Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for ECCI TRACKSTAR 6000

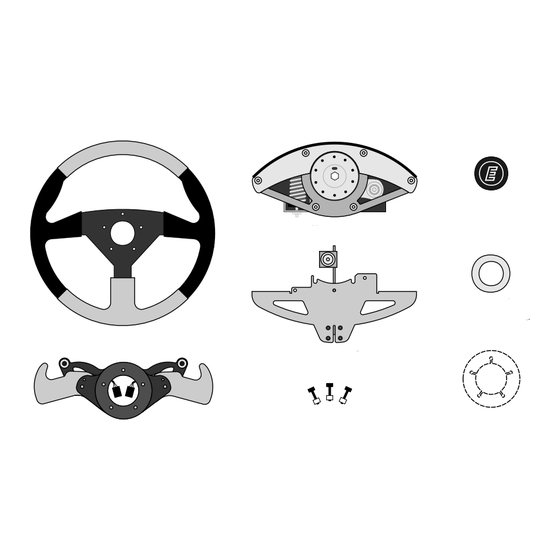

- Page 4 Review the list of wheel unit parts [Figures 1a & 1b] and verify that everything is present to complete assembly. ECCI recommends keeping the original box and packing materials in case the unit needs to be shipped in the future. If shipping is needed, the unit MUST be shipped partially disassembled as originally received, or damage will result.

- Page 8 assembly by putting two screws through the steering wheel at the ten and two o’clock position. Hold the heads in place on the wheel with a piece of masking tape. Note that the flanged button retaining ring must be placed between the steering wheel and the shift paddle set.

- Page 10 COCKPIT MOUNTING In addition to removable desktop mounting, the TRACKSTAR 6000 wheel unit is easily adapted to a custom driving cockpit. When attaching the unit permanently to a fixed framework, the table mounting bracket need not be used. The unit can be mounted directly to the cockpit sub-frame in its upright orientation or inverted under a monitor shelf.

- Page 12 If the user desires more brake pedal pressure resistance than the standard adjustments offer, a Race Brake kit is available from ECCI as an accessory. The Race Brake Kit dramatically increases the hardness of the pedal and the effort to reach full travel from 50lbs of the standard PMB to 145lbs.

- Page 16 A special bracket for the top mount may need to be fabricated. STABILIZING THE PEDAL UNIT The PMBII ECCI also offers an accessory part which locks the pedals in a fixed relationship to a driver’s seat. Called the “Instant Cockpit”, this is a telescoping t-bracket that locks the pedal chassis to the base of any chair.

- Page 20 Up to 240 degrees or travel is available with the Trackstar 6000. With heavier spring settings the role of FLDS is reduced. Most drivers will prefer moderate to light spring settings when using an FLDS equipped system.

- Page 22 STEERING SPRING RESISTANCE ADJUSTMENT The MONOPOINT II system relies on a single spring pack of up to three springs. The springs are designed to rest one inside another. Figure 24 shows the various possible combinations of springs along with recommended preload settings. To adjust overall steering resistance pressure, perform the following steps: Loosen the locknut on the preload adjusting screw underneath the steering unit, directly below the springs [Figure 21].

- Page 24 Momo will provide a very high level of damping resistance. ECCI units have a very different feel than other driving systems and there is a period of user acclimation needed before getting best results from such adjustments.

- Page 26 No driver disk or outside software is necessary. When the unit is plugged in it will be automatically recognized as “ECCI HI-DEF USB” in your operating system and software titles. If you have multiple game controllers, make sure that the ECCI HI-DEF is at the top of the controllers list.

- Page 27 Game Controllers from the menu. The Game Controllers dialog box should appear. Windows should automatically recognize that the ECCI HI-DEF USB controller is connected. If this does not appear check your connections, and if still no control shows up, reboot and start again.

- Page 28 Linked axis mode emulates a simple two-axis joystick. Steering acts on the joystick X-axis and gas and brake pedals work in opposite directions on the ‘Y-axis’. Linked mode is simple to activate. Disconnect the USB plug from the computer and wait ten seconds. Next hold down one of the buttons or paddles on the wheel while you plug the unit back into the USB port.

- Page 29 If this does not get the desired result, you may need to get a heavier PMBII accessory spring from ECCI or the Race Brake Kit. All but a very few users find their optimal setting by just adjusting calibration with the stock spring.

- Page 30 ECCI pots. When replacements are needed order the ECCI HP Racing pots. The USB HD uses a different pot for steering and pedals. Make sure to specify what you need. The steering pot is 100K the pedals use 50K.

- Page 31 If you noticed irregularities in the flow of numbers this might be indicative of a worn pot. To re-set your pot position to fall within range or for instructions on replacing a worn pot consult the ECCI pot service webpage mentioned in step 6.1. CARING FOR YOUR ECCI SYSTEM The exterior surfaces of ECCI systems are powder coated steel with vinyl overlay graphics and for some units a Lexan steering unit cover..

Need help?

Do you have a question about the TRACKSTAR 6000 and is the answer not in the manual?

Questions and answers