Table of Contents

Advertisement

Quick Links

Download this manual

See also:

Training Manual

Advertisement

Table of Contents

Summary of Contents for Anilam 4200T

- Page 1 4200T CNC Programming and Operations Manual www.anilam.com...

- Page 2 P/N 70000412F - Warranty Warranty ANILAM warrants its products to be free from defects in material and workmanship for one (1) year from date of installation. At our option, we will repair or replace any defective product upon prepaid return to our factory.

-

Page 3: Table Of Contents

4200T CNC Programming and Operations Manual P/N 70000412F - Contents Section 1 - Programming Concepts Introduction ............................1-1 Programs ............................1-1 Axis Descriptions..........................1-2 Z Axis............................1-2 C Axis ............................1-2 X Axis ............................1-3 Part Zero Definition .......................... 1-3 Polar Coordinates .......................... - Page 4 4200T CNC Programming and Operations Manual P/N 70000412F - Contents Manual Mode Settings ........................3-7 Activating Manual Mode Rapid or Feed..................3-8 Adjusting the Feedrate........................3-8 Adjusting Rapid Move Speed......................3-9 Setting Absolute Zero ......................... 3-10 Part Zero............................. 3-10 Jog Moves............................3-11 Changing the Jog Mode......................

- Page 5 4200T CNC Programming and Operations Manual P/N 70000412F - Contents Programming a Pecking Cycle (G78) ..................... 5-11 Programming a Chip Break Cycle (G79) ..................5-12 Programming a Longitudinal Grooving Cycle (G81)............... 5-13 Programming a Radial Grooving Cycle (G82) ................5-15 Types of Threading ........................

- Page 6 4200T CNC Programming and Operations Manual P/N 70000412F - Contents Copying Program Blocks........................ 6-11 Printing a Portion of a Program ...................... 6-12 Pasting Copied Blocks into a Program Listing................6-12 Numbering (or Re-numbering) Program Blocks ................6-13 Writing Blocks to Another Program ....................6-13 Reading a Program into Another Program ..................

- Page 7 4200T CNC Programming and Operations Manual P/N 70000412F - Contents Automatic Draw Restart ........................ 8-7 Erasing the Draw Display......................8-7 Running Draw for Selected Blocks ....................8-7 Starting Draw at a Specific Block....................8-8 Ending Draw at a Specific Block ....................8-8 Adjusting Draw Display ........................

- Page 8 4200T CNC Programming and Operations Manual P/N 70000412F - Contents Selecting a Program for Running ....................10-2 Selecting a Program for Editing and Utilities ..................10-3 Listing a Program ........................... 10-3 Deleting a Program ........................10-3 Logging to Other Drives ......................... 10-4 Marking and Unmarking Programs....................10-5...

- Page 9 4200T CNC Programming and Operations Manual P/N 70000412F - Contents Automatic Execution Starting at a Specific Block ................11-5 Using Arrow Keys to Select Starting Block ................. 11-5 Using SEARCH to Select Starting Block..................11-5 Clearing a Halted Program......................11-5 Using Draw while Running Programs.....................

- Page 10 4200T CNC Programming and Operations Manual P/N 70000412F - Contents Performing Arc Moves (G02 or G03) ..................13-6 Setting Software Limits (G22) ..................... 13-7 Homing the Machine (G28)......................13-9 Making a Rough Turning Cut (G76).................... 13-9 Making a Rough Facing Cut (G77) ................... 13-10 Cutting Threads (G83) ......................

- Page 11 4200T CNC Programming and Operations Manual P/N 70000412F - Contents Chaining Geometry Elements to Create a Shape ................ 14-26 Viewing a Listing of Geometry Elements..................14-28 Deleting Geometry Elements ....................... 14-28 Deleting All Geometry Elements ....................14-29 Activate/Deactivating Geometry Elements ................... 14-29 Shape Editor Hot Keys .........................

- Page 12 4200T CNC Programming and Operations Manual P/N 70000412F - Contents Section 16 - Advanced Programming Features Block Separator..........................16-1 Modifiers............................16-1 Expressions and Functions ......................16-2 System Variables ........................... 16-3 User Variables..........................16-4 Local Variables ........................... 16-4 Common (Global) Variables......................16-4 Read Only Variables ........................

- Page 13 4200T CNC Programming and Operations Manual P/N 70000412F - Contents Keypad Equivalent Keyboard Keys ....................17-2 Section 18 - Off-line Software Passwords............................18-1 Exiting the Software ........................18-1 Windows Off-line Software Installation................... 18-3 Running Off-line Software from Windows ................... 18-3 System Settings ..........................18-3 Maximum Memory Allocated.......................18-3...

-

Page 14: Introduction

4200T CNC Programming and Operations Manual P/N 70000412F - Programming Concepts Section 1 - Programming Concepts Introduction This section contains programming concepts for the beginning programmer. It contains terminology and concepts that should be mastered before writing programs. Programs A program is a precise sequence of machine instructions. Each program consists of blocks of information that instruct the movements and sequence of events to machine a workpiece. -

Page 15: Axis Descriptions

4200T CNC Programming and Operations Manual P/N 70000412F - Programming Concepts Axis Descriptions Z Axis Refer to Figure 1-1. Motion along the Z-axis is linear. Positive Z motion is toward the tailstock and negative Z motion is toward the headstock. -

Page 16: Part Zero Definition

4200T CNC Programming and Operations Manual P/N 70000412F - Programming Concepts X Axis Refer to Figure 1-2. In relation to the tool, positive X motion is away from the centerline of the part. Negative X motion is toward the centerline of the part. -

Page 17: Polar Coordinates

4200T CNC Programming and Operations Manual P/N 70000412F - Programming Concepts Example (using front tooling and Incremental Mode): In X, to travel 2 inches toward the part centerline (negative direction), program X-4. (In Incremental Mode, an X-4 command moves the tool 2 inches per side.) In Z, to travel 6 inches towards the chuck (negative... -

Page 18: Absolute Positioning

4200T CNC Programming and Operations Manual P/N 70000412F - Programming Concepts Absolute Positioning Refer to Figure 1-5. When the CNC is in the Absolute Mode, all positions are measured from Absolute Zero. The Absolute Zero Reference, also called Part Zero, is not a fixed position on the machine; you select the point. -

Page 19: Incremental Positioning

4200T CNC Programming and Operations Manual P/N 70000412F - Programming Concepts Incremental Positioning Refer to Figure 1-6. Incremental positions are measured from the machine’s current position. This is convenient for performing an operation at regularly spaced intervals. INCREMEN Figure 1-6, Incremental Positioning NOTE: If an Incremental command to X0, Z0 is programmed, the CNC remains at the current position. -

Page 20: Developing Part Programs

4200T CNC Programming and Operations Manual P/N 70000412F - Programming Concepts D1 D2 D3 R=Radius D=Diameter DIARAD Figure 1-7, Diameter and Radius Programming The default, set by the machine builder, is usually Diameter. NOTE: In canned cycles (with the exception of area clearance), all X values are given as radial, regardless of whether diameter or radius programming is used. - Page 21 4200T CNC Programming and Operations Manual P/N 70000412F - Programming Concepts 6. Subsequent blocks in the program set spindle information, call tool number, turn on coolant, etc., and make the initial move toward the workpiece. 7. The remaining blocks in the program describe the moves, canned cycles, and tool changes required to complete the machining of the workpiece.

-

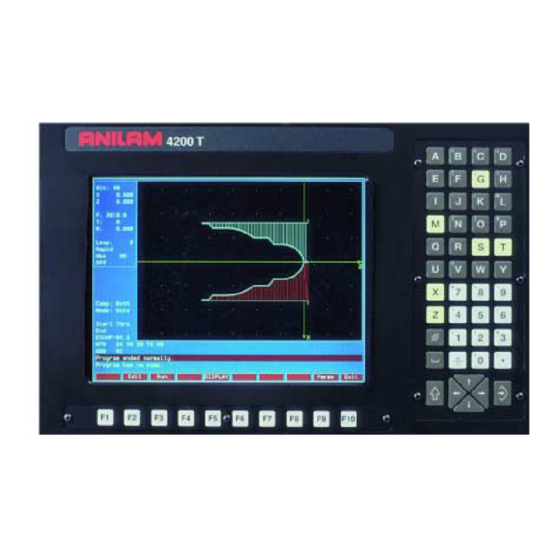

Page 22: Cnc Console

4200T CNC Programming and Operations Manual P/N 70000412F - CNC Console and Software Basics Section 2 - CNC Console and Software Basics CNC Console Refer to Figure 2-1. The CNC console consists of a 14-inch color screen and two keypads: one to the right of the screen and the other one underneath. -

Page 23: Keypad

4200T CNC Programming and Operations Manual P/N 70000412F - CNC Console and Software Basics Keypad Refer to Figure 2-2. The keypad to the right of the monitor is laid out in two groups. Alphanumeric Keys Editing Keys Figure 2-2, Keypad Keys All rights reserved. -

Page 24: Alphanumeric Keys

4200T CNC Programming and Operations Manual P/N 70000412F - CNC Console and Software Basics Alphanumeric Keys Refer to Figure 2-2, Keypad Keys. Alphanumeric Keys enable you to key-in position coordinates (X and Z) and program G, M, S and T codes. - Page 25 4200T CNC Programming and Operations Manual P/N 70000412F - CNC Console and Software Basics Key Face Primary Function Shift Function Letter R Underscore Letter S/Spindle Speed Backslash Designator Letter T/Tool words Single Quote Letter U None Letter V Question Mark...

