratiotronic Unibloc With Pilot Exploded Diagrams And Parts List

Operating Instructions For TD/TAD4 Dual Fuel Burner 12.3.7 100mm Ratiotronic Unibloc with pilot exploded diagrams and parts list June 13 137 of 165 TD/TAD4 Manual Rev 4... - Page 138 Operating Instructions For TD/TAD4 Dual Fuel Burner June 13 138 of 165 TD/TAD4 Manual Rev 4...

-

Page 139: Butterfly Gas Valve

Operating Instructions For TD/TAD4 Dual Fuel Burner 12.4 Butterfly Gas Valve 12.4.1 General Arrangement June 13 139 of 165 TD/TAD4 Manual Rev 4... -

Page 140: Exploded Diagram

Operating Instructions For TD/TAD4 Dual Fuel Burner 12.4.2 Exploded Diagram June 13 140 of 165 TD/TAD4 Manual Rev 4... -

Page 141: Siemens Vgd20 And Vgd40 Gas Valve Blocks

Operating Instructions For TD/TAD4 Dual Fuel Burner 12.5 Siemens VGD20 and VGD40 Gas Valve Blocks Double gas valves for use on gas trains, consisting of 2 class «A» safety shutoff valves. Suited for use in connection with gases of the gas families I...III. - Page 142 Operating Instructions For TD/TAD4 Dual Fuel Burner Commissioning notes Commissioning work must be carried out by qualified staff. If environmental conditions produce corrosion (e.g. sea climate), apply protective coating. Check wiring carefully prior to commissioning. Standards CE conformity in accordance with the directives of the European Union...

- Page 143 Operating Instructions For TD/TAD4 Dual Fuel Burner VGD40 The double gas valves VGD40... are double seat disk valves of the normally closed type. The stems are guided on both sides of the disks, thus ensuring a precise stroke and tight shutoff. To improve the control performance, the disks at the bottom are pro-filed.

- Page 144 Operating Instructions For TD/TAD4 Dual Fuel Burner Power Output Curves June 13 144 of 165 TD/TAD4 Manual Rev 4...

-

Page 145: Siemens Skp Actuators

Operating Instructions For TD/TAD4 Dual Fuel Burner 12.5.1 Siemens SKP actuators The combination of actuator and valve provides the following functions: - Safety shutoff valve (SKP15...) - Safety shutoff valve with gas pressure governor / controller (SKP25..., SKP55..., and SKP75...) The electrohydraulic SKP... - Page 146 Operating Instructions For TD/TAD4 Dual Fuel Burner • All activities (mounting, installation and service work, etc.) must be performed by qualified staff • Check to ensure that the impulse pipes are properly fitted and tight • Fall or shock can adversely affect the safety functions. Such actuators must not be put into operation, even if they do not exhibit any damage.

- Page 147 Operating Instructions For TD/TAD4 Dual Fuel Burner impulse pipes for the combustion air and the combustion chamber pressure must have an inside diameter of at least 8 mm. The impulse pipe for the combustion chamber pressure must be fitted such that the gases will cool down in the vicinity of the impulse pipe and condensing gases cannot enter the controller but will return to the combustion chamber.

- Page 148 Operating Instructions For TD/TAD4 Dual Fuel Burner June 13 148 of 165 TD/TAD4 Manual Rev 4...

- Page 149 Operating Instructions For TD/TAD4 Dual Fuel Burner June 13 149 of 165 TD/TAD4 Manual Rev 4...

- Page 150 Operating Instructions For TD/TAD4 Dual Fuel Burner June 13 150 of 165 TD/TAD4 Manual Rev 4...

-

Page 151: Vps 504 Valve Proving System

Operating Instructions For TD/TAD4 Dual Fuel Burner 12.6 VPS 504 Valve Proving System The VPS 504 is the valve proving system used for double block gas valves. The valve proving system complies with EN 1643: Equipment operates independent of residual... - Page 152 Operating Instructions For TD/TAD4 Dual Fuel Burner Specifications Operating pressure max. 500 mbar (50 kPa) 4.0 l Test volume 20 mbar Pressure increase by motor pump Nominal voltage 230 V AC (-15%) to -240 V (+6%), VPS 504 series 05: 24 VDC...

- Page 153 Operating Instructions For TD/TAD4 Dual Fuel Burner Electrical Connections June 13 153 of 165 TD/TAD4 Manual Rev 4...

