Rohde & Schwarz ZVB4 Manual

Vector network analyzer

Hide thumbs

Also See for ZVB4:

- Service manual (198 pages) ,

- Quick start manual (102 pages) ,

- Operating manual (813 pages)

Table of Contents

Advertisement

Quick Links

Download this manual

See also:

Service Manual

Advertisement

Chapters

Table of Contents

Troubleshooting

Summary of Contents for Rohde & Schwarz ZVB4

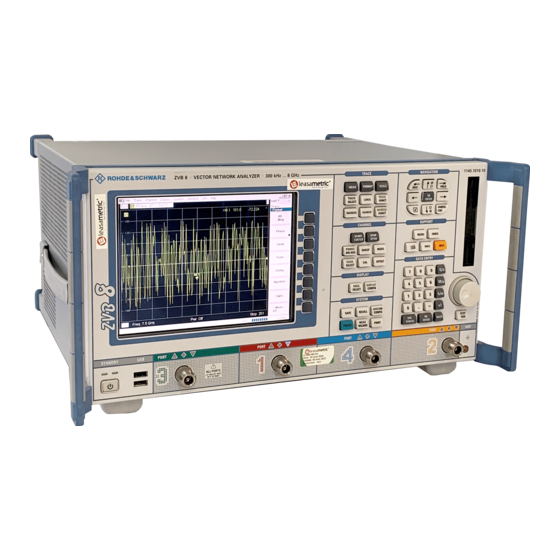

- Page 1 Test and Measurement Division Manual Vector Network Analyzer R&S ZVB4 / ZVB8 1145.1010.06/10 Printed in the Federal Republic of Germany 1145.1084.82.01...

- Page 2 Dear Customer, throughout this manual, the Vector Network Analyzer R&S® ZVB is abbreviated as R&S ZVB. R&S® is a registered trademark of Rohde & Schwarz GmbH & Co. KG Trade names are trademarks of the owners. 1145.1084.82.01...

- Page 3 Safety Instructions This unit has been designed and tested in accordance with the EC Certificate of Conformity and has left the manufacturer’s plant in a condition fully complying with safety standards. To maintain this condition and to ensure safe operation, the user must observe all instructions and warnings given in this operating manual.

- Page 4 Safety Instructions 10. Ensure that the connections with information Electrostatics via the connectors may dam- technology equipment comply with IEC950 / age the equipment. For the safe handling and EN60950. operation of the equipment, appropriate measures against electrostatics should be im- 11.

- Page 5 Certified Quality System Certified Environmental System ISO 9001 ISO 14001 DQS REG. NO 1954 QM DQS REG. NO 1954 UM Qualitätszertifikat Certificate of quality Certificat de qualité Sehr geehrter Kunde, Dear Customer, Cher client, Sie haben sich für den Kauf eines Rohde & You have decided to buy a Rohde &...

- Page 6 Spare Parts Express Service Phone: +49 89 4129 - 12465 Fax: +49 89 41 29 - 13306 E-mail:werner.breidling@rsd.rohde-schwarz.com In case of urgent spare parts requirements for this Rohde & Schwarz unit, please contact our spare parts express service. Outside business hours, please leave us a message or send a fax or e-mail.

- Page 7 Adressen/Addresses FIRMENSITZ/HEADQUARTERS (Tel) Phone Austria Rohde & Schwarz-Österreich Ges.m.b.H. (Tel) +43 (1) 602 61 41-0 (Fax) Fax Am Europlatz 3 (Fax) +43 (1) 602 61 41-14 E-mail Gebäude B rs-austria@rsoe.rohde-schwarz.com 1120 Wien Rohde & Schwarz GmbH & Co. KG (Tel) +49 (89) 41 29-0 Mühldorfstraße 15 ·...

- Page 8 Adressen/Addresses China Rohde & Schwarz China Ltd. (Tel) +86 (28) 86 52 76 06 Germany Zweigniederlassung Büro Bonn (Tel) +49 (228) 918 90-0 Representative Office Chengdu (Fax) +86 (28) 86 52 76 10 Josef-Wirmer-Straße 1-3 · D-53123 Bonn (Fax) +49 (228) 25 50 87 Unit G, 28/F, First City Plaza sophia.chen@rsbp.rohde- Postfach 140264 ·...

- Page 9 Adressen/Addresses Kazakhstan Rohde & Schwarz Kazakhstan (Tel) +7 (32) 72 67 23 54 India Rohde & Schwarz India Pvt. Ltd. (Tel) +91 (22) 26 30 18 10 Representative Office Almaty (Fax) +7 (32) 72 67 23 46 Mumbai Office (Fax) +91 (22) 26 73 20 81 Pl.

- Page 10 Adressen/Addresses Netherlands Rohde & Schwarz Nederland B.V. (Tel) +31 (30) 600 17 00 Saudi Arabia Gentec (Tel) +966 (1) 293 20 35 Perkinsbaan 1 (Fax) +31 (30) 600 17 99 Haji Abdullah Alireza & Co. Ltd. (Fax) +966 (1) 466 16 57 3439 ND Nieuwegein info@rsn.rohde-schwarz.com P.O.Box 43054...

- Page 11 Adressen/Addresses United Rohde & Schwarz UK Ltd. (Tel) +44 (870) 735 16 42 Taiwan Rohde & Schwarz Taiwan (Pvt.) Ltd. (Tel) +886 (2) 28 93 10 88 Kingdom 3000 Manchester Business Park (Fax) +44 (1252) 81 14 77 Floor 14, No. 13, Sec. 2, Pei-Tou Road (Fax) +886 (2) 28 91 72 60 Aviator Way sales@rsuk.rohde-schwarz.com...

- Page 12 Service and Repairs R&S ZVB Contents of the Manuals for the ZVB Network Analyzer Service manual - instrument This service manual for the instrument contains information on checking specs, instrument align- ment, repairs and troubleshooting. The service manual – instrument contains all the information you will need to repair the instrument by means of board replacement.

- Page 13 R&S ZVB Manuals Service and Repairs Contact your Rohde & Schwarz Service Center or the Rohde & Schwarz Express Spare-Part Delivery Service to solve your service problems or to order spare parts and boards. A list of Rohde & Schwarz representatives and the address of our Express Spare-Part Delivery Service can be found at the beginning of this service manual.

