Advertisement

Quick Links

WEAR YOUR

SAFETY GLASSES

FORESIGHT IS BETTER

THAN NO SIGHT

READ INSTRUCTIONS

BEFORE OPERATING

CAUTION!

Read All Operating Instructions Carefully Before

Attempting Any Machining Operations.

General Description

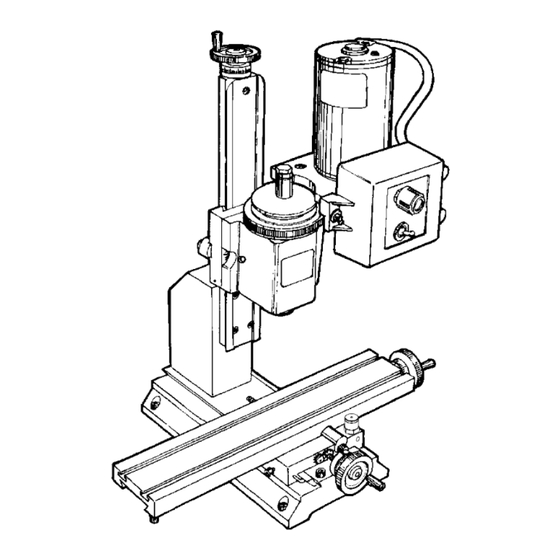

At first glance, a vertical mill looks similar to a drill

press, but there are some important design differences;

for example, the mill has a spindle that can take side loads

as well as end loads and an accurate method of moving

work in relation to the spindle on all three axes. It is wise

to memorize these "X," "Y" and "Z" axes, because, since

the advent of complex electronically controlled milling

machines, these terms have become common "shop talk,"

even outside engineering departments. Feed screws with

calibrated handwheels control movements on these three

axes. The handwheel calibrations are quite accurate and

should be used whenever possible.

Angles can be machined by removing the headstock

alignment key and rotating the milling head to the

appropriate angle to the work or by holding the work at

an angle to the spindle.

Z

FIGURE 1—The axes of movement for milling on a standard

3-axis vertical milling machine.

(NOTE: Lighter than normal cuts should be taken when the

alignment key is not in place.) The latter method must be

used for drilling on 5000/5400-series mills to keep the drill

movement parallel with the machine slide. Angle drilling

can also be accomplished without removing the alignment

key by using the optional rotary column attachment (P/N

3500). (The Model 2000 mill is also capable of angle

drilling due to its multi-axis design.) All machine slides

SHERLINE PRODUCTS INC. • 3235 Executive Ridge • Vista • California 92081-8527 • FAX: (760) 727-7857

Toll Free Order Line: (800) 541-0735 • International/Local/Tech. Assistance: (760) 727-5857 • Internet: www.sherline.com

X

Y

Vertical Milling Machine

Operating Instructions

have an adjustable gib to compensate for any "play" that

may develop. (See "adjusting gibs" on page 12 of the

Assembly and Instruction

It is assumed that anyone purchasing a vertical milling

machine has had some experience working with metal

cutting tools; therefore, these instructions are somewhat

limited for a beginner. There is enough information,

however, to enable a good craftsman to get started. Using a

vertical mill correctly takes more skill and experience than

is required for lathe operation because of the additional

axis (vertical) and the more varied type of work that can

be performed.

The machine must be well maintained, for it is subject to

higher stresses than a lathe. This particular mill is one of

the smallest being manufactured and is an extremely useful

tool. However, it would be unreasonable to clamp a 3-pound

piece of stainless steel to the work table and expect to make

a 1-pound part from it. The key point is to work within the

capabilities of the machine, and those limitations can only

be determined by the operator.

Helpful Tips for Milling

•

This is a small, light-duty mill and should not be used

to remove large amounts of stock that could be easily

removed with a hacksaw. For efficiency, select a piece

of stock as close to finished size as possible.

•

Stresses on a mill are quite high when cutting most

materials; therefore, gib and backlash adjustments must

be properly maintained.

