Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Geberit HDPE

- Page 1 VALID FROM 1. NOVEMBER 2018 DRAINAGE SYSTEMS INSTALLATION GUIDE...

- Page 2 Geberit Drainage Systems Introduction Introduction Geberit HDPE is the total solution for all types of drainage including above ground, below ground and chemical waste. It provides the appropriate solution for every requirement whether it is conventionally installed or prefabricated. BBA British Board of Agrément...

-

Page 3: Table Of Contents

Contents 1 Geberit HDPE and Geberit Silent-db20 systems – general information Geberit HDPE overview Geberit Silent-db20 overview Features and benefits of Geberit drainage systems Pipe specification Geberit HDPE Pipe specification Geberit Silent-db20 2 Characteristics and chemical resistance Chemical resistance – The significance of pH values 3 Geberit Silent-db20 systems –... - Page 4 6.1.1 Geberit Sovent – planning 6.1.2 Geberit Sovent – stack sizing 6.1.3 Geberit Sovent – installation Geberit air admittance valve overview 6.2.1 Geberit air admittance valve – GRB90 6.2.2 Geberit air admittance valve – GRB50 7 Buried drain systems Buried drain systems – overview Trench details Managing thermal movement –...

-

Page 5: Geberit Hdpe And Geberit Silent-Db20 Systems - General Information

Combined with the flexibility of Geberit HDPE is the total solution for all types of several jointing methods and the option of off-site pre- drainage including above ground, below ground (within fabrication, Geberit HDPE offers substantial material and building footprint) and chemical waste. -

Page 6: Geberit Silent-Db20 Overview

Geberit Drainage Systems Introduction Geberit Silent-db20 overview Geberit Silent-db20 is a drainage system for buildings Advantages of the Geberit Silent-db20 system: with increased levels of sound proofing. Its outstanding • Improved acoustic properties. acoustic insulation properties are achieved by: • Geberit Silent-db20 pipes and fittings are compatible • Patented high density material specifically developed with the existing Geberit HDPE Drainage System. -

Page 7: Features And Benefits Of Geberit Drainage Systems

The density of polyethylene varies between 910 – 960 kg/m . Geberit HDPE, up to 955 kg/m is of the highest quality and has excellent durability. HDPE is light weight, which is beneficial particularly with regards to handling, transportation and installation. Geberit Silent-db20: Density 1700kg/m3 Increased density improves acoustic properties. - Page 8 Thermal expansion 0.17mm/m.K Heat expansion of Geberit HDPE is relatively high. As a rule of thumb, for every 50°C increase in temperature, an expansion of 10mm per linear metre of pipe can be anticipated.

- Page 9 Joint integrity Many years of experience with welding Geberit HDPE pipes have shown that butt welds do not give any problems as the welding parts are circular on the inside and do not add to the normal risk of blocking.

- Page 10 Silent-db20 is approximately 230°C. Simple tools allow for easy processing. Non-toxic Plastics are well suited for use in the food industry as packaging materials, containers, bottles etc. Geberit HDPE pipes are used for milk transportation lines in mountain areas and in the food canning and packaging industry. Working pressures Geberit HDPE and Geberit Silent-db20 pipes are designed for drainage systems.

-

Page 11: Pipe Specification Geberit Hdpe

6.993 48.683 12.5 372.050.16.0 12.2 290.6 663.8 11.083 77.289 12.5 Thinner wall HDPE pipes Only use for above ground drainage and low (less than 450m bar negative pressure) siphonic rainwater applications Nominal Wall Inside Area Weight Weight Series thickness dia. -

Page 12: Pipe Specification Geberit Silent-Db20

49.6 19.3 1.93 2.83 305.000.14.1 56.6 25.1 2.51 3.53 306.000.14.1 67.8 36.1 3.60 4.97 307.000.14.1 4.90 7.38 308.000.14.1 75.4 7.54 10.87 310.000.14.1 118.7 11.87 16.00 312.000.14.1 167.4 16.74 22.50 315.001.14.1 Standard length of Geberit Silent-db20 pipes is 3 metres (3000mm). -

