Summary of Contents for Biotek 50 TS

- Page 1 50™ TS Washer Instructions for Use (For In Vitro Diagnostic Use) April 2017 © April 2017 Part Number 1551010 Revision A BioTek Instruments, Inc.

- Page 2 BioTek Instruments, Inc. Changes made to the information in this document will be incorporated in new editions of the publication. No responsibility is assumed by BioTek for the use or reliability of software or equipment that is not supplied by BioTek or its affiliated dealers.

-

Page 3: Contact Information

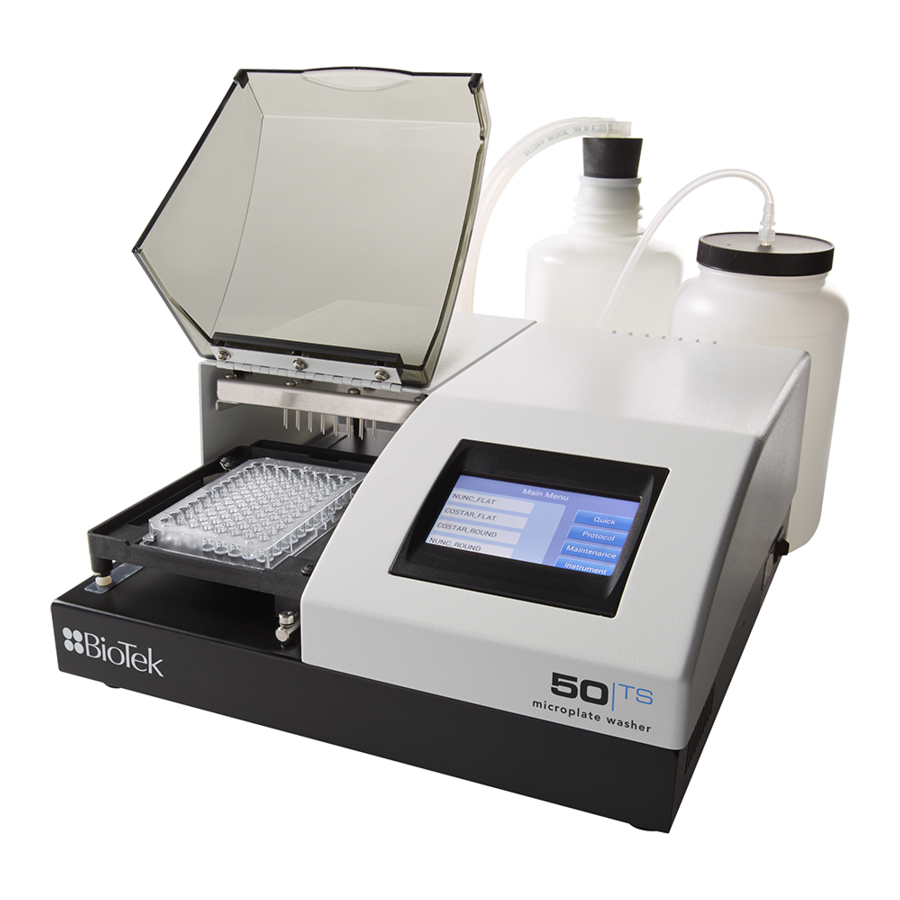

50™ TS Washer Operator’s Manual. Intended Use Statement • The 50™ TS Washer provides microplate priming, dispensing, and washing for ELISA™, fluorescence and chemiluminescence immunoassays, cellular and agglutination assays. BioTek Instruments, Inc. - Page 4 iv | Preface • If the instrument has an “IVD” label it may be used for clinical and non-clinical purposes, including research and development. If there is no such label the instrument may only be used for research and development or other non-clinical purposes Quality Control It is considered good laboratory practice to run laboratory samples according to instructions and specific recommendations included in the assay package insert for...

- Page 5 Warning! Lubricants. Do not apply lubricants to the microplate carrier or carrier track. Lubricant on the carrier mechanism will attract dust and other particles, which may obstruct the carrier path and cause the instrument to produce an error. BioTek Instruments, Inc.

