Summary of Contents for Top Air TA1200

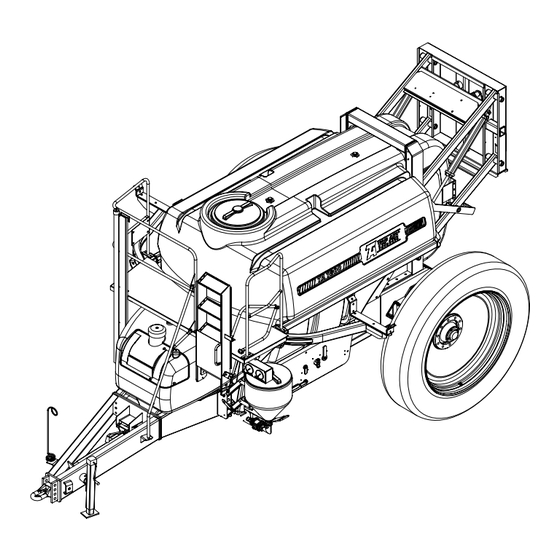

- Page 1 TA1200/1600 OPERATOR'S MANUAL PARTS LIST 401962 T-TANK SPRAYER 1200 & 1600 GALLON 1200 SPRAYER - 60'/80'/90' BOOMS 1600 SPRAYER - 80'/90'/110'/120'/132' BOOMS 402061...

-

Page 2: Table Of Contents

Introduction TABLE OF CONTENTS SECTION I - SAFETY Load Sensing Closed-Center System ..3-6 AXLE ADJUSTMENT GENERAL HAZARD INFORMATION .... 1-2 Wheel Spacing Combinations ....3-7 SAFETY DECALS ........1-3 Adjustment Procedure ......3-8 GENERAL SAFETY INFORMATION .... 1-4 WING ADJUSTMENTS CHEMICAL HAZARDS ........ -

Page 3: Introduction

NOTE: The information, specifications, and illustrations in the manual are on the basis of information available at the time it was written. Due to continuing improvements in the design and manufacture of Alliance/Top Air products, all specifications and information contained herein are subject to change without notice. - Page 4 Introduction NOTES...

- Page 5 Safety SECTION I SAFETY GENERAL HAZARD INFORMATION ....1-2 SAFETY DECALS ..........1-3 GENERAL SAFETY INFORMATION ....1-4 CHEMICAL HAZARDS ........1-4 SERVICE PLATFORM ........1-5 ELECTRICAL SAFETY ........1-5 CLEAN WATER TANK ........1-5 BEFORE OPERATING OR SERVICING ..1-6 DURING OPERATION ........

-

Page 6: General Hazard Information

Safety GENERAL HAZARD INFORMATION Most accidents involving product operation, maintenance and repair are caused by failure to observe basic safety rules or precautions. An accident can often be avoided by recognizing potentially hazardous situations before an accident occurs. A person must be alert to poten- tial hazards. -

Page 7: Safety Decals

Safety SAFETY DECALS •401956 IMPORTANT Replace lost, damaged, painted, or unreadable decals immediately. If parts that have decals are replaced, also make sure to install new decals. These decals inform and remind the operator with operational information and safety messages. •Revised 011405... -

Page 8: General Safety Information

Safety GENERAL SAFETY CHEMICAL HAZARDS INFORMATION • Always wear personal protective equipment when working with or near • Do not allow children to play on or chemicals. This equipment includes, near, and prevent inexperienced or but is not limited to: protective unauthorized persons from operating eyewear, gloves, shoes, socks, long- this equipment. -

Page 9: Service Platform

Safety • Always disconnect power before SERVICE PLATFORM attempting any electrical repair. • Mount and dismount the sprayer only • Disassembly or attempted repairs, if where steps and/or handholds are accomplished incorrectly, can create provided. electrical shock and/or short hazards. Only qualified personnel should •... -

Page 10: Before Operating Or Servicing

Safety DURING OPERATION BEFORE OPERATING OR SERVICING • Do not allow anyone to ride on the equipment. Never dismount from a • Secure drawbar pin with a locking moving tractor. Severe injury or death device and lock tractor drawbar in can occur from being run over by the centered position. -