-

Page 26: Editing Keys

4200T CNC Programming and Operations Manual P/N 70000412F - CNC Console and Software Basics Editing Keys Refer to Table 2-2. Use the editing keys to edit programs and move around the screen. Table 2-2, Editing Keys Label or Key Face... -

Page 27: Soft Keys

4200T CNC Programming and Operations Manual P/N 70000412F - CNC Console and Software Basics Table 2-3, Programming Word Keys (Continued) Label or Name Key Face Function POSITIVE/NEGATIVE Used to indicate positive or INDICATOR negative direction or value, plus or minus; in Manual Data Input (MDI) mode, press key to insert a minus (-) sign. -

Page 28: Pop-Up Menus

4200T CNC Programming and Operations Manual P/N 70000412F - CNC Console and Software Basics Pop-up Menus Refer to Figure 2-3. Pop-up menus are temporary menus that enable you to make additional selections. Pop-up menus automatically appear where needed. Each pop-up menu contains a highlight bar. Use the keys to move the highlight bar up and down the menu. -

Page 29: Typeover And Insert Modes

4200T CNC Programming and Operations Manual P/N 70000412F - CNC Console and Software Basics Typeover and Insert Modes The edit mode has two text entry modes: “typeover” and “insert”. By default, the CNC runs in the typeover mode. In the typeover mode, new characters replace characters marked by the cursor (the white underline). - Page 30 4200T CNC Programming and Operations Manual P/N 70000412F - CNC Console and Software Basics Messages Figure 2-4, Message Window All rights reserved. Subject to change without notice. 31-July-05...

-

Page 31: Manual Panel

4200T CNC Programming and Operations Manual P/N 70000412F - Manual Operation and Machine Setup Section 3 - Manual Operation and Machine Setup This section describes the functions of the keys and switches on the Manual Panel. It also provides information on manual operations. -

Page 32: Manual Panel Keys

4200T CNC Programming and Operations Manual P/N 70000412F - Manual Operation and Machine Setup Manual Panel Keys Manual Operation Keys enable you to control machine movements manually. These keys are located on the Manual Panel. See Table 3-1. Table 3-1, Manual Operation Keys... -

Page 33: Manual Panel Leds

4200T CNC Programming and Operations Manual P/N 70000412F - Manual Operation and Machine Setup Table 3-1, Manual Operation Keys (Continued) Label or Name Key Face Purpose JOG + Moves selected axis in positive direction. Used in all Jog modes. Feedrate determined by machine builder. -

Page 34: Manual Mode Screen

4200T CNC Programming and Operations Manual P/N 70000412F - Manual Operation and Machine Setup Manual Mode Screen Refer to Figure 3-2. When the CNC is in Manual Mode, it displays the Manual screen. The Manual screen is the first screen displayed when you turn on the CNC. -

Page 35: Machine Status Display Area Labels

4200T CNC Programming and Operations Manual P/N 70000412F - Manual Operation and Machine Setup Distance To Go Displays distance to go with respect to X and Z commanded coordinates. Machine Status Display Area Displays operating information. Active Soft Key Refer to Table 3-2. Soft key functions change from screen to screen. -

Page 36: Program Area Labels

4200T CNC Programming and Operations Manual P/N 70000412F - Manual Operation and Machine Setup DWELL: A timed pause, indicated in number of seconds or revolutions. Units are specified as seconds or revolutions, during builder setup. OVERRIDE: Indicates whether the feedrate override setting applies to both feed and rapid moves or to feed moves only. -

Page 37: Shutting Down The Cnc

4200T CNC Programming and Operations Manual P/N 70000412F - Manual Operation and Machine Setup Shutting Down the CNC To shut down the CNC: 1. Press The servos disengage and the CNC reverts to Manual STOP. Mode. 2. Press SHIFT (F10). The CNC displays the Software Options menu. -

Page 38: Activating Manual Mode Rapid Or Feed

4200T CNC Programming and Operations Manual P/N 70000412F - Manual Operation and Machine Setup Before you make a manual move, make any necessary mode settings. Modes set from the Manual screen remain active if the CNC is put in a program operating mode until the mode is changed by the program or operator. -

Page 39: Adjusting Rapid Move Speed

4200T CNC Programming and Operations Manual P/N 70000412F - Manual Operation and Machine Setup When the is set to 100%, the CNC makes all Feed FEEDRATE OVERRIDE moves at the programmed feedrate. To run the CNC at a percentage of the programmed feedrate, adjust the . -

Page 40: Setting Absolute Zero

4200T CNC Programming and Operations Manual P/N 70000412F - Manual Operation and Machine Setup Setting Absolute Zero Refer to Figure 3-3. In Absolute Mode, all positions are measured from Absolute Zero. Absolute Zero is the point the CNC recognizes as X0, Z0 when the Absolute Positioning Mode is active. -

Page 41: Jog Moves

4200T CNC Programming and Operations Manual P/N 70000412F - Manual Operation and Machine Setup When the machine is powered up, its present location is automatically set as the Absolute Zero Reference. When the CNC is shut down, the position of the Absolute Zero Reference is lost. -

Page 42: Jogging The Machine (In Increments)

4200T CNC Programming and Operations Manual P/N 70000412F - Manual Operation and Machine Setup Jogging the Machine (in Increments) In Manual Mode, you can position the machine with jog increments. Jog increments advance the machine in selected increments: 1, 10, or 100 times the machine resolution. -

Page 43: Using Manual Data Input Mode

Operating a Handwheel Mounted on the Manual Panel In some 4200T systems, one handwheel is mounted on the Manual Panel. In Manual Mode, you can use the handwheel to jog any controlled axis (X or Z). The machine builder must enable the handwheel option in the Setup Utility. -

Page 44: Operating Handwheels Mounted On The Machine

4200T CNC Programming and Operations Manual P/N 70000412F - Manual Operation and Machine Setup Refer to Table 3-4 for selections available with the handwheel. Table 3-4, Handwheel Jog Resolution Settings Jog Mode Setting Handwheel Resolution FEED Not Available RAPID Not Available... -

Page 45: Preparatory Functions: G-Codes

4200T CNC Programming and Operations Manual P/N 70000412F - Preparatory Functions: G-Codes Section 4 - Preparatory Functions: G-Codes Preparatory Functions: G-Codes G-codes initiate motion commands, canned cycles, various machine functions and other CNC capabilities. More than one G-code may be specified per block. - Page 46 4200T CNC Programming and Operations Manual P/N 70000412F - Preparatory Functions: G-Codes Table 4-1, Modal and Non-Modal G-Codes Modal Non-Modal G-Code Function G-Code Function Positioning-Rapid Traverse Dwell Linear Interpolation Ellipse Circular Interpolation-CW Exact Stop Check Circular Interpolation-CCW Probe Move Stored Stroke Limit ON...

-

Page 47: Rapid Traverse (G0)

4200T CNC Programming and Operations Manual P/N 70000412F - Preparatory Functions: G-Codes Rapid Traverse (G0) Format: G0 initiates rapid traverse. The machine builder sets the actual rapidrate in the Setup Utility. Use rapid traverse to position the tool prior to or after a cut. -

Page 48: Linear Interpolation (G1)

4200T CNC Programming and Operations Manual P/N 70000412F - Preparatory Functions: G-Codes Linear Interpolation (G1) Format: Linear Interpolation (G1) initiates feed motion in a straight line. It is used for cutting a part. Straight-line motion can be linear or angular. The block could contain any combination of the available axes. -

Page 49: Angular Motion Programming Example

4200T CNC Programming and Operations Manual P/N 70000412F - Preparatory Functions: G-Codes Angular Motion Programming Example Angular (vectored) motions are straight-line motions involving motion in both the X- and Z-axes. They require two dimensions (X and Z) to define the endpoint of motion. Table 4-4 demonstrates how G1 is used in a program. -

Page 50: Circular Interpolation (G2 And G3)

4200T CNC Programming and Operations Manual P/N 70000412F - Preparatory Functions: G-Codes Circular Interpolation (G2 and G3) Arc input format: G2 (G3) Xn Zn In Kn Radius format: G2 (G3) Xn Zn Rn Circular Interpolation initiates circular moves, including arcs. Table 4-5 contains the parameters necessary to program these moves. - Page 51 4200T CNC Programming and Operations Manual P/N 70000412F - Preparatory Functions: G-Codes Examples of Circular Interpolation Refer to Table 4-6 and Figure 4-4. Both the MM and Inch equivalents are provided. Table 4-6, Circular Interpolation in Absolute Mode, Inches (MM)

-

Page 52: Partial Arcs

4200T CNC Programming and Operations Manual P/N 70000412F - Preparatory Functions: G-Codes Table 4-7 provides the incremental version of the part program diagrammed in Figure 4-4, Circular Interpolation. Table 4-7, Circular Interpolation in Incremental Mode, Inches (MM) G70 (G71) G90 G1 X0 Z0 Activate Inch and Absolute G95 F.010 (25.4) -

Page 53: Ellipse (G5)

Block 21 commands an infinite dwell. The time or revolution countdown is displayed in the Machine Status area of the Manual screen. NOTE: ANILAM recommends that you use the Programmed Stop M- code (M00) instead of G4T0. Ellipse (G5) Format: G5 Xn Zn ln Kn An Bn Ln Use G5 to program a full or partial ellipse. -

Page 54: Non-Modal Exact Stop Check (G9)

4200T CNC Programming and Operations Manual P/N 70000412F - Preparatory Functions: G-Codes Non-modal Exact Stop Check (G9) Format NOTE: Rapid moves are always performed in In-Position Mode. Refer to Table 4-9 for a list of G-codes related to Exact Stop Check (G9). -

Page 55: Setting Software Limits (G22)

