Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Ryobi 990r

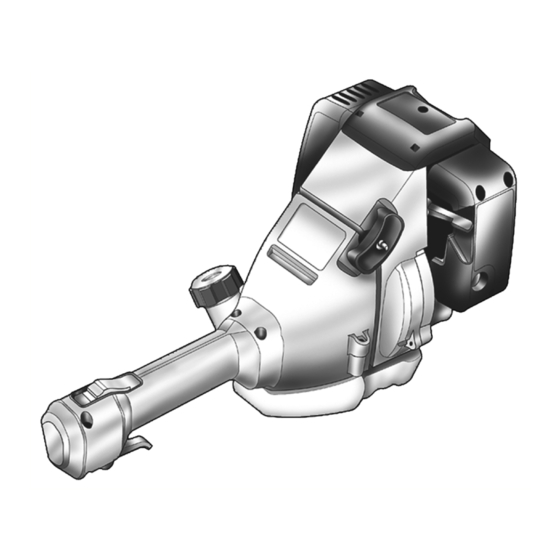

- Page 1 990r OPERATOR’S MANUAL MODEL NO. 990r IMPORTANT MANUAL DO NOT THROW AWAY...

-

Page 2: Table Of Contents

SERVICE INFORMATION Service on this power equipment within and after the warranty period can be performed by any Ryobi Authorized Service Dealer. Dial 1-800-345-8746 in the United States and 1-800-265-6778 in Canada to obtain the listing of servicing dealers in your area. -

Page 3: California Emission Regulations

If fuel has been spilled, allow it to dry completely before starting the engine. • Move the trimmer at least 3 m (10 ft) from the fueling point before starting the engine. • Thoroughly inspect the trimmer for loose or damaged parts before each use. -

Page 4: Safety Warnings For Brush Blade

Do not operate the trimmer with loose or damaged parts. • Use the right tool. Do not use this trimmer for any job except that for which it is intended. • Do not force the tool at a rate faster than it is able to cut effectively. -

Page 5: Safety And International Symbols

SAFETY WARNINGS (Continued) SAFETY AND INTERNATIONAL SYMBOLS This operator's manual describes safety and international symbols and pictographs that may appear on this product. Read the operator's manual for complete safety, assembly, operating and maintenance and repair information. SYMBOL SIGNIFICATION • SAFETY ALERT SYMBOL. Indicates caution, warning or danger. - Page 6 SAFETY WARNINGS (Continued) SYMBOL SIGNIFICATION • PRIMER BULB. Push primer bulb, fully and slowly, 5 to 7 times. • CHOKE CONTROL. FULL CHOKE position. • CHOKE CONTROL. PARTIAL CHOKE position. • CHOKE CONTROL. RUN position. • THROWN OBJECTS AND ROTATING CUTTER CAN CAUSE SEVERE INJURY.

-

Page 7: Assembly Instructions

ADJUSTING THE J-HANDLE The J-handle is shipped completely assembled on Model 990r (Fig. 1). Use the following instructions to adjust the J-handle to the correct operating position. 1. Loosen the four (4) mounting screws on the J-handle. It is not necessary to remove the screws. -

Page 8: Installing The Brush Blade

ASSEMBLY INSTRUCTIONS (Continued) INSTALLING THE BRUSH BLADE 1. Remove the line guard. 2. Insert the locking rod into the locking rod slot. Rotate the line spool clockwise. Remove the line spool and retainer washer from the shaft (Fig. 6). Line Guard Blade Guard Locking Rod Retainer Washer... -

Page 9: Installing The Line Spool

Make sure the blade is flat against the washer after the lock nut is tightened. If the blade is off-center, the trimmer will be damaged by vibration, and the blade may fly off. Failure to obey this warning may cause injury to yourself or others. -

Page 10: Operating Split Boom Coupler

ASSEMBLY INSTRUCTIONS (Continued) OPERATING THE SPLIT BOOM ® COUPLER Model 990r is equipped with a Split Boom ® coupler, which enables optional attachments to be installed on this unit. The optional attachments are: Sweeper/Blower ...SB720r Vacuum ...LV720r Edger ...LE720r Cultivator ...GC720r Straight Shaft Trimmer...SS720r... -

Page 11: Recommended Oil Type

THIS ENGINE IS CERTIFIED TO OPERATE ON UNLEADED GAS ONLY. NOTE: BE SURE TO READ THESE INSTRUCTIONS CAREFULLY BEFORE ATTEMPTING TO START OR OPERATE THIS UNIT. Using old or improper oil or fuel can cause engine damage. This type of damage will void the engine warranty. RECOMMENDED OIL TYPE Using the proper type and weight of oil in the crankcase is extremely important. - Page 12 Change the oil as follows: 1. Remove the oil fill plug / dipstick. 2. Pour the oil into a container by tipping the trimmer in a vertical position (Fig. 18). Be sure to allow ample time for complete drainage. Dispose of oil properly.