- Page 6 Precautions The following precautions are provided to help avoid damage to the instrument: Caution: Service. The instrument should be serviced by BioTek authorized service personnel. Only qualified technical personnel should perform troubleshooting and service procedures on internal components.

- Page 7 70% ethyl, isopropyl, or methyl alcohol, 40% formaldehyde, and 20% sodium hydroxide. Never use acetic acid, DMSO, or other organic solvents. These chemicals may cause severe damage to the instrument. Contact BioTek for more information and prior to using other questionable chemicals.

- Page 8 (e.g., unshielded intentional RF sources), because these may interfere with the proper operation. Caution: Use BioTek-Provided Bottles Only. Do not substitute the fluid supply and waste bottles provided by BioTek with other commercially-available bottles.

- Page 9 Directive 98/79/EC: In Vitro Diagnostics (if labeled for this use) • Product registration with competent authorities. • Traceability to the U.S. National Institute of Standards and Technology (NIST). • EN 61010-2-101 Particular requirements for in vitro diagnostic (IVD) medical equipment. BioTek Instruments, Inc.

-

Page 10: Safety Symbols

x | Preface Safety Symbols Some of these symbols appear on the instrument or accessories: Alternating current Both direct and alternating current Courant alternatif Courant continu et courant alternatif Wechselstrom Gleich - und Wechselstrom Corrientealterna Corriente continua y corrientealterna Correntealternata Corrente continua e correntealternata Direct current Earth ground terminal... - Page 11 | xi Consult instructions for use Consulter la notice d’emploi Gebrauchsanweisung beachten Consultar las instrucciones de uso Consultare le istruzioni per uso BioTek Instruments, Inc.

- Page 12 Installation This section provides detailed installation instructions. Unpack and Inspect the Instrument ........... 2 Setting Up the 50 TS ................3 Connect the Fluid Supply and Waste System ........4 Install the Microplate Carrier ............13 Attach the Mist Shield ..............15...

-

Page 13: Unpack And Inspect The Instrument

BioTek will arrange for immediate repair or replacement of your instrument. Unpack the accessories and the washer. Washers are shipped with two or three 2-liter supply bottles and one 2-liter waste bottle. The 50 TS with Buffer Switching (“V” version) includes three supply bottles. -

Page 14: Setting Up The 50 Ts

Important: The manifold dispense tubes have a protective Teflon collar at the tip. This is to prevent dripping. Do not remove these coverings! Operating Environment The 50 TS washer is sensitive to extreme environmental conditions. For optimal operation, install the washer: •... -

Page 15: Connect The Fluid Supply And Waste System

Connect the Fluid Supply and Waste System Caution. The washer manifold, the vacuum port, and the supply Finger-tighten only!! bottles have Luer fittings. Place the supply and waste bottles on the same horizontal plane as the washer. This ensures optimum pump performance. ... - Page 16 5” (12.7 cm) from the check valve. Reinsert the Luer fitting and connect it to the port on the Valve Output back of the washer. Fluid supply with Buffer Switching: tubing connects to internal valves BioTek Instruments, Inc.

- Page 17 5. Connect the three supply bottles, A, B, C, to their respective ports. 50™ TS Washer...

- Page 18 Connect the Waste System Finger-tighten only all fittings! All 50 TS models except 8MF, 8M, 8F: Connecting the Waste system tubing on the back of the washer 1. Remove the waste bottle cover and replace it with the stopper from the waste tubing set.

- Page 19 Vacuum 50 TS/8F, 8M, 8MF models (for vacuum filtration) Installing the Waste system for vacuum filtration models: 8F, 8M, and 8MF models. 1. Attach the Y-shaped tubing to the two waste ports on the back of the wash manifold (two center ports).

- Page 20 Waste. 1. If you have not already done so, connect the waste and fluid supply bottles as described on the previous pages. 2. Connect the cables from the supply and waste bottles to the select box: BioTek Instruments, Inc.