4200T CNC Programming and Operations Manual P/N 70000412F - Preparatory Functions: G-Codes Setting Software Limits (G22) Format: G22 Xn Zn In Kn Activates Software Limits, Modal Format: Cancels Software Limits and allows free movement within the machine limits. Refer to Table 4-10. -

Page 56: Maximum Spindle Speed (G24)

4200T CNC Programming and Operations Manual P/N 70000412F - Preparatory Functions: G-Codes Figure 4-5, Front Tooling Software Limits Figure 4-6, Rear Tooling Software Limits Maximum Spindle Speed (G24) Format: G24 Sxxxx Refer to Table 4-11. Table 4-11, G24 Address Words... -

Page 57: Probe Move (G31)

4200T CNC Programming and Operations Manual P/N 70000412F - Preparatory Functions: G-Codes The S-word can contain up to four digits (Sxxxx, range 0001 to 9999). Leading zeros can be omitted. Once you program a G24 command, the CNC prevents the programmed spindle speed from exceeding the entered amount (Sxxxx). -

Page 58: Offsets (Work Coordinate System Select) (G53)

4200T CNC Programming and Operations Manual P/N 70000412F - Preparatory Functions: G-Codes Refer to Table 4-13 for a sample Program Listing containing the G33 command. E or F, not both, must be programmed. At least one axis address must accompany F/E value. F (pitch) is usually used in MM programming. - Page 59 4200T CNC Programming and Operations Manual P/N 70000412F - Preparatory Functions: G-Codes Notes: 1. All of the above will clear any G92 active Tool Table. 2. Typically, the table found in the Tool Table is used (F1) to set the values and the values activated in the part program by programming G53 with O# (such as G53 O1).

-

Page 60: Modal Corner Rounding/Chamfering (G59)

4200T CNC Programming and Operations Manual P/N 70000412F - Preparatory Functions: G-Codes Changing Fixture Offsets Using Calibrate Keys To change offset using the calibrate keys: 1. Move the machine to the desired position. 2. Highlight the offset. 3. Press CalibX. - Page 61 4200T CNC Programming and Operations Manual P/N 70000412F - Preparatory Functions: G-Codes Figure 4-8, G59 Part Program Refer to Figure 4-8. The diagram illustrates the part programmed in Table 4-15. In this example, G59 is used to command modal corner rounding.

-

Page 62: Cancel Modal Corner Rounding (G60)

4200T CNC Programming and Operations Manual P/N 70000412F - Preparatory Functions: G-Codes To change the radius between intersections, refer to the previous program. If you wanted to change the radius of the corner rounding of N45 to R0.25, you would need to insert a G59 command (G59 R0.25) between lines N40 and N45. -

Page 63: Contouring Mode (Cutting Mode) (G64)

4200T CNC Programming and Operations Manual P/N 70000412F - Preparatory Functions: G-Codes While the In-Position Mode (G61) is active, the CNC approaches target and performs an in-position check before the next move is executed. The CNC comes to a complete stop at the completion of each command. This could cause tool dwell marks to appear on the workpiece, but prevents the CNC from rounding off sharp corners. -

Page 64: Using Macros (G65, G66, G67)

4200T CNC Programming and Operations Manual P/N 70000412F - Preparatory Functions: G-Codes Using Macros (G65, G66, G67) NOTE: Before using macros, you must learn how variables and parameters are used in a program or subprogram. Refer to “Section 16 - Advanced Programming Features”... - Page 65 4200T CNC Programming and Operations Manual P/N 70000412F - Preparatory Functions: G-Codes A subprogram consists of fixed dimensions, but a macro contains variables and parameters that can change every time the macro is used. Macros can be stored in the same file as the main program or in a separate file.

-

Page 66: Inch Mode (G70) Or Mm Mode (G71)

4200T CNC Programming and Operations Manual P/N 70000412F - Preparatory Functions: G-Codes Inch Mode (G70) or MM Mode (G71) Inch Mode Format: G70 MM Mode Format: You can change the unit of measurement display via the Inch Mode (G70) or MM Mode (G71) commands. G70 switches the CNC to Inch Mode. - Page 67 4200T CNC Programming and Operations Manual P/N 70000412F - Preparatory Functions: G-Codes ABSINC Figure 4-9, Absolute vs. Incremental Programming Table 4-24, Absolute vs. Incremental Programming Examples Absolute Incremental Point 1 Point 2 Z-.1 Point 3 X1.0 Point 4 Point 5 Z-1.6...

-

Page 68: Presetting The Axes (G92)

Homes X and Z-axes. N03 G92 X4 Z6 Sets current position to X4, Z6. NOTE: Anilam recommends that you do not use G92 to set Part Zero. If the machine loses power, this reference point will be lost. 4-24 All rights reserved. Subject to change without notice. -

Page 69: Cutting Feedrates In Feed Per Minute (G94)

4200T CNC Programming and Operations Manual P/N 70000412F - Preparatory Functions: G-Codes Cutting Feedrates in Feed per Minute (G94) G94: (FPM) Inch or MM per minute feedrate programming. Refer to Table 4-27. Feedrates programmed in Feed Per Minute (FPM) (G94) are either in Inch (G70) or MM (G71) Mode. In FPM Mode, the moves are made at a specified rate per minute. -

Page 70: Setting Spindle Speed To Constant Surface Speed (G96)

4200T CNC Programming and Operations Manual P/N 70000412F - Preparatory Functions: G-Codes Setting Spindle Speed to Constant Surface Speed (G96) CAUTION: Program a G24 Sxxxx (Maximum Spindle RPM) prior to G96. This prevents the RPM of the spindle from reaching maximum speed when a move to the centerline (X0) is programmed. -

Page 71: Programming A Z-Axis Turning/Boring Cycle With A Defined Profile (G73)

4200T CNC Programming and Operations Manual P/N 70000412F - Canned Cycles Section 5 - Canned Cycles Programming a Z-Axis Turning/Boring Cycle with a Defined Profile (G73) Format G73 Wn An Rn Sn Cn Bn Pn In Jn Kn Refer to Table 5-1. The table lists the Address Words that define the G73 (longitudinal) and G74 (radial) area clearance cycles. - Page 72 4200T CNC Programming and Operations Manual P/N 70000412F - Canned Cycles The subprogram profile is programmed after the end of the main program and uses the letter O. The profile program can contain lines, arcs and angles. You can use the shape editor. An optional finish pass removes the finish stock amount defined by parameters R (X) and S (Z).

- Page 73 4200T CNC Programming and Operations Manual P/N 70000412F - Canned Cycles Table 5-2, G73 Part Program Program Block Description N1 G70 G90 G0 X0 Z0 T0 Sets Inch/MM Mode and Absolute Mode. Places machine at X0,Z0 with no tool offsets active.

-

Page 74: Programming An X-Axis Facing/Boring Cycle With Defined Profile (G74)

4200T CNC Programming and Operations Manual P/N 70000412F - Canned Cycles Programming an X-Axis Facing/Boring Cycle with Defined Profile (G74) Format G74 Wn An Rn Sn Cn Bn Pn In Jn Kn Refer to Table 5-1, G73 and G74 Address Words. - Page 75 4200T CNC Programming and Operations Manual P/N 70000412F - Canned Cycles 0.60 Dia. (82.55MM) 0.2" R. 2 places (5.08 MM) 3.25" Dia. (82.55MM) 0.10" X 45 deg. CHAMFER (2.54MM) 0.05" X 45 deg. 0.40" CHAMFER (10.16MM) (1.27MM) 0.70" (17.78MM) 74-2 Figure 5-4, G74 Part Program Refer to Figure 5-4.

- Page 76 4200T CNC Programming and Operations Manual P/N 70000412F - Canned Cycles The following subprogram describes the part profile called into the main program above. The CNC calculates actual moves based on the profile described in the subroutine. N7 O8 (Subprogram) Establishes name of Subprogram (O8).

-

Page 77: Programming A Z-Axis Rough Turning Or Boring Cycle (G76)

4200T CNC Programming and Operations Manual P/N 70000412F - Canned Cycles Programming a Z-Axis Rough Turning or Boring Cycle (G76) Use the Z-Axis Rough Turning Cycle (G76) to clear stock along the Z-axis (outer diameter, O.D.) or to bore a hole (inner diameter, I.D.). Refer to Table 5-4 for a list and description of the Address Words associated with G76. - Page 78 4200T CNC Programming and Operations Manual P/N 70000412F - Canned Cycles G81 Address Words Refer to Figure 5-5. The G76 turning cycle removes stock material along the Z-axis, from the outer diameter of the work. The tool must be positioned appropriately before the canned cycle begins.

-

Page 79: Programming An X-Axis Radial (Facing) Roughing Cycle (G77)

4200T CNC Programming and Operations Manual P/N 70000412F - Canned Cycles Programming an X-Axis Radial (Facing) Roughing Cycle (G77) Format: G77 Xn Zn Cn An Bn Dn En Refer to Table 5-5 for a list and description of the Address Words used to define G77. - Page 80 4200T CNC Programming and Operations Manual P/N 70000412F - Canned Cycles G77 can be used for I.D. or O.D cuts. B determines the standoff position in Z, from which the tool advances to the start of the facing cycle. The CNC calculates the depth of each pass and the number of passes necessary to reach finish depth (Z).