Page 11: Before Transporting

Safety BEFORE DURING TRANSPORT TRANSPORTING • Use good judgment when transporting • This sprayer is not equipped with equipment on highways. Regulate brakes. Ensure that the towing vehicle speed to road conditions and has adequate weight and braking maintain complete control. capacity to tow this implement. -

Page 12: Pressurized Oil

Safety PRESSURIZED OIL • Repair all oil leaks. Leaks can cause • Always use a board or cardboard fires, personal injury, and when checking for a pressurized oil environmental damage. leak. Escaping fluid under pressure, even a pinhole-sized leak, can •... - Page 13 Operation SECTION II OPERATION PREPARING TRACTOR .......... 2-2 PREPARING SPRAYER Inspection ............2-2 Lubrication ............2-2 HITCHING TO TRACTOR Drawbar Connection ........... 2-3 Transport Chain Connection ....... 2-4 Hydraulic Connections ........2-4 Electrical Connections ........2-6 TRANSPORTING............2-7 BOOM OPERATION ..........2-8 Unfolding Boom ..........

-

Page 14: Preparing Tractor

Operation PREPARING SPRAYER PREPARING TRACTOR • Inspection Before operating sprayer, read the tractor operator’s manual and gain an Perform the service checks as outlined understanding of its safe methods of below. Repair or replace any damaged operation. or worn parts before operating. Check the tractor brakes and warning Boom Rest Set-up: Refer to page 4-2 lights. -

Page 15: Section Ii - Operation

Operation Verify and/or adjust the sprayer hitch HITCHING TO TRACTOR height before coupling to the tractor. The • Drawbar Connection sprayer hitch is adjusted by unbolting the hitch and reinstalling in a different set of holes provided. NOTE: The sprayer must be relatively level in order for the tank volume indicator to read accurately. -

Page 16: Transport Chain Connection

Operation • Transport Chain Connection • Hydraulic Connections (Drawbar Style Hitch Only) After cleaning hydraulic hose couplers, connect to tractor hydraulic circuits as follows: Sprayer Pump Hydraulics 401930 Tractor must be equipped with a transport chain support. Attach chain in manner illustrated. - Page 17 Operation To protect the sprayer pump from Place the tractor SCV control lever in the damage due to excessive speed, adjust EXTEND position to energize the circuit flow to minimum setting prior to hydraulic circuit. When the circuit is operating circuit for the first time. When energized, oil will circulate constantly in operation, adjust flow per instructions through the sprayer hydraulic valve.

-

Page 18: Electrical Connections

Shut off engine receptacle, an SAE J-S60A 7-pin socket and apply parking brake before can be purchased from your Top Air disconnecting hoses. dealer (Part number 92824). NOTE: Accumulators used in this hy-... -

Page 19: Transporting

Operation Use good judgment when transporting TRANSPORTING equipment on highways. Regulate speed to road conditions and maintain complete control. It is probable that this implement is taller, wider and longer than the towing tractor. Become aware of and avoid all obstacles and hazards in the travel path of the equipment, such as power lines, ditches, etc. -

Page 20: Boom Operation Unfolding Boom

Operation BOOM OPERATION 2. Press and hold MAIN BOOM switch in <RAISE> position until boom is • Unfolding Boom fully raised. This ensures that the transport latch is not supporting the weight of the boom. 3. Press and hold RH WING TILT and LH WING TILT switches in <UP>... -

Page 21: Folding Boom

Operation • Folding Boom 2. Press and hold OUTER WING switch in <RETRACT> position until outer wings are fully retracted. 3. Press and hold MAIN BOOM switch in <RAISE> position until boom is fully raised. 4. Press and hold RH WING TILT and LH WING TILT switches in <UP>... -

Page 22: Filling Sprayer Quick Fill

Operation • Tank Mixing FILLING SPRAYER • Quick Fill Spray chemicals can be added to the solution tank by either pouring directly into the top tank access hatch, or through the use of an optional inductor (described elsewhere in this section). Before adding chemicals, ensure that the tank contains at least 50 gallons of water. -

Page 23: Basic Sprayer Operation Initial Settings

Operation approximately 15 psi. (Rotate gauge BASIC SPRAYER cluster to side of sprayer for convenient OPERATION viewing.) • Initial settings 5. Next, slowly open FILTER PURGE CONTROL valve until the pressure drops approximately an additional 5 psi. NOTE: These are initial settings, and further adjustment may be needed to suit individual agitation and boom pressure 401968... -