-

Page 14: Table Of Contents

FSQ FVREF "Überschrift 2" \* MERGEFORMAT Fehler! Form atvorlage nicht definiert. R&S ZVB Contents Table of Contents - Chapter 1 "Performance Test" 1 Performance Test....................1.1 Preliminary Remarks ........................1.1 Test Equipment and Accessories ....................1.2 Performance Test ..........................1.3 Checking the Frequency Uncertainty ..................1.3 Checking the Harmonics ......................1.4 Checking the Maximum Output Power..................1.5 Checking the Accuracy of Output Power..................1.6... -

Page 15: Performance Test

R&S ZVB Preliminary Remarks 1 Performance Test Preliminary Remarks • The required characteristics of the spectrum analyzer are checked after a warm-up time of at least 60 minutes; this ensures that the guaranteed data is met. • The values stated in the following sections are not guaranteed data; only the specifications in the data sheet are binding. -

Page 16: Test Equipment And Accessories

Performance Test R&S ZVB Test Equipment and Accessories Item Type of Recommended characteristics or Recommended R&S Application equipment features model Order No. Spectrum a) Counter mode: FSU 26 1129.9003.26 Frequency uncertainty analyzer Min. resolution: 100 Hz Harmonics Max. rel. frequency deviation: 10 Output linearity b) Linearity Input linearity... -

Page 17: Performance Test

R&S ZVB Performance Test Performance Test Compare with data sheet Checking the Frequency Uncertainty Instrument: Spectrum analyzer (see Chapter “Test Equipment“, Item1) Test cable (see Chapter “Test Equipment“, Item7) Test setup: Connect the spectrum analyzer to (port 2 to port 4) Spectrum analyzer settings: - [ PRESET ] - [ FREQ : 1 GHz ]... -

Page 18: Checking The Harmonics

Performance Test R&S ZVB Checking the Harmonics Instrument: Spectrum analyzer (see Chapter "Test Equipment", Item1) Test cable (see Chapter “Test Equipment", Item7) Test setup: Connect the spectrum analyzer to port1 (port 2 to port 4) Spectrum analyzer settings: Note: Synchronize the reference oscillators in the spectrum analyzer and in the ®... -

Page 19: Checking The Maximum Output Power

R&S ZVB Performance Test Checking the Maximum Output Power Instrument: Power sensor or Power meter with power sensor (see Chapter “Test Equipment“, Item2) Test setup: Connect power sensor to port1 (port 2 to port 4) Power sensor settings: For measurement frequencies, see Performance Test Report {f ®... -

Page 20: Checking The Accuracy Of Output Power

Performance Test R&S ZVB Checking the Accuracy of Output Power Instrument: Power sensor or Power meter with power sensor (see Chapter “Test Equipment“, Item2) Test setup: Connect the power sensor to port 1 (port 2 to port 4) Power sensor settings: For measurement frequencies, see Performance Test Report {f ®... -

Page 21: Checking The Output Linearity

R&S ZVB Performance Test Checking the Output Linearity Instrument: Spectrum analyzer (see Chapter “Test Equipment“, Item1) Test cable (see Chapter “Test Equipment“, Item7) Test setup: Connect the spectrum analyzer to port 1(port 2 to port 4) Spectrum analyzer settings: Note: Synchronize the reference oscillators in the spectrum analyzer and in the ®... -

Page 22: Checking The Power Measurement Uncertainty

Performance Test R&S ZVB Checking the Power Measurement Uncertainty Instrument: Power sensor or Power meter with power sensor (see Chapter “Test Equipment“, Item2) Signal generator (see Chapter “Test Equipment“, Item5) Power splitter (see Chapter “Test Equipment“, Item6) Calibration kit (see Chapter “Test Equipment“, Item4) Test cable (see Chapter “Test Equipment“, Item7) Preparation/ Connect the signal generator to the power-splitter input using the test... -

Page 23: Checking The Input Linearity

R&S ZVB Performance Test Checking the Input Linearity Instrument: Spectrum analyzer (see Chapter “Test Equipment“, Item1) Test cable (see Chapter “Test Equipment“, Item7) Calibration kit (see Chapter “Test Equipment“, Item4) ® R&S ZVB settings: - [ Preset ] - [ Meas : Wave Quantities: a1 Src Port 1] [ Meas : Wave Quantities: a2 Src Port 2] [ Meas : Wave Quantities: a3 Src Port 3] [ Meas : Wave Quantities: a4 Src Port 4]... -

Page 24: Checking The Input Noise Level

Performance Test R&S ZVB Checking the Input Noise Level Test equipment Calibration kit (see Chapter “Test Equipment“, Item4) Test setup: Connect the Match Male from the calibration kit to port 1 (port 2 to port 4) ® R&S ZVB settings: - [ Preset ] - [ Meas : Wave Quantities: b1 Src Port 1 (b2 Src Port 2, b3 Src Port 3, b4 Src Port 4)]... -

Page 25: Checking The Matching (Raw)

R&S ZVB Performance Test Checking the Matching (raw) Instrument: Network analyzer (see Chapter “Test Equipment“, Item3) Calibration kit (see Chapter “Test Equipment“, Item4) Test cable (see Chapter “Test Equipment“, Item7) Preparation/ Connect the test cable to the network analyzer and perform a 1-port test setup: calibration at the end of the cable. -

Page 26: Checking The Dynamic Range

Performance Test R&S ZVB Checking the Dynamic Range Test equipment: Calibration kit N (see Chapter “Test Equipment“, Item4) Test setup: Connect Short Male to port1 and port 2 (port 3 and port 4) (use Short Female with Through Male as a second Short Male) ®... -

Page 27: Checking The Dynamic Range Reduced Due To Spurious

R&S ZVB Performance Test Checking the Dynamic Range reduced due to Spurious Test equipment: Calibration kit N (see Chapter “Test Equipment“, Item4) Test setup: Connect Short Male to port1 and port 2 (port 3 and port 4) (use Short Female with Through Male as a second Short Male) ®... -

Page 28: Checking The Dc Measurement Inputs

Performance Test R&S ZVB Checking the DC Measurement Inputs Test equipment: DC Power Supply NGSM 32/10 (see Chapter “Test Equipment“, Item9) Multimeter URE3 (see Chapter “Test Equipment“, Item10) DC cable (see Chapter “Test Equipment“, Item11) Test setup: Connect the Power Supply to the Input DC MEAS 1V (DC MEAS 10V) of the ZVB using the DC cable ®... -

Page 29: Performance Test Report

Performance Test Report Table 1-1: Performance Test Report ROHDE & SCHWARZ Performance Test Report ZVAB Version 30.09.04 Model (ZVB4/ZVB8) Item number: 1045. Serial number Tested by: Date: Signature: General: All Tables apply to port1; values for ports 2 to 4 are identical. - Page 30 Performance Test Report R&S ZVB Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Port . Page 1.4 1 dB Harmonics Source power +8dBm Freq. Harmonics 50 MHz 100 MHz ________ 150 MHz ________ 50,001 MHz 100 MHz ________ 150 MHz ________...