Page 13: Characteristics And Chemical Resistance

For full details see chemical resistance tables in the Apple juice appendix to this guide to assess the performance of Tartaric acid Geberit HDPE at various temperatures. Citric acid The pH value is therefore important in assessing the Washing solutions... -

Page 14: Geberit Silent-Db20 Systems - Acoustics

When pipes pass through concrete floor slabs and walls - Decouple walls from one another (Fig 2) the pipe must be isolated with Geberit Insulation Hose. - Use pre-wall installation and wall-hung WC’s to decouple the flushing noise from the building •... -

Page 15: Additional Acoustic Products

Geberit Drainage Systems Geberit Silent db20 systems – acoustics Additional acoustic products Geberit Isol Acoustic Wrap Pos. Description Material Thickness Details (mm) The covering foil 0.07 Black with printed prevents moisture product logo penetration at the same time as serving... - Page 16 Geberit Drainage Systems Geberit Silent db20 systems – acoustics Installation instructions For optimum performance the Geberit Isol must cover all the pipework and be overlapped at joins and fixed with The pipe must be free from dust and grease tape to prevent the escape of sound.

-

Page 17: Jointing Methods

Jointing methods Jointing methods Within an ever more competitive culture, installers The many Geberit jointing methods offer solutions for and specifiers are continually striving to reduce costs, all situations and each type of connection has different labour and materials used in the construction process. -

Page 18: Butt Welding

A simple reliable connection. Application Butt welding is the easiest jointing method, providing the many advantageous benefits of prefabrication; Geberit HDPE needs no other component in order to be butt welded. It can be used in all circumstances where prefabrication Hand Mitre Saw is used on site or in the workshop. -

Page 19: Butt Welding By Hand

Geberit Drainage Systems Jointing methods Butt welding by hand A Geberit welding plate KSS-160 or KSS-200, 4.1.1 must be used. (for pipes Ø 40 to 75mm) Check temperature Indicative values fo r welding and warming up times. of the welding plate. -

Page 20: Butt Welding By Machine

Geberit Drainage Systems Jointing methods Butt welding by machine A Geberit MEDIA 160 or UNIVERSAL 315 welding 4.1.2 machine must be used. (for pipes Ø 40 to 315mm) Place pipe parts in the tension plates and fix them in a line. -

Page 21: Electrofusion Coupling

3.5 cm The joint obtained is simple, quick and strong once made. The heater wires remain encased in the HDPE so there is no chance of corrosion. The use of Geberit approved Remove burr. Welding ends must remain dry during the equipment and fittings is essential to ensure a good weld whole welding process. -

Page 22: Electrofusion Coupling (For Pipes Ø 40 To 160Mm)

Geberit Drainage Systems Jointing methods Electrofusion coupling A Geberit Electrofusion machine ESG 40/200 4.2.1 (240V) or Advance Welding AW315G (110V) (for pipes Ø 40 to 160mm) electrofusion machine must be used. B.500.000/192 Insert pipe or fitting Geberit Electrofusion ends into the sleeve... -

Page 23: Electrofusion Coupling (For Pipes Ø 200 To 315Mm)

Geberit Drainage Systems Jointing methods Electrofusion coupling A Geberit starter switch ESG – T2 (230v) or Advance Welding 4.2.2 AW315G (110V) electrofusion machine must be used. (for pipes Ø 200 to 315mm) Dry, clean, scrape or abrade welding ends to full insertion Geberit electrofusion depth. -

Page 24: Conversion To A Slip Coupling

Geberit Drainage Systems Jointing methods Ring-seal sockets Conversion to a 4.2.3 slip coupling To turn the coupling into a slip coupling, the central ring can be removed as shown below. B.500.000/191 Available from Ø 40 to 160mm. Connection properties a Non-rigid, removable. -