-

Page 81: Programming A Pecking Cycle (G78)

4200T CNC Programming and Operations Manual P/N 70000412F - Canned Cycles Programming a Pecking Cycle (G78) Format G78 Zn Rn Fn In Pn Refer to Table 5-6 for a list and description of the Address Words used to define a Pecking Cycle (G78). -

Page 82: Programming A Chip Break Cycle (G79)

4200T CNC Programming and Operations Manual P/N 70000412F - Canned Cycles Programming a Chip Break Cycle (G79) Format G79 Zn Rn Fn In Jn Kn Wn Un Pn Refer to Table 5-7 for a list and description of the Address Words used to define a Chip Break Cycle (G79). -

Page 83: Programming A Longitudinal Grooving Cycle (G81)

4200T CNC Programming and Operations Manual P/N 70000412F - Canned Cycles The peck distance will never be more than I or less than K. To prevent binding of the chips, tool, and workpiece in deep-hole drilling, as the depth increases, the peck distance (J) decreases. The retract depth (U) variable allows the programmer to fully retract the tool from the hole, at specified incremental depths. - Page 84 4200T CNC Programming and Operations Manual P/N 70000412F - Canned Cycles After the tool reaches total depth (X), it remains at the bottom of the groove until the dwell time (D, optional) elapses. The CNC calculates the number and width of passes from the total length (Z) required and the tool width (W).

-

Page 85: Programming A Radial Grooving Cycle (G82)

4200T CNC Programming and Operations Manual P/N 70000412F - Canned Cycles Table 5-9, G81 Programming Example Program Block Description N1 O7 *GROOVY Establishes program name and number. N2 G90 G70 G0 T0 X0 Z0 M5 Sets Absolute/Inch/Rapid Modes. Cancels tool offsets and positions tool at X0, Z0. - Page 86 4200T CNC Programming and Operations Manual P/N 70000412F - Canned Cycles Tool Path Part Outline X0, Z0 Figure 5-12, G82 Address Words Refer to Figure 5-12. The G82 canned cycle creates a groove along the radial (X) axis. Use a groove-cutting tool for this cycle. The cycle has built-in compensation for tool width.

-

Page 87: Types Of Threading

4200T CNC Programming and Operations Manual P/N 70000412F - Canned Cycles Types of Threading Refer to Table 5-11. The following terms will help explain the threading cycles given in subsequent sections. Table 5-11, Types of Threading Threading Description Compound Threading The tool enters the work on an angle (A) specified by the programmer. -

Page 88: Cutting Longitudinal Threads With Canned Cycles (G83, Uni-Directional)

4200T CNC Programming and Operations Manual P/N 70000412F - Canned Cycles Cutting Longitudinal Threads with Canned Cycles (G83, Uni-directional) Format G83 En Zn Cn Dn An Sn Rn Xn Vn Bn Wn Refer to Table 5-12 for a list and description of the Address Words used to define a Uni-directional Longitudinal Threading Cycle (G83). - Page 89 4200T CNC Programming and Operations Manual P/N 70000412F - Canned Cycles Refer to Figure 5-13. The figure describes the motion of the CNC during a G83 canned cycle. The G83 canned cycle creates a longitudinal thread along the Z-axis, utilizing multiple-pass threading. G83 supports an X-axis taper distance or angle.

-

Page 90: Cutting Longitudinal Threads With Canned Cycles (G84, Bi-Directional)

4200T CNC Programming and Operations Manual P/N 70000412F - Canned Cycles Cutting Longitudinal Threads with Canned Cycles (G84, Bi-directional) Format G84 En (Fn) Zn Cn Dn An Sn Rn Bn Wn Refer to Table 5-13 for a list and description of the Address Words used to define a Bi-directional Longitudinal Threading Cycle (G84). - Page 91 4200T CNC Programming and Operations Manual P/N 70000412F - Canned Cycles Refer to Figure 5-14. The figure describes the motion of the CNC during a G84 canned cycle. The G84 canned cycle creates a longitudinal thread along the Z-axis, utilizing multiple-pass threading. G84 does not support an X-axis taper distance or angle, but allows bi-directional threading.

- Page 92 4200T CNC Programming and Operations Manual P/N 70000412F - Canned Cycles G84 Programming Example Figure 5-15, G84 Programming Example Refer to Figure 5-15 for a diagram of the part programmed in Table 5-14. The Listing provides a sample Program Listing for a G84 threading canned cycle.

-

Page 93: Cutting Radial Threads With Canned Cycles (G85, Uni-Directional)

4200T CNC Programming and Operations Manual P/N 70000412F - Canned Cycles Cutting Radial Threads with Canned Cycles (G85, Uni-directional) Format: G85 En (Fn) Xn Cn Dn An Sn Rn Zn Vn (Bn) Wn Refer to Table 5-15 for a listing and description of Address Words associated with the G85 comman7d. - Page 94 4200T CNC Programming and Operations Manual P/N 70000412F - Canned Cycles tool path part edge Figure 5-16, G85 Canned Cycle NOTE: All variables are sign (+/-) dependent. Moves can be defined as Outer Diameter/Inner Diameter, and toward or away from the chuck or part centerline.

- Page 95 4200T CNC Programming and Operations Manual P/N 70000412F - Canned Cycles G85 Radial (Face) Plunge Thread Example SCROLL THD PITCH = 0.125" (3MM) X0, Z0 4.00" (101.6MM) 1.40" (35.56MM) .20" (5.08MM) G85-B Figure 5-17, Radial (Face) Threading Example Refer to Figure 5-17 . The figure shows a part diagram for a G85 cycle.

-

Page 96: Cutting Radial Threads With Canned Cycles (G86, Bi-Directional)

4200T CNC Programming and Operations Manual P/N 70000412F - Canned Cycles Cutting Radial Threads with Canned Cycles (G86, Bi-directional) Format G86 En (Fn) Xn Cn Dn An Sn Rn Bn Wn Refer to Table 5-17 for a listing and description of the Address Words associated with the G86 canned cycle. - Page 97 4200T CNC Programming and Operations Manual P/N 70000412F - Canned Cycles Refer to Figure 5-18 . The diagram describes the motion of the CNC during the G86, multiple-pass thread cutting. In Radial Bi-directional threading (G86), passes are performed along the X-axis (face). G86 is designed for compound threading.

-

Page 98: Tapping A Hole With A Canned Cycle (G87)

4200T CNC Programming and Operations Manual P/N 70000412F - Canned Cycles Tapping a Hole with a Canned Cycle (G87) NOTE: The machine must support spindle M-codes (spindle forward, spindle reverse and spindle off) in order to use this cycle. Format... - Page 99 4200T CNC Programming and Operations Manual P/N 70000412F - Canned Cycles Refer to Figure 5-19 . The diagram describes the Address Words used to define a G87 Tapping Cycle. G87 is used for tapping holes. The CNC feeds from the retract plane to the depth of the hole in Z. The spindle stops and reverses motion, and retracts the tool from the hole.

-

Page 100: Programming A Boring Cycle (G88)

4200T CNC Programming and Operations Manual P/N 70000412F - Canned Cycles Programming a Boring Cycle (G88) Format G88 Zn Xn Cn An Bn Refer to Table 5-19 for a listing and description of the Address Words associated with the G88 canned cycle. - Page 101 4200T CNC Programming and Operations Manual P/N 70000412F - Canned Cycles Refer to Figure 5-20 . The G88 boring cycle removes stock material along the Z-axis, from the inner diameter of the work. The tool must be positioned appropriately before the canned cycle begins. Perform boring cycles only on a workpiece that has been pre-drilled.

-

Page 102: Lathe Tool Probe Cycles (Option)

Lathe Tool Probe Cycles (Option) This document describes operation and an overview of the lathe tool probe canned cycles available on the 4200T CNC product. Probing is an option on the 4200T CNC. The cycles provided perform the most common tool probing functions. Custom cycles to perform specific functions can be written using the G31 primitive and parametric programming. -

Page 103: Tool Probe G-Code Cycle Designations

4200T CNC Programming and Operations Manual P/N 70000412F - Canned Cycles Tool Probe G-code Cycle Designations Before running any of these probing cycles you must go into Probing Setup and set the probing setup parameters. G150 Tool Probe Calibration Cycle This is used to set the X and Z datum for diameter, length, and establish the center of the probe stylus. - Page 104 4200T CNC Programming and Operations Manual P/N 70000412F - Canned Cycles To set the Probe Parameters: • On the Software Options menu, select Software Utility. • On the Setup Options menu, select Builder Setup. • On the Builder Setup menu, select Probing.

-

Page 105: Probe Orientation

4200T CNC Programming and Operations Manual P/N 70000412F - Canned Cycles Probe Orientation Probe orientation is the position the tool is placed. G146 may be used to position the tool. If orientation 2 is to be used, the tool would be placed at the back right corner of the stylus at the appropriate distance from X and Z. - Page 106 4200T CNC Programming and Operations Manual P/N 70000412F - Canned Cycles G151 Tool Preset Cycle Bring the probe arm down and jog the tool into the orientation position. The tool that is being set must be active before calling this cycle.

-

Page 107: Description Of Tool Probe Cycles

4200T CNC Programming and Operations Manual P/N 70000412F - Canned Cycles Description of Tool Probe Cycles This section contains detailed descriptions of the tool probe cycles: • Establishing a Position on the Machine • Tool Probe Calibration Cycle ( G150 ) •... - Page 108 4200T CNC Programming and Operations Manual P/N 70000412F - Canned Cycles Tool Probe Calibration Cycle (G150) Format: G150 An Bn Sn Dn This cycle is used to calibrate the probe. This is used to set the X and Z datums establishing the center of the probe stylus and the effective probe stylus size for setting tool diameter registers.

- Page 109 4200T CNC Programming and Operations Manual P/N 70000412F - Canned Cycles Tool Preset (G151) Format: G151 Bn Cn Sn Dn This tool preset ( G151 ) can be run from within a program or from the manual mode. Refer to Table 5-21 .

