Table of Contents

Advertisement

Quick Links

Advertisement

Chapters

Table of Contents

Troubleshooting

Summary of Contents for SDI Solo 365

- Page 1 User Manual www.sdifire.com...

- Page 2 Avoid prolonged, direct exposure to the vapor generated by Solo 365. Safety Data Sheets for the Solo 370 battery pack and Solo ES6 Smoke Cartridge are available. It is recommended to review the safety data sheets for Solo 370 Battery Pack and Solo ES6 Smoke Cartridge before use (see www.sdifire.com/support).

- Page 3 Information • Read this User Manual completely before using your • Do not use your Solo 365 if it is not operating correctly (see fault nding guides) and consult Solo 365. Troubleshooting (Section 9) of this manual. If required seek technical advice (Section 10).

-

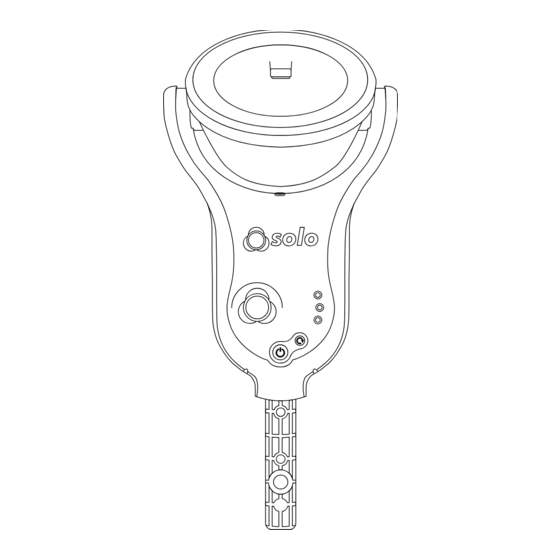

Page 4: Kit Contents

Kit Contents Solo 365 Electronic Smoke Detector Tester Kit containing: Solo 371 Smoke Generator x 1 Solo 370 Lithium Ion Battery Pack x 1 Solo ES6 Smoke Cartridge x 1 Solo 365 Head Unit x 1 www.sdifire.com... - Page 5 Solo 365 Universal USB Charger x1 Quick Start Guide x1 USB Lead x1 Product Registration Card x1 www.sdifire.com...

-

Page 6: Table Of Contents

6.6 Replacing the Battery 4 Using Solo 365 Page 18 7 Consumables & Accessories Page 11 4.1 Attaching Solo 365 to Solo Access Poles Page 19 8 Spares 4.2 Powering on Solo 365 8.1 Removing the Clear Cup 4.3 Carrying Out a Simple Test 8.2 Replacing the Clear Cup... -

Page 7: General Instructions

Buyer to the nal customer whichever period is the shorter. 1.2 Acknowledgement Solo™ is a registered trade mark of SDi. All other brand names mentioned are trademarks or registered marks of their respective holders, and are hereby acknowledged. ©2017 SDi LLC All Rights Reserved. - Page 8 Thank you for purchasing the Solo 365 Smoke Detector Tester. This manual is designed to assist you to get the best and most efcient use of the Solo 365 and provides all the information required to perform routine service and maintenance tasks with ease.

-

Page 9: Preparation For First Use

• When replacing a generator, any dust or debris within the powered USB socket using the supplied mains adaptor. the Solo 365 housing can be removed using an air • Ensure the battery is fully charged before use. duster. Any condensation can be removed by wiping •... -

Page 10: Inserting The Smoke Cartridge

3.3 Inserting the Smoke Cartridge 3.4 Inserting the Battery • Remove cartridge from bag. • Once the battery is charged clip the battery pack into • Do not insert smoke cartridge until generator has the battery compartment. (Fig. 3). been fully fitted into the main unit. See installing the •... -

Page 11: Using Solo

4.1 Attaching Solo 365 to Solo Access Poles When working at height it is recommended Solo 365 is designed for use with the Solo range of access that a competent person carries out a suitable poles. (purchased separately). The product is not risk assessment. -

Page 12: Carrying Out A Simple Test

Flashing Orange: Delayed start NOTE: For the best results the detector should be fully within the cup. Solo 365 may be used in ceiling voids and Slow ashing Red: Consumable low oor voids provided the detectors can be accessed safely. -

Page 13: Delayed Start

On occasion it may be necessary to test detectors that do In low light levels an LED torch will automatically illuminate not easily t into the Solo 365 smoke cup or are obstructed from underneath the cup. This makes for easy alignment in some way. -

Page 14: Asd Adaptor Testing Asd Systems

5.1 Testing an ASD System Figure 8 An ASD System can be tested by using the ‘Delayed Start Mode’ and replacing the cup with the Solo 365 ASD Adaptor (Product Code: Solo 372-001). (Fig. 6) Users should note that using the Solo365 in this conguration is outside the scope of the... -

Page 15: Testing With The Asd Adaptor

5.3 Testing with the ASD Adaptor Power Solo 365 on Select the ‘Delayed Start Mode’ by pressing the ‘function button’ for one second – the status LEDs will ash orange Within 20 seconds ensure Solo365 is locat- ed over the sampling hole on the aspirating pipe to carry out the test (Fig. -

Page 16: Removing & Replacing

Removing & Replacing Consumables 6.2 Replacing the Smoke Cartridge All critical parts of Solo 365 can be replaced in the eld Remove the cartridge from the bag without having to return the unit for service. Ensure Slide cartridge completely into generator housing that the unit is switched off during the replacement of following the guide rails (Fiig. -

Page 17: Removing The Smoke Generator

6.3 Removing the Smoke Generator 6.5 Removing the Battery for Charging Ensure the unit is switched off and the Smoke Ensure the unit is switched off and open the back Cartridge is removed (Section 6.1) cover. Disengage clip ‘1’ and lift. Repeat for clip ‘2’ to Unclip and remove the battery remove the used generator (Fig. -

Page 18: Consumables & Accessories

Consumables & Accessories Consumables ES6-6 PACK-024 Solo 365 Smoke Cartridges x 6 SOLO370- Solo 365 Lithium Ion Battery 1 PACK-024 Pack x1 SOLO371-024 Solo 365 Smoke Generator SERVICE360-024 Solo 365 Service Pack containing: Spare 1058 x 1, Solo 370 x 1 &... -

Page 19: Spares

Spares 8.1 Removing the Clear Cup 8.3 Removing & Replacing the Membrane Align the notch on the left hand side arm and Ease the membrane off the clear cup gently disengage by squeezing the cup and gently Take the replacement membrane and stretch it pulling the arm outwards. -