Page 24: Spray Tank Rinsing Rinsing - Complete System

Operation 3. Dispense rinse water through boom SPRAY TANK RINSING by running pump with the following • Rinsing - Complete System settings, stopping pump when solution tank is empty: 401968 401968 Valve Settings 1. Run pump for approximately 30 PUMP INLET SELECTOR <SOLUTION TANK>... -

Page 25: Electric Command Center (Option)

Operation • ELECTRIC COMMAND Pump Inlet/Outlet controls CENTER (Opt. Equipment) Pump Inlet and Pump Outlet control switches are “circuit selectors” and do COMMAND CENTER not modulate flow like the Agitation and Filter Purge switches. Although their function is nearly identical to the manual valves of the standard Command Center, it should be noted that there is no <OFF>... -

Page 26: Chemical Inductor (Option)

Operation CHEMICAL INDUCTOR (Opt. 6. Close INDUCTOR DRAIN valve when tank is completely empty. equipment) • 7. Close INDUCTOR FLOW valve then Basic Operation set AGITATION CONTROL and FILTER PURGE CONTROL to proper settings. 8. Close Lid. 9. Raise tank to storage position. 401967 NOTE: Solution tank should contain at least 50 gallons of liquid. -

Page 27: Chemical Container And Inductor Tank Rinsing

Operation • 4. To rinse inductor tank, close lid, open Chemical Container and INDUCTOR MIX valve and squeeze Inductor Tank Rinsing rinse wand handle for approximately 10 seconds. 5. Close INDUCTOR MIX valve and release rinse wand when rinsing is complete. -

Page 28: Foam Marker (Option)

Operation • FOAM MARKER (Optional Basic Operation Equipment) FOAM MARKER CONTROL LEFT RIGHT FOAM FOAM FREQUENCY MIXTURE 401969 Before starting spray operation, test foam output to ensure that foam density and delivery rate are acceptable. (Additional 401969 information on troubleshooting foam The optional foam marker for this sprayer output can be found in the automatically mixes foam concentrate... - Page 29 Maintenance SECTION III MAINTENANCE LUBRICATION ..............3-2 SPRAYER PUMP SET-UP Load Sensing Closed-Center System .......3-3 Pressure-Compensating Closed-Center System ..3-4 Open-Center System ..........3-4 Sprayer Pump Specifications........3-5 HYDRAULIC MANIFOLD SET-UP Open-Center System ..........3-6 Load Sensing Closed-Center System .......3-6 AXLE ADJUSTMENT Wheel Spacing Combinations ........3-7 Adjustment Procedure ..........3-8 WING ADJUSTMENTS Inner Wing Adjustments ..........3-9...

-

Page 30: Lubrication

Maintenance LUBRICATION Lubricate the sprayer as shown below. 8 HOURS EP-2 8 HOURS EP-2 8 HOURS EP-2 8 HOURS EP-2 401961 •Revised 011405... -

Page 31: Sprayer Pump Setup

Maintenance SPRAYER PUMP SETUP reverts to an energy-conserving low pressure and volume output when no hydraulic flow is being requested. NOTE: The information in this section pertains explicitly to the Ace brand hydrau- 1. Install flow limiter in motor inlet. This lic driven spray pumps. -

Page 32: Pressure-Compensating Closed-Center System

Maintenance • Pressure Compensating NOTE: If sufficient pressure cannot be reached, it may be necessary to enlarge Closed-Center System the restrictor orifice. To do so, remove orifice and drill hole to a slightly larger size. Do not run the pump without a restrictor installed. -

Page 33: Sprayer Pump Specifications

Maintenance 3. Connect hydraulic hoses to tractor as described in the OPERATION SECTION of this manual. 4. Start tractor and set engine speed to the RPM that will be used while spraying. 5. Move hydraulic lever to RETRACT to start pump. 6. -

Page 34: Hydraulic Manifold Set-Up

Maintenance HYDRAULIC MANIFOLD 6. Unscrew pressure hose from “P” port on manifold. Install 0.062” inlet SET-UP restrictor and reattach hose. 7. Unscrew fittings from LS port on manifold. 8. Using a hex wrench, install orifice plug in bottom of LS port cavity. Reinstall fittings on LS port. -