- Page 110 4200T CNC Programming and Operations Manual P/N 70000412F - Canned Cycles Tool Wear/Breakage Cycle (G154) Format: G154 Bn Cn Sn Dn In Kn Un Refer to Table 5-22 . Table5-22, G154 Address Word Address Word Description (Distance away) The distance away from the probe stylus.

- Page 111 4200T CNC Programming and Operations Manual P/N 70000412F - Canned Cycles Protected Probe Positioning Cycle (G146) Format: G146 Xn Zn Fn When an X and Z move is programmed using the G146 (Protected Probe Positioning Cycle), the control will stop and alarm if the probe stylus is triggered before reaching the target set in the X and Z parameters.

-

Page 112: Activating The Program Editor

4200T CNC Programming and Operations Manual P/N 70000412F - Program Editor Section 6 - Program Editor Activating the Program Editor Program blocks are written with the Program Editor. Activate the Program Editor to put the CNC in Edit Mode. You must create program files before you can write or edit programs. - Page 113 4200T CNC Programming and Operations Manual P/N 70000412F - Program Editor Program Listing First Block Soft Keys Softkeys Status Line Figure 6-1, Edit Screen Refer to Figure 6-1 to write and edit programs from the Edit Screen. Refer to Table 6-1 for an overview of the Edit screen.

-

Page 114: Edit Soft Keys

4200T CNC Programming and Operations Manual P/N 70000412F - Program Editor Edit Soft Keys Refer to Table 6-2 for a list of the soft keys in the edit mode. Table 6-2, Edit Soft Keys Soft Key Label Function Help Activates Edit Help Menu. -

Page 115: Editing Shift Soft Keys

4200T CNC Programming and Operations Manual P/N 70000412F - Program Editor Editing Shift Soft Keys The Edit screen contains ten soft keys when it activates. Four additional soft keys activate when you press . Refer to Table 6-3 for a list of SHIFT shift soft keys in the edit mode. -

Page 116: Deleting A Program Block

4200T CNC Programming and Operations Manual P/N 70000412F - Program Editor Deleting a Program Block There are two ways to delete program blocks from a Program Listing: Press DelBlk (F4) to delete one block at a time. Use the BLOCK Operations Delete feature to delete several blocks at a time. -

Page 117: Going To A Line Of The Program Listing

4200T CNC Programming and Operations Manual P/N 70000412F - Program Editor Going to a Line of the Program Listing The Go to Line feature enables you to go to any line in the Program Listing. Go to Line operates independently of block numbering. Blocks can be numbered sequentially by any increment (1, 5, 10...). -

Page 118: Searching The Program Listing For Selected Text

4200T CNC Programming and Operations Manual P/N 70000412F - Program Editor Searching the Program Listing for Selected Text Use the Find Word and Find Next features to search blocks for selected text. Enter the text to be found. The CNC searches out the first (Find Word) and subsequent occurrences (Find Next) in the Program Listing. -

Page 119: Restoring A Block

4200T CNC Programming and Operations Manual P/N 70000412F - Program Editor Restoring a Block If a block has been deleted, you can restore it to the program by using Undelete Block. The last block deleted is the first block restored. There... -

Page 120: Abbreviating Statements

4200T CNC Programming and Operations Manual P/N 70000412F - Program Editor If Yes (F1) or No (F2) is chosen, the CNC replaces (F1) or leaves the text unchanged (F2), then moves to the next occurrence of the entered text. The Change Word feature deactivates when all occurrences of the text have been found or if you press Only (F4). -

Page 121: Marking (Highlighting) Programming Blocks

4200T CNC Programming and Operations Manual P/N 70000412F - Program Editor Marking (Highlighting) Programming Blocks Many editing features require you to mark (highlight) affected program blocks before the edit is performed. To mark program blocks: 1. In Edit Mode, place the insertion point at the beginning of the first block to be marked. -

Page 122: Copying Program Blocks

4200T CNC Programming and Operations Manual P/N 70000412F - Program Editor Copying Program Blocks NOTE: You can cut, save and paste blocks within a Program Listing. Paste features works for pasting blocks between two different programs as long as you don’t exit the editor. Use the Edit Program or Pick Program to edit another program within the editor. -

Page 123: Printing A Portion Of A Program

4200T CNC Programming and Operations Manual P/N 70000412F - Program Editor 6. Highlight BLOCK operations, and press . The BLOCK ENTER operations Pop-Up Menu activates. 7. Highlight Cut, and press . The CNC saves the blocks in ENTER memory and deletes the original blocks from the Program Listing. -

Page 124: Numbering (Or Re-Numbering) Program Blocks

4200T CNC Programming and Operations Manual P/N 70000412F - Program Editor Numbering (or Re-numbering) Program Blocks To number or re-number blocks in a program: 1. In Edit Mode, mark all the blocks in the program. 2. Press Editing (F8). The soft key highlights and the EDITING Pop-Up Menu activates. -

Page 125: Reading A Program Into Another Program

4200T CNC Programming and Operations Manual P/N 70000412F - Program Editor NOTE: The Write feature does not use or overwrite information in the buffer, where cut and saved blocks are stored. When Write is used, the information in the buffer remains unchanged. -

Page 126: Playing Recorded Keystrokes

4200T CNC Programming and Operations Manual P/N 70000412F - Program Editor Playing Recorded Keystrokes The Play keys feature retrieves recorded keystrokes and prints them on the screen. To retrieve recorded keystrokes: 1. In Edit Mode, press Misc (F9). The soft key highlights and the MISC Pop-Up Menu activates. -

Page 127: Accessing The Most Recently Used Programs

4200T CNC Programming and Operations Manual P/N 70000412F - Program Editor 5. Press Continue (F10) to return to the Edit screen. NOTE: While the program is printing, press Cancel (F9) to cancel the print job. Accessing the Most Recently Used Programs Use the Pick Program feature, from the MISC Pop-Up Menu, to access and display any of the last ten programs opened in the Edit Mode. -

Page 128: Canceling Unsaved Edits

4200T CNC Programming and Operations Manual P/N 70000412F - Program Editor Canceling Unsaved Edits If edits have not been saved, they can be canceled. To cancel unsaved edits: 1. In Edit Mode, press and then press Quit ( + F10). - Page 129 4200T CNC Programming and Operations Manual P/N 70000412F - Edit Help Section 7 - Edit Help Edit Help provides diagrams and entry fields to program move types and canned cycles for blueprint programming. NOTE: To select menu items (2 through 9, +/-, or .), press the key corresponding to the desired item, and then press .

- Page 130 4200T CNC Programming and Operations Manual P/N 70000412F - Edit Help LINES ARCS RAD/CHAMFER MUT IPLE T HREADING CLEARING COMPENS AT ION DRILL/T AP GENERAL Feed/Rev. Feed/Min. Inc r. G70 G90 G0 G95 X0 Z0 F .006 T 0 Absolute X1.0 Z0.1 T 1...

- Page 131 4200T CNC Programming and Operations Manual P/N 70000412F - Edit Help Soft Keys Figure 7-2, Main Edit Help Menu Soft Keys Figure 7-3, Sample Help Template Menu All rights reserved. Subject to change without notice. 31-July-05...

-

Page 132: Edit Help Menu

4200T CNC Programming and Operations Manual P/N 70000412F - Edit Help Edit Help Menu Main Edit Help Menu (Figure 7-2) displays categories for which Help Menus are available. Refer to Table 7-2, Edit Help Menu Features for a description of Main Edit Help Menu features. - Page 133 4200T CNC Programming and Operations Manual P/N 70000412F - Edit Help Table 7-2, Edit Help Menu Features Feature Description Menu Item Number Use this number to select a menu item. Help Templates In the Edit Help Menu, help templates access template help menus.

- Page 134 4200T CNC Programming and Operations Manual P/N 70000412F - Edit Help Table 7-3, Edit Help G-Code Menu G-Code Label and Description Dwell. Programs a timed or infinite dwell. Exact Stop (Single Block). Non-modal exact stop check. Activates exact stop check for a single block.

- Page 135 4200T CNC Programming and Operations Manual P/N 70000412F - Edit Help Table 7-4, Edit Help M-Code Listing M-Code Function Program stop Optional program stop End of program Spindle ON FWD Spindle ON REV Spindle OFF Coolant ON Coolant OFF Jump to new program...

-

Page 136: Edit Help Soft Keys

4200T CNC Programming and Operations Manual P/N 70000412F - Edit Help Edit Help Soft Keys Refer to Table 7-5 for a list of the soft keys available in the Main Edit Help Menu. Table 7-5, Edit Help Soft Keys Soft Key Label Description Moves highlight to the next Help Template. -

Page 137: Help Template Menu

4200T CNC Programming and Operations Manual P/N 70000412F - Edit Help Help Template Menu Selecting a help template from the Edit Help Menu activates the Help Template Menu for the selected move type or Canned Cycle. (Refer to Figure 7-3, Sample Help Template Menu). - Page 138 4200T CNC Programming and Operations Manual P/N 70000412F - Edit Help Table 7-6, Help Template Menus (Continued) Template Description Reference Table DRILL/TAP Table 7-14, DRILL/TAP Help Template Menu (Drill and Tapping Cycles) The following features appear in each of the Help Template Menus:...

-

Page 139: Help Graphic Screens

4200T CNC Programming and Operations Manual P/N 70000412F - Edit Help Help Graphic Screens The Help Graphic screens list and give instructions on entering move types and Canned Cycles into the Program Listing. Refer to Figure 7-4. Help Graphics screens are available for templates... - Page 140 4200T CNC Programming and Operations Manual P/N 70000412F - Edit Help The following features are available in the Help Graphic screens: Menu Item Number Menu items 2 through 9 are inactive in the Help Graphic screen. A new selection can be made...