- Page 21 10 | For washers with Buffer Switching, connect the supply bottle cables to the appropriate ports in the select box. If a port is left empty, insert one of the supplied “shorting plugs” (all ports must be filled). For washers without Buffer Switching, connect the supply bottle cable to port A and then insert the shorting plugs into ports B and C.

- Page 22 2. Place the manifold gently onto the two support pins on the manifold mounting bracket closest to the front of the washer. 3. Insert the thumbscrews (2). Do not overtighten. See also Connect the Fluid Supply and Waste System page 4 descriptions of the manifold tubing connections. BioTek Instruments, Inc.

- Page 23 12 | Install the 8,16-Well Manifold Secure the 16 Well manifold on the 3 posts with the 3 thumb screws. 1. Orient the manifold with the aspirate and dispense tubes facing down, and the fittings for the supply and waste tubing facing the back of the washer.

-

Page 24: Install The Microplate Carrier

2. Line up the pin on the underside of the carrier with the slot on the carrier transport rail and install the carrier. Rail guides under the carrier sit on rail. Standard microplate carrier with plate. Carrier base for biomagnetic separation and vacuum filtration plate carriers. BioTek Instruments, Inc. - Page 25 14 | Vacuum Filtration and Biomagnetic Separation Carrier The 50 TS: “F” or “M” models ship with one or two microplate carriers which fit into the microplate carrier base. Vacuum filtration plate carrier Biomagnetic separation plate carrier 1. Install the microplate carrier base as described above; except 8F models: the vacuum filtration carrier is already attached to the carrier base.

-

Page 26: Attach The Mist Shield

3. Vacuum Filtration models: make sure there is sufficient room behind the washer for the waste tubing attached to the special carrier to move during operation. Attach the Mist Shield The mist shield is also called the aerosol cover. BioTek Instruments, Inc. - Page 27 16 | Mist Shield: open 1. Insert the two thumbscrews into the slots on the washer’s left side. Do not tighten completely. 2. With the door toward the front of the washer, slide the mist shield down onto the thumbscrew shafts while inserting the two pins into the slots on the top left side.

- Page 28 2. Insert the power cord into the power supply and into an appropriate wall outlet. Verify Performance Before using the 50 TS washer for the first time, verify that it is operating properly by turning the washer on. Turning on the washer initiates a system BioTek Instruments, Inc.

-

Page 29: Optimize Performance

If the Error Codes on page 1 problem is something you can fix, turn off the washer, fix the problem, and then turn the washer back on. Otherwise, contact BioTek’s Technical Assistance Center. provides recommended procedures to... - Page 30 Section 3 Getting Started This section introduces the basics of operating the 50 TS. For more detailed and comprehensive instructions, please refer to the operator's manual. AutoPrime ..................2 Wash a Plate ..................4 Optimize Performance ................ 7 Run a Predefined Protocol ..............8 Create a Protocol ................

- Page 31 Quick Prime Select Quick>Prime BioTek defines two types of prime: • Manifold: uses a smaller amount of fluid to condition the dispense tips. Priming Press the “ ” button to run a manifold prime immediately before a wash or dispense step...

- Page 32 • will trigger priming; up to 24 hours. Submerge • Set the Duration , if desired. Flow rate, volume, and • buffer valve, if applicable. 3. LHC users: click Send transfer the settings to the instrument. BioTek Instruments, Inc.

- Page 33 Wash a Plate Two ways to wash a plate: • Quick Wash: use the Quick menu to wash strips or a plate using default instrument settings. • Protocol: run a predefined wash protocol: touch your choice on the Main Menu. Protocols let you customize the wash parameters to improve assay...

- Page 34 4. Press Wash Protocol Predefined protocols, including sample protocols provided with the 50 TS reside on the Main Menu. Touch a protocol to run it. See Create a Protocolon page 13. If more precise positioning of the aspirate tubes, more or fewer wash cycles, or a slower aspirate travel rate would improve your results, e.g.

