Summary of Contents for TCS 682-15

-

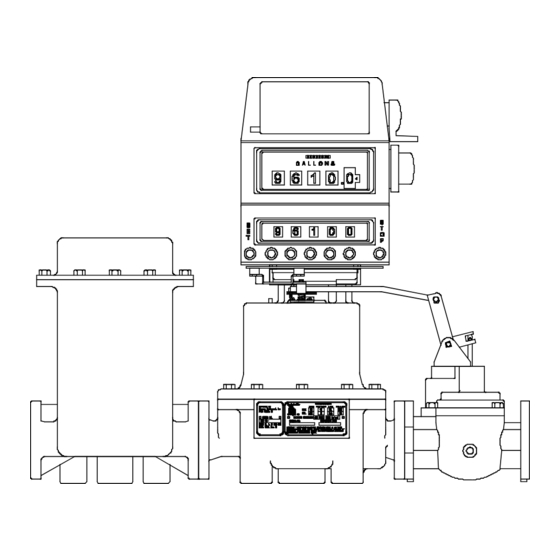

Page 1: Service Manual

“The Standard of Measurement” 682-15 Piston Flow Meter SERVICE MANUAL TOTAL CONTROL SYSTEMS 2515 Charleston Place • Fort Wayne, IN 46808 (800) 348-4753 • (260) 484-0382 • Fax (260) 484-9230 sales@tcsmeters.com • www.tcsmeters.com... -

Page 2: Specifications

SPECIFICATIONS Type Reciprocating 3 Piston Positive Displacement Connections 1-1/2” companion flange Flow Rate Minimum: 0.2 GPM (0.76 LPM) Maximum: 40 GPM (151 LPM) Working Pressure 150 PSI maximum (10.5 Bar) Working Model 682SP: -20°F to 200°F (-28.9°C to 93.3°C) Temperature Models 682AF &... - Page 3 682 METER OPERATION The 682 meter is a true Positive Displacement Meter, with the inlet and outlet on the same horizontal plain (straight in - straight out). Within the meter, three plungers are fitted within their respective cylindrical measuring chambers. The plungers are joined to a wobble plate, which has a shaft extending from its upper surface.

- Page 4 The TCS model 682 series flow meter is virtually unaffected by changing viscosities. The inline meter design allows the TCS model 682 series flow meter to have a wide operating range (0.2 to 40 GPM) and fluid compatibility that has been proven over many years of...

-

Page 5: Installation And Start-Up

INSTALLATION AND START UP Best Plumbing Configuration Meters and piping should be installed to prevent drainage of product from the meter when the system is not running. One way to do this is to have the inlet and outlet of the meter lower than the associated system plumbing (sump position). -

Page 6: Storage Instructions

STORAGE INSTRUCTIONS Short periods of non-use of the meter (a week or less) will present no problem, provided that the meter remains full of product. For long periods of non-use, such as winter storage, the following procedure is recommended. Before long term storage, a good practice is calibration of the meter to determine that it is functioning properly. -

Page 7: Pressure Drop Curve

KEY FEATURES OF 682 METER TYPICAL ACCURACY CURVE 32 SSU SOLVENT -0.1 -0.2 GALLONS PER MINUTE The 682 meter's linear accuracy (percent of error over or under the zero - error level) remains within design parameters (+/- 0.2%) over its 0.2 to 40 GPM flow range. This exceeds the maintenance requirements for accurate custody transfer of product, as specified in the National Institute of Standards and Technology (NIST) Handbook 44. - Page 8 VISCOUS LIQUIDS PERFORMANCE...

- Page 9 682 METER EXCHANGE PROGRAM Overview TCS offers an exchange program on the 682 AF and SP meters. The exchange price, equa l to less than 1/3 the price of a new meter, after the credit given from the returned meter core. This makes the exchange program a powerful value - added option for 682 owners.

- Page 10 DIMENSIONS Measurements are in Inches.