-

Page 141: Using Help Graphic Screens To Enter Program Blocks

4200T CNC Programming and Operations Manual P/N 70000412F - Edit Help Using Help Graphic Screens to Enter Program Blocks The Program Editor displays Help Graphic screens for writing and editing program blocks. When a Help Graphic screen is first displayed, the first entry field is highlighted. -

Page 142: Available Help Graphic Screens

4200T CNC Programming and Operations Manual P/N 70000412F - Edit Help Available Help Graphic Screens Help Graphic Screens are available for each of the templates shown and described in Table 7-7. The table shows the Edit Help Menu Templates and Template Menus. The input labels and entry fields are defined for each move type available in Edit Help. - Page 143 4200T CNC Programming and Operations Manual P/N 70000412F - Edit Help Table 7-8, LINES Help Template Menu LINES LINES Templates and Parameters Move Description CNC moves in a straight line along the Z-axis. Z End Pt.: Z endpoint CNC moves in a straight line along the X-axis.

- Page 144 4200T CNC Programming and Operations Manual P/N 70000412F - Edit Help Table 7-8, LINES Help Template Menu (Continued) LINES LINES Templates and Parameters Move Description CNC moves along a vectored path from ANGLE/RADIUS the current location to the endpoint. Angle: B, angle measured from the Z-axis (3 o’clock equals 0 degrees).

- Page 145 4200T CNC Programming and Operations Manual P/N 70000412F - Edit Help Table 7-9, ARCS Help Template Menu ARCS Templates and Parameters Move Description CNC moves along a radial path from the RADIUS/END current location to the programmed endpoint. X End Pt.: X endpoint Z End Pt.:...

- Page 146 4200T CNC Programming and Operations Manual P/N 70000412F - Edit Help Table 7-9, ARCS Help Template Menu (Continued) ARCS Templates and Parameters Move Description CNC moves along a radial path from the CENTER/X current location to the programmed endpoint. X Center Pt.: I, incremental centerpoint of the arc in X.

- Page 147 4200T CNC Programming and Operations Manual P/N 70000412F - Edit Help Table 7-9, ARCS Help Template Menu (Continued) ARCS Templates and Parameters Move Description CNC performs an arc move into another ARC/ARC arc move. The first arc ends and the second arc begins at the point where the two arcs are tangent.

- Page 148 4200T CNC Programming and Operations Manual P/N 70000412F - Edit Help Table 7-10, RAD/CHAMFER Help Template Menu RAD/CHAMFER RAD/CHAMFER Templates and Parameters Move Description The CNC performs a LINE move to the intersecting ARC, moves around the arc, RADIUS and then moves along the second LINE to the specified endpoints.

- Page 149 4200T CNC Programming and Operations Manual P/N 70000412F - Edit Help Table 7-10, RAD/CHAMFER Help Template Menu (Continued) RAD/CHAMFER RAD/CHAMFER Templates and Parameters Move Description The CNC performs an automatic corner CORNER CHAMF chamfer (where practical) at all intersecting elements (LINES, ARCS).

- Page 150 4200T CNC Programming and Operations Manual P/N 70000412F - Edit Help Table 7-11, MULTIPLE Help Template Menu MUTIPLE MULTIPLE Templates and Parameters Move Description The CNC performs a LINE move DEFINITION along the First Angle to the intersection of the Second Angle,...

- Page 151 4200T CNC Programming and Operations Manual P/N 70000412F - Edit Help Table 7-11, MULTIPLE Help Template Menu (Continued) MUTIPLE MULTIPLE Templates and Parameters Move Description The CNC performs a LINE move RAD/RAD along the 1st Angle to the intersecting arc. After completing...

- Page 152 4200T CNC Programming and Operations Manual P/N 70000412F - Edit Help Table 7-11, MULTIPLE Help Template Menu (Continued) MUTIPLE MULTIPLE Templates and Parameters Move Description The CNC performs a LINE move CHAMF/CHAMF along the 1st Angle to the intersecting chamfer. After...

- Page 153 4200T CNC Programming and Operations Manual P/N 70000412F - Edit Help Table 7-11, MULTIPLE Help Template Menu (Continued) MUTIPLE MULTIPLE Templates and Parameters Move Description The CNC performs a LINE move CHAMF/RAD along the 1st Angle to the intersecting chamfer. After...

- Page 154 4200T CNC Programming and Operations Manual P/N 70000412F - Edit Help Table 7-12, THREADING Help Template Menu THREADING THREADING Templates and Parameters Move Description The G83 cycle creates a longitudinal thread along the Z-axis using multiple UNI-DIRECT. passes to reach full thread depth. The...

- Page 155 4200T CNC Programming and Operations Manual P/N 70000412F - Edit Help TPI: E, Threads per inch. Used in Inch programming. Lead: F, pitch (single pass threading) or amount of travel in Z per revolution (multi-pass threading). Used in MM programming.

- Page 156 4200T CNC Programming and Operations Manual P/N 70000412F - Edit Help threading Canned Cycle. Num. Starts: W, used only in multiple pass threading, the number of staggered starts used to reach depth. Default: 1. NOTE: Specifying the Num. of Starts changes the way the CNC interprets all other threading variables.

- Page 157 4200T CNC Programming and Operations Manual P/N 70000412F - Edit Help angle (described by the A parameter), Num. Starts: W, used to program the number of and cuts only on the leading edge of the starts in a multiple start thread. Default: 1 (Single tool.

- Page 158 4200T CNC Programming and Operations Manual P/N 70000412F - Edit Help Table 7-12, THREADING Help Template Menu (Continued) THREADING THREADING Templates and Parameters Move Description The CNC feeds the tap from the initial TAPPING start position (R) into a pre-drilled hole along the Z-axis.

- Page 159 4200T CNC Programming and Operations Manual P/N 70000412F - Edit Help Table 7-13, CLEARING Help Template Menu CLEARING CLEARING Templates and Parameters Move Description The G73 Area Clearance Cycle rough turns a AREA CLR TURN work piece to a profile described in a subprogram.

- Page 160 4200T CNC Programming and Operations Manual P/N 70000412F - Edit Help Table 7-13, CLEARING Help Template Menu (Continued) CLEARING CLEARING Templates and Parameters Move Description The G74 Area Clearance Cycle rough faces a AREA CLR FACE work piece to a profile described in a subprogram.

- Page 161 4200T CNC Programming and Operations Manual P/N 70000412F - Edit Help Depth/Pass: C, maximum incremental will not exceed the maximum depth of cut (C). depth of cut per side for each pass. The rear angle of the tool (E) is checked...

- Page 162 4200T CNC Programming and Operations Manual P/N 70000412F - Edit Help Table 7-13, CLEARING Help Template Menu (Continued) CLEARING CLEARING Templates and Parameters Move Description The G81 cycle creates a groove along the Z- LON'L GROOVE axis using the length (Z), and depth (X) parameters.

- Page 163 4200T CNC Programming and Operations Manual P/N 70000412F - Edit Help Table 7-14, DRILL/TAP Help Template Menu DRILL/TAP DRILL/TAP Templates and Parameters s Move Description The Pecking cycle drills a hole using a PECKING pecking action. The depth of each peck...

- Page 164 4200T CNC Programming and Operations Manual P/N 70000412F - Edit Help Table 7-14, DRILL/TAP Help Template Menu (Continued) DRILL/TAP DRILL/TAP Templates and Parameters s Move Description The G88 Boring cycle removes stock material along the Z-axis in a series of BORING passes.

-

Page 165: Programming Modal G-Codes In Edit Help

4200T CNC Programming and Operations Manual P/N 70000412F - Edit Help Programming Modal G-Codes in Edit Help Certain G-Codes define the way the CNC will interpret commands entered by an operator. These G-Codes set the CNC to interpret measurement units as Inch or Metric, numerical values as Absolute or Incremental, set tool movement to feed or rapid rate, set spindle speed to feedrate per minute or per revolution of the spindle. -

Page 166: Programming Line Moves In Edit Help

4200T CNC Programming and Operations Manual P/N 70000412F - Edit Help Programming LINE Moves in Edit Help NOTE: Refer to Table 7-6, Help Template Menus. This table gives a list of all Help Graphic Templates, and the Table location for the corresponding Input Labels and Entry Fields. -

Page 167: Angle Direction For Front And Rear Tool Posts

4200T CNC Programming and Operations Manual P/N 70000412F - Edit Help Table 7-16, LINE Move Types LINE Move Types Defined By Vector − An XZ endpoint (menu item 4) OR − An angle measured from the Z-axis (3 o’clock position equal to 0 degrees), and... - Page 168 4200T CNC Programming and Operations Manual P/N 70000412F - Edit Help Rear Tool Post Positive Angle Rotation (CCW) 0 Degrees (3 o'clock position along the Z axis) Negative Angle Rotation (CW) TOOLPST2 Figure 7-7, Rear Tool Post Positive and Negative Directions...