-

Page 154: Variotronic Vt Oil Metering Valve

Operating Instructions For TD/TAD4 Dual Fuel Burner 12.7 Variotronic VT Oil Metering Valve 12.7.1 General Description The Variotronic oil valve has been designed to work primarily in conjunction with electronic positioning motors for the accurate control of fluids, fuel oils and liquids as defined in the specification of recommended applications. -

Page 155: Adjustment Of The Valve

Operating Instructions For TD/TAD4 Dual Fuel Burner E. The entire metering spindle and spool sleeve can be removed from the top plate. The spindle has a Viton 'O' ring and there is a Viton 'O' ring between the cap and the valve body. -

Page 156: Exploded Diagram

Operating Instructions For TD/TAD4 Dual Fuel Burner 12.7.8 Exploded Diagram June 13 156 of 165 TD/TAD4 Manual Rev 4... -

Page 157: Dh Series Pump

35 bar. The Dunphy DH series pump has been specifically designed to overcome the problems associated with current grades of fuel oils in a variety of different situations, giving accurate pressure control combined with reliability and performance. -

Page 158: Pressure Regulation

The pressure of the oil bears on the cross hysteresis effects to an absolute minimum. sectional area of the piston. This facility eliminates the need to insulate The Dunphy DH Series of oil pumps has been the pump and the flexible's and ensures that purposefully designed, in-house, both are kept at the correct temperature. -

Page 159: Technical Data Summary

Operating Instructions For TD/TAD4 Dual Fuel Burner 12.8.2 Technical Data Summary Pump Model Code DHO-1 DH1-1 DH1-2 DH2-1 DH2-2 Gearwheel Capacity litres/hr 1500 2250 4500 Gearwheel Capacity gall/hr Weight - kg 17.5 20.9 Shaft Diameter - mm Fuel Types 1.3 cSt. @ 40°C up to 130 cSt. @ 80°C... -

Page 160: Installation Operation Maintenance

Operating Instructions For TD/TAD4 Dual Fuel Burner 12.8.3 Installation Operation Maintenance Distillate fuel oils should be supplied to the 12.8.3.1 Installation pump inlet port at a slight positive pressure. Where suction lift is required, the Dunphy The DH Series can be supplied for either technical department should be consulted. -

Page 161: Fault Finding

Operating Instructions For TD/TAD4 Dual Fuel Burner 12.8.4 Fault Finding Symptom or Fault Probable Cause Pump motor runs, but no oil delivered. Pump coupling loose on either pump side or motor side. Fuel starvation. Oil system air locked. -

Page 162: Oil Flow Diagrams

Operating Instructions For TD/TAD4 Dual Fuel Burner 12.8.5 Oil Flow Diagrams ROTATION ROTATION OIL RETURN OIL UNDER PRESSURE OIL UNDER SUCTION PLAN VIEW PLAN VIEW PLUG OR VACUUM GAUGE PLUG OR PRESSURE GAUGE PLUG OR PRESSURE GAUGE PLUG OR VACUUM GAUGE... - Page 163 Operating Instructions For TD/TAD4 Dual Fuel Burner ROTATION ROTATION OIL RETURN OIL UNDER PRESSURE OIL UNDER SUCTION PLAN VIEW PLAN VIEW PLUG OR VACUUM GAUGE PLUG OR PRESSURE GAUGE PLUG OR PRESSURE GAUGE PLUG OR VACUUM GAUGE PRESSURE REGULATOR OIL OUTLET TO NOZZLE...

- Page 164 Operating Instructions For TD/TAD4 Dual Fuel Burner litres/Hr 3000 DH2-2 NOTES DHO-1 2000 DH2-2 DH2-1 1000 DH1-1 DH2-1 DH1-2 DHO-1 DH1-1 DHO-1 NOZZLE CAPACITY SINGLE STAGE PUMPS 2850 RPM TYPICAL POWER CONSUMPTION 1425 RPM litres/Hr 2500 DH2-2 2000 DH2-2 1500...

- Page 165 Operating Instructions For TD/TAD4 Dual Fuel Burner DUNPHY COMBUSTION LTD QUEENSWAY ROCHDALE ENGLAND OL11 2SL Tel +44 (0) 1706 649217 Fax: +44 (0) 1706 655512 Internet – http://www.dunphy.co.uk June 13 165 of 165 TD/TAD4 Manual Rev 4...

Need help?

Do you have a question about the TD and is the answer not in the manual?

Questions and answers

how do you alter the pressure set point to lift the safety valve for inspection