- Page 31 R&S ZVB Performance Test Report Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Port . Page 1.4 1 dB Harmonics Source power +8 dBm Freq. Harmonics 2.1 GHz 4.2 GHz ________ 6.3 GHz ________ 2.5 GHz 5.0 GHz ________ 3.0 GHz 6.0 GHz ________...

- Page 32 Performance Test Report R&S ZVB Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Port . Page 1.5 1 dB Maximum output power Test frequency 300 kHz ________ 1 MHz ________ 2 MHz ________ 5 MHz ________ 10 MHz ________ 20 MHz...

- Page 33 R&S ZVB Performance Test Report Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Port . Page 1.6 0. dB Accuracy of output power -10 dBm Test frequency 300 kHz – 3 ________ 1 MHz – 3 ________ 2 MHz –...

- Page 34 Performance Test Report R&S ZVB Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Port . Page 1.7 0.06 dB Output linearity Reference –10 dBm Freq. Level 50 MHz 20 dB ________ 15 dB ________ 10 dB ________ 5 dB ________...

- Page 35 R&S ZVB Performance Test Report Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Port . Page 1.7 0.06 dB Output linearity Reference –10 dBm Freq. Level 2.1 GHz 20 dB ________ 15 dB ________ 10 dB ________ 5 dB ________...

- Page 36 Performance Test Report R&S ZVB Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance ZVB8 only: Page 1.7 0.06 dB Port . Output linearity Reference –10 dBm Freq. Level 4.1 GHz 20 dB ________ 15 dB ________ 10 dB ________ 5 dB...

- Page 37 R&S ZVB Performance Test Report Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Port . Page 1.8 0.2 dB Power measurement uncertainty Test frequency 300 kHz ________ 1 MHz ________ 2 MHz ________ 5 MHz ________ 10 MHz ________ 20 MHz...

- Page 38 Performance Test Report R&S ZVB Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Port . Page 1.9 0.06 dB Input linearity Reference –10 dBm 50 MHz 20 dB -0.1 ________ 15 dB -0.1 ________ 10 dB -0.1 ________ 5 dB...

- Page 39 R&S ZVB Performance Test Report Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Port . Page 1.9 0.06 dB Input linearity Reference –10 dBm 4 GHz 20 dB -0.1 ________ 15 dB -0.1 ________ 10 dB -0.1 ________ 5 dB...

- Page 40 Performance Test Report R&S ZVB Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Port . Page 1.10 Input noise level Test frequency 423.450 kHz ________ –70 1.12345 MHz ________ –70 2.12345 MHz ________ –70 5.12345 MHz ________ –70 10.12345 MHz...

- Page 41 R&S ZVB Performance Test Report Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Port . Page 1.11 1 dB Matching (raw) Test frequency 300 kHz ________ 1 MHz ________ 2 MHz ________ 5 MHz ________ 10 MHz ________ 20 MHz ________...

- Page 42 Performance Test Report R&S ZVB Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Port . Page 1.12 Dynamic range Test frequency 300 kHz ________ 1 MHz ________ 2 MHz ________ 5 MHz ________ 10 MHz ________ 20 MHz ________ 50 MHz...

- Page 43 R&S ZVB Performance Test Report Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Port . Page 1.13 Dynamic range reduced due to spurious Test frequency 16 MHz ________ 32 MHz ________ 48 MHz ________ 96 MHz ________ 192 MHz ________...

- Page 44 Performance Test Report R&S ZVB Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Accuracy Page 1.14 1 mV DC meas 1 V Pos. Input -1000 m V - 27.5 ________ + 27.5 -300 mV - 10.0 ________ + 10.0 -10 mV...

- Page 45 R&S ZVB Table of Contents - Alignment Table of Contents - Chapter 2 "Alignment" 2 Alignment......................2.3 Service Menu ...........................2.3 Manual Alignment and Recording Correction Values ..............2.4 Measuring Equipment ......................2.4 Aligning the Frequency Accuracy.....................2.5 Aligning the DC Inputs......................2.6 Correction ValueRecording ......................2.8 Factory System Error Calibration ...................2.11 1145.1078.82 I-2.1...

- Page 46 Table of Contents - Alignment R&S ZVB This page has been left blank intentionally. 1145.1078.82 I-2.2...

-

Page 47: Alignment

R&S ZVB Manual Alignment and Recording Correction Values 2 Alignment This chapter describes the alignment of the frequency reference and the recording of correction data after a board has been replaced. The following manual alignments or corrections can be performed on the ZVB: •... -

Page 48: Manual Alignment And Recording Correction Values

Manual Alignment and Recording Correction Values R&S ZVB Manual Alignment and Recording Correction Values In the sequel, the test equipment and the instrument preparations required to manually align the ZVB and each of the alignments are described. Preliminary remarks The analyzer must be allowed to warm up for at least 30 minutes before alignment. This is the only way of ensuring that the guaranteed data are met. -

Page 49: Aligning The Frequency Accuracy

R&S ZVB Manual Alignment and Recording Correction Values Aligning the Frequency Accuracy Test equipment Frequency counter (section "Test Equipment", item 1): Error <1x10 Frequency range to 10 MHz Test setup: Connect the frequency counter to the 10-MHz reference output at the rear of the ZVB. -

Page 50: Aligning The Dc Inputs

Manual Alignment and Recording Correction Values R&S ZVB Aligning the DC Inputs At the outset, ensure that the correction parameters "Multiplier" M and "Offset" F have been preset to M=1 and F=0 for both inputs. This can be done using the Service Functions 3.1.2.5 and 3.1.2.2 which are described below under Service Functions. - Page 51 R&S ZVB Manual Alignment and Recording Correction Values etc. for the second measurement input. Set Service Function (Writing to the EProm) 3.1.2.2 When correction value programming for the two DC voltage measurement inputs has been completed, end the NWA application and restart. Check the alignment by applying the four voltages +1 V, -1 V, +10 V and -10 V and, as a further check, 0 V.

-

Page 52: Correction Valuerecording

Manual Alignment and Recording Correction Values R&S ZVB Correction Value Recording Required test equipment (see Table 2-1): • PC with ZVAB-Service program • Power meter with power sensor • Signal generator Connect the PC, ZVB, power meter and signal generator via the IEC/IEEE-bus interface. Start the ZVAB-Service program. - Page 53 R&S ZVB Manual Alignment and Recording Correction Values Generator and reference-channel absolute measurements Test setup: NRV-Z51 power sensor to port1 Buttons in the RUN section: Measurement Generator linearity Reference channel absolute Generator frequency response Measurements are then performed in the same way on the remaining ports. If all three correction values for the generator side of a port are to be recorded, click on the appropriate bar: Port 1...