-

Page 169: Using Angles To Program Moves

4200T CNC Programming and Operations Manual P/N 70000412F - Edit Help Using Angles to Program Moves Refer to Figure 7-9 . Angles can be used to program LINE Moves or lines used to define other types of moves. Figure 7-9, Using Angles to Program Moves Refer to Table 7-17 . -

Page 170: Programming Multiple Move Commands In Edit Help

4200T CNC Programming and Operations Manual P/N 70000412F - Edit Help Programming MULTIPLE Move Commands in Edit Help Refer to Figure 7-10 . The figure shows the MULTIPLE Help Template Menu, accessed through the Edit Help Menu. Figure 7-10, MULTIPLE Help Template Menu MULTIPLE moves allow the programmer to input more than one move on a single program block. -

Page 171: Introduction

4200T CNC Programming and Operations Manual P/N 70000412F - Draw Mode Section 8 - Draw Mode Introduction The CNC has two Draw Modes: Draw Simulation Mode Real Time DRAW Mode. NOTE: In this manual, Draw (with a capital D) refers to the CNC’s Draw Simulation Mode. -

Page 172: Starting Draw

4200T CNC Programming and Operations Manual P/N 70000412F - Draw Mode Starting Draw Start Draw Simulation Mode from the Program Directory. The Display (F5) and Parms (F9) settings determine how Draw looks and runs. You can use the soft keys to make some changes during a program simulation. -

Page 173: Putting Draw In Hold

4200T CNC Programming and Operations Manual P/N 70000412F - Draw Mode The Draw screen displays the following information to the left of the Draw window: Blk: Block Number currently being simulated. X Current Position. Z Current Position. Currently active feed rate. -

Page 174: Draw Parameters

4200T CNC Programming and Operations Manual P/N 70000412F - Draw Mode Draw Parameters Refer to Figure 8-2. Figure 8-2, Draw Parameters Pop-up Menu Draw shows the following features during simulation: Feature Displayed as Rapid moves Dotted Lines - when turned on... -

Page 175: Drawing Compensated Moves

4200T CNC Programming and Operations Manual P/N 70000412F - Draw Mode Drawing Compensated Moves The ToolComp setting determines if and how Draw displays compensated moves. This lets you see the effects of compensation on the moves in a program. The Draw ToolComp setting does not affect program execution to cut a part. -

Page 176: Setting Grid Size

4200T CNC Programming and Operations Manual P/N 70000412F - Draw Mode Setting Grid Size You can adjust the grid size. The units are determined by the CNC’s current mode. [Default: 1.00] To set the Grid size: 1. With the Draw Mode active, press Parms (F9). Parameter Pop-Up Menu activates. -

Page 177: Automatic Draw Restart

4200T CNC Programming and Operations Manual P/N 70000412F - Draw Mode Automatic Draw Restart The Run parameter determines whether Draw automatically restarts after a DISPLAY setting change. This enables you to make more than one setting change before restarting Draw. -

Page 178: Starting Draw At A Specific Block

4200T CNC Programming and Operations Manual P/N 70000412F - Draw Mode Starting Draw at a Specific Block 1. With the Draw Mode active, press Parms (F9). Parameter Pop-Up Menu activates. 2. Highlight Start N#, and press . Start N# Pop-Up Menu ENTER activates. -

Page 179: Fitting The Display To The Viewing Window

4200T CNC Programming and Operations Manual P/N 70000412F - Draw Mode Fitting the Display to the Viewing Window Draw can automatically scale the display to fit in the viewing area. To fit the display to the viewing area: 1. In Draw Mode, press Display (F5). A pop-up activates. -

Page 180: Using The Window Zoom

4200T CNC Programming and Operations Manual P/N 70000412F - Draw Mode Using the Window Zoom Refer to Figure 8-4. Figure 8-4, Display Window (Zoom) Draw lets you zoom in on any portion of the display. To zoom in on a portion of the display: 1. -

Page 181: Changing The Viewing Area Without Changing The Scale

4200T CNC Programming and Operations Manual P/N 70000412F - Draw Mode Changing the Viewing Area without Changing the Scale Refer to Figure 8-5. Figure 8-5, Display Pan To shift a portion of the screen in a desired direction without changing the scale factor, use the Draw Pan command. -

Page 182: Activating The Tool Page

4200T CNC Programming and Operations Manual P/N 70000412F - Tool Page and Tool Management Section 9 - Tool Page and Tool Management This section discusses entering information into the Tool Page, including Tool Nose Radius compensations (G40, G41 and G42) and Tool-Length Offsets for X and Z. - Page 183 4200T CNC Programming and Operations Manual P/N 70000412F - Tool Page and Tool Management Tool Number Column Position Display Tool Offset Information (entered by user) Active Row Display Softkey Labels Soft Key Labels Figure 9-1, Tool Page All of the CNC’s Jog features can be run from the Tool Page. The handwheels (if present) can also be used.

-

Page 184: Entering Values In The Tool Page

4200T CNC Programming and Operations Manual P/N 70000412F - Tool Page and Tool Management Entering Values in the Tool Page The row numbers shown on the Tool Page correspond to Tool Numbers. When the CNC executes a program block that activates a tool number, the values entered on that row of the Tool Page are also activated. -

Page 185: Clearing Tool Information (Delete Row)

4200T CNC Programming and Operations Manual P/N 70000412F - Tool Page and Tool Management Clearing Tool Information (Delete Row) To clear a row: 1. Go to the Tool Page and position the cursor at the row being cleared. 2. Press ClrLine (F3). All values in the row return to zero. -

Page 186: Setting Tool-Length Offsets

4200T CNC Programming and Operations Manual P/N 70000412F - Tool Page and Tool Management Figure 9-2, Tool-Length Offsets Refer to Table 9-1. The T code used to activate a tool number consists of the Word Address T and the corresponding tool number. T codes can be programmed alone on a block or with axis commands, M-codes and other data. -

Page 187: Entering Tool Page Tlo's Using The Calibration Function

4200T CNC Programming and Operations Manual P/N 70000412F - Tool Page and Tool Management NOTE: If desired, a skim cut can be made prior to determining the Tool- Length Offset. In Z, the skim cut is a shallow face cut to ensure an even work surface. -

Page 188: Tool Offset Modification

4200T CNC Programming and Operations Manual P/N 70000412F - Tool Page and Tool Management Tool Offset Modification Refer to Table 9-2 and Table 9-3. Table 9-2, Tool Offset Address Words Address Word Description X offset X wear offset Z offset... -

Page 189: Activating A Tool Number In The Manual Mode

4200T CNC Programming and Operations Manual P/N 70000412F - Tool Page and Tool Management Activating a Tool Number in the Manual Mode NOTE: Make sure the correct offsets have been entered in the Tool Page before manually activating a tool. - Page 190 4200T CNC Programming and Operations Manual P/N 70000412F - Tool Page and Tool Management Figure 9-3, Tool Nose Radius When tool compensation is not active, the CNC positions the tool’s Theoretical Cutting Point on the programmed path. This creates a problem when programming a contoured part because Tool Nose Radius will introduce an error on angular and arc moves.

- Page 191 4200T CNC Programming and Operations Manual P/N 70000412F - Tool Page and Tool Management Figure 9-4, Left of Path Compensation (G41) Refer to Figure 9-4. When left hand tool compensation is activated, the tool offsets to the left of the programmed path (looking from behind the tool as it moves).

-

Page 192: Selecting A Tool Location Code

4200T CNC Programming and Operations Manual P/N 70000412F - Tool Page and Tool Management Selecting a Tool Location Code 0) Button Tool 1) Back Bore 2) Bore 3) Turn 4) Back Turn 5) Back Face 6) Plunge Bore 7) Plunge Face... -

Page 193: Tool Nose Radius Programming Examples

4200T CNC Programming and Operations Manual P/N 70000412F - Tool Page and Tool Management Tool Nose Radius Programming Examples Refer to Table 9-5. G40 or G41/G42 commands must be accompanied by a motion statement within the same block. The motion must be in rapid or feed (G0 or G1). -

Page 194: Left Of Path Tnr Program (G41)

4200T CNC Programming and Operations Manual P/N 70000412F - Tool Page and Tool Management Left of Path TNR Program (G41) Refer to Figure 9-7. The diagram shows a part design for an O.D. turning tool. It uses Absolute measurements and shows Inch and MM equivalents. - Page 195 4200T CNC Programming and Operations Manual P/N 70000412F - Tool Page and Tool Management Refer to Table 9-6. The table lists and describes the program required to program the part in the diagram. Diameter Mode is used. Table 9-6, G41 Programming Example...

-

Page 196: Right Of Path Tnr Program (G42)

4200T CNC Programming and Operations Manual P/N 70000412F - Tool Page and Tool Management Right of Path TNR Program (G42) Refer to Figure 9-8. The diagram shows a part design for a boring tool (inner diameter), using Absolute measurements and showing Inch and MM equivalents. - Page 197 4200T CNC Programming and Operations Manual P/N 70000412F - Tool Page and Tool Management Refer to Table 9-7. The table lists and describes the program required to machine the part in the diagram. Diameter mode is used. Table 9-7, G42 Programming Example...

-

Page 198: Canceling Tool Nose Radius Compensation (G40)

4200T CNC Programming and Operations Manual P/N 70000412F - Tool Page and Tool Management Canceling Tool Nose Radius Compensation (G40) NOTE: The G40 code must be programmed with a linear feed code (G00 or G01) currently active or indicated in the G40 program block. -

Page 199: Choosing The Correct Tnr Compensation

4200T CNC Programming and Operations Manual P/N 70000412F - Tool Page and Tool Management Choosing the Correct TNR Compensation Refer to Figure 9-9. There is only one question a programmer needs to ask to determine which Tool Nose Radius Compensation to use. Looking from... - Page 200 4200T CNC Programming and Operations Manual P/N 70000412F - Tool Page and Tool Management Figure 9-10, Changing Compensation Refer to Figure 9-10 and Table 9-9. In this example, the tool makes an O.D. cut toward the chuck with G41 active and clears the part (X+). Then, the tool contacts the part O.D.