-

Page 13: Starting/Stopping Instructions

STARTING/STOPPING INSTRUCTIONS 1. CHECK THE OIL LEVEL IN THE CRANKCASE, AND PUT THE IGNITION SWITCH IN THE "RUN" (I) POSITION. See Figure 20 for the location of the ignition switch. 2. FULLY PRESS AND RELEASE THE PRIMER BULB 5 TO 7 TIMES. See Fig. 21 for the primer bulb location. -

Page 14: Operating Instructions

ADJUSTING THE TRIMMING LINE LENGTH Your trimmer is equipped with a bump head that allows the operator to release more trimming line without stop- ping the engine. To release additional line, lightly tap the trimming head on the ground (Fig. 23) while operating the trimmer at high speed. -

Page 15: Maintenance And Repair Instructions

MAINTENANCE AND REPAIR INSTRUCTIONS MAINTENANCE SCHEDULE These required maintenance procedures should be performed at the frequency stated in the table. They should also be included as part of any seasonal tune-up. FREQUENCY Daily or Before Fill fuel tank. Starting Check oil level. Engine Every Change oil after initial use. -

Page 16: Line Installation

MAINTENANCE AND REPAIR INSTRUCTIONS (Continued) LINE INSTALLATION The trimming line may be replaced by two different meth- ods - rewinding the existing reel or installing a prewound reel. REWINDING THE EXISTING REEL To rewind the existing reel you must: 1. Check for the correct line size. 2. -

Page 17: Installing A Prewound Reel

MAINTENANCE AND REPAIR INSTRUCTIONS (Continued) Winding the Existing Reel 1. Take approximately 12.7 m (50 ft) of new trimming line, loop it into two equal lengths. Insert each end of the line through one of the two holes in the inner reel (Fig. -

Page 18: Gear Housing Service

MAINTENANCE AND REPAIR INSTRUCTIONS (Continued) GEAR HOUSING SERVICE WARNING The gear housing gets very warm after long peri- ods of use. Do not touch the housing until it has cooled. 1. Check the gear housing for lubricant every 50 hours of operation. -

Page 19: Air Filter Maintenance

MAINTENANCE AND REPAIR INSTRUCTIONS (Continued) AIR FILTER MAINTENANCE NOTE: CLEAN AND RE-OIL THE AIR FILTER EVERY 10 HOURS OF OPERATION. Your unit’s air filter is one of the most important areas to maintain. If it is not maintained, you will void the warranty. Before cleaning, make sure the unit is turned off. -

Page 20: Carburetor Adjustment

The condition of the air filter is important to the operation of the trimmer. A dirty air filter will restrict the air flow, which upsets the fuel-air mixture in the carburetor. The resulting symptoms are often mistaken for an out-of- adjustment carburetor. -

Page 21: Inspecting/Cleaning The Muffler

MAINTENANCE AND REPAIR INSTRUCTIONS (Continued) CARBURETOR ADJUSTMENT (Continued) 8. Final Idle Speed Adjustment: Adjust the idle speed by turning the idle speed screw in (clockwise) or out (counterclockwise) until the cutting head does not rotate. Do not squeeze the throttle trigger when adjusting the idle speed screw. - Page 22 MAINTENANCE AND REPAIR INSTRUCTIONS (Continued) Inspection and Cleaning Inspect the inlet port of the muffler and outlet port of the cylinder for excessive carbon build-up. Excessive deposits around the exhaust ports or exhaust holes will cause poor engine performance. If carbon build-up cannot be cleaned, replace the muffler. Inspect the muffler mounting holes for elongation.

-

Page 23: Rocker Arm Clearance

MAINTENANCE AND REPAIR INSTRUCTIONS (Continued) REPLACING THE SPARK PLUG Use a Champion RDZ19H spark plug. Correct air gap is .025 in (0.635 mm). Remove plug after every 50 hours of operation and check its condition. Allow the engine to cool before removing the spark plug. 1. - Page 24 MAINTENANCE AND REPAIR INSTRUCTIONS (Continued) 3. Remove the rocker arm cover and gasket, using a T- 25 Torx ® screwdriver (Fig. 50). Fig. 50 4. Position the crankshaft so the piston is at the top of the compression stroke (the rocker arms are free and loose).

-

Page 25: Cleaning And Storage

Always turn off your trimmer before you clean or perform any maintenance on it. Cleaning Use a small brush to clean off the outside of the trimmer. Do not use strong detergents on plastic housing or handle. They can be damaged by household cleaners that contain aromatic oils such as pine and lemon, and by solvents such as kerosene. -

Page 26: Troubleshooting Chart

PROBLEM Engine Is Difficult to Start or Will Not Start Engine Will Not Idle Engine Will Not Accelerate Engine Lacks Power or Stalls When Cutting Cutting Head Will Not Advance Line Starter Rope Is Difficult to Pull or Engine Locks If further assistance is required, contact your local authorized service dealer or call 1-800-345-8746. -

Page 27: Your Warranty Rights And Obligations

• The owner will not be charged for diagnostic labor which leads to the determination that a warranted part is defective, if the diagnostic work is performed at an Authorized Ryobi Service Center. •... -

Page 28: Warranty

RYOBI Operator’s Manual. This war- ranty does not apply to any damage to the RYOBI Product that is the result of improper maintenance or to any RYOBI Product that has been altered or modified so as to adversely affect the products operation, performance or durability or that has been altered or modified so as to change its intended use.

Need help?

Do you have a question about the 990r and is the answer not in the manual?

Questions and answers