Page 35: Axle Adjustment

Maintenance • Wheel Spacing Combinations AXLE ADJUSTMENT WARNING: Use exceptional care when operating sprayer equipped with single tires and set at narrow wheel spacing. The possibility of tipping over during turns or travel on rough roads is increased under these conditions. The axle spacing is infinitely adjustable between minimum and maximum settings. -

Page 36: Adjustment Procedure

Maintenance • Adjustment Procedure WARNING: Improper axle adjustment can cause axle to 1. Hitch sprayer to tractor to help separate from sprayer, resulting in an stabilize unit. accident and personal injury. Check fastener torques after first hour of use 2. Raise sprayer and place on stands. and weekly thereafter. -

Page 37: Wing Adjustments

Maintenance WING ADJUSTMENTS c. Rotate gull wing link tube until bumper on inner wing contacts Several areas of adjustment have been intermediate wing. Continue to designed into the booms to maintain rotate tube as necessary to align proper wing folding operation throughout holes at flange joint. - Page 38 Maintenance Main Wing Fold Cylinder until wing is aligned with wing rest. b. To pull wing further away from tank, (80’/90’ booms only prior to S/N loosen inner jam nut, (furthest from B21100200) cylinder) 1/2 turn on cylinder adjustment bolt, followed by tightening outer jam nut.

- Page 39 Maintenance 5. Fully retract main wings, then lower Gull Wing Link onto wing rests. If either intermediate (80’/90’ booms only) wing does not fold completely, extend main wings and shorten the gull wing link on that side a half turn at a time until wing latches will no longer engage when the wings are extended.

-

Page 40: Outer Wing Level Adjustment

Maintenance Intermediate Wing Adjustment Use the following procedure to adjust the alignment of the boom with the wing rests. (110’/120’/132’ booms Only) Latch Plate Latch Pin 1. Begin with the wings in the unfolded position. 2. Retract outer wings and extend tilt cylinders to fully tilt wings upward. -

Page 41: Wing Tilt Indicator Adjustment

Maintenance To adjust levelness of outer wing, add or Wing Tip Breakaway remove washers behind rubber bumper. Mechanism An additional area of level adjustment can be obtained by loosening the bolts securing the ramp casting on the breakaway mechanism, and sliding the casting along its mounting slots. -

Page 42: Twin Link Suspension Adjustment

Maintenance Boom Twin Link Suspension NOTE: Lift and properly support either end of boom as necessary to create Adjustment clearance between stop plate and boom 80’/90’ booms before S/N B21100200 support plate before unbolting stop plates and adjusting shims. 5. Lift and properly support one end of boom 6"-14"... -

Page 43: Filters

Maintenance FILTERS action in the tank will break down most of this material and allow it to become dissolved. However, some foreign This sprayer uses three filters to help material will not break down, such as ensure proper spraying operation. rocks, paper labels, etc., and eventually These filters will need to be cleaned the filter will need to be removed for... -

Page 44: Foam Marker System Filter Maintenance

Maintenance • FOAM MARKER SYSTEM Power Box Plumbing Schematic • Filter Maintenance Air Filters Clean the primary filter pad, (located behind the louvered openings on the power unit box) after every 100 hours of use. To clean filter, remove from power unit box and wash in warm soapy water or blow dust free with compressed air. -

Page 45: Winterizing Sprayer

Maintenance 4. Add approximately ½ pint of RV WINTERIZING SPRAYER antifreeze solution to concentrate tank. Before storing the sprayer in freezing climates, perform the following 5. Disconnect liquid line at rinse tank. winterizing procedure. 6. Attach hose to a suitable temporary 1. -

Page 46: Troubleshooting

TROUBLESHOOTING Use this section to assist with troubleshooting problems. The most common solutions for each problem are listed. Contact your Top Air dealer if additional assistance is needed. WARNING: Residual pressure may exist in sprayer plumbing even when unit is not in use. - Page 47 Maintenance 3. Excessive agitation flow. Reduce flow by rotating agitation valve lever closer to <OFF> setting. 4. Excessive filter purge flow. Reduce flow by rotating filter purge valve lever closer to <OFF> setting. Boom will not lower from transport 1. Transport latch not disengaged. If height excessive weight is on transport latch, the latch may not disengage.