Page 25: Ring-Seal Sockets

The pipe must be fully inserted into the socket, because the socket does not act as an expander. Owing to the pipe Connection properties thickness and the low thermal conductivity of HDPE, the a Non-rigid, demountable joint. socket seal has a very satisfactory resistance to heat and b Non-tension-resistant. -

Page 26: Flanged Joint

Geberit Drainage Systems Jointing methods Flanged joint Available from Ø 50 to 315mm. Connection properties a Rigid, mechanical joint. b Tension-resistant. c Demountable. Application Flanges are normally used as demountable joints for low pressure installations (industrial plant, pump connection, tanks and swimming pools). -

Page 27: Screw-Threaded Joints

This type of joint is also used for connection to pipe spigots in other materials. The standard version is to be buttwelded onto the Geberit Flange bushing HDPE pipe end and the extended version (available in certain diameters) can be electrowelded or buttwelded onto the pipe end. -

Page 28: Jointing For Geberit Silent-Db20

Geberit Drainage Systems Jointing methods Jointing methods for Geberit Silent-db20 Geberit Silent-db20 uses the normal HDPE jointing methods including butt welding, electrofusion couplings, and mechanical couplings. If using butt welding the plaining blades fitted to the butt welding machine must be changed to carbide steel blades –... - Page 29 Geberit Drainage Systems Jointing methods Double Sleeve Coupling Insert the pipe into expansion side of the coupling. Comprising a double pushfit jointed coupling with Prepare and one end containing a grab ring to lock the coupling chamfer pipe. onto the pipe.

-

Page 30: Jointing Geberit Drainage Systems To Other Materials Using Adapters

Female iron BSP connector systems to other materials Provides female iron connection to male iron BSP using adapters threaded fittings. Body made from HDPE with a metal reinforcing ring for butt welding onto standard Geberit Trap nut adapter HDPE pipes and fittings. - Page 31 BSP fittings. Body made from brass with HDPE loose hard soldering to lead pipe. Body made from brass with nut and EPDM seal for mechanical jointing to HDPE and HDPE loose nut and EPDM seal for mechanical jointing screw thread jointing to other materials.

- Page 32 PVC-U/ABS/PP pipes For pushfit into 110mm PVC-U ring seal socket to accept 90mm HDPE into a seal ring socket. Geberit HDPE Metric O/D to imperial uPVC OD size adapter for imperial size traps 32mm to 1 ⁄ ” and 1 ⁄...

- Page 33 125°C) evenly around the socket, moving the blow Body made from HDPE with one end enlarged to lamp constantly. The sleeve will now shrink and give an match Ensign cast iron clamp joint.

- Page 34 Geberit Drainage Systems Jointing methods Clamping coupling Adapter to clay socket Metal clamp joint for mechanical jointing of HDPE pipes HDPE adapter for connecting into clay sockets by cold to pipes and fittings of other materials. Suitable for caulking. adapting to Ensign cast iron. To be used in conjunction Adapter to clay/fire element with Reinforcing ring.

-

Page 35: System Installation

They may also be used for For all fixations of Geberit HDPE pipes Ø 40 - 315mm underground drainage applications, provided the pipe except for anchor brackets. -

Page 36: Bracketry For Geberit Silent-Db20

Contact Geberit Technical for advice. please see section 5.2.1 for additional data on fixing using drop rods. Geberit Silent-db20 pipes are to be fixed with anchor brackets and guide brackets. The distance between the anchor bracket and the guide bracket is maximum of 6 metres or nominal outside diameter spacing of guide brackets whenever stability is required in the system. -

Page 37: Managing Thermal Movement - Above Ground Systems

The thrust force is the slide resistance between << >> the rubber seal and HDPE pipe. This force depends on the pipe diameter. - Page 38 2” Thermal expansion sockets – Mounting instructions 1 Prepare pipe insertion end. 2 Lubricate pipe end and rubber seal with silicone only. Geberit HDPE: 80mm at Geberit HDPE: 105mm at 0°C (32°F) 20°C (68°F) 3 Mark insertion depth on the pipe.