Page 20: Troubleshooting

Power the unit off and on again. If the problem remains ensure that Solo 365 is Smoke not being generated powered off before performing any of the... -

Page 21: Support & Technical

10.1 Maintenance The Solo 365 unit contains no user serviceable parts. Do not disassemble. In the case of a build-up of dust or dirt on the surface of the product, wipe with a slightly damp lint-free cloth. The area around the smoke duct and within the cup should be cleaned periodically to remove any dirt or uid. - Page 22 SDi Fire www.sdifire.com 3535 Route 66, Building 6, Neptune, NJ 07753 (732) 751-9266 service@sdifire.com As our policy is one of continuous improvement, details of products described within this publication are subject to change without notice. All information provided here is believed to be correct at the time of going to press. Every effort has been made to ensure the accuracy of information which is provided in good faith but nothing contained herein is intended to incorporate any representation or warranty, either express or implied or to form the basis of any legal relations between the parties hereto, additional to or in lieu of such as may be applicable to a contract of sale or purchase.

- Page 30 3535 Route 66, Bldg 6 Neptune, NJ 07753...

- Page 31 8) Shut the control unit off and then back on. The sensor is now reset. Try running the machine now. If it still fails it MUST be returned for Calibration Diagnostic Mode. The Trutest Request Return Materials Authorization (RMA) can be requested at: http://www.sdire.com/site/support/support_rma_request_form/ www.sdire.com...

- Page 32 User Manual OPERATING, SAFETY AND MAINTENANCE INSTRUCTIONS Issue 2.1e Read and understand this manual before using Trutest. Failure to do so will increase the risk of injury. TRUT771...

- Page 34 Issue: 2.1e Trutest User Manual Date: 01/12/08 __________________________________________________________________ SAFETY INSTRUCTIONS Before operating Trutest, read this User Manual and become familiar with it and the equipment. Safe and efficient operation can be achieved only if the equipment is properly operated and maintained. Accidents are caused by failure to follow fundamental rules and precautions.

- Page 35 Issue: 2.1e Trutest User Manual Date: 01/12/08 ___________________________________________________________________ ___________________________________________________________________ WARNING WORKING WITH TOOLS AT HEIGHT CAN BE DANGEROUS. Falling objects can cause serious injury or death. Trutest is designed to be used at height. It may be mounted solely on the top of SOLO telescopic operating poles.

- Page 36 Issue: 2.1e Trutest User Manual Date: 01/12/08 __________________________________________________________________ __________________________________________________________________ CAUTION AEROSOL CANISTERS CAN BE HAZARDOUS. Pressurized containers can explode if correct method of storage and use is not observed. Contents can be ignited under certain conditions. When using/handling/storing the Trutest aerosol: •...

- Page 37 Issue: 2.1e Trutest User Manual Date: 01/12/08 ___________________________________________________________________ This page is intentionally blank ___________________________________________________________________ PRIMARY INFORMATION...

- Page 38 Issue: 2.1e Trutest User Manual Date: 01/12/08 __________________________________________________________________ TABLE OF CONTENTS Safety Instructions Table of Contents iii. Preface viii Important Notes for the User Statement Of Guarantee And Liability TECHNICAL DESCRIPTION 1.1. Why Test Sensitivity? 1.2. Why Test In-Situ? 1.3. Why Trutest? 1.4.

- Page 39 Issue: 2.1e Trutest User Manual Date: 01/12/08 ___________________________________________________________________ OPERATING INSTRUCTIONS 4.1. Preparing to Test 4.2. Selecting the Detector Type 4.3. Selecting the Test Mode 4.3.1. Max/Min Test 4.3.2. Fast Ramp Test 4.3.3. Slow Ramp Test 4.4. Selecting a Detector Setup for Max/Min Mode 4.5.

- Page 40 Issue: 2.1e Trutest User Manual Date: 01/12/08 __________________________________________________________________ 6.5. Troubleshooting Guide FREQUENTLY ASKED QUESTIONS 7.1. Questions on Usage 7.2. Questions on Sensitivity & Calibration 7.3. Questions on effects of Temperature & Humidity 7.4. Questions on Trutest Aerosol 7.5. Questions on Batteries and Power 7.6.

-

Page 41: Preface

Issue: 2.1e Trutest User Manual Date: 01/12/08 ___________________________________________________________________ iii. PREFACE This manual is: designed to outline the correct methods of operating and maintaining your Trutest system. written in a logical order for first time users. designed to be detailed. It is not, however, possible to cover all situations, possible problems or questions. -

Page 42: Important Notes For The User

Issue: 2.1e Trutest User Manual Date: 01/12/08 __________________________________________________________________ IMPORTANT NOTES FOR THE USER Safety Read this manual and the Safety Instructions before using Trutest. The user must be thoroughly acquainted with the procedures in the manual to ensure maximum safety in use. User Registration Card Copy the serial number onto your registration card and return in order to register the product with the manufacturer. -

Page 43: Statement Of Guarantee And Liability

Issue: 2.1e Trutest User Manual Date: 01/12/08 ___________________________________________________________________ STATEMENT OF GUARANTEE AND LIABILITY No Climb Products Ltd. warrants this Trutest system described herein to be free from defect in material and factory workmanship for a period of one year from the date of shipment and agrees to repair such products which, under normal usage and service, disclose the defect to be the fault of No Climb Products. -

Page 44: Technical Description

Issue: 2.1e Trutest User Manual Date: 01/12/08 __________________________________________________________________ TECHNICAL DESCRIPTION 1.1. WHY TEST SENSITIVITY? Over-sensitive detectors are more prone to false alarms. Under-sensitive detectors tend to delay the alarm signal (if they alarm at all). sensitivity of modern smoke detectors are well controlled during manufacture but detectors in the field are subject to airborne contaminants, aging and outside interference - factors which can all significantly affect sensitivity. -

Page 45: Trutest Principles

Issue: 2.1e Trutest User Manual Date: 01/12/08 ___________________________________________________________________ 1.4. TRUTEST PRINCIPLES Trutest is fully automatic. The user merely determines which type of detector is under test and which type of test he wishes to perform. This information is input via a simple menu prompt system into the control unit carried on a shoulder strap. -

Page 46: Introduction To Trutest

Issue: 2.1e Trutest User Manual Date: 01/12/08 __________________________________________________________________ INTRODUCTION TO TRUTEST 2.1. INTRODUCTION Trutest is a technologically advanced, fully field-portable device for in-situ testing of smoke detector sensitivity. The equipment is suitable for testing photoelectric and ionization detectors; conventional, addressable and analogue addressable. -

