Fike CyberCat 1016 Installation Manual

Addressable fire alarm control system

Hide thumbs

Also See for CyberCat 1016:

- Operation & maintenance manual (136 pages) ,

- Programming manual (128 pages)

Subscribe to Our Youtube Channel

Summary of Contents for Fike CyberCat 1016

- Page 1 Installation Manual 10-064, CyberCat 1016 10-066, CyberCat 254 Addressable Fire Alarm Control System P/N 06-326, Rev. 14 September 2015...

- Page 2 Authority Having Jurisdiction is mandatory. Fike can not be held liable for any incidental or consequential damages arising from the loss of property or other damages or losses resulting from the use or misuse of Fike products beyond the cost of repair or replacement of any defective components.

- Page 3 TABLE OF CONTENTS REVISION HISTORY Document Title: CyberCat Addressable Fire Alarm System Installation Manual Document Reorder Number: 06-326 Revision Section Date Reason for Change All Sections 09/2004 Initial Release Added CyberCat 254 and programming All Sections 12/2004 menu’s Added Networking, Isolator devices, All Sections 05/2005 sounder bases...

-

Page 4: Table Of Contents

TABLE OF CONTENTS SECTION DESCRIPTION PAGE Introduction ........................1-1 About This Manual ......................1-1 Product Support ....................... 1-1 Safety Information ......................1-1 Terms Used In This Manual ..................... 1-2 Related Documentation ....................1-3 System Overview ......................2-1 System Description ......................2-1 2.1.1 CyberCat Features ...................... - Page 5 TABLE OF CONTENTS SECTION DESCRIPTION PAGE 3.6.15 Amplifier Card ........................ 3-24 3.6.15.1 Class A Speaker Card ....................3-24 3.6.16 Relay Control Assembly ....................3-25 3.6.17 Relay Card ........................3-25 3.6.18 Class A Peripheral Bus Card ..................3-25 3.6.19 FCC Digital Paging Assembly ..................3-26 3.6.20 Local Operating Console ....................

- Page 6 TABLE OF CONTENTS SECTION DESCRIPTION PAGE Installation ........................4-1 System Installation Sequence ..................4-1 Select the Enclosure Mounting Location................4-1 Select the Enclosure Mounting Option................4-2 Mount the Enclosure ......................4-2 4.4.1 Install the Dead-front Door ....................4-2 Wire Selection ........................4-5 Circuit Class Designations ....................

- Page 7 TABLE OF CONTENTS LIST OF EXHIBITS EXHIBIT DESCRIPTION PAGE Related Documentation ....................1-3 Related Documentation – Continued ................1-4 Example CyberCat Block Diagram .................. 2-1 Minimum System Configurations ..................2-4 System Ordering Formats ....................3-1 CyberCat System Controller with Display ............... 3-2 CyberCat Extended Display ....................

- Page 8 TABLE OF CONTENTS EXHIBIT DESCRIPTION PAGE 3-47 HPM4 Relay Card ......................3-25 3-48 Relay Card ........................3-25 3-49 Class A Peripheral Bus Card ..................3-25 3-50 FCC Digital Paging Card ....................3-26 3-51 Local Operating Console ....................3-27 3-52 LOC w/ RDU ........................3-27 3-53 Photo Detector .......................

- Page 9 TABLE OF CONTENTS EXHIBIT DESCRIPTION PAGE 4-13 AC Power Connections ....................4-13 4-14 Battery Connections ...................... 4-14 4-15 CyberCat Board Terminal Connections ................. 4-16 4-16 P2 Relay Connections ....................4-17 4-17 RS232 Wiring ........................ 4-17 4-18 RS485 Peripheral Bus Wiring ..................4-17 4-19 RS485 DACT Wiring ......................

- Page 10 TABLE OF CONTENTS Reserved for future use. viii CyberCat 254/1016 Installation Manual UL S2203 Rev 14, 09/2015 P/N: 06-326...

-

Page 11: Introduction

Fike has a worldwide distribution network. Each distributor sells, installs, and services Fike equipment. Look on the inside of the door, left side, there should be a sticker with an indication of the distributor who sold the system. If you cannot locate the distributor, please call Fike Customer Service for locating your nearest distributor, or go to our web-site at www.fike.com. -

Page 12: Terms Used In This Manual

1.0 INTRODUCTION TERMS USED IN THIS MANUAL The following are various terms used in this manual with a brief description of each. Ω - Symbol for “ohm”. Unit of resistance. AC Normal State - (“AC Normal” Green LED ON) The system is in the AC Normal state when appropriate AC power is being applied to the system. -