-

Page 49: Schematics

Maintenance • Hydraulic ORIFICE LATCH 0.062 ACTUATOR LH TILT RH TILT CYLINDER CYLINDER LH INNER WING RH INNER WING CYLINDER CYLINDER 1.4 L ACCUMULATOR 400 PSI PRECHARGE MAIN BOOM LIFT ORIFICE CYLINDER 0.030 LH OUTER WING RH OUTER WING CYLINDER CYLINDER ORIFICE ORIFICE... -

Page 51: Electrical

Maintenance • Electrical Serial #B20630210 & Lower 401963 •Revised 011405 3-23... - Page 52 Maintenance • Electrical Beginning Serial #B20630210 401963 •Revised 011405 3-24...

-

Page 53: Sprayer Calibration

Maintenance SPRAYER CALIBRATION Density Weight of Specific Conversion Solution Gravity Factor (DCF) Use the following procedure to assist 7.0 lb/gal. 0.84 0.92 with spray nozzle sizing and calibrating 8.0 lb/gal. 0.96 0.98 the sprayer. Additional information can 8.34 lb/gal. 1.00 1.00 (Water) be found in the spray controller owner’s... -

Page 54: Verify Nozzle Flow

Maintenance • Verify nozzle flow The following procedure should be repeated periodically to verify the flow rate of the spray nozzles. 1. Install a new tip on a nozzle body near center of sprayer boom. 2. Turn on sprayer and set flow such that tip pressure is within the nozzles’... -

Page 55: Section Iv - Set-Up

Set-Up SECTION IV SET-UP BOOM REST INITIAL SET-UP ........ 4-2... - Page 56 Set-Up 110'/120'/132' Boom Rest Initial Set-up Fig. 1 To minimize shipping height from the factory, the wing rests are installed in the lowest position as shown in Fig. 1. Use the following procedure to reposi- tion the wing rests prior to first use. 1.

-

Page 57: Section V - Parts

Parts SECTION V PARTS PAGE FRAME, TONGUE, HITCH ...... 5-2 AXLE MOUNTING ........5-4 AXLE ASSEMBLY ........5-5 HUB & SPINDLE ........5-6 WHEELS & TIRES ........5-8 MAST .............5-10 LIFT ASSEMBLY, H-FRAME....5-11 FRAME ATTACHMENTS ......5-12 PLATFORM, RAILINGS ......5-14 LADDER, RAILING ........5-16 GAUGE PANEL ........5-17 MAIN TANK..........5-18 RINSE TANK..........5-20... -

Page 58: Frame, Tongue, Hitch

Parts FRAME, TONGUE, HITCH PAINT GALLON SPRAY Black 9000913 9000533 Green 9002594 9001791 9002593 9002197 Primer, Gray 9000592 Primer, White 9001669 Graphite 95201 265915 •401930 •401931 •Revised 011405... - Page 59 Parts FRAME, TONGUE, HITCH ITEM DESCRIPTION PART NO. NOTES 1200 1600 110'/120'/132' Booms Frame Weldment 402075* 400654* Tongue Weldment 402097* 400709* •403785* Hitch Assembly Below Below Capscrew, 3/4-10NC x 2 1/2 9390-147 > •10 Lockwasher, 3/4 9404-033 > •10 Nut, 3/4-10NC 9394-016 >...

-

Page 60: Axle Assembly

Parts AXLE 401932 ITEM DESCRIPTION PART NO. QTY. NOTES 1200 1600 Axle Weldment, Non-Suspended 402642B Axle Assembly, Suspended 402063 400752 See page 5-5 Clamp 400667B Capscrew, 1-8NC x 6 9390-195 Lockwasher, 1" 9404-041 Nut, 1/8NC 9394-020 Hub & Spindle Assembly 401593B 400765B Capscrew, 5/8-11NC x 5 1/2 9390-135... - Page 61 Parts SUSPENDED AXLE 8 HOURS EP-2 401932 ITEM DESCRIPTION PART NO. QTY. NOTES 1200 1600 Upper Axle Weldment 400751B < Lower Axle Weldment < 400741B Bushing < 9003415 3 1/4 x 3 x 2 Lg. Grease Zerk, 1/8 NPT 90° <...