- Page 54 Manual Alignment and Recording Correction Values R&S ZVB The measurement can be performed simultaneously on all ports using a setup comprising an LO divider, four power splitters, two NRVDs and four NRV-Z51 sensors (for 2-port models: two power splitters and one NRVD with two sensors). Abs b Ports REF and MEAS channel relative measurement (a and b wave)

-

Page 55: Factory System Error Calibration

R&S ZVB Manual Alignment and Recording Correction Values Factory System Error Calibration A complete factory N-port system-error calibration is performed on all the network analyzer’s measurement ports. This involves directly connecting the O, S and M calibration standards to each port and then connecting the ports together in pairs using a cable as a T standard. - Page 56 R&S ZVB Instrument Construction and Function Description Table of Contents - Chapter 3 "Repairs" Repairs......................3.1 Instrument Construction and Function Description..............3.1 Block Diagram ..........................3.2 Description of the Block Diagram ....................3.4 Board Replacement........................3.12 Board Overview ........................3.13 Replacing Front Module Processor A90...................3.14 Replacing the Lithium Battery on the Front Module Processor ..........3.17 Replacing Hard Disk A60......................3.20 Replacing LCD A70 and the DC/AC Converter ................3.21...

- Page 57 Instrument Construction and Function Description R&S ZVB 1145.1078.82 I-3.2...

-

Page 58: Repairs

R&S ZVB Instrument Construction and Function Description 3 Repairs This chapter describes the ZVB’s construction, simple procedures for repairs, troubleshooting and board replacement. A selftest which checks the diagnostic voltages of the board and indicates limit violations is provided for troubleshooting and diagnostics. Chapter 4 of this service manual describes the installation of options and firmware updates. -

Page 59: Block Diagram

15 to 21 MHz RECEIVER REF PORT 3 RECEIVER MEAS PORT 3 NETCON DIGITAL NETCON ANALOG BRIDGE PORT 4 GENERATOR PORT 4 PORT 4 RECEIVER REF PORT 4 RECEIVER MEAS PORT 4 POWER SUPPLY Fig. 3-1 Block diagram of ZVB4/8 4 ports 1145.1078.82... - Page 60 NETCON ANALOG DIGITAL GRAPHICS DISPLAY BRIDGE PORT 2 GENERATOR PORT 2 PORT 2 RECEIVER REF PORT 2 RECEIVER MEAS PORT 2 FREQUENCY OPTION REFERENCE OCXO ZVAB-B4 SYNTHESIZER DIVIDER POWER SUPPLY Fig. 3-2 Block diagram of the ZVB4/8 2 ports 1145.1078.82...

-

Page 61: Description Of The Block Diagram

R&S ZVB Description of the Block Diagram The block diagram shown in Fig. 3-1 applies to the ZVB4 4 ports and the ZVB8 4 ports, Fig. 3-2 to the ZVB4 2 ports and the ZVB8 2 ports The ZVB is a vector network analyzer covering 300 kHz to 4 GHz (ZVB4) or 300 kHz to 8 GHz (ZVB8). - Page 62 R&S ZVB Instrument Construction and Function Description Network controller The network controller comprises two boards, the netcon analog and the netcon digital which are screwed together to form a single unit. The boards are four-channel – in other words, one network controller is required for two ports (2 measurement channels + 2 reference channels).

- Page 63 Instrument Construction and Function Description R&S ZVB Frequency reference The frequency reference board generates the highly stable and spectrally pure clock signals, required by the ZVB, which can be phase-locked to external synchronisation signals. The various function blocks are: The 128 MHz VCXO (voltage-controlled crystal oscillator) which generates a stable, low-noise reference frequency for the synthesisers, for the A/D converters and for digital signal processing.

- Page 64 Model 03: Fitted with one synthesizer Model 04: Fitted with three synthesizers These synthesizer models are incorporated as follows in the various ZVB models: Sy model 02 Sy model 03 Sy model 04 ZVB4 2 ports -------- -------- 2xsource, 1xLO ZVB8 2 ports --------...

- Page 65 Instrument Construction and Function Description R&S ZVB LO divider The LO signal from the synthesiser is distributed via the LO-divider board between the receiver boards associated with the reflectometers that have been installed. A maximum of four reflectometers can be supplied with the LO signal in this way.

- Page 66 R&S ZVB Instrument Construction and Function Description Front unit The front unit comprises a mounting plate on which the LCD, the flexible switch board and key pad, and the tachogenerator are accommodated. The front module controller is mounted in the controller tray in the instrument frame. LC display All results and setting information the user requires is displayed on the colour LCD.

- Page 67 Instrument Construction and Function Description R&S ZVB Power supply The power supply produces all the voltages required to power the ZVB. It can be turned off with a switch on the instrument’s rear panel. The power supply is a primary-switched power supply with power factor correction (PFC) and standby circuit (+12 V standby).

- Page 68 • for an SPI-EEPROM on the motherboard • Furthermore, the software can detect which device (ZVB4 or ZVB8) is present using the MBCON. In addition to the voltages delivered by the power supply, +28 V is produced from +12 V on the motherboard by means of a boosting switching regulator.

-

Page 69: Board Replacement

Board Replacement R&S ZVB Board Replacement The following section is a detailed description of board replacement. Chapter 5 tells you how to order spare parts. It contains a list of mechanical parts and their order numbers as well as drawings relating to board replacement. -

Page 70: Board Overview

R&S ZVB Board Replacement Board Overview Table 3-1 Overview: Board Replacement Board Measures taken after replacement Function test Alignment Other Recording of correction values System error calibration Front module controller Check error log BIOS update Lithium battery Check error log Hard disk Check error log System error calibration... - Page 71 Board Replacement R&S ZVB Replacing Front Module Controller A90 (See Chapter 5, Spare Parts List, Item 580, and drawings 1145.1010, 1145.1290) The front module controller is located behind the front unit. Opening the instrument and removing the front unit Turn off the instrument and disconnect from the mains. Remove the 4 screws from the front handles (410), left and right, and take off the front handles.

- Page 72 R&S ZVB Board Replacement Installing the new front module controller and putting the instrument back together Carefully insert the new front module controller on the motherboard and screw into place with 10 sems screws (590). Caution: With type FMR6 1091.2520.00, there is a danger of shorting between board components, tracks and screws (590).

- Page 73 Board Replacement R&S ZVB Turn on the instrument and wait for the first beep. Press the DEL key. The instrument should now display the setup menu. • Select Advanced BIOS Features • Enter • Select First Boot Device • Select Floppy using page up/down key •...