Page 13: Related Documentation

1.0 INTRODUCTION RELATED DOCUMENTATION To obtain a complete understanding of the specific features of the CyberCat or to become familiar with related functions in general, refer to the documentation listed below. Please reference the most current version or the version noted on the label located on the product. Exhibit 1-1: Related Documentation Document Title Part Number... -

Page 14: Related Documentation – Continued

1.0 INTRODUCTION Exhibit 1-2: Related Documentation – Continued Document Title Part Number Fire-Phone Housing Installation Instructions 06-568 FCC Microphone Housing (P/N 10-2757) Installation Instructions 06-569 Class A Speaker Card (P/N 10-2746) Installation Instructions 06-574 FCC Paging Control Card (P/N 10-2741) Installation Instructions 06-575 Amplifier Card (P/N 10-2773) Product Manual 06-576... -

Page 15: System Overview

254 devices in any combination. An optional loop card can be added to the CyberCat 1016 to increase the total number of signaling line circuits to four. This increases the total system capacity to 1,016 devices. Each CyberCat is capable of being networked (up to 128 panels total) providing 130,048 devices total. -

Page 16: Cybercat Features

- Audit Control: Not Provided POWER ♦ 6 amps useable alarm power, 2A standby- CyberCat 1016 expandable to 12 amps alarm power, 4 A standby ♦ Operation from 120VAC/ 60 Hz or 240VAC 50 /60Hz ♦ Two 24V DC, 2A continuous auxiliary power outputs (CyberCat 1016 Expandable to 5 circuits with SPS) ♦... -

Page 17: Listings And Approvals

2.0 SYSTEM OVERVIEW 2.1.2 LISTINGS AND APPROVALS Approval Agency File Number Underwriters Laboratories S2203 Type: Local, Remote Station (PPU), Central Station (PPU), Proprietary Supervising Station (PPU/SSU), Auxiliary Local Energy (PPU) Service Type: A-Automatic Fire Alarm, M-Manual Fire Alarm, Releasing Device Service, WF-Water- flow alarm, SS-Sprinkler Supervisory Service, DACT, Voice Evacuation and Emergency Communication Systems Type Signaling: Non-coded... -

Page 18: Minimum System Configurations

Notes: 1. Only one transformer (120VAC or 240VAC) can be used. 2. DACT must be purchased from Fike for proper operation with the CyberCat panel. 3. Available on CyberCat 1016 only. 4. Included in 10-080 Class A Peripheral Bus Assembly. - Page 19 2.0 SYSTEM OVERVIEW Exhibit 2-2: MINIMUM SYSTEM CONFIGURATIONS – CONT. This table indicates the minimum components needed to meet the intended applications. Y = Yes N = No O = Optional Part Number Description 10-2814 (Note 1) LOC Digital Paging Assembly 10-2800 (Note 2) Local Operating Console (LOC) 10-2801 (Note 2)

- Page 20 2.0 SYSTEM OVERVIEW Exhibit 2-2: MINIMUM SYSTEM CONFIGURATIONS – CONT. This table indicates the minimum components needed to meet the intended applications. Y = Yes N = No O = Optional Part Number (isolator version) Description 10-2154 Battery Enclosure, 33 AH maximum 10-2236 Battery Enclosure, 75 AH maximum 10-2780...

-

Page 21: System Components

3.0 SYSTEM COMPONENTS BASIC EQUIPMENT PACKAGES The CyberCat system is available in two basic equipment packages: CyberCat 1016 Control System (P/N 10-064-c-p-L-d-o) and CyberCat 254 Control System (P/N 10-066-c-p-L-d-o). Each package includes the equipment enclosure, CyberCat control board, transformer, and necessary mounting hardware. -

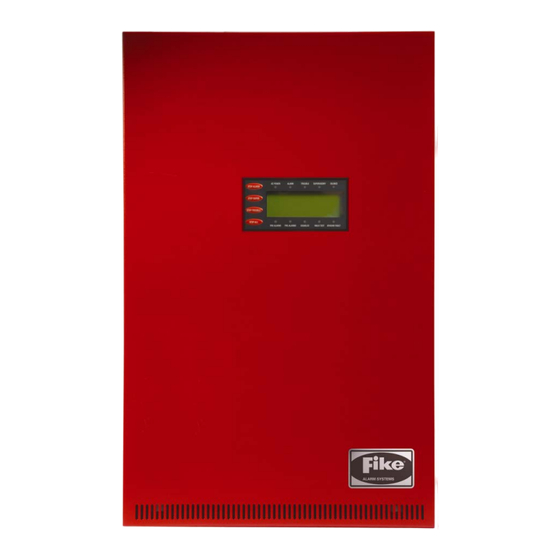

Page 22: Cybercat System Controller With Display

3.0 SYSTEM COMPONENTS The Standard display (See Exhibit 3-2) is an integral part of the CyberCat controller. It is mounted directly to the controller and provides the function and navigation buttons that are used to operate and program the system. Exhibit 3-2: CyberCat System Controller with Display When the controller is to be installed in an enclosure equipped with one of the optional dead-front doors, the standard display is replaced with an Extended Display (P/N 10-2680) as shown in Exhibit 3-3. -