-

Page 35: Run A Predefined Protocol

Minimally, a wash protocol has one wash cycle, which is an aspirate step followed by a dispense step. By default, the 50 TS’s wash protocol has three wash cycles followed by a Final Aspirate step. You can customize the wash... - Page 36 Maintenance chapter. Vacuum Inline Filter: Installing the hydrophobic inline vacuum filter before using the 50 TS is strongly recommended. Before Running the Washer • Fill the wash/rinse bottles with sufficient fluid. Make sure the supply tube is in the liquid.

- Page 37 Main Menu Maintenance qualification (QC) protocol. Running a Protocol When you run a protocol on the 50 TS the following prompt may appear, depending on the type of protocol. 50™ TS Washer...

- Page 38 BioTek installs these predefined protocols onboard compatible 50 TS models. Run predefined protocols from the Main Menu (Home). Protocol settings have been optimized based on experience in our applications lab. Sample Wash Protocols for all 50 TS Models with 8, 8s, and 12 Well Manifolds: Protocol Name...

- Page 39 Aspirate Height: Z Offset Aspirate Position: Y Offset Aspirate Rate Aspirate Delay Crosswise Aspiration Final Aspirate Final Aspirate Delay Sample Wash Protocols for all 50 TS Models with 8,16 Well Manifolds: Protocol Name COSTAR_ COSTAR_ NUNC_ NUNC_ FLT16_96 FLT16_384 FLT16_96...

- Page 40 Bottom Wash First Prime Before Start Prime Volume Prime Flow Rate Aspirate Height Horizontal Aspirate Position Aspirate Rate Aspirate Delay Crosswise Aspiration Final Aspirate Final Aspirate Height Final Horizontal Aspirate Position 0 Final Aspirate Rate Final Aspirate Delay BioTek Instruments, Inc.

- Page 41 12 | Qualification Protocols Maintenance Select the menu on the Home screen. DISPENSE µL/well Dispense Height (Z) Flow Rate accuracy_qc_test accur_qc_test384 ASPIRATE Height (Z) Asp Horizontal (Y) Travel Rate residual_qc_test resid_qc_test384 Vacuum Filtration Volume: µL/well Flow Rate VAC30 Maintenance Protocols MAINTENANCE DAY_RINSE DECONTAMINATION...

-

Page 42: Create A Protocol

3. Enter a unique name for the new protocol. 4. Select the Plate Type press Save 5. Press and select the type of action to perform. 6. Define the parameters for the step and add more steps, as needed. BioTek Instruments, Inc. - Page 43 14 | To fine-tune a protocol to improve assay performance, select the protocol Edit and press at the Protocol Definition screen. Then, select the step and press Edit to modify its parameters. Press Info to change the protocol’s name or plate type. Select a step and then use the Copy, Paste, and Save time by Cut buttons as needed to add, remove or...

- Page 44 Bottom Flow Rate, Bottom Dispense Height, Bottom Horizontal Position, Prime Before Start, Prime Volume, Prime Flow Rate. Aspirate Height, Horizontal Aspirate Position, Aspirate Rate, Aspirate ASPIR Delay, Crosswise Aspirate, Crosswise On, Crosswise Height, Crosswise Horizontal Position, Final Aspiration, Final Aspirate Delay. BioTek Instruments, Inc.

- Page 45 16 | Wash Protocol Parameters Method Action/Description Default Number of One wash cycle includes, at minimum, one aspirate and Cycles dispense sequence. Other options added to the protocol, like shake and soak, are also performed in each cycle. Pre-prime, when selected, is performed one time before the wash cycles. Bottom Wash adds another cycle to the protocol when enabled.

- Page 46 180-60. The washer displays the corresponding millimeters. A negative offset moves the dispense tubes back, away from the front of the washer. A positive offset moves the dispense tubes toward the front of the washer. A setting of 0 indicates no offset. BioTek Instruments, Inc.

- Page 47 18 | Options Actions Default Bottom Wash First? Specify bottom wash parameters to position the manifold deep in the well. For example, set the Bottom Bottom washing adds Disp Height to between 30-50 steps. Reagent is an initial aspirate- dispensed and aspirated simultaneously at this height dispense sequence to to create cleaning turbulence.