Page 47: Components

Issue: 2.1e Trutest User Manual Date: 01/12/08 ___________________________________________________________________ 2.2. COMPONENTS The complete set of equipment is comprised of the following main components (not all of which are necessarily supplied): • Main unit • Control unit • Synthetic test aerosols • Two interconnecting cables (differing lengths) •... -

Page 48: Test Aerosols

Issue: 2.1e Trutest User Manual Date: 01/12/08 __________________________________________________________________ 2.2.3. Test Aerosols Trutest uses a form of synthetic test smoke stored in a pressurized aerosol container. This produces a fine mist of aerosol particles to simulate the smoke from a real fire. The aerosol formula and canister are specific to Trutest, and cannot be substituted with any other test aerosol. - Page 49 Issue: 2.1e Trutest User Manual Date: 01/12/08 ___________________________________________________________________ This page is intentionally blank ___________________________________________________________________ INTRODUCTION TO TRUTEST...

-

Page 50: Assembly Instructions

Issue: 2.1e Trutest User Manual Date: 01/12/08 __________________________________________________________________ ASSEMBLY INSTRUCTIONS 3.1. GENERAL Trutest is used in the following assembly: Fig. 1 __________________________________________________________________ ASSEMBLY INSTRUCTIONS... -

Page 51: Components Of Trutest

Issue: 2.1e Trutest User Manual Date: 01/12/08 ___________________________________________________________________ 3.2. COMPONENTS OF TRUTEST 3.2.1 The Control Unit Fig. 2 Carried on a shoulder strap by the operator, the control unit incorporates a microprocessor, LCD display, keyboard and rechargeable battery pack. Commonly used test limits may be pre-stored within the microprocessor for instant recall when required (see Section 4.5., Entering New Test Parameters for Max/Min Mode). -

Page 52: The Main Unit

Issue: 2.1e Trutest User Manual Date: 01/12/08 __________________________________________________________________ 3.2.1.4 The rechargeable battery pack within the control unit will provide sufficient power for a day of testing. It may then be recharged overnight via the battery charger provided. Note: The control unit features an auto power down. If left on, it will automatically switch off after fifteen minutes, thereby saving battery power. - Page 53 Issue: 2.1e Trutest User Manual Date: 01/12/08 ___________________________________________________________________ Fig. 3 Components of the Main Unit: 3.2.2.1 The Aerosol Canister (A). The aerosol canister contains an "environment friendly", pressurized formulation which produces the test aerosol cloud. The aerosol particle sizes simulate the spectrum of particles generated by the smoke of a real fire.

- Page 54 Issue: 2.1e Trutest User Manual Date: 01/12/08 __________________________________________________________________ __________________________________________________________________ CAUTION AEROSOL CANISTERS CAN BE HAZARDOUS. Pressurized containers can explode if correct method of storage and use is not observed. Contents can be ignited under certain conditions. When using/handling/storing the Trutest aerosol: •...

- Page 55 Issue: 2.1e Trutest User Manual Date: 01/12/08 ___________________________________________________________________ Note: Only aerosol cans specifically marked for use within Trutest can be used within this device. The use of any other aerosols will invalidate results and may cause irreparable damage to Trutest. Always re-order the same aerosol part number.

-

Page 56: Telescopic Operating Pole

Issue: 2.1e Trutest User Manual Date: 01/12/08 __________________________________________________________________ Specifications). Before testing a detector, the user should always check that the correct size seal is being used in order that a good seal is maintained around the detector. The diaphragm helps to seal the detector within the cup, reducing leaks, and together with the slight positive pressure within the sensing loop, preventing the ingress of clean air into the sensing loop after the aerosol concentration has been... -

Page 57: Battery Charger

Issue: 2.1e Trutest User Manual Date: 01/12/08 ___________________________________________________________________ WARNING Trutest is used above head height. • Read the Safety Instructions at the start of this User Manual. Failure to do so will increase the risk of injury. • When using Trutest at height, extreme care should be taken. -

Page 58: Carry / Store Case

Issue: 2.1e Trutest User Manual Date: 01/12/08 __________________________________________________________________ CAUTION Trutest uses a pressurized aerosol canister. • Read the Safety Instructions at the start of this User Manual. Failure to do so will increase the risk of injury. • Always follow the instructions on the canister. -

Page 59: Fitting The Aerosol Canister

Issue: 2.1e Trutest User Manual Date: 01/12/08 ___________________________________________________________________ 3.4. FITTING THE AEROSOL CANISTER The aerosol canister is inserted into the main unit from the base of the main unit as follows: Locate the main unit at a convenient working height, not above the head. -

Page 60: Preparatory Checks

Issue: 2.1e Trutest User Manual Date: 01/12/08 __________________________________________________________________ 3.5. PREPARATORY CHECKS Before assembling Trutest for use, check the following: Ensure that the battery in the unit is fully charged. Ensure that you have the correct poles and extensions required to access the height of the detector. - Page 61 Issue: 2.1e Trutest User Manual Date: 01/12/08 ___________________________________________________________________ WARNING • Always ensure that Trutest aerosol canister is firmly located and secured in Trutest, before raising the unit above head height. This will mean that the canister will not be displaced during operation. Attach the interconnecting cable between Trutest main unit and control unit of appropriate length for the height you will be working.

- Page 62 Issue: 2.1e Trutest User Manual Date: 01/12/08 __________________________________________________________________ WARNING • Do not use Trutest unless it is mounted correct securely manner on the specified operating poles. • Always ensure that the spring buttons on the operating poles and the stem at the base of Trutest’s main unit are fully engaged, before raising the unit above head height.

- Page 63 Issue: 2.1e Trutest User Manual Date: 01/12/08 ___________________________________________________________________ This page is intentionally blank ___________________________________________________________________ ASSEMBLY INSTRUCTIONS...