Page 23: Cybercat Controller Terminal Locations

3.0 SYSTEM COMPONENTS Exhibit 3-4 shows the location of the various connectors on the CyberCat 254 (P/N 10-2525) and CyberCat 1016 (P/N 10-2472) controller boards. The function and specifications for each connection is listed in order of terminal block designation (P) on the following pages. Exhibit 3-4: CyberCat Controller Terminal Locations Controller Specifications: Controller Dimensions (HxWxD):... -

Page 24: Cybercat Controller Terminal Specifications

3.0 SYSTEM COMPONENTS Exhibit 3-5: CyberCat Controller Terminal Specifications Terminal Terminal Function and Electrical Block Labels Ratings/Requirements Wiring Requirements • 120 VAC Transformer P/N 02-10881 AC XFMR 16 AWG THHN wiring minimum Secondary Standby = 3A @ 25.35 VAC Terminal block accepts 12 AWG – 16 AWG Alarm = 6A @ 25 VAC wire •... -

Page 25: Cybercat Controller Terminal Specifications – Cont

Resettable The CyberCat controller has a total power Power limited and supervised Aux Out (+, -, capability of 6 amps. The CyberCat 1016 is • Regulated auxiliary power output rated 24 shld) expandable to 12 amps with the addition of... -

Page 26: Cybercat Controller Terminal Specifications – Cont

12,000 ft. (3657m) maximum wire length Power limited and supervised Loop 2 from panel to last device using 14 AWG • Available on CyberCat 1016 only (+, -, shld, -, Shielded cable should be used for • Supports up to 254 addressable devices... -

Page 27: Cybercat Controller Terminal Specifications – Cont

SLM is NOT compatible with the CyberCat 254 controller • See Section 4.11 Connects optional Supplemental Power Supply Module, P/N 10-2474-P to the CyberCat 1016 controller • SPS is NOT compatible with the CyberCat 254 controller • For Fike use only •... -

Page 28: System Enclosures

Refer to the referenced Fike document for detailed enclosure information and installation instructions. Enclosures can be ordered as part of the basic equipment package as shown in Exhibit 3-1 or separately as shown in Exhibit 3-9. -

Page 29: Standard Enclosure

Only one component can be installed at this location. Refer to Fike document 06-480 for standard enclosure installation details. The standard enclosure can be ordered with either of the dead-front door options described in 3.3.1.1 and 3.3.1.2. -

Page 30: Standard Enclosure With Solid Dead-Front

The dead-front door is hinged on the left side, which allows it to be easily opened to reveal the system components for maintenance purposes. Refer to Fike document 06-480 for standard enclosure installation details. 3.3.1.2 STANDARD ENCLOSURE WITH... -

Page 31: Fcc Enclosure With Nineteen Card Dead-Front

− Fire-Phone card, P/N 10-2728 − Supplemental fire-phone card, P/N 10-2730 − Paging Control card, P/N 10-2741 − City Tie Disconnect switch, P/N 10-2721 Refer to Fike document 06-570 for FCC enclosure installation details. UL S2203 CyberCat 254/1016 Installation Manual 3-11... -

Page 32: Fcc Enclosure With Twenty-Three Card Dead-Front

− Fire-Phone card, P/N 10-2728 − Supplemental fire-phone card, P/N 10-2730 − FCC Paging Control card, P/N 10-2741 − City Tie Disconnect switch, P/N 10-2721 Refer to Fike document 06-570 for FCC enclosure installation details. 3-12 CyberCat 254/1016 Installation Manual UL S2203... -

Page 33: Fcc Enclosure With Option-2 Back-Box

**Relay Control Assembly and Relay Control Card are mounted to the Relay Mounting Plate and share common mounting locations (2 spots). Only two of either component or combination thereof can be installed. Refer to Fike documents 06-607 and 06-619 for Option 2 Enclosure installation details. UL S2203... -

Page 34: Fcc Enclosure With Twenty-Five Card Dead-Front

− Supplemental fire-phone card, P/N 10-2730 − City Tie Disconnect switch, P/N 10-2721 Refer to Fike document 06-570 for FCC enclosure installation details. Note: This enclosure cannot be used to mount the CyberCat controller as there is no location for mounting of the system display. -