•

End mills must run true and be sharp. Holding end

mills in a drill chuck is a poor practice. Use collets or

an end mill holder instead. The 3/8" end mill holder

(P/N 3079) allows you to use a large range of readily

available 3/8" end mills with your machine. (Several

other size inch and metric end mill holders are also

available.)

•

Fly cutting is an excellent way of removing stock from

flat surfaces.

•

Normal machine alignment is adequate for most

work, but if the work is exceptionally large or requires

extreme accuracy, shims may be employed to improve

machine alignment.

•

For accurate setups you should have and know how to

use a dial indicator.

Guide.)

4/21/16

Advertisement

Summary of Contents for Sherline Products 5000 series

-

Page 1: Operating Instructions

All machine slides SHERLINE PRODUCTS INC. • 3235 Executive Ridge • Vista • California 92081-8527 • FAX: (760) 727-7857 4/21/16 Toll Free Order Line: (800) 541-0735 • International/Local/Tech. Assistance: (760) 727-5857 • Internet: www.sherline.com... - Page 2 • Often, more time will be spent making fixtures to hold work than doing the actual machining. • To help save time on many simple setups, a good mill vise is a must. A drill press vise is not designed for the P/N 3012 HOLD-DOWN forces involved in milling.

- Page 3 machining at the end of the job rather than at the beginning. • The method of holding the work is also determined by the type of machining to be performed. For instance, work that involves only small drilling jobs does not have to be held as securely as work to be milled.

- Page 4 Study the relationship of cutting edges to the material being cut as shown in Figure 4. Note that in one case the tool will tend to climb onto the work, whereas in the other case the tool will tend to move away from the cut. The result is that climb milling should normally be avoided except for very light finishing cuts.

- Page 5 FIGURE 7—Indicating in the center of a hole. FIGURE 6—Indicating in the jaws of a vise. Shown is a Starrett “Last Word” Indicator. Starrett gauges are available in numerous in the spindle and see that it runs perfectly true. Using a sizes and types.

- Page 6 of making a part to much closer tolerances than those of the machine with which he is working. The accuracy of the parts you make is limited only by your skill as a craftsman and the quality of your measurement equipment. Accuracy should be the ultimate goal of every machinist! Cutting Speeds for Milling Speed Adjustment Chart...

- Page 7 As a convenience to our customers, Sherline keeps in FIGURE 66—Mill inventory many of the popular sizes of end mills that are column saddle lock appropriate for use on our machines. See our “Cutting Tools Price List” for selection. End mills may also be purchased on-line or from your local industrial machine MILL SADDLE shop supply outlet.

- Page 8 34220 54020/54120 40580 SHERLINE PRODUCTS INC. • 3235 Executive Ridge • Vista • California 92081-8527 • FAX: (760) 727-7857 3/6/17 Toll Free Order Line: (800) 541-0735 • International/Local/Tech. Assistance: (760) 727-5857 • Internet: www.sherline.com Mill Instructions, Pg. 8 OF 10...

- Page 9 SHERLINE Lathes and Mills KEY TO MATERIALS: A=Aluminum, B=Brass, C=Composite, DC=Die Cast, P=Plastic, U=Urethane, S=Steel PART NO. DESCRIPTION MATERIAL PART NO. DESCRIPTION MATERIAL 12970 Headstock Spacer Block (Deluxe Mill) 40340 110-32 x 1” Skt. Hd. Cap Screw 30220 Toggle Switch Retaining Ring 40370 Leadscrew Support 30230...

- Page 10 PART NO. DESCRIPTION MATERIAL PART NO. DESCRIPTION MATERIAL 43140 DC Speed Control Tab, Small 50220 1/4-20 x 1-3/4” Skt. Hd. Cap Screw 43150 DC Speed Control Tab, Large 50240 Headstock Pivot Pin, Mill 43160 Belt Guard, Outer 50280 Thrust Collar, Mill 43170 6-32 x 1-3/8”...

Need help?

Do you have a question about the 5000 series and is the answer not in the manual?

Questions and answers