- Page 62 Parts 10-BOLT HUB ASSEMBLY WITH 3 3/4” SPINDLE 400995 IT E M D E S C R IP T IO N PA R T N O . Q T Y. N O T E S H ub & Sp ind le A ss e m b ly 4 0 1 5 9 3 B 4 0 0 7 6 5 B S e a l...

- Page 63 Parts NOTES...

-

Page 64: Wheels, Tires

Parts WHEELS, TIRES 401940 •Revised 011405... - Page 65 Parts WHEELS, TIRES ITEM DESCRIPTION PART NO. QTY. NOTES Singles Wheel & Tire Assembly 16378 TL380/90R46A 8 Star R-1 Wheel Only 16477Y 13 x 46 10 Hole Wheel & Tire Assembly 16376 TL480/80R42F 3 Star R-1 Wheel Only 16369Y 16 x 42 10 Hole Wheel &...

-

Page 66: Mast

Parts MAST ITEM DESCRIPTION PART NO. QTY. NOTES 1200 1600 1200 1600 RH Mast Weldment 402089* 400679* LH Mast Weldment 402090* 400680* Cross Tube Weldment 401239* > > Bracket 401852* > > Capscrew, 3/4-10NC x 2 9390-145 > > Lockwasher, 3/4 9404-033 >... -

Page 67: Lift Assembly, H-Frame

LIFT ASSEMBLY, H-FRAME ITEM DESCRIPTION PART NO. QTY. NOTES H-Frame Weldment 401042* 401099 Flat Head Screw, 5/16-18NC x 1 9400-101 Lockwasher, 5/16 9404-019 Nut, 5/16-18NC 9394-004 Lower Parallel Lift Weldment 400700* Upper Parallel Lift Weldment 400702* Self-Lubricating Bushing, 1 1/4 x 1 9003828 401071 1 1/4 x 9 1/8”... -

Page 68: Frame Attachments

Parts FRAME ATTACHMENTS •401934 •Revised 011405 5-12... - Page 69 Parts FRAME ATTACHMENTS ITEM DESCRIPTION PART NO. QTY . NOTES 1200 1600 1200 1600 LH Side Assenbly 402807* 401115* > Panel 402083* 400736* > Bracket 400722B > > Bracket 400723B > > RH Valve Bracket 401165B > > LH Valve Bracket 401166B >...

-

Page 70: Platform, Railings

Parts PLATFORM, RAILINGS 401935 •Revised 011405 5-14... - Page 71 Parts PLATFORM, RAILINGS ITEM DESCRIPTION PART NO. QTY. NOTES (60'/80'-90'/110'-132') 1200 1600 Platform Weldment 402093* •403875* LH Perimeter Weldment 402817* 401838* RH Perimeter Weldment 402818* 401839* Platform Railing Weldment 401124* > LH Platform Railing Weldment 401169* •403773* Handrail Weldment •402633* 401213* Serrated Flg.

- Page 72 Parts LADDER ITEM DESCRIPTION PART NO. QTY. NOTES 1200 1600 Ladder Weldment 402624* 401139* Latch Pin Weldment 401879B > Pin, 1/2 x 5 3/8 401880 > Poll Pin, 3/16 x 2 1/2 9392-107 > Spring, 3/4 x 2 1/2 TA510035 >...

-

Page 73: Gauge Panel

Parts GAUGE PANEL ITEM DESCRIPTION PART NO. QTY. NOTES Gauge Bracket Mount Weldment 401114B Gauge Bracket Weldment 401870B Cover, Back - Gauge 401103B Flange Screw, 3/8-16NC x 1 91262 Shoulder Washer, 3/8 ID 9003862 Flange Nut, 3/8-16NC 91263 Bumper 9003850 Pop Rivet, 3/16 TA0-908386-0 Spacer... -

Page 74: Main Tank

Parts MAIN TANK 401936 5-18... - Page 75 MAIN TANK Parts ITEM DESCRIPTION PART NO. QTY. NOTES 1200 1600 Tank, 1200 And 1600 Gallon 401207 401108 Tank Lid TA805210 > O-Ring TA805190 > Lower Baffle Weldment 401817 > Upper Baffle Weldment 401818 > Upright 402696 401819 Panel 401820 >...