- Page 39 Geberit Drainage Systems System installation Installation One secure fixed anchor bracket must be installed per floor when branch connections exist and at a maximum of 6 metre centres on plain straight runs of pipe. The special shape of the seal allows the pipe to slide...

- Page 40 Geberit Drainage Systems System installation Horizontal installation For horizontal pipework the position of the expansion joint will vary. 1 On the long runs of pipe with no branch connections, the expansion fitting must be fitted at a maximum of 6 metre centres.

-

Page 41: Deflection Leg - Guidance On Use

Geberit Drainage Systems System installation Deflection Leg - Guidance on use 5.2.2 A deflection leg is a length/section of pipe specified within the system to accommodate the movement as a result of thermal movement. Deflection legs for pipe lengths of greater than 15m are not recommended as the bending leg will be larger than the maximum bracket spacing. -

Page 42: Rigid Fixing

Rigid fixing of the Geberit HDPE system can be achieved by using a proprietary bracketry system (that may in incorporate struts or very strong drop rods) or the Geberit Pluvia rail system, as outlined below. - Page 43 Rigid fixing - Anchor brackets Rules: Anchor brackets must be stronger than the possible forces generated during thermal expansion or contraction of Geberit HDPE pipes. Examples of anchor brackets: The examples of anchor brackets below show typical rigid installations. Anchor bracket with flat iron and electrowelding tape.

-

Page 44: Suspended Rail System

W = indication coefficient for steel profile. Suspended rail system 5.2.4 The Geberit Pluvia rail system was developed for the suspended installation of horizontal pipework. The system includes a metal rail that absorbs all the forces generated when the pipe tries to expand. -

Page 45: Waterproofing

50cm Wherever a waterproof layer is required, the Geberit sealing for passages through walls or ceilings provides a perfect watertight seal between the Geberit HDPE pipe and the waterproof membrane. Type 1: PVC to be welded with PVC sheet Type 2: PE to be welded with Samafil FPO-A-foil. -

Page 46: Fire Protection

0-45° To comply with building regulations B3 where pipes pass through fire rated barriers, Geberit provides intumescent fire sleeves that also incorporate a separate acoustic sleeving. Geberit Fire Protection Sleeve RS90 Plus EN is tested to BS EN 1366-3:2009 – Fire resistance tests for Fig. A Fig. B Fig. C service installations. -

Page 47: Alternate Stack Ventilation System

Total connection load The maximum permissible load with waste water of a Geberit Due to its high capacity and excellent performance, the Geberit Sovent fitting is an ideal drainage solution for: Sovent stack d110 is 12 l/s, for d160 it is 17.0 l/s. The pipe dimension of the stack, with main ventilation through the roof, •... - Page 48 Installation per floor Planning of further stacks If the waste water load of the stack d110 is greater than A Geberit Sovent fitting must be planned in every floor where there are connections to the stack. The maximum 12 l/s, the following measures must be planned: distance between two Sovent fittings must not exceed 6m.

- Page 49 ø 110 mm / DN 100. 45° Planning of a discharge stack according to Geberit Sovent rules 1 Planning of a discharge stack according to Planning of branch discharge and branch ve ntilation pipes according to country-specific...

- Page 50 Geberit Drainage Systems Alternative stack ventilation system Transition to the underground or collector pipe Zones without connections in the stack offset A branch ventilation pipe must be fitted at the end of each Sovent discharge stack for reducing the pressure.

- Page 51 Geberit Drainage Systems Alternative stack ventilation system Discharge stack with offset Additional connections to the Sovent discharge stack If an offset is necessary in the the discharge stack, this Normally, all pipes can be connected to the Sovent can be configured without further measures at max. 45º...

- Page 52 Mixed installations of the Sovent d110 and Airbourne sound insulation of Sovent fittings Sovent d160 When Geberit Sovent fittings are used, it is possible to assume the same airbourne sound propagation as in Mixed installations of Sovent fittings ø 110 / DN 100 Geberit HDPE stack branch fittimgs.