Page 35: Optional Dead-Front Cover Plates

3.0 SYSTEM COMPONENTS OPTIONAL DEAD-FRONT COVER PLATES For enclosures equipped with dead-front doors, the following cover plates can be ordered to enable you to blank off any unused openings in the dead-front panel. The cover plates are made of 18 gauge steel with a Red or Black enamel finish to match the enclosure. -

Page 36: Optional Circuit Modules

SUPPLEMENTAL POWER SUPPLY (SPS), P/N 10-2474-P The Supplemental Power Supply (See Exhibit 3-24) can be added to a base CyberCat 1016 system to double the power capacity. includes a power supply circuit board and secondary transformer (-1 for 120VAC primary; -2 for 240VAC primary), which adds 2A external standby power and 6A alarm power to the system. -

Page 37: Supplemental Loop Module (Slm)

SUPPLEMENTAL LOOP MODULE (SLM), P/N 10-2473 The Supplemental Loop Module (See Exhibit 3-25) can be added to a base CyberCat 1016 system to double the addressable loop capacity from 508 devices to 1016. Loop specifications and wiring for P31 and P32 are same as P8 and P9 from the main controller. It interfaces to P15 on the CyberCat controller using four standoffs supplied with the SLM. -

Page 38: Fiber Optic Network Module

It interfaces to P20 using four standoffs supplied with the Fiber Optic Network Module. Exhibit 3-29: Fiber Optic Refer to Fike document 06-387, for more information. Network Module 3-18 CyberCat 254/1016 Installation Manual... -

Page 39: Fourteen Button Remote Display Unit

Exhibit 3-30: Fourteen Button status changes. Remote Display Unit Refer to Fike document 06-610, for more information. Note: This unit can only be used on systems with panel firmware V3.0 or higher. -

Page 40: Two Button Remote Display Unit

The unit is equipped with an internal piezo and five status LEDs that provide instant audible and visual notification of system status changes. Refer to Fike document 06-610, for more information. Note: This unit can only be used on systems with panel Exhibit 3-32: Two Button firmware V3.0 or higher. -

Page 41: Intelligent Graphic Annunciator

When an event occurs, the intelligent data will be transferred via the RS485 output to the graphic and the specific device or zone LED will light as programmed. Refer to Fike document 06-231, for more information. Exhibit 3-35: Graphic Annunciator 3.6.7 FIREFIGHTER’S SMOKE CONTROL STATION (FSCS) -

Page 42: Twenty Zone Remote Annunciator

Upon receipt of confirmation, the LED will transition from flashing to continuously on. The card is designed to mount directly to Fike’s dead-front door panels. Refer to Fike document 06-444, for more information. -

Page 43: Twenty Zone Annunciator Card (Panel Mount)

Exhibit 3-41: Audio Control Card Refer to Fike document 06-558, for more information. 3.6.13 FIRE-PHONE CARD, P/N 10-2728 The Fire-Phone Card (See Exhibit 3-42) is used with Fike’s voice alarm communication system. It provides twenty configurable switches that can be used to selectively connect system fire phones to the voice systems fire-phone bus. -

Page 44: Fire-Phone Card

(P/N 10-2728) to add an additional twenty (20) control switches for the addressable firefighter’s phone system. The card is designed to mount directly to Fike’s dead-front door panels. Refer to Fike document 06-560, for more information. Exhibit 3-43: Supplemental Fire-Phone Card 3.6.15 AMPLIFIER ASSEMBLY, P/N 10-2773-P... -

Page 45: Relay Control Assembly

Exhibit 3-46: Relay Control Assembly 2769), and Interface Cable (P/N 10-2784). The CRM4 and HPM4 relay modules must be ordered separately. Refer to Fike document 06-580 and 06-443, for more information. Note: The HPM4 relay card (See Exhibit 47) is compatible with the Relay Control Assembly only. -

Page 46: Fcc Digital Paging Assembly

The assembly includes the FCC digital paging card (P/N 10-2727), paging control card (P/N 10-2741), and master paging microphone (P/N 10-2757). Refer to Fike document 06-564 for more information. The digital paging assembly is designed to be mounted within the fire command center enclosure. -

Page 47: Local Operating Console

LOC digital paging card (P/N 10-2816), paging control card (P/N 10-2798), and paging microphone (P/N 10- 2813). Refer to Fike document 06-613 for more information. The LOC is designed to be strategically mounted throughout the facility to give authorized personnel and emergency responders remote microphone and operational control capabilities over the voice system. -

Page 48: Intelligent Detectors

SLC devices as well to facilitate peer to peer system operation. A brief description of each intelligent detector and its features is provided in this section for reference purposes. Refer to Fike document P/N 06-326-2, “CyberCat Operations Manual” for details of detector operation and available programming features. -