-

Page 64: Operating Instructions

Issue: 2.1e Trutest User Manual Date: 01/12/08 __________________________________________________________________ OPERATING INSTRUCTIONS 4.1. PREPARING TO TEST Check that the unit has been correctly assembled as described in the assembly instructions (Chapter 3) before turning on the power. In particular, ensure that the battery has been charged, and the aerosol canister has been correctly installed (see section 3.4., Fitting the Aerosol Canister). -

Page 65: Selecting The Detector Type

Issue: 2.1e Trutest User Manual Date: 01/12/08 ___________________________________________________________________ Fast ramp photo hi profile Press Start to test Slow ramp hi profile Press Start to test The user must determine which type and model of detector is to be tested, and which type of test is to be performed. The control unit requires up to three pieces of information to be set prior to performing the test. -

Page 66: Selecting The Test Mode

Issue: 2.1e Trutest User Manual Date: 01/12/08 __________________________________________________________________ 4.3. SELECTING THE TEST MODE Use the "Test mode" key on the keypad to toggle between these three types of test: 1. Max/min (see section 4.3.1.) 2. Fast ramp (see section 4.3.2.) 3. -

Page 67: Fast Ramp Test

Issue: 2.1e Trutest User Manual Date: 01/12/08 ___________________________________________________________________ Max. is the maximum reading of obscuration in %/ft required to activate the detector. This figure can be determined from the higher sensitivity rating of the detector (printed on the label on the base of most UL listed detectors or from the manufacturers’... -

Page 68: Slow Ramp Test

Issue: 2.1e Trutest User Manual Date: 01/12/08 __________________________________________________________________ 4.3.3. Slow Ramp Test This is the most accurate measurement of sensitivity within Trutest, and is used to carry out normal quantitative measurements. Because of delays built into certain detectors the ramp rate needs to be fairly slow to give an accurate reading. -

Page 69: Entering New Test Parameters For Max/Min Mode

Issue: 2.1e Trutest User Manual Date: 01/12/08 ___________________________________________________________________ Select option 1 by pressing the numeric key "1". A screen similar to the following will appear: 01: NO_NAME_01 photo Which one 01-18? The display shows a detector setup that has been entered previously. - Page 70 Issue: 2.1e Trutest User Manual Date: 01/12/08 __________________________________________________________________ From any of the default screens, (see Section 4.1., Preparing to Test) press the 'Set-up' key on the keypad. The following menu screen will appear: 1.Recall Setup 2.Change Setup 3.Number of Tests Select option 2 by pressing the number "2"...

- Page 71 Issue: 2.1e Trutest User Manual Date: 01/12/08 ___________________________________________________________________ and “up” respectively. Press “Enter” to modify or enter data in that field. With the cursor positioned adjacent to the detector name field, pressing the “Enter” key reveals the following screen: 06: NO_NAME_06 ABCDEFGHIJKLM01234 - NOPQRSTUVWXYZ56789 A new cursor, “^”, shows beneath the first character of the detector...

-

Page 72: Starting The Test Sequence

Issue: 2.1e Trutest User Manual Date: 01/12/08 __________________________________________________________________ For the ramp speed field (slow ramp or fast ramp), the “Enter” key toggles between “slow ramp” and “fast ramp”. When all parameters have been entered/modified as required, move the cursor to the “exit” field and press “Enter”. Trutest saves all the changes and returns to the screen, which was displayed prior to entering setup. - Page 73 Issue: 2.1e Trutest User Manual Date: 01/12/08 ___________________________________________________________________ Fast ramp photo hi profile Resetting sensor 7 NO_NAME_01 min=1.00 max=2.00 Resetting sensor 7 This ‘initialization stage’ can be carried out without the Trutest cup positioned over the detector e.g. when moving from one test to another, but must be in place for the test to begin (see below).

-

Page 74: The End Of The Test

Issue: 2.1e Trutest User Manual Date: 01/12/08 __________________________________________________________________ NO_NAME_01 min=1.00 max=2.00 Reading=0.62 %/ft 4.6.4 At this point the user is simply a witness as Trutest performs the test. He/she should watch the detector to ensure that the diaphragm is sealed around the top and wait for the LED of the detector to activate when the detector reaches its alarm level. - Page 75 Issue: 2.1e Trutest User Manual Date: 01/12/08 ___________________________________________________________________ shown on the result screen. When the "Enter" key is pressed, the display returns to the default screen, still showing the amount of smoke cleared from the internal sensing loop. For example (max/min screen): NO_NAME_01 min=1.00 max=2.00...

-

Page 76: Results

Issue: 2.1e Trutest User Manual Date: 01/12/08 __________________________________________________________________ RESULTS 5.1. GENERAL OBJECTIVE OF RESULTS Trutest has been designed to perform on-site sensitivity tests on all makes of smoke detector. The sensitivity of a detector may be defined as the density (concentration) of smoke required to trigger an alarm. Testing with Trutest should enable the user to identify: The ability of the detector to respond to the presence of a pre- defined external smoke stimulus. -

Page 77: Results Screen For Max/Min Test

Issue: 2.1e Trutest User Manual Date: 01/12/08 ___________________________________________________________________ 5.2.3 If the obscuration level reaches the maximum level attainable (see section 8., Technical Specifications) and the detector has not alarmed, the test will stop automatically and the message “Full scale” will replace the “Result”... -

Page 78: Warnings Shown On Result Screens

Issue: 2.1e Trutest User Manual Date: 01/12/08 __________________________________________________________________ Result: Detector passed Reading=2.30 %/ft Press Enter 5.3.3 If the detector LED does not illuminate (the detector does not activate) by the “max” level, and the key is pushed to stop the test, the results display will read (for an alarm level of 3.1%/ft in this example): Result: Failed insensitive... -

Page 79: Stored Results

Issue: 2.1e Trutest User Manual Date: 01/12/08 ___________________________________________________________________ Should more than one of these messages be relevant at the time of a result screen display, only the highest priority warning will be shown. A two-second warning beep will accompany any of these warning messages to alert the user. -

Page 80: Interpretation Of Results

Issue: 2.1e Trutest User Manual Date: 01/12/08 __________________________________________________________________ 5.6. INTERPRETATION OF RESULTS IMPORTANT - READ CAREFULLY It should be noted when using Trutest, that there are a large number of factors affecting the sensitivity readings, which should only be judged within the conditions and limits quoted in the Technical Specifications. -

Page 81: Action If A Detector Fails A Test With Trutest

Issue: 2.1e Trutest User Manual Date: 01/12/08 ___________________________________________________________________ 5.7. ACTION IF A DETECTOR FAILS A TEST WITH TRUTEST If a detector fails a sensitivity test, there are steps you should take prior to condemning it. Ensure that the aerosol canister in Trutest is not nearly empty. This can easily be determined by shaking the canister and listening for any remaining liquid. -

Page 82: Service And Maintenance

Issue: 2.1e Trutest User Manual Date: 01/12/08 __________________________________________________________________ SERVICE AND MAINTENANCE Trutest is a high quality electronic test instrument and as such, regular calibration and servicing as well as care in use are essential. Regular calibration ensures reliability, and continuing accuracy in use. It is recommended that this product be returned to an authorized service center annually. -