- Page 48 The valid range is 0 to 5000 milliseconds. The delay applies to the normal (initial) aspiration when Secondary (aka Crosswise) Aspirate is disabled. If Secondary Aspiration is enabled, the delay applies to the second, not the initial, aspiration. BioTek Instruments, Inc.

- Page 49 20 | Options Actions Default Secondary A secondary or crosswise aspiration is a two-step aspirate aspiration. The wells are first aspirated at the horizontal (Crosswise) aspirate position. The aspirate tubes rise a fixed number of steps and then do a second aspiration at the secondary position.

- Page 50 System Startup To turn on the 50 TS, press the on/off switch on the right side of the base. The 50 TS performs a self-test each time it is started. If the self-test fails, the washer will beep and display an error code. Note the error code and then press to stop the beeping.

- Page 51 22 | 3. Name the new protocol, choose the plate type and press Save 4. Select to "Add" or “Edit” steps or otherwise change the protocol. Edit Press when finished. Exit When editing a protocol, press Info to change the protocol’s name or plate type.

-

Page 52: Instrument Configuration - Setup Controls

AutoPrime Instrument Settings Manifold Selection Your 50 TS was initially configured for and shipped with a wash manifold. The washer’s manifold setting must match the type of manifold installed on the instrument. If you change the hardware, you must also change the setting. - Page 53 Clearance Liquid Level Sensor 50 TS washers support Liquid Level Alert: with a level sensing device inside the supply and waste bottles. The sensor is activated when a supply bottle’s fluid level drops to approximately 400-450 mL and the waste bottle’s fluid level rises to approximately 1400-1450 mL.

- Page 54 | 25 wash buffers that are prone to harden or crystallize. See AutoPrime on page BioTek Instruments, Inc.

- Page 55 Section 4 Maintenance This section contains recommendations for maintaining the 50 TS. For more detailed and comprehensive instructions, please refer to the operator's manual. About Maintaining the Washer ............2 Recommended Maintenance Schedule ..........3 Daily Maintenance: Rinse/Soak the Fluid Path ........8 Clean Components................

- Page 56 The schedule summarizes the recommended maintenance tasks, and indicates approximately how often to perform each task. Beyond that, it is difficult for BioTek to recommend a fixed frequency for each task. The risk and performance factors of your assays must determine the frequency with which to conduct these tasks.

- Page 57 Decontaminate the Washer Decontaminate the external surfaces Run DECONTAMINATION Prepare the Washer for Storage or Shipment Run LONG_SHUTDOWN Replace Components Check valves As Needed " " Vacuum filtration carrier gasket BioTek Instruments, Inc.

- Page 58 Prime Programs Most of the onboard programs are predefined Maintenance prime protocols. (Instrument qualification protocols are also run from the Maintenance menu.) Maintenance Program: DAY_RINSE Prime Volume: 60 mL Flow Rate: Soak After Prime? Maintenance Program: RINSE_AND_SOAK Prime Volume: 60 mL Flow Rate: Soak After Prime? Soak Duration:...

- Page 59 60 mL, rate 5, soak 2 Buffer A: 60 mL, rate 5, no soak mins Prime: Buffer B: 60 mL, rate 5, no soak Prompt: "Connect rinse bottle to C" Prime: Buffer C: 60 mL, rate 5, soak 2 mins BioTek Instruments, Inc.

- Page 60 Consider these approximate dead volumes when defining priming values to adequately prime the tubing before running a wash or dispense protocol. BioTek recommends priming with two or three times the dead volume for a dry instrument and when changing fluids. For example: dead volume (20 mL washer + 5 mL manifold) x 2 = 50 mL prime volume.

- Page 61 Washer/Manifold Dead Volume 50 TS without Buffer Switching 20 mL 50 TS with Buffer Switching ("V" models) with full 28” supply tubing 35 mL 50 TS “V” model with supply tubing cut to 8” 25 mL All manifolds except the 2x8 Well manifold...