-

Page 76: Rinse Tank

RINSE TANK ITEM DESCRIPTION PART NO. QTY. NOTES Rinse Tank, 165 Gallon 401107 Serial #B20630210 & Lower Rinse Tank, 165 Gallon 401181 Begin Serial #B20630211 Nylon Strap, 2” TA500499 42” Clip, Strap TA510025 Capscrew, 3/8-16NC x 4 1/2 Full Thd TA0-907131-0 Nut, 3/8-16NC 9394-006... - Page 77 Parts NOTES 5-21...

-

Page 78: Sight Gauge

Parts SIGHT GAUGE ITEM DESCRIPTION PART NO. QTY. NOTES 1200 1600 Sight Gauge Weldment 402806B 400745B Decal, Volume Indicator 9004129 9003686 Lg. Flange Screw, 3/8-16NC x 3/4 95585 > Lg. Flange Nut, 3/8-16NC 91263 > Tube, Sight Gauge 402831 400746 Cap, Gauge Tube 401885 >... -

Page 79: Strainer

Parts STRAINER ITEM DESCRIPTION PART NO. QTY. NOTES With Inlet Port Strainer Complete TA855650 402255 2" Flange Strainer Head TA868841 Screen, 50 Mesh (Red) TA869070 > Gasket, EPDM TA867486 > Bowl, Polypropylene TA868842 > O-Ring, Viton TA868843 > Cap, Polypropylene TA868844 >... -

Page 80: Spray Pump

SPRAY PUMP PART NO. ITEM DESCRIPTION QTY. NOTES 1200 1600 Spray Pump, Ace (FMC-200-HYD-304) TA825195 TA825195 80,90’ Booms Spray Pump, Ace (FMC-150 HYD 206) TA825250 Opt / 1600-60’ Boom Spray Pump, Ace (PTOC-150-1000B) TA825715 Opt / 60’ Boom Spray Pump, Ace (PTOC-150-600-B) TA825710 Opt / 60’... - Page 81 Parts PLUMBING OVERHEAD LAYOUT 401971 5-25...

-

Page 82: Spray System

Parts TA1600 SPRAY SYSTEM ITEM DESC R IPTION PAR T N O. QTY. N OTES Tee, 2" Flange TA815007 Elbow, 1" Flange x 3/4" HB 90° TA815017 Elbow, 2" Flange x 2" HB 90° TA815021 Plug, 2" Flange TA815023 Elbow, 2" Flange x 1" HB 90° TA815024 Ball Valve, 2"... -

Page 83: Spray System

Parts TA1200 SPRAY SYSTEM ITEM DESCRIPTION PART NO. QTY. NOTES 80/90' Slider-RH Side Panel 401859B > Slider-LH Side Panel 401860B > Panel-LH Side 402083* > 2" Female Coupler 90° TA811830 > 2" STD Flange Tee TA815007 > 2" Flange x 1 1/2 OR 2" HB... - Page 84 Parts NOTES 5-28...

- Page 85 Parts SPRAY SYSTEM ITEM DESCRIPTION PART NO. QTY. NOTES Tee, 2" Flange TA815007 Clamp, 2" Full Port Flange TA816000 Gasket, 2" Full Port Flange TA816001 Clamp, 2" Flange TA815025 Gasket, 2" Flange TA811944 Clamp, 1" Flange TA815026 Gasket, 1" Flange TA815029 Hose Clamp,13/16"...

-

Page 86: Electric Controls (Option)

Parts ELECTRIC CONTROLS - OPTIONAL •401986 •Revised 011405 5-30... -

Page 87: Electric Controls (Option)

Parts ELECTRIC CONTROLS - OPTIONAL IT E M D E S C R IP T IO N PA R T N O . Q T Y. N O T E S P a ne l 4 0 2 0 8 8 * U s e d W ith 1 2 0 0 P a ne l 4 0 2 0 7 0 *... -

Page 88: 2-Point Hitch (Option)

Parts 2-POINT HITCH - OPTIONAL •401931 ITEM DESCRIPTION PART NO. QTY. NOTES Washer 250392 2-Point Turning Weldment 402835B 2-Point Hitch Weldment 402843B 403747 2-Point Pin (Vertical) 403792 2-Point Pin (Horizontal) 403794 Jack Stand Weldment 403798B Hitch Weldment 403801B Thrust Bearing 9000906 Bushing 9001917... - Page 89 Parts NOTES 5-33...