- Page 74 R&S ZVB Board Replacement Replacing the Lithium Battery on the Front Module Controller (See Chapter 5, Spare Parts List, Item (582), and drawings 1145.1010, 1145.1290) The lithium battery is located on the front module controller behind the front unit. Caution Do not expose lithium batteries to high temperatures or naked flames.

- Page 75 Board Replacement R&S ZVB Removing the lithium battery Carefully lift up and pull out the battery. Note: Lithium battery 3.4 V (dia. 20 mm * 3 mm) R&S Item No. 0858.2049.00 Front Module Controller Typ FMR6 Connector for rotary pulse generator Contact side of switching foil (keyboard) up Battery LAN 1 LAN 2...

- Page 76 R&S ZVB Board Replacement Putting into operation Connect the mains cable and turn on at the power switch. The instrument is now in standby mode. Select Service Level 2 (see Service Functions). When the instrument has been started, check the protocol file for errors: [ INFO : Error Log ] 1145.1078.82 3.19...

-

Page 77: Replacing Hard Disk A60

Board Replacement R&S ZVB Replacing Hard Disk A60 (See Chapter 5, Spare Parts List, Item 710, and drawings 1145.1010 and 1145.1290) The hard disk is located between the controller tray and the boards. The spare disk is delivered with the software pre-installed. -

Page 78: Replacing Lcd A70 And The Dc/Ac Converter

R&S ZVB Board Replacement Replacing LCD A70 and the DC/AC Converter (See Chapter 5, Spare Parts List Items 910, 930 and drawings 1145.1290, 1145.1384) The LCD and the associated DC/AC converter are accommodated on a mounting plate. The connection to the front module controller is made with cables which should also be replaced individually. The replacement procedure is as follows: Opening the instrument and removing the front unit Turn off the instrument and disconnect from the mains. - Page 79 Board Replacement R&S ZVB Installing and putting into operation a new LCD or DC/AC converter Reinstall the new LCD or new DC/AC converter by reversing the disassembly procedure, refit all screws and reconnect the cables that have been disconnected (drawing 1145.1384). When replacing the display (921) or display cable (945), use a new adhesive label (946) to secure the cabling.

-

Page 80: Replacing Flexible Switch Board (Keyboard) A16 / Key Pad A15

R&S ZVB Board Replacement Replacing Flexible switch board (Keyboard) A16 / Key Pad A15 (See Chapter 5, Spare Parts List, Items 860, 870, 875, 877 and drawings 1145.1010, 1145.1384) The flexible switch board (keyboard) and key pad are located behind the front cover and the keyboard frame Opening the instrument and removing the front unit Turn off the instrument and disconnect from the mains. - Page 81 Board Replacement R&S ZVB Note: Thread the foil cable’s connector through the slot in the mounting tray. Position the key pad so that the pins on the flexible switch board pass through the holes in the key pad. Place the rear of the display unit on the key pad (870, 875). N.B.: Position the display unit so that the pins on the flexible switch board pass through the holes in the mounting tray.

-

Page 82: Replacing The Front Cover

R&S ZVB Board Replacement Replacing the Front Cover (See Chapter 5, Spare Parts List, Items 300, 303, 306, 310, 313, 316, 320, 323, and drawing 1145.1010) The front cover is the outermost front panel with lettering. Each instrument type has its own front cover. Turn off the instrument and disconnect from the mains. -

Page 83: Replacing Disk Drive A30

Board Replacement R&S ZVB Replacing Disk Drive A30 (See Chapter 5, Spare Parts List, Item 670 and drawing 1145.1290) Opening the instrument and removing the disk drive Turn off the instrument and disconnect from the mains, screw off the 4 rear-panel feet (460) and pull off the enclosure (400) backwards. -

Page 84: Replacing Usb Board A40

R&S ZVB Board Replacement Replacing USB Board A40 (See Chapter 5, Spare Parts List, Item 1050 and drawings 1145.1290 and 1145.1384) The USB board is located behind the front cover and the keyboard frame next to the ON key. Opening the instrument and removing the USB-board Turn off the instrument and disconnect from the mains. -

Page 85: Replacing Power Supply A20

Board Replacement R&S ZVB Replacing Power Supply A20 (See Chapter 5, Spare Parts List, Items 790 and drawings 1145.1010, 1145.1290) The power supply is installed at the rear of the instrument frame. Removing the power supply Turn off the instrument and disconnect from the mains, screw off the 4 rear-panel feet (460) and pull off the enclosure (400) towards the rear. -

Page 86: Replacing Fuse Board A21

R&S ZVB Board Replacement Replacing Fuse board A21 (See Chapter 5, Spare Parts List, Item 735, and drawings 1145.1010, 1145.1290) The fuse board is installed on the left-hand side of the power supply. Removing the power supply and the fuse board Turn off the instrument and disconnect from the mains, screw off the 4 rear-panel feet (460) and pull off the enclosure (400) backwards. -

Page 87: Replacing A Fan

Board Replacement R&S ZVB Replacing a Fan (See Chapter 5, Spare Parts List, Item 15 and drawings 1145.1010, 1145.1290, 1145.1332) The fans, three in all, are located behind the right-hand side panel. Opening the instrument and removing the fan Turn off the instrument and disconnect from the mains, screw off the 4 rear-panel feet (460) and pull off the enclosure (400) backwards. -

Page 88: Replacing Motherboard A10

R&S ZVB Board Replacement Replacing Motherboard A10 (See Chapter 5, Spare Parts List, Item 510 and drawings 1145.1010, 1145.1290) The motherboard is located on the base of the instrument. Opening the instrument and removing the motherboard Turn off the instrument and disconnect from the mains, screw off the 4 rear-panel feet (460) and pull off the enclosure (400) backwards. - Page 89 Board Replacement R&S ZVB Undo the RF cabling from the reflectometers (165, 170, 175) to the LO divider (125) and to the motherboard. Release the 50-pin flat cable and disconnect from the reflectometers Remove screws (151, 156, 161) and take out the reflectometers. Undo RF cabling at the LO divider (125).

- Page 90 R&S ZVB Board Replacement Installing the motherboard and reassembling the instrument N.B.: The Eprom on the new motherboard contains the serial No. of the instrument. Therefore, it should not be installed in any instrument other than the one for which it was ordered. The motherboard is the passport of the instrument and unique for every unit.