Page 49: Photo/Heat Combination Detector

3.0 SYSTEM COMPONENTS 3.7.3 PHOTO/HEAT COMBINATION DETECTOR, P/N 63-1053 PHOTO/HEAT DETECTOR WITH ISOLATOR, P/N 63-1059 The Photo/Heat Detector (See Exhibit 3-55) is an intelligent, spot- type smoke detector that utilizes the light obscuration principle to detect smoke. In addition to the photoelectric sensing chamber, the detector is equipped with a thermistor based, 135°F heat detection circuit. -

Page 50: Photoelectric Duct Detector

3.0 SYSTEM COMPONENTS 3.7.5 PHOTOELECTRIC DUCT DETECTOR, P/N 63-1057 PHOTOELECTRIC DUCT DETECTOR WITH ISOLATOR, P/N 63-1062 The Photoelectric Duct Detector (See Exhibit 3-57) is an intelligent, spot-type smoke detector that utilizes the light obscuration principle to detect smoke. The detector is designed for use inside the duct detector housing only and should not be used for open area applications. -

Page 51: Faast Aspirating Smoke Detector

3.0 SYSTEM COMPONENTS 3.7.6 FAAST ASPIRATING SMOKE DETECTORS STANDARD FAAST UNIT, P/N 68-140 FAAST XT UNIT, P/N 68-302 The FAAST aspirating smoke detectors (See Exhibit 3-59) are intelligent air sampling-type smoke detectors that continuously draw air from the controlled environment through a series of sampling holes to monitor the environment for smoke particulate. -

Page 52: Detector Bases

3.0 SYSTEM COMPONENTS DETECTOR BASES Several detector bases are available to allow connection of the addressable detectors to the panel’s signaling line circuits (SLC). Each base provides a twist-lock feature for securing the detector to the base. Each base also provides a connection point for an optional Remote LED (P/N 02-3868), as described in Section 3.9. A brief description of each detector base and its features is provided in this section for reference purposes. -

Page 53: Remote Testing And Notification Accessories

3.0 SYSTEM COMPONENTS REMOTE TESTING AND NOTIFICATION ACCESSORIES The following accessories add functionality to the CyberCat detection system by allowing quick, convenient inspections at eye level and effective audible and visual notification options. 3.9.1 REMOTE ANNUNCIATOR, P/N 02-3868 (System Sensor RA100Z) The remote annunciator (See Exhibit 3-64) can be used with any of the CyberCat detector bases, including the duct detector housing. -

Page 54: Addressable Modules

SLC devices as well to facilitate peer to peer system operation. A brief description of each addressable module and its features is provided in this section for reference purposes. Refer to Fike document 06-326-2, “CyberCat Operations Manual” for details of module operation and available programming features. -

Page 55: Monitor Module

Refer to Fike manual 06-467, “Conventional Zone Module Compatibility Document” for a list of detectors and bases approved for use with the module. -

Page 56: Supervised Control Module

2 amps maximum at 24VDC. The Solenoid Protection Assembly (See Exhibit 3-73) must be used when connecting a solenoid to the SCM. Refer to Fike document 06-186 for compatible sprinkler solenoids (Factory Mutual Approved Groups A-G). Refer to Fike document 06-344, for more information. -

Page 57: Relay Module

It should be powered via the CyberCat 50 panel’s 24VDC continuous auxiliary power. Refer to Fike document 06-158, for more information. Exhibit 3-76: VESDA HLI 3.12 PROGRAMMING AND CONFIGURATION EQUIPMENT The items discussed in this section are not UL listed; however, one or more of these items must be used to facilitate proper configuration of the CyberCat system. -

Page 58: Hand Held Programmer

3.12.4 INTERFACE CABLE, P/N 10-1874A The 10-1874A interface cable (See Exhibit 3-79) consists of a RJ11 jack, serial cable, and a RJ11 to DB9 connector (wired Fike specific). It should be used when connecting the C-Linx Software to the CyberCat using a computer with a DB9 serial (com) port. -

Page 59: Batteries And Battery Enclosures

Conduit knockouts are provided to provide entry of battery wiring. The box lid is installed onto the back-box using the 4 mounting screws provided. Refer to Fike document 06-534, for more information. 3.13.3.2 75AH BATTERY ENCLOSURE (BATTERIES NOT INCLUDED) - Page 60 3.0 SYSTEM COMPONENTS Reserved for future use. 3-40 CyberCat 254/1016 Installation Manual UL S2203 Rev 14, 09/2015 P/N: 06-326...