-

Page 53: Geberit Sovent - Stack Sizing

Stack sizing installation Basic requirements for selecting Sovent dimensions In general, the installation of a Geberit Sovent system follows the same rules as the installation of a The dimensions of the individual connection pipes, conventional drainage system. It does, however, require... -

Page 54: Geberit Air Admittance Valve Overview

(white print). system or recirculating air ventilation. • As a replacement for indirect secondary The air admittance valves GRB90 can be connected to the pipes, Geberit HDPE and Geberit Silent-db20 of the ventilation systems. dimensions ø 75 – ø 110mm. • For individual ventilation systems used in existing drainage objects with drainage malfunctions. - Page 55 Geberit Drainage Systems ≤ 150 cm Alternative stack ventilation system Please note the following points in order for the air admittance valve to function correctly: • The air admittance valve is allowed to be installed under the overflow edge. 19 cm • The air admittance valve must be installed vertically.

-

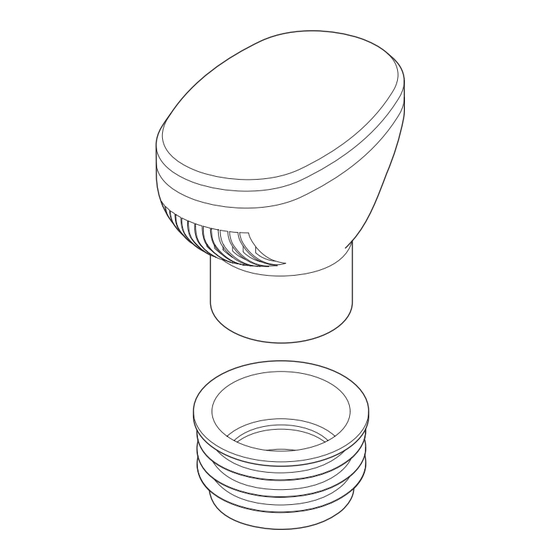

Page 56: Geberit Air Admittance Valve - Grb50

Geberit Drainage Systems Alternative stack ventilation system Geberit air admittance The indicated articles are not included in the scope of 6.2.2 delivery; they have to be ordered separately. valve - GBR50 364.565.16.1 306.050.14.1 Silent-db20 Silent-db20 HDPE HDPE ø 56/DN 56 ø... -

Page 57: Buried Drain Systems

Underground drainage Special consideration for buried drain application The Geberit HDPE drainage system has a proven track Geberit HDPE system is suitable for buried drain record for soil and waste installations. It can also be used... -

Page 58: Trench Details

Buried drain systems Trench details Fig. 2 Loadings on buried pipes need to be carefully calculated. Please contact Geberit on 0800 077 8365 for assistance 20 cm calculating loadings on Geberit drainage pipes. For all trenching work the local guidelines, standards and regulations must be observed. -

Page 59: Managing Thermal Movement - Buried Drain Applications

Geberit Drainage Systems Buried drain systems Managing thermal movement - Buried drain application Like above ground systems, the key aspect of underground installation is the management of expansion/thermal movement. Use of expansion sockets PL (pipe length) ID (insertion depth) SL (socket length) -

Page 60: Rigid Installation - Embedded In Concrete

Embedding in concrete Basically, Geberit HDPE material absorbs within itself Reduced small branches of large pipe diameters must thermal movement due to its high elasticity. In the case be secured by an additional anchor point (electrofusion of large diameters however (e.g. -

Page 61: Pipes Penetrating Through Building Walls

In such cases, Geberit HDPE is an ideal material, since Length DL = 10 . ∆ S . Ø... -

Page 62: Connection To Manhole

(Art nr. 3xx.454.16.1) 5 Anchor point if required Open manhole Geberit access pipe with oval access cover Plastic pipes should only be connected with manholes by means of a special manhole sleeve. Since settling of ground has to be expected such a sleeve must have the same ideal characteristics as Geberit HDPE: it must assure tightness and at the same time flexibility. -