-

Page 91: Replacing A Reflectometer A510 To 540

Board Replacement R&S ZVB Replacing a Reflectometer A510 to 540 (See Chapter 5, Spare Parts List, Items 165, 175 and drawing 1145.1010) The boards are located under the motherboard. Opening the instrument and removing the board Turn off the instrument and disconnect from the mains, screw off the 4 rear-panel feet (460) and pull off the enclosure (400) backwards. -

Page 92: Replacing The Inner Conductor Of A Port Connector

R&S ZVB Board Replacement Replacing the Inner Conductor of a Port Connector (See Chapter 5, Spare Parts List, Item 110, and drawings 1145.1010, 1145.3593, 1145.3664) Opening the instrument and removing the reflectometer Turn off the instrument and disconnect from the mains, screw off the 4 rear-panel feet (460) and pull off the enclosure (400) backwards. -

Page 93: Replacing The Bridge Unit

Board Replacement R&S ZVB Replacing the Bridge unit (See Chapter 5, Spare Parts List, Item 100 and drawings 1145.1010, 1145.3664) Opening the instrument and replacing the reflectometer Turn off the instrument and disconnect from the mains, screw off the 4 rear-panel feet (460) and pull off the enclosure (400) backwards. - Page 94 R&S ZVB Board Replacement Select Service Level 2 (see Service Functions). When the instrument has been started, check the protocol file for errors: [ INFO : Error Log ] Record generator and receiver correction data (see Recording Correction Data). Perform factory system error calibration (see Factory System Error Calibration). 1145.1078.82 3.37...

-

Page 95: Replacing The Reflectometer Fan

Board Replacement R&S ZVB Replacing the Reflectometer Fan (See Chapter 5, Spare Parts List, Item 190 and drawings 1145.1010, 1145.3664) Opening the instrument and removing the reflectometer Turn off the instrument and disconnect from the mains, screw off the 4 rear-panel feet (460) and pull off the enclosure (400) backwards. -

Page 96: Replacing Network Controller Board A130, A140

R&S ZVB Board Replacement Replacing Network Controller Board A130, A140 (See Chapter 5, Spare Parts List, Items 100, 105 and drawing1145.1010) The board is in the upper section of the instrument. Opening the instrument and removing the board Turn off the instrument and disconnect from the mains, screw off the 4 rear-panel feet (460) and pull off the enclosure (400) backwards. -

Page 97: Replacing Synthesizer Board A150, A160

Board Replacement R&S ZVB Replacing Synthesizer Board A150, A160 (See Chapter 5, Spare Parts List, Items 110, 115 and drawing 1145.1010) The board is located in the upper section of the instrument. Opening the instrument and removing the board Turn off the instrument and disconnect from the mains, screw off the 4 rear-panel feet (460) and pull off the enclosure (400) backwards. -

Page 98: Replacing Lo Divider A600

R&S ZVB Board Replacement Replacing LO Divider A600 (See Chapter 5, Spare Parts List, Item 125 and drawing 1145.1010) The board is located under the motherboard. Opening the instrument and removing the board Turn off the instrument and disconnect from the mains, screw off the 4 rear-panel feet (460) and pull off the enclosure (400) backwards. -

Page 99: Replacing Frequency Reference Board A100

Board Replacement R&S ZVB Replacing Frequency Reference Board A100 (See Chapter 5, Spare Parts List, Item 120 and drawings 1145.1010, 1145.1770) Opening the instrument and replacing the board Turn off the instrument and disconnect from the mains, screw off the 4 rear-panel feet (460) and pull off the enclosure (400) backwards. -

Page 100: Troubleshooting

R&S ZVB Troubleshooting Troubleshooting The instructions in this manual describe troubleshooting down to the board level. Any defective boards can then be replaced and the instrument put back into operation. A selftest which checks the board diagnostic voltages and displays limit violations is provided to facilitate troubleshooting and diagnosis. We recommend that you return your instrument to the technical specialists at an R&S service facility for board replacement and any further repairs that may be needed (see the address list at the beginning of this manual). -

Page 101: Troubleshooting - Power-Up Problems

Troubleshooting R&S ZVB Troubleshooting - Power-up Problems • Fault: It is not possible to turn on the ZVB. Action Cause of fault / remedy Check mains switch on the rear panel Mains switch OFF: Turn on at mains switch. ⇓ Check LED is yellow (standby) LED does not come on: Measure voltage at X92.C23... -

Page 102: Troubleshooting Boot Problems

R&S ZVB Troubleshooting Troubleshooting Boot Problems • Fault: ZVB does not start the measurement application. The first action the ZVB performs after power-up is booting BIOS for the processor. When the processor has been successfully initialised, the Windows XP start-up procedure begins. Then, the measurement application is loaded as an autostart program. -

Page 103: Troubleshooting - Boot Error

Troubleshooting R&S ZVB Troubleshooting - Boot Error If the message below appears on the screen when the boot procedure has been completed, Warning: Boot error occurred. For details browse Error Log file. the cause of the error can be found in the Error-Log file. Setup INFO Info... -

Page 104: Troubleshooting With The Selftest

R&S ZVB Troubleshooting Troubleshooting with the Selftest The selftest is used to check supply voltages to the boards, including voltages generated on the boards themselves. On the frequency reference board, two clock signals (128 MHz and ADC-CLK) are also measured. Starting the selftest: •... - Page 105 Troubleshooting R&S ZVB Total selftest status: user mode ---PASSED--- Instrument Type: ZVB8 with 4 Ports Part Number: 1145.1010k10 Product ID: 01.00 Serial Number: 100124 IP Addresses IP Address: 0.0.0.0&nbs; Subnet Mask: 0.0.0.0 IP Address: 0.0.0.0 Subnet Mask: 0.0.0.0 IP Address: 127.0.0.1 (Localhost) Subnet Mask: 255.0.0.0 SyMapping: ZVB8_P4 LO Divider: is active...

- Page 106 R&S ZVB Troubleshooting Voltages Nd2 Test description Result State +5VA_ADC 2.250V 2.750V 2.484V PASSED +2.5VD_MDD1 1.125V 1.375V 1.260V PASSED +2.5VD_MDD2 1.125V 1.375V 1.260V PASSED +1.5VD_FCON 0.675V 0.825V 0.752V PASSED -5VA_ADC 2.250V 2.750V 2.460V PASSED DGND1 0.000V 0.200V 0.000V PASSED DGND2 0.000V 0.200V 0.000V...

- Page 107 Troubleshooting R&S ZVB +5V SUPPLY 2.300V 2.700V 2.500V PASSED +10.5VA SUPPLY 2.300V 2.800V 2.576V PASSED +10.5VB SUPPLY 2.300V 2.800V 2.592V PASSED +12V FAN 2.000V 2.600V 2.204V PASSED +12V SUPPLY 2.000V 2.600V 2.204V PASSED -12V SUPPLY 1.600V 2.000V 1.796V PASSED Voltages Rm3 Test description Result State...

- Page 108 R&S ZVB Troubleshooting Interpreting the Results of the Selftest Negative voltages are transformed into positive voltages by means of a positive voltage and a resistor network because the A/D converters that are used can handle only positive voltages. This is why an acceptable negative voltage may elicit a FAIL because the associated positive voltage is out of tolerance.