-

Page 61: Installation

Section 4.19 SELECT THE ENCLOSURE MOUNTING LOCATION The mounting location for the CyberCat system enclosure(s) is very important. Fike recommends that all system enclosures be installed in an area that is readily accessible with sufficient room to allow easy installation and maintenance, and that is capable of maintaining a nominal room temperature of 0°-49°C / 32°- 120°F, with a relative humidity of 93 percent. -

Page 62: Select The Enclosure Mounting Option

SELECT THE ENCLOSURE MOUNTING OPTION All of Fike’s system enclosures are designed to be surface or flush mounted. For surface mounting, you will utilize the mounting holes provided in the back of each enclosure to secure it to the wall. For flush mounting, you will need to cut an opening in the wall to fit the back-box dimensions (See Exhibits 4-1 &... -

Page 63: Standard Enclosure Dimensions

15.34 in [38.97 cm] 18.72 in [47.55 cm] 9.88 in [25.10 cm] 16.47 in [41.83 cm] Note: Refer to Fike document 06-480, “Standard CyberCat Enclosure Installation Instructions” for further details. UL S2203 CyberCat 254/1016 Installation Manual P/N: 06-326 Rev 14, 09/2015... -

Page 64: Fcc Enclosure Dimensions

38.00 (96.5) 3.95 (10) 23.59 (60) G 40.00 (101.6) 21.42 (54.4) 9.88 (25.1) Note: Refer to Fike document 06-570, “Fire Command Center Enclosure Installation Instructions” for further details. CyberCat 254/1016 Installation Manual UL S2203 Rev 14, 09/2015 P/N: 06-326... -

Page 65: Wire Selection

P3 – Computer Interface Connection P21 – Supplemental Power Supply AC Power Input P4 – VESDA HLI Interface Connected to power-limited or non-power-limited field wiring, P5 – Fike Guard Interface but not both. P6 – RS-485 Peripheral Buss P7 – Auxiliary Power P8 &... -

Page 66: Verify Field Wiring

4.0 INSTALLATION VERIFY FIELD WIRING The integrity of the field wiring shall be tested before installing field devices or landing the field wiring to the system controller. With the end of each circuit open, the following tests shall be conducted: 1. -

Page 67: Connect Ac Power To The Transformer

4.0 INSTALLATION PRIMARY SECONDARY XFMR XFMR PRIMARY SECONDARY XFMR XFMR Exhibit 4-4: Standard Enclosure Transformer Mounting Locations Exhibit 4-5: Fire Command Center Enclosure Transformer Mounting Locations 4.10 CONNECT AC POWER TO THE TRANSFORMER System AC line power (120 VAC or 240 VAC, 50/60 Hz) must originate from a dedicated circuit at the main building power distribution center. -

Page 68: Connect Ac Power To Transformer

4.0 INSTALLATION Caution Never swap transformer Primary (H1 and H2) and Secondary (X1 and X2) by connecting AC feed to secondary terminals. Doing so will cause the transformer to step-up the power resulting in certain damage to the controller. 4. Install the AC ground wire (G) under the transformer onto the mounting stud identified with a grounding sticker. -

Page 69: Install Optional Modules

4.0 INSTALLATION 4.11 INSTALL OPTIONAL MODULES Several optional modules can be installed onto the CyberCat controller to expand its operational capabilities. The modules contain static sensitive components; therefore, handle them by the edges only and avoid touching the integrated components. Keep each module in the protective static bag it was shipped in until time for installation. -

Page 70: Install The Controller

4.0 INSTALLATION 4.12 INSTALL THE CONTROLLER Fike recommends that the system electronics not be installed until after all construction cleanup has been completed in order to avoid potential damage due to dust and debris. Before installing the CyberCat controller, thoroughly clean the enclosure to remove any dirt, dust, and debris. -

Page 71: Mounting The Controller

4.0 INSTALLATION 3. Align the mounting holes provided in the four corners of the controller board with the stand-offs and secure in place using the four hex-nuts supplied with the enclosure as shown in Exhibit 4-11. Do NOT install a hex nut on the center stand-off. Exhibit 4-11: Mounting the Controller Exhibit 4-11 depicts the CyberCat controller configuration when installed in a standard enclosure. -

Page 72: Mounting The Extended Display

4.0 INSTALLATION The following general steps shall be used to install the extended display: 1. Install the extended display onto the threaded mounting studs provided on the back of the dead-front door as shown in Exhibit 4-12 and secure in place with four 6-32 hex nuts. 2. -

Page 73: Connect The Ac Power To The Controller

4.0 INSTALLATION 4.13 CONNECT AC POWER TO THE CONTROLLER WARNING AC power connections to the CyberCat Controller must be made with the main power breaker locked out. The following general steps shall be used to connect AC power to the controller: 1. -