-

Page 201: Motion Of Tool During Tnr Compensation

4200T CNC Programming and Operations Manual P/N 70000412F - Tool Page and Tool Management Motion of Tool during TNR Compensation (1) At start-up of compensation Refer to Figure 9-11. In linear to linear, or linear to circular moves, the position at the end of the start-up block (block with G41 or G42) will be perpendicular to the next programmed move in the axis. -

Page 202: Compensation Around Acute Angles

4200T CNC Programming and Operations Manual P/N 70000412F - Tool Page and Tool Management Compensation around Acute Angles During compensated moves around sharp angles, the CNC “rounds off” the intersection of the two moves to prevent wasted movement. The CNC will do this for any angles less than or equal to the Compensation Cutoff Angle. -

Page 203: Changing The Numbers Of Look Ahead Blocks

4200T CNC Programming and Operations Manual P/N 70000412F - Tool Page and Tool Management Diagram B shows the tool path resulting when a Compensation Cutoff angle is used. The CNC introduces a 0 degree radius arc move between programmed moves 1 and 2. This alters the tool path, eliminating wasted motion. -

Page 204: Setting Wear Offset Adjustment While Running A Program

4200T CNC Programming and Operations Manual P/N 70000412F - Tool Page and Tool Management Setting Wear Offset Adjustment While Running a Program Wear offset adjustment is used to increment or decrement an X or Z tool offset for adjustment purposes. This can only be used when you are in single-step or auto mode (program run). -

Page 205: Changing The Program Directory's Display

4200T CNC Programming and Operations Manual P/N 70000412F - Program Management Section 10 - Program Management The Program Directory provides access to all of the program management and disk utilities. These functions include creating, loading, deleting, undeleting, and copying programs. The Program Directory also provides access to the floppy disk drives and the communications utilities. -

Page 206: Creating A New Part Program

4200T CNC Programming and Operations Manual P/N 70000412F - Program Management To switch the Program Directory display mode, press Display (SHIFT + F9). The display setting showing only part program names is usually the easiest to use. Press (SHIFT + F9) to cycle through the four program display modes. -

Page 207: Selecting A Program For Editing And Utilities

4200T CNC Programming and Operations Manual P/N 70000412F - Program Management Selecting a Program for Editing and Utilities When you press Edit (F8), the highlighted program opens for editing. NOTE: If you activate the Program Editor while running a program, the editor will open the loaded program. -

Page 208: Logging To Other Drives

4200T CNC Programming and Operations Manual P/N 70000412F - Program Management Logging to Other Drives The Program Directory displays the programs in the C:\USER directory by default, but it can be set to show programs stored in other drives or subdirectories. -

Page 209: Marking And Unmarking Programs

4200T CNC Programming and Operations Manual P/N 70000412F - Program Management Marking and Unmarking Programs Some operations can be performed on more than one program at a time. The Program Directory allows you to select (Mark) one, some or all of the programs in the USER listing. -

Page 210: Deleting Groups Of Programs

4200T CNC Programming and Operations Manual P/N 70000412F - Program Management Deleting Groups of Programs 1. From the Program Directory, mark all programs to be deleted. 2. Press Delete (F3). The CNC prompts you to confirm the deletion and the soft keys change. -

Page 211: Renaming Programs

4200T CNC Programming and Operations Manual P/N 70000412F - Program Management Renaming Programs To rename a program: 1. From the Program Directory, highlight a program. 2. Press Utility (F9). The Utility Pop-Up Menu activates. 3. Highlight Rename, and press . The CNC prompts, “Rename ENTER [PROGRAM] to ?:”... -

Page 212: Formatting Floppy Disks

4200T CNC Programming and Operations Manual P/N 70000412F - Program Management Formatting Floppy Disks Before programs can be copied to a floppy disk, the disk must be formatted. Most disks come pre-formatted. The CNC can format a disk when necessary. -

Page 213: Displaying System Information

4200T CNC Programming and Operations Manual P/N 70000412F - Program Management Displaying System Information Refer to Figure 10-2. The System Information screen displays specific details about the CNC and software package. Most of the information on this screen is only required when the machine is setup or when troubleshooting a problem. -

Page 214: Copying Programs From/To Unspecified Locations

4200T CNC Programming and Operations Manual P/N 70000412F - Program Management Copying Programs from/to Unspecified Locations To copy programs to or from an unspecified location: 1. From the Program Directory, press Utility (F9). The Utility Pop-Up activates. 2. Highlight More, and press . -

Page 215: Printing Programs From Unspecified Locations

4200T CNC Programming and Operations Manual P/N 70000412F - Program Management Printing Programs from Unspecified Locations The CNC can print to any standard IBM PC compatible printer. To print programs from unspecified locations: 1. From the Program Directory, press Utility (F9). The Utility Pop-Up activates. -

Page 216: Deleting An Unspecified Program

4200T CNC Programming and Operations Manual P/N 70000412F - Program Management Deleting an Unspecified Program Use the Del ? (SHIFT + F3) soft key to delete an unspecified program. It enables the user to delete programs in another drive without logging into that drive. -

Page 217: Optimizing Your Hard Disk

To minimize fragmentation, you must optimize your hard disk periodically. Your CNC has a built-in disk optimizer. ANILAM recommends that you optimize your hard disk bi- monthly, or at the very least, once every six months. -

Page 218: Maximizing Program Storage Space

4200T CNC Programming and Operations Manual P/N 70000412F - Program Management Maximizing Program Storage Space The CNC has a fixed amount of space available for programs. Check the space available with the System Information feature. Refer to Figure 10-2, System Information Screen. -

Page 219: Running A Program One Step At A Time

4200T CNC Programming and Operations Manual P/N 70000412F - Running Programs Section 11 - Running Programs NOTE: All programs should be verified in Draw prior to running them. Refer to “Section 8 - Draw Mode.” There are three modes of programmed operation. -

Page 220: Toggling Between Motion And Single-Step Mode

4200T CNC Programming and Operations Manual P/N 70000412F - Running Programs Program Area essage Line Position Displays Machine Status Display Area Active Active Soft Key Softkey (Highlighted) (Highlights) Figure 11-1, Single-Step/Motion Screen To run a program in Single-Step Mode, do the following: 1. -

Page 221: Single-Step Execution Of Selected Program Blocks

4200T CNC Programming and Operations Manual P/N 70000412F - Running Programs Single-Step Execution of Selected Program Blocks Using Arrow Keys to Select Starting Block Select the starting block before starting the program: 1. Load the desired program and return to the Manual screen. -

Page 222: Position Display

4200T CNC Programming and Operations Manual P/N 70000412F - Running Programs Position Display The Position Displays for X and Z show: Machine Movement to the programmed (commanded) position in reference to Machine Home. Program Movement to the programmed (commanded) position in reference to Part Zero. -

Page 223: Holding Or Canceling An Auto Run

4200T CNC Programming and Operations Manual P/N 70000412F - Running Programs Holding or Canceling an Auto Run Press to hold program execution. To restart a program that is on HOLD hold, press . To cancel a program that is on hold, press Manual START (F4). -

Page 224: Using Draw While Running Programs

4200T CNC Programming and Operations Manual P/N 70000412F - Running Programs Using Draw while Running Programs In Real Time Draw, the CNC displays moves as it executes them. S.Step (F5) or Auto (F6) and the Draw (F10) soft key will be highlighted. -

Page 225: Teach Mode

4200T CNC Programming and Operations Manual P/N 70000412F - Running Programs To switch the display between the Large Position Display and the default position displays in S.Step or Auto Mode, press B. Teach Mode Use Teach Mode to input data into a program from Manual Mode. Axes positions, modal status and MDI commands can be input directly into the program. -

Page 226: Canceling Teach Mode

4200T CNC Programming and Operations Manual P/N 70000412F - Running Programs 1. If no command or axis data is typed onto the command line and is pressed, the CNC will store all axes positions with a G90 START code. 2. If no axis data, only command data is typed onto the command line... -

Page 227: Parts Counter And Program Timer

4200T CNC Programming and Operations Manual P/N 70000412F - Running Programs Parts Counter and Program Timer The CNC keeps track of program run-time (TIMER) and the number of completed parts (PARTS). The CNC displays Run-time in hours, minutes, and seconds. These two features are available in the Manual, Auto, and S.Step Modes. -

Page 228: Background Mode

4200T CNC Programming and Operations Manual P/N 70000412F - Running Programs Table 11-2, M-Codes Used with Parts Counter and Program Timer M-Code Function M9355 X0 Prevents the parts counter from resetting to zero. M9356 X0 Disables the Timer and Counter. -

Page 229: Introduction

4200T CNC Programming and Operations Manual P/N 70000412F - S Function, M Functions, and C Axis Programming Section 12 - S Function, M Functions, and C-Axis Programming Introduction This section provides S and M code formats. Refer to Table 12-1. The codes are included in the part program or activated in Manual Mode. -

Page 230: Miscellaneous Functions (M-Codes)

4200T CNC Programming and Operations Manual P/N 70000412F - S Function, M Functions, and C Axis Programming Miscellaneous Functions (M-Codes) Refer to Table 12-3. Miscellaneous codes control a variety of machine tool functions. The machine builder assigns them. Be familiar with the M- codes available on your machine-control combination. -

Page 231: Order Of Execution

4200T CNC Programming and Operations Manual P/N 70000412F - S Function, M Functions, and C Axis Programming Table 12-4, Control M-Codes (Continued) M-Code Function M100 Mirror image. M100 programmed with axis (M100 X) activates “mirror image” (ON) for that axis. Mirror image reverses the sign (+/-) of subsequent numbers. -

Page 232: C-Axis Jog

4200T CNC Programming and Operations Manual P/N 70000412F - S Function, M Functions, and C Axis Programming C-Axis Jog The Manual Panel can be used to jog the C-Axis to position. To set the Manual Panel for jogging the C-Axis, set the Axis Selector to C and use the Jog+ and Jog- keys as needed. -

Page 233: Activating The Sci Mode