- Page 11 TROUBLE SHOOTING THE 682 METER The following is a list of common problems that can be encountered with a 682 meter, and possible causes and solutions for them. PROBLEM: The meter allows product to pass through it, but the register on the meter doesn't move.

-

Page 12: Meter Assembly

METER ASSEMBLY 682-15... - Page 13 METER ASSEMBLY 682-15 ITEM# DESCRIPTION Screw, 3/8-16 X 1-1/8 297-050361 297-050361 1-126333 Washer, 3/8 Split Lock 15-050641 15-050641 1-126334 Counter Support 1-312518 1-312518 1-312518 Roll Pin 49-052910 49-052910 3-130752 Drive Shaft 1-114815 1-114815 1-126900 Screw, 10-24 X 1/2 252-50001 252-50001...

- Page 14 Wear on the AF/SP valve (#57) or SS valve insert (#57). Wear on the valve seat (#58). Wrinkles on the sleeves in cylinders (TCS 1-126891) of the body. NOTE: Honing sleeves with Emory wheel may buff out wrinkles. A. Mount valve seat (#58) to body (#60), with seat gasket (#59).

- Page 15 682 METER BONNET REPAIR INSTRUCTIONS A. Remove all parts and seals from the meter bonnet and clean them. You may air blast parts with a glass bead material to clean parts. B. Check for excessive wear. NOTE: Problems with any of these following items will require a new bonnet or shafts.

- Page 16 COMPENSATOR SHAFT SEAL KIT INSTRUCTIONS 1) Remove screws that bolt the meter cover assembly to the meter body. Loosen and remove the entire meter cover assembly. 2) Cut seal wire and remove seal pin from index disc. 3) Unscrew hex nut from the compensator shaft. Remove compensator washer,...

- Page 17 PLUNGER CUP REPLACEMENT 1) Remove plunger assembly from 5) Form the cup by turning the meter body. plunger assembly in your hand 2) Loosen and remove two (2) round using your thumb to roll the edge head screws and lift plunger cup slightly.

- Page 18 AIR ELIMINATOR ASSEMBLY 640-15...

- Page 19 AIR ELIMINATOR ASSEMBLY 640-15 ITEM# DESCRIPTION Cover 64002-2 64002-3 Bracket Assembly 64019 64019 Lock Washer 1-126316 1-126316 Screw 64010 64010 Short Link Pin 64023 64023 Connecting Arm 64007 64007 Lever Arm 64006 64006 Cotter Pin 1-126318 1-126318 Float Assembly 64005 64005 Pipe Plug 2-051913...

-

Page 20: Hydraulic Valve Assembly

HYDRAULIC VALVE ASSEMBLY 650-15... - Page 21 HYDRAULIC VALVE ASSEMBLY 650-15 ITEM# DESCRIPTION QTY. Retaining Ring 6-052482 6-052482 Washer, Flat 65034 65034 Spacer 1-130852 1-130852 Preset Bracket 1-226102 1-226102 Screw 65005 65005 Locknut 65008 65008 Swivel Block 1-128140 1-128140 Connecting Link 65025 65025 Cotter Pin 1-126318 1-126318 Washer 65003 65003...

- Page 22 NOTES...

-

Page 23: Warranty

TCS's sole obligation that shall represent the buyer's sole and exclusive remedy shall be to repair or at TCS's option to replace any product or part determined to be defective. In no event shall TCS be liable for any special, direct, indirect, incident, consequential or other damages of similar nature, including without limitation, loss of profits, products, production time, or loss of expenses of any nature incurred by the buyer or any third party. - Page 24 682SM Rev.5, 01/01/0 5 TOTAL CONTROL SYSTEMS 2515 Charleston Place • Fort Wayne, IN 46808 (800) 348-4753 • (260) 484-0382 • Fax (260) 484-9230 sales@tcsmeters.com • www.tcsmeters.com...

Need help?

Do you have a question about the 682-15 and is the answer not in the manual?

Questions and answers