Page 83: Replacing The Fuse

Issue: 2.1e Trutest User Manual Date: 01/12/08 ___________________________________________________________________ 6.1.3. Replacing the Fuse The fuse holder is located on the side of the control unit and is clearly labeled. Never replace the fuse with any other type / rating than that recommended in the specifications. -

Page 84: Annual Servicing

Issue: 2.1e Trutest User Manual Date: 01/12/08 __________________________________________________________________ 6.2. ANNUAL SERVICING In order to maintain the accuracy and performance from this instrument, it is recommended that Trutest be returned to an authorized service center for an annual service and re-calibration. This should be performed annually or after 5,000 tests, whichever is the sooner. -

Page 85: Warning Messages

Issue: 2.1e Trutest User Manual Date: 01/12/08 ___________________________________________________________________ 6.4. WARNING MESSAGES The following warning messages are generally preceded by a two-second continuous beep from the control unit. 6.4.1. Low Battery 6.4.1.1 When the NiCd Battery is drained almost completely, the Low Battery Warning message is displayed. -

Page 86: Empty Aerosol Can

Issue: 2.1e Trutest User Manual Date: 01/12/08 __________________________________________________________________ 6.4.2.1 A warning message will occur when the number of tests remaining before service goes below 250. The message appears on the result screen, for example: Service due soon! Detector passed Reading=1.97 %/ft Press Enter The user can determine exactly how far away he/she is from an obligatory service by interrogating the control unit (see section 6.3.,... -

Page 87: Sensor Drift

Issue: 2.1e Trutest User Manual Date: 01/12/08 ___________________________________________________________________ 6.4.4. Sensor Drift If the following message appears on a result screen: Sensor drifted! Detector passed Reading=2.64 %/ft Press Enter this means that the sensor may be dirty, blocked or misaligned. The results may be unreliable and care should be taken with their interpretation. -

Page 88: Min/Max Error

Issue: 2.1e Trutest User Manual Date: 01/12/08 __________________________________________________________________ 6.4.7 Min/Max Error Should the setup parameters for a min/max test be entered in such a manner that the full-scale obscuration value of Trutest is exceeded for that type of detector, Trutest alerts the user prior to saving setup information. -

Page 89: Troubleshooting Guide

Issue: 2.1e Trutest User Manual Date: 01/12/08 ___________________________________________________________________ 6.5. TROUBLESHOOTING GUIDE The following problems do not require professional servicing. problem cannot be remedied using this guide, contact your authorized service center for assistance. Problem Possible Causes Remedy Blank screen, no Blown fuse. -

Page 90: Frequently Asked Questions

Issue: 2.1e Trutest User Manual Date: 01/12/08 __________________________________________________________________ FREQUENTLY ASKED QUESTIONS 7.1. QUESTIONS ON USAGE Does Trutest suit all makes of smoke detector? Yes, Trutest has been developed specifically to this end. It is used normally to test against the maximum and minimum values printed on the base of the detector, or in the manufacturers’... -

Page 91: Questions On Sensitivity & Calibration

Issue: 2.1e Trutest User Manual Date: 01/12/08 ___________________________________________________________________ 7.2. QUESTIONS ON SENSITIVITY & CALIBRATION How do I know that Trutest will give accurate results? Trutest has been tested at Underwriters Laboratories in the United States, where it has been given a generic listing as an accessory for automatic fire detection systems. -

Page 92: Questions On Effects Of Temperature & Humidity

Issue: 2.1e Trutest User Manual Date: 01/12/08 __________________________________________________________________ 7.3. QUESTIONS ON EFFECTS OF TEMPERATURE & HUMIDITY What is the effect of temperature on performance: Extensive tests have been carried out to determine the effect of temperature on the performance of Trutest. As Trutest uses a liquefied gas aerosol canister, the critical operating temperatures are determined by the gas characteristics. -

Page 93: Questions On Trutest Aerosol

Issue: 2.1e Trutest User Manual Date: 01/12/08 ___________________________________________________________________ 7.4. QUESTIONS ON TRUTEST AEROSOL consistent repeatable aerosol characteristics? Very. This is a function of the aerosol canister, chemical formulation, valve and spray nozzle. All are subject to strict quality control (as is the rest of Trutest). What effect does "aging of smoke"... -

Page 94: Questions On Batteries And Power

Issue: 2.1e Trutest User Manual Date: 01/12/08 __________________________________________________________________ Can any other smoke aerosol canister be used in the device? No. The tool is designed to use only the special Trutest aerosol canisters, and a different product would not work or give correct results. Other formulations could cause serious damage to both the detector under test and Trutest. -

Page 95: Questions On Results And Displays

Issue: 2.1e Trutest User Manual Date: 01/12/08 ___________________________________________________________________ How does the user know what stage of the test cycle is running? Either by looking at the message on the display or by hearing different beeps from the control unit. What memory has Trutest? The microprocessor has an internal memory for storing detector settings. - Page 96 Issue: 2.1e Trutest User Manual Date: 01/12/08 __________________________________________________________________ How do we cope with detectors fitted in situations where Trutest can not reach or fit? The detectors which cannot be accessed can either be removed from their bases and placed in more accessible bases (exchanging the detectors) or powered up separately and tested.

- Page 97 Issue: 2.1e Trutest User Manual Date: 01/12/08 ___________________________________________________________________ This page is intentionally blank ___________________________________________________________________ FREQUENTLY ASKED QUESTIONS...

-

Page 98: Technical Specifications

Issue: 2.1e Trutest User Manual Date: 01/12/08 __________________________________________________________________ TECHNICAL SPECIFICATIONS 8.1. TRUTEST SPECIFICATIONS Part No. Component Dimensions Weight SOLO100 Telescopic Operating Pole 3lb 15oz (1.80kg) Length (extended) 14ft 9ins (4.50m) 4ft 2ins Length (not extended) (1.26m) SOLO101 Extension Pole 44ins 12oz (1.13m) (0.35kg) - Page 99 Issue: 2.1e Trutest User Manual Date: 01/12/08 ___________________________________________________________________ OPERATING DATA Trutest uncertainties in sensitivity measurements: (Note: For correct interpretation of results, the tolerance of the detector under test and any other measurement uncertainties must also be taken into account). Specified at 68°F +/- 5°F <...