-

Page 90: Inductor Plumbing

INDUCTOR PLUMBING - OPTIONAL 401942 (December 2012) 5-34... - Page 91 INDUCTOR PLUMBING - OPTIONAL ITEM DESCRIPTION PART NO. QTY. NOTES Full Jet Celcon Tip - FL15 TA848450 Mesh Strainer (8079-PP-50-NY) TA865240 T-Jet Cap (8027-NY) TA865180 T-Jet Cap, Extra Long (8027-1-NY) TA867250 Tube, Inductor Bottle Washer TA1-114776-0 Reducer Bushing, 3/4 x 1/4” Poly TA814651 Street Elbow, 3/4”...

-

Page 92: Inductor Mounting

INDUCTOR MOUNTING - OPTIONAL INDUCTOR MOUNTING - OPTIONAL 401942 401942 5-40 5-36 (December 2012) - Page 93 INDUCTOR MOUNTING - OPTIONAL ITEM DESCRIPTION PART NO. QTY. NOTES 15-Galllon Tank With Lid (Yellow) 403597 Includes Item 2 15-Galllon Tank With Lid (Gray) 407469 Lid, 16” - Complete TA805210 U-Bolt 9004014 Tank Strap TA500499 5.5 Ft Clip, Tank Strap TA510025 Capscrew, 3/8-16UNC x 2 3/4 9390-062...

-

Page 94: Decals

Parts DECALS ITEM DESCRIPTION PART NO. QTY. NOTES 1200 1600 Decal, Warning - Axle Adjustment 9003846 > Sus-Axle Decal, Warning - Axle Adjustment 9004286 Non-Sus-Axle Decal, Logo TA510041 > Decal, Sprayer Valve 9003674 > Decal, Sprayer Valve 9003675 > Decal, Sprayer Operation 9003676 >... -

Page 95: Foam Marker

FOAM MARKER ITEM DESCRIPTION PART NO. QTY. NOTES Foam Marker Assembly 9003844 Includes Items 1 thru 16 Pump, Concentrate 9003941 Pump, Water TA750312 Mixing Chamber 9003943 Check Valve, 1/4” TA750314 Check Valve Kit #407106 Compressor TA750019 Filter TA750020 Bulkhead, 3/8” 9003944 Hose Barb Stem 9003942... - Page 96 Parts FOAM MARKER ASSEMBLY •401972 5-40...

- Page 97 Parts FOAM MARKER ASSEMBLY ITEM DESCRIPTION PART NO. QTY. NOTES Plate, RH Foamer Bracket 402290B Replaces 401770B 404589B (120 'Boom) Plate, LH Foamer Bracket 402291B Repalces 401771B 404590B (120' Boom) RH Foamer Bracket 402285B Repalces 401499B LH Foamer Bracket 402286B Replaces 401570B U-Bolt, 3/8-16 x2 3/4 x 1 1/2 TA510036...

- Page 98 Parts SPRAY PUMP ITEM DESCRIPTION PART NO. QTY. NOTES Pump Complete, ACE 200-304 TA825195 Includes Items 1 thru 20 Pipe Plug TA826325 Pipe Plug, S.S. (Option) TA826300 Volute, 2" x 1 1/2" TA830738 Nut, 3/8NF TA830731 Star Washer, 3/8 S.S. TA829500 Impeller, Cast Iron - Ext.

- Page 99 Parts HYDRAULIC SPRAY PUMP - (ACE HYD 150-206) SPRAY PUMP - (ACE HYD 150-206) ITEM DESCRIPTION PART NO. QTY. N O T E S ITEM DESCRIPTION PART NO. QTY. NOTES Pump Complete, ACE FMC-150-HYD-206 TA825250 Includes Items 1 thru 20 Pump Complete, ACE FMC-150-HYD-206 TA825250 Includes Items 1 thru 20...

- Page 100 Parts HYDRAULIC SPRAY PUMP - (HYPRO 9306C-HM1C) SPRAY PUMP - (HYPRO 9306C-HM1C) I T E M D E S C R I P T I O N P A R T N O . QTY. N O T E S ITEM DESCRIPTION PART NO.

- Page 101 NOTES 5-45 (December 2012)

- Page 102 PRINTED IN USA TC/MANUALS/402061///DECEMBER 2012-3...

Need help?

Do you have a question about the TA1200 and is the answer not in the manual?

Questions and answers