Page 63: Appendix: Chemical Resistance

Geberit Drainage Systems Chemical resistance Appendix: Chemical Resistance Geberit HDPE Proport. Performance at Flow ough substance 20˚C 40˚C 60˚C The following symbols and abbreviations are used to indicate the composition of the flow substances: Acetic aldehyde Acetic aldehyde % Percentages refer to mass proportions in %. - Page 64 Geberit Drainage Systems Chemical resistance Geberit HDPE Geberit HDPE Proport. Performance at Proport. Performance at Flow ough substance 20˚C 40˚C 60˚C Flow ough substance 20˚C 40˚C 60˚C Anilin chlorhydrate Butanon Anise oil Butantriol Anone (cyclohexanone) Butindial Anthraquinone sulphonic acid Butoxyl (methosybutylacetate)

- Page 65 Geberit Drainage Systems Chemical resistance Geberit HDPE Geberit HDPE Proport. Performance at Proport. Performance at Flow ough substance Flow ough substance 20˚C 40˚C 60˚C 20˚C 40˚C 60˚C Chlorobenzol Dextrose (glucose, grape sugar) Chloroform Diamin hydrate Chloromethyl, gaseous Diethyl ether (ether, ethyl ether)

- Page 66 Geberit Drainage Systems Chemical resistance Geberit HDPE Geberit HDPE Proport. Performance at Proport. Performance at Flow ough substance Flow ough substance 20˚C 40˚C 60˚C 20˚C 40˚C 60˚C Ethyl chloride Fruit juices, unfermented Ethylene Fruit juices, fermented Ethylene chloride Fruit wine...

- Page 67 Geberit Drainage Systems Chemical resistance Geberit HDPE Geberit HDPE Proport. Performance at Proport. Performance at Flow ough substance Flow ough substance 20˚C 40˚C 60˚C 20˚C 40˚C 60˚C Hydrosilicofluoric acid Hydrosilicofluoric acid Magnesium carbonate Hydrosulphite Magnesium chloride Hydroxylamine sulphate Magnesium fluorsilicate...

- Page 68 Geberit Drainage Systems Chemical resistance Geberit HDPE Geberit HDPE Proport. Performance at Proport. Performance at Flow ough substance Flow ough substance 20˚C 40˚C 60˚C 20˚C 40˚C 60˚C 50/31/19 Oxygen 50/33/17 Ozone, gaseous 50 pphm 10/20/70 Ozone, gaseous 2% Mixed acid...

- Page 69 Geberit Drainage Systems Chemical resistance Geberit HDPE Geberit HDPE Proport. Performance at Proport. Performance at Flow ough substance Flow ough substance 20˚C 40˚C 60˚C 20˚C 40˚C 60˚C Phtalic acid Prussic acid (hydrocyanic acid) Phtalic acid Pseudocumol Phtalic acid ester Pyridine...

- Page 70 Geberit Drainage Systems Chemical resistance Geberit HDPE Geberit HDPE Proport. Performance at Proport. Performance at Flow ough substance Flow ough substance 20˚C 40˚C 60˚C 20˚C 40˚C 60˚C Sodium fluoride Sodium hexacyanoferrate Taningan extra (synthetic tanning substances) Sodium hydrogen carbonate Tannic acid (tannine)

- Page 71 Geberit Drainage Systems Chemical resistance Geberit HDPE Proport. Performance at 20°C 40°C 60°C Flow through substance Wax alcohols Waxes Walnut oil Washing agents Washing up liquid Water, distillied Water, fully desalinized Water de-ionized Water chlorinated driking water Water, ozonized drinking water...

- Page 72 Subject to change without notice. The information in this document contains general descriptions of the technical options available, which do not always have to be present in the individual cases. The required features should therefore be specified in each individual case at the time of closing the contract. © Geberit. November 2018.

Need help?

Do you have a question about the HDPE and is the answer not in the manual?

Questions and answers