-

Page 100: Aerosol Data

Issue: 2.1e Trutest User Manual Date: 01/12/08 __________________________________________________________________ 8.2. AEROSOL DATA Description: Part Number: AERO400 General Description: An environmentally friendly aerosol canister for use with Trutest Smoke Detector Sensitivity Tester. Specifications: Dimensions: 2.1ins (53mm) dia x 6.8ins (173mm) Pressure: 18 bar maximum Material: Aluminum monobloc Contents:... - Page 101 Issue: 2.1e Trutest User Manual Date: 01/12/08 ___________________________________________________________________ UL Listing: 77TL Smoke-Automatic Fire Detector Accessory. Generic listing. Environmental Information: Tetrafluoroethane currently regulated under the Montreal Protocol and may be used as a replacement for regulated CFC's. ___________________________________________________________________ CAUTION AEROSOL CANISTERS CAN BE HAZARDOUS. Pressurized containers can explode if correct method of storage and use is not observed.

-

Page 102: Appendix A - Authorized Service Centers

Issue: 2.1e Trutest User Manual Date: 01/12/08 __________________________________________________________________ APPENDIX A - AUTHORIZED SERVICE CENTERS A.1 UNITED KINGDOM No Climb Products Limited Edison House 163 Dixon’s Hill Road Welham Green Hertfordshire AL9 7JE Telephone: +44 (0)1707 282760 Facsimile: +44 (0)1707 282777 Email: sales@detectortesters.com Website:... -

Page 104: Appendix B - Results Page

Issue: 2.1e Trutest User Manual Date: 01/12/2008 APPENDIX B - RESULTS PAGE Serial Number of Trutest Used_________________ Date of Tests_________ Sheet _____ of ______ Name of Test Engineer_____________ Name of Client __________________ Location (Site, Town, City, Country) _____________ Detector Tested Location Type of Test Result... -

Page 106: Appendix C. - Detector Performance Tables

Issue: 2.1e Trutest User Manual Date: 01/12/08 __________________________________________________________________ APPENDIX C. - DETECTOR PERFORMANCE TABLES C.1. Method for Producing Detector Performance Tables If you cannot find the details for the particular type and model of detector you wish to test, the following procedure should be followed: Test a representative sample of the same model and type (e.g. -

Page 107: Detector Performance Sheet C2

Issue: 2.1e Trutest User Manual Date: 01/12/08 Detector Performance Sheet Site:__________________________________ Date: ___________________ Model System Type Detector Type Max. Min. Diaphragm Manufacturer Ref. No. Conventional / Photoelectric / Pink or Gray Addressable Ionization 1 Model The manufacturer’s reference or model number for this detector. 2 Max. - Page 108 PORTALEVEL ® USER MANUAL...

- Page 109 Contents Introduction and Key Features What does the Portalevel ® The Portalevel ® Operating Instructions Introduction Preparation 2.21 Function Test 2.22 Dip Test 2.23 Cylinder Preparations 2.24 Temperature Calibration Procedure Identification (CPI) 2.31 Test Procedure 1 2.32 Test Procedure 2 Troubleshooting Frequently Asked Questions Accessories...

-

Page 110: Introduction And Key Features

1. Introduction and key features What does the Portalevel ® The Portalevel ® Max is designed to be a portable way to non-invasively locate the liquid level inside any single skinned cylinder. Portalevel s are capable of detecting the ® presence of any liquid externally;... - Page 111 Portalevel ® The Portalevel ® Max also includes; sensor, and ultrasonic gel (couplant). SPA: The SPA capability Gromit: The gromit at enables an increased the top of the unit is strength of signal output to the ultra secure simple achieve better readings for fastening for the sensor poor condition cylinders, more challenging...

-

Page 112: Operating Instructions

2. Operating Instructions POINTS TO CONSIDER BEFORE PROCEEDING: Do not proceed before reading section 1. Do not proceed before familiarising yourself with the Training section on page 27. Introduction There are three basic procedures which must be carried out when using the Portalevel ®... -

Page 113: Preparation

1. Preparation Preparation for testing is simple, quick and ensures you get the most reliable and accurate results from your testing. The FUNCTION Test and DIP Test both ensure the main unit and sensor are working correctly. CYLINDER PREPARATIONS ensure that you test on the best possible area of the cylinder wall. -

Page 114: Cylinder Preparations

CYLINDER PREPARATIONS: It is important to prepare the cylinders well to attain accurate and reliable readings. To perform CYLINDER PREPARATIONS: Step 1: Find on the cylinder the side which has the least damage, rust or chipped paint. For accurate testing you must find a vertical strip down the side of the cylinder which is as smooth as possible. -

Page 115: Calibration Procedure Identification (Cpi)

2. Calibration Procedure Identification (CPI) T he purpose of this test is to identify whether method 1 or 2 should be used for the cylinder being tested. The details and differences between methods 1 and 2 are explained in the next section. To perform CPI: Step 1: Place a strip of gel or water down the vertical strip on the cylinder you chose during CYLINDER PREPARATIONS. - Page 116 3. Testing PROCEDURE 1: TO BE USED WHERE HIGHER READINGS ARE FOUND IN THE GAS PHASE COMPARED TO THE LIQUID PHASE. Step 1: Place a strip of gel or water down the vertical strip on the cylinder you chose during CYLINDER PREPARATIONS. Step 2: Place the sensor on the area covered with gel or water and on the UPPER portion of the cylinder, where you are certain the sensor will be above the liquid level.

- Page 117 Below liquid level Note: Some cylinders are prone to giving ‘false levels’;that is the bar graph may disappear after moving the sensor even though the Liquid Level has not been passed. If you think you may have found a false Liquid Level, simply move the sensor slightly to the left or right to check if the bar graph returns, as false levels can usually be caused by irregularities in a specific part of the steel wall.

- Page 118 PROCEDURE 2: TO BE USED WHERE HIGHER READINGS ARE FOUND IN THE LIQUID PHASE COMPARED TO THE GAS PHASE. Step 1: Place a strip of gel or water down the vertical strip on the cylinder you chose during CYLINDER PREPARATIONS. Step 2: Place the sensor on the area covered with gel or water and on the LOWER portion of the cylinder, where you are certain the sensor will be below the Liquid Level.

- Page 119 Above liquid level Note: Some cylinders are prone to giving ‘false levels’, that is the bar graph may disappear after moving the sensor even though the Liquid Level has not been passed. If you think you may have found a false Liquid Level, simply move the sensor slightly to the left or right to check if the bar graph returns, as false levels can usually be caused by irregularities in a specific part of the steel wall.

- Page 120 Troubleshooting ISSUE 1: “The readings on the main unit did not change when the sensor was placed anywhere on the cylinder” SOLUTION: Firstly, ensure you are using an adequate quantity of water or gel to couple the sensor to the cylinder and also ensure that the rubber pad of the sensor is clean and undamaged.