- Page 62 Daily Maintenance: Rinse/Soak the Fluid Path Maintenance Programs Run these predefined maintenance programs to clean the fluid path. Run these programs daily: See page: page 8 DAY_RINSE OVERNIGHT_LOOP page 9 RINSE_AND_SOAK page 9 Run these programs as needed: See page: LONG_SHUTDOWN DECONTAMINATION page 18...

- Page 63 Removing Protein Residuals and Fungi Growth Important: Solutions containing proteins, such as bovine serum albumin (BSA), will compromise the washer’s performance over time unless a strict maintenance regime is adhered to. Do not use alcohol to flush out BSA. BioTek Instruments, Inc.

- Page 64 10 | BioTek recommends performing the following additional maintenance procedures to thoroughly flush out protein particles and other contaminants from the washer’s fluid path, when necessary: Daily Using PBS or an enzyme-active detergent (like Terg-a-zyme): If the washer will be idle between plates for longer than 45 minutes, flush the proteins from the washer: Fill a supply bottle with PBS and connect it to the washer.

- Page 65 Do not immerse the instrument, spray it with liquid, or use a “wet” cloth. Do not allow the cleaning solution to run into the interior of the instrument. If this happens, contact the BioTek Service Department. Do not soak the touchscreen—this will cause damage.

- Page 66 12 | • Soft-bristled brush Clean the Bottles • Clean the supply and waste bottles with DI/distilled water before the first use, before each refill, and if they have been idle for any length of time. • Accumulated algae, fungi, or mold may require decontamination. Decontaminate the Washer on page 18.

- Page 67 2. Insert the black vent plug into the vent port on the front of the carrier. 3. Select VAC30_TEST 4. When the run is completed, if disinfectant/detergent was used, rerun the protocol once or twice with DI water. BioTek Instruments, Inc.

- Page 68 18 to disinfect the manifold and tubing; • Most importantly: See Clean the Aspirate and Dispense Tubes on page Tools for cleaning dispense and aspirate tubes BioTek provides custom styluses for unclogging dispense and aspirate tubes: Color Manifold Wire Part In Kit PN Diameter Number 50™...

- Page 69 Disconnect the tubing from the back of the manifold. • Remove the thumbscrews that hold it in place. Disassembled 8-channel manifold 2. Use a Phillips screwdriver to remove the metal plate on top of the manifold (eight screws). Remove the gasket (rubber top seal). BioTek Instruments, Inc.

- Page 70 16 | 3. Clean the dispense and aspirate chambers on the manifold top with hot soapy water and a soft-bristled brush. Thoroughly clean the walls of the chambers. 4. Clean the insides of the aspirate and dispense tubes with the appropriate stylus (aspirate or dispense).

- Page 71 6. Remount the manifold and replace the tubing. 7. Replace the mist shield. 8. Run a Prime program using 200 mL. 9. Verify dispenser performance visually or by completing the Dispense Error! Bookmark not defined.. Precision Test 8,16 Well Manifold BioTek Instruments, Inc.

- Page 72 The recommended is at least monthly, and frequency for decontamination before shipment of the instrument to BioTek for calibration or repair. Important! BioTek Instruments, Inc. recommends the use of the following decontamination solutions and methods based on our knowledge of the instrument and recommendations of the Centers for Disease Control and Prevention (CDC).

- Page 73 Commercial bleach is typically 10% NaClO; if this is the case, prepare a 1:20 • dilution. Household bleach is typically 5% NaClO; if this is the case, prepare a 1:10 • dilution. BioTek Instruments, Inc.

- Page 74 20 | Isopropyl alcohol/ethanol is not recommended for removing proteins (such as bovine serum albumin). Do not use stronger bleach solutions than recommended. Extended exposure to • high concentrations of bleach can deteriorate some waste system components. Decontaminate the External Surfaces and Components The bleach solution is caustic;...

- Page 75 While the program is running, you will need to periodically check the display and follow instructions for changing the supply bottles. 4. Flush all the bleach/disinfectant from the instrument by running at least once with DI water. DAY_RINSE BioTek Instruments, Inc.