Page 74: Install Batteries

4.0 INSTALLATION 4.14 INSTALL BATTERIES The CyberCat enclosure is capable of housing up to two (2) 18 AH batteries. Where larger or additional battery Amp-Hours are required, a separate battery cabinet can be installed to house the batteries. The battery cabinet must be installed in the same room as the control panel with a maximum wire length of 10 ft. (3 m). -

Page 75: Apply Power To The Panel

4.0 INSTALLATION 4.15 APPLY POWER TO THE PANEL Prior to connecting any field wiring to the panel, apply power the controller and verify proper operation. The following general steps shall be used to apply power to the controller: 1. Insert (P1) and (P21) terminal blocks to the controller and supplemental power supply (SPS), if applicable. -

Page 76: Connect Field Wiring

(P3) PANEL PROGRAMMING INTERFACE (P4) VESDA HLI RS-232 INTERFACE (P7) 24VDC AUX. POWER (P5) FIKE GUARD CIRCUIT (RESETTABLE) RS-232 INTERFACE OPTIONAL DACT (P7) 24VDC AUX. POWER (P6) DACT INTERFACE CIRCUIT (CONTINUOUS) -

Page 77: General Relay Wiring

RS232 port (P4) and shall be located within 50 ft. (15.24m) from the control panel. Exhibit 4-17: RS232 Wiring (P3-P5) P5 - dedicated for connection to the Fike Guard voice evacuation system. Fike Guard is considered a permanent connection to the RS232 port (P5) and shall be located within 50 ft. -

Page 78: Auxiliary Power Wiring

4.0 INSTALLATION P6 (DACT) is dedicated for connection of the optional internal Fire Communicator as shown in Exhibit 4-19. Refer to Fike document 06-479 for more details. Exhibit 4-19: (P6) RS485 DACT Wiring 4.16.4 AUXILIARY POWER WIRING (P7) The panel provides one power-limited 24VDC, resettable power output (two leftmost contacts on P7) as shown in Exhibit 4-20. -

Page 79: Slc Wiring

4.0 INSTALLATION 4.16.5 SIGNALING LINE CIRCUIT WIRING (P8 & P9) Communication between the control panel and each intelligent, addressable device takes place through a Signaling Line Circuit (SLC). The SLC is supervised and power-limited. Exhibits 4-21, 4-22 and 4-23 illustrate how to wire the SLC loop to meet the requirements of NFPA Class B, Class A, or Class X circuits. For details on how to wire each addressable device to the SLC loop, refer to the installation instructions supplied with each device. -

Page 80: Class X Wiring

4.0 INSTALLATION 4.16.5.2 CLASS A OR CLASS X WIRING Exhibit 4-22 shows typical wiring of a supervised and power-limited four-wire SLC that meets NFPA 72, Class A requirements. This wiring method includes a redundant path. In the event of a single wire break, the communication to devices after the break continues. -

Page 81: Notification Appliance Circuit Wiring

P10 and P11 are two separate notification appliance circuits (NAC’s) that provide the ability to activate compatible, UL-listed notification appliances listed in Fike document 06-186, “Device Compatibility manual”. The NAC circuits are supervised, power-limited, and can be wired Class B (using 1.2K EOL) or Class A (no EOL), as shown in Exhibits 4-24 and 4-25. -

Page 82: Initial Power-Up With Field Wiring Connected

AUTO PROGRAM or ENGINEERED CONFIGURE. Any combination of these two methods may also successfully accomplish matching the field devices to the installation configuration requirements. Refer to Fike Document 06-539, “CyberCat Programming Manual” for specific details on how to configure the system. -

Page 83: Appendix A Battery Calculation Form

APPENDIX A Power calculations must be completed to determine standby and alarm current loads for the system to ensure that the system power supply is capable of providing the required quantity of power during normal system operation and fire alarm conditions. The power requirements cannot exceed the capabilities of the system power supply. - Page 84 1.2 represents a battery derating factor of 20 percent. CyberCat 254 and 1016 control panels can support charging up to 75 AH standby batteries. The CyberCat 1016 panel with the SPS installed can support charging up to an additional 75 AH set of batteries for a system total of 150 AH.

- Page 85 APPENDIX A Section 3 – Auxiliary Power (CSC + SPS) Total Standby Alarm Total Alarm Standby Current per Current per Current per Current per Item Device Description Unit (Amps) Unit (Amps) item (Amps) item (Amps) 68-140 FAAST 0.500 0.650 68-302 FAAST XT 0.500 0.650 55-042/047 SCM w/ Solenoid...

