Advertisement

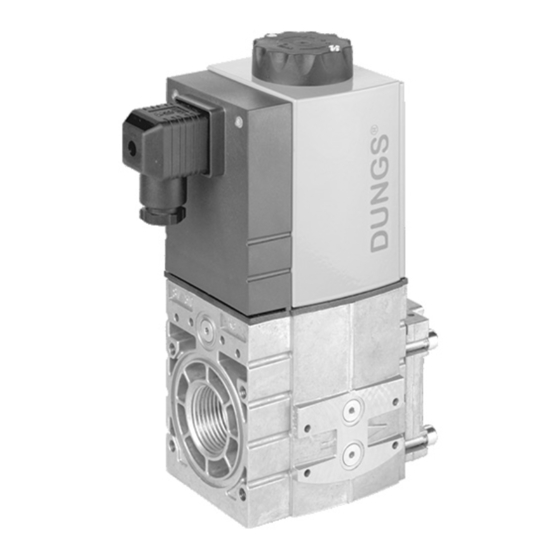

SV-(DLE) 10../604

Safety Shutoff Valve

Installation Instructions

SV/604

Normally closed automatic shutoff valve with proof of closure. Fast opening, fast closing.

SV-DLE/604

Normally closed automatic shutoff valve with proof of closure. Slow opening, fast closing. Valve features

adjustable max. flow and adjustable inital lift.

Body size

SV / SV-DLE 1005/604

SV / SV-DLE 1007/604

SV / SV-DLE 1010/604

SV / SV-DLE 1012/604

SV / SV-DLE 1015/604

SV / SV-DLE 1020/604

Gases

Natural gas, propane, butane; other noncorrosive gases.

When used with manufactured gases, quarterly leak

checks are required. Suitable for dry, 0.1% by volume H

Maximum Operating Pressure

10 PSI (700 mbar)

Maximum Close Off Pressure

15 PSI (1000 mbar)

Ambient / Fluid Temperature

-40°F to +140°F; (-40°C to +60°C)

Electrical Ratings Available

120 Vac - 50 to 60 Hz

Enclosure Rating

NEMA Type 4 for indoor applications

NEMA Type 12 for outdoor applications

Power Consumption

SV / SV-DLE 1005/604 20VA

SV / SV-DLE 1007/604 20VA

SV / SV-DLE 1010/604 25VA

SV / SV-DLE 1012/604 25VA

SV / SV-DLE 1015/604 45VA

SV / SV-DLE 1020/604 45VA

• Read these instructions carefully.

• Failure to follow them and/or improper installation may

cause explosion, property damage and injuries.

• The system must meet all applicable national and local

code requirements such as but not limited to the follow-

ing fuel gas codes: NFPA 54, IFGC (International Fuel Gas

Code), or CSA B149.1 (for Canada) or the following

equipment codes and standards: CSD-1, NFPA 86,

ANSI Z83.4/CSA 3.7, ANSI Z83.18,

ANSI Z21.13/ CSA 4.9, or CSA B149.3 (for Canada).

1 ... 6

SPECIFICATIONS

Size (NPT)

1/2"

3/4"

1"

1 1/4"

1 1/2"

2"

524 Apollo Drive,Suite 10 Lino Lakes, MN 55014 U.S.A.

Industrial Combustion Components

Phone: (651) 792-8912 Fax: (651) 792-8919 E-mail: info@karldungsusa.com

Tel: 804.236.3881 Fax: 804.236.3882 E-mail: findparts@burnerparts.com

Electrical Connection

DlN-Connector with 1/2" NPT conduit adapter.

Operating Time

100 % duty cycle

Closing Time

< 1 second

Opening Time

SV/604: < 1 sec.

SV-DLE/604: 10 to 20 sec. (70 °F)

Max. Flow Adjustment (SV-DLE/604)

S.

Adjustable: 0 to 100 % of total flow. When adjusted to low

2

flows, flow repeatability upon opening is +/-15%.

Initial Lift Adjustment (SV-DLE/604)

Adjustable: 0 to 70 % of total flow; 0 to 35% of stroke

Materials in contact with Gas

Housing: Aluminum & Steel, free of non-ferrous metals

Sealings on valve seats: NBR-based rubber

Mounting Position

Solenoid upright vertical

to solenoid horizontal

Strainer

23 Mesh, installed in the housing upstream valve seat

Test Ports

G 1/8 ISO 228 taps available on both sides upstream and

downstream of valve seat, on inlet and outlet of SV also on

flange (SV 1010-1020 only). See Page 4 for details.

Approvals

CSA: Certified File No.1350312

FM Approved: Report 3014562

Commonwealth of Massachusetts Approved Product

Approval code G1-1107-35

ATTENTION

• Installation must be done with the supervision of a

licensed burner technician.

• Check the ratings in the specifications to make sure that

they are suitable for your application.

• Never perform work if gas pressure or power is applied,

or in the presence of an open flame.

• Once installed, perform a complete checkout including

leak testing.

• Verify proper operation after servicing.

Karl Dungs, Inc

Burnerparts.com

Advertisement

Table of Contents

Summary of Contents for Dungs SV-DLE 1005/604

-

Page 1: Specifications

Test Ports Power Consumption G 1/8 ISO 228 taps available on both sides upstream and SV / SV-DLE 1005/604 20VA downstream of valve seat, on inlet and outlet of SV also on SV / SV-DLE 1007/604 20VA flange (SV 1010-1020 only). See Page 4 for details. - Page 2 MOUNTING Recommended Preparation Recommended Piping Procedure • Examine the SV-(DLE) for shipping damage. • Use new, properly reamed and threaded pipe. • The main gas supply must be shut off before • Apply good quality pipe sealant, putting a moderate installing the valve.

- Page 3 WIRING Wiring the SV-(DLE) • Use 14 or 16 guage wire rated for at least 75˚C (167˚F). • Disconnect all power to the valves before wiring to • Connect the wiring to the appropriate screw terminals in the DIN connector. prevent electrical shock and equipment damage.

- Page 4 TEST PORTS Test Ports G1/8 ISO 228 test ports available on both sides of the valve. Each side has one test port upstream (2), one downstream (3) of the valve seat. One Inlet (1) and outlet The position of the side taps #2 and #3 on the (4) of valve body.

- Page 5 VALVE LEAKAGE TEST This leak test procedure tests the external sealing and valve isolation valve, and the inlet and outlet gas piping for each seat sealing capabilities of two SV automatic safety shutoff automatic safety shutoff valve. The presence of bubbles valves in series.

- Page 6 FLOW CURVE PRESSURE DROP FOR OTHER GASES To determine the pressure drop when using a gas other than natural gas, use the flow formula below and f value located in the chart below to determine the “corrected” flow rate in CFH through the valve for the other gas used. For example, when using propane, divide the volume (CFH) of propane required for the application by the calculated value f (f = 0.66 for propane).

Need help?

Do you have a question about the SV-DLE 1005/604 and is the answer not in the manual?

Questions and answers