- Page 76 Section 5 Instrument Testing This section provides guidelines for qualifying the 50 TS. For more detailed and comprehensive instructions, please refer to the operator's manual. About Instrument Qualification ............2 Qualification Schedule ................ 2 Liquid Tests ..................5 Self-Test ..................10 Dispense Precision Test (8, 8s, 2X8, and 12 Well) ......

- Page 77 About Instrument Qualification Instrument qualification for the 50 TS involves three activities: qualifying installation and setup, qualifying wash, dispense and aspirate routines, and qualifying long-term stability. This is referred to as Installation Qualification ), Operational Qualification ( ), and Performance Qualification ( respectively.

- Page 78 Evacuation Efficiency Test: Measures the residual volume per well after • the aspiration aspect of plate washing. The lower the residuals per well, the better the evacuation efficiency of the washer. BioTek Instruments, Inc.

- Page 79 50 TS/8F and 8MF models: Vacuum Filtration Evacuation Efficiency • Test Measures the total residual volume of the plate after evacuation to verify it is performing to specifications. If your washer is equipped with Buffer Switching (“V” models), we recommend performing this additional test annually (starting one year after installation): Annual Buffer Switching Test.

- Page 80 Buffer Switching valve module to ensure that each valve is calibrated to deliver the same volume of fluid. Each valve is calibrated at the factory prior to shipment. The valves are stable over time, thus the recommended test frequency is annually. BioTek Instruments, Inc.

- Page 81 Pipette 1 mL Tween 20 into 1 liter (1000 mL) of deionized water and mix • well, or • Pipette 10 mL of BioTek Solution #1 100X Concentrate Wetting Agent (PN 7773002) into 1 liter of deionized water and mix well. 50™ TS Washer...

- Page 82 Mix 100 mL of Solution #1 with 0.0500 grams of FD&C #1 blue dye, • • Mix 10 mL of BioTek Solution #2 10X Concentrate Blue Test Dye (PN 7773001) with 90 mL of Solution #1 prepared above Solution #3: Dispense Precision Solution Mix 590 mL of deionized water with 10 mL of either Solution #2 prepared •...

- Page 83 Evacuation Efficiency Tests residual_qc_test resid_qc_test384 Aspirate Height: Z Offset 28 steps 3.56 mm 22 steps 2.79 mm Y Offset Position -.91 mm 0 mm Aspirate Travel Rate 5.0 mm/sec 5.8 mm/sec Aspirate Delay 0000 0000 Secondary Aspirate Vacuum Filtration models: 96-well filter plates Protocol VAC30_TEST Aspiration Type...

- Page 84 Secondary Aspirate Dispense Precision Test Accuracy QC Test Dispense Volume 1120 µL/well Dispense Flow Rate Dispense Height: Z Offset 180 steps (22.87 mm) Y Offset Prime Before Start Prime volume and flow rate 5 mL at rate 5 BioTek Instruments, Inc.

- Page 85 10 | Self-Test The Self-Test is performed automatically whenever the instrument is turned on. It can also be performed manually from the Main Menu: Select and press Start. Instrument>Options Self-Test checks the vacuum, manifold, and manifold-to-carrier • movement. If the test passes, the Main Menu is displayed and the washer is ready for use.

- Page 86 4. Read the plate in an absorbance reader (blank on air) using the dual- wavelength method (630-450 nm). Print or export the results. Note: If you are using one of BioTek’s keypad-based readers, such as the ELx800™ or ELx808™, ensure that the reader is not running in Rapid mode.

- Page 87 This is the in grams. Total Dispense Weight The Total Dispense Weight should be 28.8 grams, ±10% (between 25.92 g and 31.68 g). If the weight falls above this range, the valve may be defective. Contact BioTek. 50™ TS Washer...

- Page 88 After cleaning the valve and Decontaminate the Washer tubing, retry the test. If the test continues to fail, contact BioTek. 7. Record results in the “Annual Buffer Switching Module Test” worksheet at the end of this section.