- Page 121 ISSUE 3: “Readings are rarely/never greater than 1000 on the side of the level where the highest readings are found.” SOLUTION: The Portalevel ® Max should, in most scenarios, be able to attain readings of more than 1000 on a cylinder. Achieving readings less than 1000 DOES NOT always prevent measurement, but in some cases may cause problems.

- Page 122 ISSUE 4: “The bar graph does not fill up, even with CAL engaged” SOLUTION: The bar graph will only fill up if very high readings are found without CAL engaged, or once CAL is engaged and the current reading is significantly larger than the value displayed when CAL was pressed.

- Page 123 ISSUE 5: “Debris/gel in sensor housing has caused the sensor mechanism to stick making it hard to use.” SOLUTION: The sensor can be removed from its housing and cleaned following the below steps. Step 1: Hold sensor in left hand with dot/top facing up. With right hand, unscrew rear cap completely by twisting anticlockwise.

- Page 124 ISSUE 6: “There is not a significant difference between above and below level readings” Step 1: Carry out a ‘Calibration Procedure Identification’ (CPI) explained in Section 2.3, page 9. Step 2: Upon completing Step 1 press CAL on the exact location where the highest readings are found.

-

Page 125: Frequently Asked Questions

Frequently Asked Questions Why do I have to use water or gel with the sensor? The use of water or ultrasonic couplant gel is essential to the operation of a Portalevel ® unit. When the sensor both emits a high energy pulse and listens for the retuning echoes, excellent mechanical contact must be maintained between the senor and the container in order for the ultrasonic signals to pass into and out of the container efficiently and without interference. - Page 126 Why can’t I test CO and FE-13 in high temperatures? When testing some liquids, it is vital that testing is done under atmospheric temperatures lower than their critical temperature. At the critical temperature of a liquid, it transforms into a vapourous state in which a liquid level no longer exists inside the container to be measured.

-

Page 127: Accessories

3. Accessories Extension Rod (Marine Model) Sensor ® Ultrasonic Gel Portalevel ® Portatherm ® Portalevel ® Max in carry case with accessories Extension rod (Extra) The Portalevel ® extension rods are primarily developed for use in the marine industry and as such come as standard with the Portalevel® Max Marine (not with the Portalevel ®... - Page 128 The extension rod (Figure 3) sections simply screw together, with the sensor at one end (F) and the handle at the other (D). The cable connecting the sensor to the main unit (B) threads through the hollow sections and out of the handle to avoid tangling. Using the adjustment nut and an Alan key, the sensor (F) can be loosened and slid horizontally along the adjustment rail (G).

-

Page 129: Portatherm

Portatherm (Optional Extra) ® Portatherm ® is an easy to use infrared thermometer which allows easy checking of a cylinders temperature prior to testing. This is useful when testing agents such as Carbon Dioxide or FE 13 in hot climates, which cannot be tested above their critical temperature. -

Page 130: Ultrasonic Gel

Low Battery: This is represented by an icon. Turn the unit off and replace the batteries with 2 x AAA batteries. Ensure the unit is off before replacing batteries. Cleaning: Clean the thermometer lens with a soft cloth or cotton swab and water/ medical alcohol. -

Page 131: Maintenance

4. Maintenance This section contains instructions on how to maintain the equipment to extend its lifetime as long as possible. Maintenance of the equipment is simple and only requires the cleaning of the sensor. For any major works or re-calibrations the unit can be returned to the manufacturer for repairs. -

Page 132: Battery Replacement

Battery Replacement You will need a small flathead screwdriver and a 9V alkaline type 6LR61 Battery. Step 1: Ensure the unit is off and turn the unit so that the front fascia faces downwards. Step 2: Take a small, flat head screwdriver and insert it into the slit at the bottom of the back side of the unit. -

Page 133: Training

5. Training This section is for new or untrained users, or for users who may need to remind themselves of how to operate a Portalevel ® The positions of the particular controls for the Portalevel Max are shown at the ®... - Page 134 The BENCH Test: Step 1: Connect the sensor to the Portalevel unit and turn the unit on. ® Step 2: Choose a vertical strip of your large container which is as continuously smooth as possible, free of chips, rust or any other kind of damage. Apply water or the ultrasonic gel along the length of this chosen vertical strip.

- Page 135 Step 6: Move the sensor back up the vertical strip of the cylinder, again in steps of roughly 5cm (2 inches), observing the bar graph each time you place the sensor onto the container wall. Be sure the vertical strip of wall you chose of the container is still well covered by whatever couplant (water or gel) you have chosen.

- Page 136 PORTALEVEL ® MINI USER MANUAL...

- Page 137 Contents Introduction and Key Features What does the Portalevel ® MINI do? Portalevel ® MINI How does a Portalevel ® MINI work? Operating Instructions Introduction Preparation 2.21 Assembly 2.22 Function Test 2.23 Dip Test 2.24 Cylinder Preparations 2.25 Temperature Calibration Procedure Identification (CPI) 2.31 Test Procedure 1 2.32 Test Procedure 2 Troubleshooting...

-

Page 138: Introduction And Key Features

1. Introduction and key features What does the Portalevel® MINI do? The Portalevel® MINI ® is designed to be a portable way to non-invasively locate the liquid level inside any single skinned cylinder. Portalevel® MINIs are capable of detecting the presence of any liquid externally; from water and liquid pressurized gases to firefighting clean agents. -

Page 139: Portalevel® Mini

Portalevel® MINI The Portalevel® MINI is specifically designed for use in environments which are hard to access or in dark environments where hands-free use is beneficial. With a calibration feature, two power settings, LED liquid level display and connectors for a neck strap, the Portalevel®... -

Page 140: How Does A Portalevel® Mini Work

How does a Portalevel® MINI work? All sound is physical vibrations which move through a material, and in the case of the sound we are used to, the vibrations move through air. Ultrasound is the same as the sound we experience, but its frequency is beyond that which humans are capable of hearing. -

Page 141: Operating Instructions

2. Operating Instructions POINTS TO CONSIDER BEFORE PROCEEDING: Do not proceed before reading section 1. Do not proceed before familiarising yourself with the Training section on page 26. Introduction There are three basic procedures which must be carried out when using the Portalevel®... -

Page 142: Dip Test

DIP Test: The DIP Test checks whether the sensor you are using is working correctly and is communicating with the Portalevel® MINI ® main unit. Step 1: Connect extension rod to unit and turn on. Step 2: Lightly dip the tip of sensor into cup of water vertically. The amount of water in the cup is not important, as long as there is enough to dip the end of the sensor so the black central patch on the end of the senor is submerged, without it touching the bottom of the cup. -