-

Page 109: Checking The Temperature Sensors

Troubleshooting R&S ZVB Checking the Temperature Sensors Select Service Level 2 (see Service Functions). Setup INFO Info When the Hardware Info softkey is pressed information about the installed hardware, the results of temperature measurements and … are displayed. Hardware Info Selftest Error Log…... -

Page 110: Service Functions

R&S ZVB Troubleshooting Service Functions The service functions allow you to examine particular circuit sections on specific boards or to make well-defined settings that would normally change automatically according to the state of the instrument (e.g. the IF). There are a number of service functions which, if used incorrectly, could cause the instrument to malfunction. - Page 111 Troubleshooting R&S ZVB Service Function Structure Group Main ID Sub ID Function Address Data Group Applies to HW (boards) Boards Boards Main ID Sub ID 0: All boards 1: Network controller1 0: All board 1: PCI 2: ND 3: NA 2: Network controller2 5: Motherboard 9: Frequency reference...

- Page 112 R&S ZVB Troubleshooting Group 1: General Functions Functions Service Data Serv. Lev. function 0 → Use disabled Enable/disables the arbitrary mode settings in 1.0.0.0.X the port configuration (e.g. LowNoise/ 1 → Use enabled LowDistortion) independently of the model 0 → Use disabled Enables/disables the peak detector and RMS 1.0.0.1.X detector independently of the model...

- Page 113 Troubleshooting R&S ZVB Motherboard Service function Functions Data Serv. lev. MB: Fan manual 2.5.0.11.1.X X= 0 to 5 MB: Fan automatic 2.5.0.11.0 MB:Read Temp 2.5.0.3.1 Front (NC) (addr.:205) MB: Read Temp 2.5.0.3.2 Rear (SY) (addr.: 204) MB: Read Temp 2.5.0.3.3 Back (PS) (addr.: 202) Frequency reference Service function...

-

Page 114: Determining Which Boards Are Defective

R&S ZVB Troubleshooting Determining which Boards are defective The table below lists boards that are probably defective based on the faults that occurred during the performance test. Defective board Problem with: Probable Also possible Frequency accuracy Frequency reference SSB phase-noise Only one port Synthesizer1 All ports... -

Page 115: Board Test

Troubleshooting R&S ZVB Board Test When boards are being tested, internal sources are used whenever possible. This means that it is always assumed that the downstream board in the signal path is OK. If a clear fault is not present, the order of the board tests given below should always be followed. -

Page 116: Testing The Frequency Reference Board

R&S ZVB Troubleshooting Testing the frequency reference board (see Test Equipment) Remove the board from the instrument. Reinsert board and extension card. Connect the output to be tested to the spectrum analyzer using an adapter cable and adapter SMA- Set the frequencies listed in the table. Check signals according to following table. -

Page 117: Testing The Synthesizer Board

The board must be replaced if the level is more than 2 dB below the specified value or the other values are more than 2 dB above their specified value. Synthesizer2 or synthesizer1 for ZVB4/8 2 ports Disconnect the LO cable at the LO divider. -

Page 118: Testing The Reflectometer Board

R&S ZVB Troubleshooting Testing the Reflectometer Generator levels It is assumed that the synthesizer section (synthesizer1) associated with the reflectometer to be tested is OK. Loosen cable W514 (GEN -> Bridge unit) at both ends and screw off at the generator output GEN. Note: When loosening, support the cable with a 7mm spanner Connect the generator output to the spectrum analyzer using the SMA cables () and adapter SMA- Set the power to 8 dBm... - Page 119 Troubleshooting R&S ZVB Frequency Output level Displayed level ax or bx 300 kHz -20 dBm 0 dBm 50 MHz -20 dBm 0 dBm 1 GHz -20 dBm 0 dBm 3 GHz -20 dBm 0 dBm 6 GHz -20 dBm 0 dBm 8 GHz -20 dBm 0 dBm...

- Page 120 R&S ZVB Troubleshooting Frequency Level Output level MEAS Output level REF 300 kHz 0 dBm -18 dBm -32 dBm 50 MHz 0 dBm -18 dBm -32 dBm 1 GHz 0 dBm -18 dBm -32 dBm 3 GHz 0 dBm -18 dBm -32 dBm 6 GHz 0 dBm...

- Page 121 Troubleshooting R&S ZVB Bridge Directivity The following is assumed: • The generator and receiver sections of the reflectometer associated with the bridge unit are OK. Screw the SHORT from an N calibration kit to the port connector. Perform a sweep from 300 kHz to 8 GHz, measure S11, save measured values (Data -> Mem : Math = Data/Mem).

-

Page 122: Testing The Lo Divider Board

R&S ZVB Troubleshooting Testing the LO Divider Board It is assumed that the LO-synthesizer section (synthesizer2 for 3-port and 4-port-models, synthesizer 1, mod. 04) is OK. Disconnect cable W656, WW659, W666 or W669, depending on which LO-branch is being tested. Connect the output under test (X6, X7, X8 or X9) to the spectrum analyzer using the adapter cable and SMA-N adapter. -

Page 123: Testing The Network Controller Board

Troubleshooting R&S ZVB Testing the Network Controller Board Testing the IF inputs It is assumed that there is one functioning reflectometer in the instrument. Disconnect the IF-MEAS and IF-REF cable from each of the reflectometers. Connect the input to be tested at the end of the appropriate IF cable (W136, W137, W138, W139, and W146, W147, W148, W149) to a functioning port using the adapter cable and SMA-N adapter . -

Page 124: Testing The Motherboard

R&S ZVB Troubleshooting Testing the Motherboard 28 V supply Using a multimeter, measure the voltage at X 100.B5 (wrt ground). Permissible deviation: ± 0.5 V Preamplifier for DC measurement inputs Apply the DC voltages listed in the table using the 4-pin Mini-DIN connector at the DC measurement input. - Page 125 R&S ZVB Table of Contents - Software Update / Installation of Options Table of Contents- Chapter 4 "Software Update / Installation of Options" 4 Software Update / Installation of Options ............4.1 Installing New ZVB Software......................4.1 Installing Options ..........................4.2 1145.1078.82 I-4.1...

- Page 126 Table of Contents - Software Update / Installation of Options R&S ZVB This page has been left blank intentionally. 1145.1078.82 I-4.2...

- Page 127 R&S ZVB Installing New ZVB Software Software Update / Installation of Options Chapter 4 provides information on updating software, restoring the operating system installation and installing options. Descriptions accompanying the software update or the options can be included in this folder as part of Chapter 4.