- Page 89 If the test fails a second time: contact BioTek TAC for assistance. Vacuum Filtration Evacuation Efficiency Test This test is designed for 50 TS models with Vacuum Filtration. Install the vacuum filtration plate carrier to perform the test. Perform this test during the...

- Page 90 (630-450 nm), to reduce the influence of scratches and foreign particles that could be in the well. Print or export the results. Note: If you are using one of BioTek’s keypad-based readers, such as the ELx800™ or ELx808™, ensure that the reader is not running in Rapid mode.

- Page 91 This is the in grams. Total Dispense Weight The Total Dispense Weight should be 38.4 grams, ±10% (between 34.56 g and 42.24 g). If the weight falls above this range, the valve may be defective. Contact BioTek. 50™ TS Washer...

- Page 92 After cleaning the See Decontaminate the Washer instrument, retry the test. If the test continues to fail, contact BioTek TAC. 7. Record results in the “Annual Buffer Switching Module Test” worksheet at the end of this section.

- Page 93 Review possible causes of poor aspiration in the Troubleshooting section in • the operator's manual. If the test fails a second time: contact BioTek TAC for assistance. Dispense Precision Test (4 Well Manifold) Important: You must create your own qualification test protocols for this...

- Page 94 • Failure may occur when a microplate other than the recommended 24-well Corning 3524 plate is used. Modify the aspirate height (Z offset) or other parameters to accommodate the different plate geometry. After modifying the protocol, retry the test using a new microplate. BioTek Instruments, Inc.

- Page 95 Review possible causes of poor aspiration in the Troubleshooting section in the operator's manual. If the test fails a second time: contact BioTek TAC for assistance. Create Qualification Protocols for 4 Well Manifold To test the 4 Well manifold, you must create your own protocols. Follow these guidelines: 1.

- Page 96 | 21 Dispense Precision Test Accuracy QC Test Dispense Volume 1120 µL/well Dispense Flow Rate Dispense Height: Z Offset 180 steps (22.87 mm) Y Offset Prime Before Start Prime volume and flow rate 5 mL at rate 5 BioTek Instruments, Inc.

-

Page 97: Specifications

Section 6 Specifications For your convenience this section contains performance and physical specifications. Physical Specifications ............... 2 Performance Specifications ..............4... - Page 98 24-well Vacuum Filtration 96-well The 50 TS Washer functions with microplates and microstrips-in-holders that comply with ANSI/SLAS microplate standards 1-2004, 2-2004, 3-2004, and 4- 2004 with a maximum plate height of .800” (20.3 mm) and flat, round, or “V” bottom microwells. For example, using the 4 Well manifold 24-well Corning 3524 plates are supported.

- Page 99 All manifold types except the 12 Well and 2x8 Well / Models: 16, 16V Vacuum 8 and 8s Well manifolds / "F" and "MF" models Filtration Magnetic bead 8 and 8s Well manifolds / "M" and "MF" models Buffer-switching "V" models receive 3 bottles; non-”V” models receive 2 bottles BioTek Instruments, Inc.

- Page 100 Performance Specifications Dispense Precision Manifold Plate Performance Type Type 8 and 8s 96-well ≤3.0% CV when measured over six 300 µL-per-well dispenses Well of deionized water with 0.1% Tween 20. 12 Well 96-well ≤3.0% CV when measured over four 300 µL-per-well dispenses of deionized water with 0.1% Tween 20.

- Page 101 300 µL of deionized water per well into a (for "F" Millipore® MSHVN4450 96-well 0.45µm plates (PN 98258) and models) vacuum aspirated for 30 seconds at vent diameter 0.047” (no plug) and blotted on a paper towel. BioTek Instruments, Inc.

- Page 102 Throughput (Processing Speed) Testing is performed with the Dispense Rate 9 (Rate 5 for 2x8 Manifold), Aspirate Rate 7 and using a Strip Wash Format. Timing is started when the manifold is over the first strip and is stopped when the last strip has been aspirated.

Need help?

Do you have a question about the 50 TS and is the answer not in the manual?

Questions and answers