- Page 86 APPENDIX A Include current draw of all notification appliances connected to the CyberCat’s two on-board notification appliance circuits (NAC 1 & 2), and to addressable Supervised Control Modules that are receiving 24vdc power from the CyberCat system controller or the supplemental power supply. Section 4 –...

-

Page 87: System Operation Posting

CyberCat system. The completed “System Operation Posting” shall either be mounted on the cabinet front or framed and located adjacent to the control unit. It can be downloaded from Fike’s Customer Portal web page, document P/N 06-632. - Page 88 APPENDIX B Reserved for future use. CyberCat 254/1016 Installation Manual UL S2203 Rev 14, 09/2015 P/N: 06-326...

-

Page 89: Operating Instructions

OPERATING INSTRUCTIONS ® CyberCat Control System (P/N 10-064/10-066) Commercial Protected Premises Control Unit Local, Auxiliary, Remote Station (PPU), Central Station (PPU), and Releasing Service These instructions must be framed and displayed next to the panel in accordance with NFPA 72, National Fire Alarm Code for Local Fire Alarm System. - Page 90 Remove AC and battery power before when all trouble conditions are cleared. performing any repair or service work on the control panel. Refer to Fike document 06-326-2, “CyberCat Operation and Supervisory – Yellow LED that flashes when the panel enters Maintenance Manual” for maintenance instructions.

-

Page 91: Appendix C Compatible Components

Exhibit C-1: Compatible Components Part Number Description CyberCat 1016 Control Board and Display (included with 10-064 system) 10-2472-exd -exd: display for dead-front panel (blank for all other systems) CyberCat 254 Control Board and Display (included with 10-066 system) - Page 92 10-2482 RS485 Network Module 10-2624 Fiber Optic Network Module The 10-2474-p Supplemental Power Supply (SPS) and 10-2473, Supplemental Loop Module (SLM) are only compatible with the CyberCat 1016 product. CyberCat 254/1016 Installation Manual UL S2203 Rev 14, 09/2015 P/N: 06-326...

- Page 93 APPENDIX C Exhibit C-3: Compatible Components – Cont. Part Number Description PERIPHERAL BUS DEVICES 10-2646 14-Button Expanded Protocol Remote Display Unit 10-2631 10-Button Expanded Protocol Remote Display Unit 10-2630 2-Button Expanded Protocol Remote Display 10-2627 Ethernet Module 10-2583 Multi-Interface Module 10-1XXX Intelligent LED Graphic Annunciators 10-2XX...

- Page 94 APPENDIX C Exhibit C-4: Compatible Components – Cont. Part Number Description INTELLIGENT DETECTORS 63-1052 Photoelectric Detector 67-033 Ionization Detector 63-1053 Photo/135° F Heat Combination Detector 60-1039 Intelligent Heat Detector, 135°-190° F (57°-88° C) Fixed Temp./ Rate of Rise 63-1054 (EBF) Detector Base, 6 inch (System Sensor) 63-1055 (EB) Detector Base, 4 inch (System Sensor)

- Page 95 APPENDIX C Exhibit C-5: Compatible Components – Cont. Part Number Description VESDA INTERFACE 68-023 VESDA Open Protocol High Level Interface (HLI) PROGRAMMING AND CONFIGURATION 55-051 Infrared (IR) Tool Remote Control for Programming/Testing Devices (non-listed) 10-2648 CyberCat Addressable Device Hand Held Programmer (non-listed) 06-327 C-Linx Software (non-listed) 10-1874A...

- Page 96 Signal Red – RAL 3001 per RAL 840-HR (Matt Finish) Black to Jet Black – RAL 9005 per RAL 840-HR C.1.2 NOTIFICATION APPLIANCES Refer to Fike document 06-186 for Compatible Notification Appliances. C.1.3 FACTORY MUTUAL APPROVED RELEASING SOLENOIDS Refer to Fike document 06-186 for compatible Releasing Devices.

-

Page 97: Appendix D Battery Cutoff

APPENDIX D BATTERY CUTOFF Exhibit D-1 below shows the components used to facilitate the battery cutoff arrangement for Fike’s CyberCat control panel. CONTROL PANEL BATTERY 24 VDC AUXILIARY CONNECTION POWER OUTPUT RELAY SLC IN SLC OUT MULTI VOLTAGE RELAY P/N 20-1173... - Page 98 APPENDIX D Reserved for future use. CyberCat 254/1016 Installation Manual UL S2203 Rev 14, 09/2015 P/N: 06-326...

- Page 100 704 SW 10 Street Tel: (816) 229-3405 P.O. Box 610 Fax: (816) 229-0314 Blue Springs, Missouri 64013 www.fike.com...

Need help?

Do you have a question about the CyberCat 1016 and is the answer not in the manual?

Questions and answers