- Page 128 R&S ZVB Installing Options Installing Options The following options can be fitted to the ZVB: Oven Controlled Crystal Oscillator (OCXO) R&S ZVAB-B4 1164.1757.02 The OCXO option is permanently integrated on the frequency reference board (mod. 03) and, as a rule, it is specified when the instrument is ordered.

- Page 129 Contents - Documents Contents - Chapter 5 "Documents" 5 Documents......................5.1 Shipping of Instrument and Ordering of Spare Parts ..............5.1 Shipping of Instrument ......................5.1 Shipping of a Module........................5.1 Ordering Spare Parts .......................5.2 Refurbished Modules .......................5.2 Return of Defective Replaced Modules..................5.2 Spare Parts............................5.3 Available Power Cables......................5.3 Spare Parts List ..........................5.5...

-

Page 130: Shipping Of Instrument And Ordering Of Spare Parts

R&S ZVB Shipping of Instrument and Ordering of Spare Parts 5 Documents This chapter provides information on the ordering of spare parts and contains the spare parts list and the documents for the complete ZVB unit. Shipping of Instrument and Ordering of Spare Parts Please contact your Rohde &... -

Page 131: Ordering Spare Parts

Shipping of Instrument and Ordering of Spare Parts R&S ZVB Ordering Spare Parts To deliver replacement parts promptly and correctly, we need the following information: • Stock No. (see component lists in this chapter) • Designation • Component number according to component list •... -

Page 132: Spare Parts

R&S ZVB Spare Part Spare Parts The Stock Nos. necessary for ordering replacement parts and modules can be found in the component lists provided later in this chapter. Important! When replacing a module, please observe the safety instructions and repair instructions provided in chapter 3 and at the beginning of this service manual When shipping a module, be sure to provide sufficient mechanical and antistatic protection. -

Page 133: Spare Parts List

Spare Parts List Mechanical Drawings 1145.1078.82... - Page 134 R&S ZVB List of ZVB parts including spare parts List of ZVB parts including spare parts The ZVB is constructed in accordance with R&S Design 2000. Rackmount: 5E 1/1 T350 Overall dimensions: B x H x T: 426.7 x 265.4 x 417.00 Accessories: 19'' Adapter ZZA-511, Stock No.

- Page 135 R&S ZVB List of ZVB parts including spare parts Position. Designation Stock No. Number Electrical Recommended Designation spare parts MZ MOTHERB. RAIL 4 ZVB 1145.2274.00 VS 6900/ISR-M2.5X8-A2 0041.1653.00 VS 965/ISR-M2.5X6-A4-PA 1148.3288.00 MZ MB RAIL CONTACT 1300.0851.00 MZ MB RAIL CONTACT 1300.0874.00 VS 6900/ISR-M2.5X6-A2 1148.3059.00...

- Page 136 MZ COVER ZVB 1145.1849.00 MZ COVER BOTTOM ZVB 1145.1961.00 VS 965/ISR-M2.5X6-A4-PA 1148.3288.00 VS 965/ISR-M2.5X6-A4-PA 1148.3288.00 KB FRONT COVER ZVB4 2-PORT 1145.1403.00 KB FRONT COVER ZVB 4 1145.1426.00 KB FRONT COVER ZVB4 4-PORT 1145.1410.00 KB FRONT COVER ZVB8 2-PORT 1145.1455.00 KB FRONT COVER ZVB 8 1145.1432.00...

- Page 137 R&S ZVB List of ZVB parts including spare parts Position. Designation Stock No. Number Electrical Recommended Designation spare parts FM LOCKING SCREW H=4.5 1093.9180.00 VS 965/ISR-M2.5X6-A4-PA 1148.3288.00 MZ CASCADE PLATE 1145.4690.00 GR FRONT MOD. CONTROLLER 6/5 1091.2908.00 LITHIUM BATTERY CR2032 0858.2049.00 VS 6900/ISR-M2.5X6-A2 1148.3059.00...

- Page 138 R&S ZVB List of ZVB parts including spare parts Position. Designation Stock No. Number Electrical Recommended Designation spare parts DX POWER SUPPLY CABLE 6P 1145.5515.00 DX POWER SUPPLY CABLE 8P 1145.5521.00 DX POWER SUPPLY CABLE 10P 1145.5538.00 VS DIN137-A3-A2 0005.0296.00 VS DIN137-A4-A2 0005.0315.00 FN POWERFILTER WITH SWITCH...

- Page 139 R&S ZVB List of ZVB parts including spare parts Position. Designation Stock No. Number Electrical Recommended Designation spare parts HS WINDOWS XP EMBEDDED 1099.8570.00 OS BARCODE LABEL FOR PCB 0071.7714.00 DRAWING 1145.1384..01 (DISPLAY UNIT) ZM MOUNTING TROUGH ZVB 3Tor 1145.2516.00 ZM MOUNTING TROUGH ZVB 4-PORT 1145.2500.00 OP SCREENED FILTER GLASS UPL/UPD...

- Page 140 R&S ZVB List of ZVB parts including spare parts Position. Designation Stock No. Number Electrical Recommended Designation spare parts 1020 GR DISPL. CONNECTOR FMR6-TOSHIB 1091.2637.00 1030 DF DISPL. CABLE TOSHIBA 1091.2666.00 1040 VS 6900/ISR-M2.5X6-A2 1148.3059.00 1050 ED USB BOARD 1145.3206.02 1060 VS 965/ISR-M2.5X5-A4-PA 1148.2752.00...

- Page 141 R&S ZVB List of ZVB parts including spare parts Position. Designation Stock No. Number Electrical Recommended Designation spare parts OS BARCODE LABEL FOR PCB 0071.7714.00 ZM RM SUBUNIT ZVAB 4/8GHz 1145.4025.04 ZM RM SUBUNIT ZVAB 4/8GHz 1145.4025.08 DRAWING 1145.3593.01 SHEET 3 (BR UNIT) MB N OUTER CONDUCTOR 1045.8888.00 ZM INNER CONDUCTOR Unit...

-

Page 142: Block Circuit Diagram

Block Circuit Diagram 1145.1078.82 5.15... - Page 147 Verdrahtungsplan Netzteil wire connections for power supply Pos. 755 Pos. 755 Pos. 750 Pos. 745 Pos. 750 (Cable 10p) (Cable 10p) (Cable 8p) (Cable 6p) (Cable 8p) 6,5V 3,6V 5,2V +12V (red) (orange) GND(+12V) GND(+6V) (black) (black) GND(-12V) GND(-6V) +3,3V (black) (black) (orange)

- Page 153 Circuit diagrams 1145.1078.82 5.17...

Need help?

Do you have a question about the ZVB4 and is the answer not in the manual?

Questions and answers