Page 143: Calibration Procedure Identification (Cpi)

2. Calibration Procedure Identification (CPI) T he Purpose of this test is to identify whether method 1 or 2 should be used for the cylinder being tested. The details and differences between methods 1 and 2 are explained in the next section. To perform CPI: Step 1: Place a strip of gel or water down the vertical strip on the cylinder you chose during CYLINDER PREPARATIONS. - Page 144 3. Testing PROCEDURE 1: TO BE USED WHERE HIGHER READINGS ARE FOUND IN THE GAS PHASE COMPARED TO THE LIQUID PHASE. Step 1: Place a strip of gel or water down the vertical strip on the cylinder you chose during CYLINDER PREPARATIONS. Step 2: Place the sensor on the area covered with gel or water and on the UPPER portion of the cylinder, where you are certain the sensor will be above the liquid level.

- Page 145 Below liquid level Note: Some cylinders are prone to giving ‘false levels’, that is the bar graph may disappear after moving the sensor even though the liquid level has not been passed. If you think you may have found a false liquid level, simply move the sensor slightly to the left or right to check if the bar graph returns, as false levels can usually be caused by irregularities in a specific part of the steel wall.

- Page 146 PROCEDURE 2: TO BE USED WHERE HIGHER READINGS ARE FOUND IN THE LIQUID PHASE COMPARED TO THE GAS PHASE. Step 1: Place a strip of gel or water down the vertical strip on the cylinder you chose during CYLINDER PREPARATIONS. Step 2: Place the sensor on the area covered with gel or water and on the LOWER portion of the cylinder, where you are certain the sensor will be below the liquid level.

- Page 147 Above liquid level Note: Some cylinders are prone to giving ‘false levels’, that is the bar graph may disappear after moving the sensor even though the liquid level has not been passed. If you think you may have found a false liquid level, simply move the sensor slightly to the left or right to check if the bar graph returns, as false levels can usually be caused by irregularities in a specific part of the steel wall.

-

Page 148: Troubleshooting

Troubleshooting ISSUE 1: “The readings on the main unit did not change when the sensor was placed anywhere on the cylinder” SOLUTION: Firstly, ensure you are using an adequate quantity of water or gel to couple the sensor to the cylinder and also ensure that the rubber pad of the sensor is clean and undamaged. - Page 149 Step 7: Now move the sensor to the side of the level where the HIGHEST readings are found (full LED bar graph should appear) and work towards the opposing side in steps until the LED bar graph reduces and disappears. Step 8: Move sensor back along cylinder in smaller steps until the bar graph rises again.

- Page 150 Step 4: Engage SPA. This will boost power to the sensor and is useful for dealing with dirty, rusty or damaged cylinders. SPA will not correct the problem however if the battery power is already low. Step 5: Trial ‘Reverse Calibration Procedure’ explained in the solution of ISSUE 3 above.

- Page 151 ISSUE 5: “Debris/gel in sensor housing has caused the sensor mechanism to stick making it hard to use.” SOLUTION: The sensor can be removed from its housing and cleaned following the below steps. Step 1: With a damp cloth, clean the various parts, taking extra care on the sensor itself, the spring, and the inside of the housing/around the magnet.

- Page 152 ISSUE 6: “The display values do not rest at or close to 0 (a value of 5 or more) after the unit it turned on, with the sensor connected but not placed on a cylinder.” SOLUTION: This is a technical fault with the sensor, please contact technical support service@sdifire.com...

-

Page 153: Frequently Asked Questions

Frequently Asked Questions Why do I have to use water or gel with the sensor? The use of water or ultrasonic couplant gel is essential to the operation of a Portalevel ® MINI unit. When the sensor both emits a high energy pulse and listens for the retuning echoes, excellent mechanical contact must be maintained between the senor and the container in order for the ultrasonic signals to pass into and out of the container efficiently and without interference. - Page 154 Why can’t I test CO and FE-13 in high temperatures? When testing some liquids, it is vital that testing is done under atmospheric temperatures lower than their critical temperature. At the critical temperature of a liquid, it transforms into a vaporous state in which a liquid level no longer exists inside the container to be measured.

-

Page 155: Accessories

3. Accessories Extension Rod Sensor Ultrasonic Gel Portalevel® MINI A Portalevel ® MINI shown in its carry case. Ultrasonic gel, sensor and extension rod extension rod sold separately Ultrasonic Gel The ultrasonic gel or couplant can be used instead of water if the user intends to test a cylinder for a reasonably long period of time, if the ambient temperature is very hot, or if the site does simply not allow open containers of water (data server rooms for example). -

Page 156: Portatherm

Portalevel® MINI Sensor Portalevel® MINI sensors are single crystal piezoelectric sensors which both emit and receive the ultrasound that the Portalevel® MINI uses to detect a liquid level. Whilst the sensors are designed to be rugged, they must be properly maintained in order to maximise their lifetime. - Page 157 Mode Button The instrument must first be turned on by pressing the ‘measure’ button before the mode can be changed. 1 Press - Minimum temperature: Pressing the mode button once, confirmed by then pressing the measure button will measure the minimum temperature when the measure button is pressed again.

-

Page 158: Maintenance

Maintenance of the equipment is simple and only requires the cleaning of the sensor. For any major works or re-calibrations the unit can be returned to SDi for repairs. Sensor Care The ultrasonic sensor is the most delicate part of a Portalevel® MINI ®... -

Page 159: Battery Replacement

Battery Replacement You will need a Philips screwdriver and 4x AA 1.5V Batteries. Step 1: Turn unit onto its front, gently slide off battery hatch. Step 2: Replace batteries with 4x AA 1.5V batteries, taking care to match the correct orientation/polarities of the batteries into the slots. -

Page 160: Training

5. Training This section is for new or untrained users, or for users who may need to remind themselves of how to operate a Portalevel® MINI ® The positions of the particular controls for the Portalevel® MINI ® are shown at the beginning of the manual in section 1.2, page 4, and the names and functions of Portalevel®... - Page 161 The BENCH Test: Step 1: Connect the extension rod to the Portalevel® MINI ® unit and turn the unit Step 2: Choose a vertical strip of your large container which is as continuously smooth as possible, free of chips, rust or any other kind of damage. Apply water or the ultrasonic gel along the length of this chosen vertical strip.

- Page 162 Step 7: As you progress up the wall of the container, the numerical readout on the Portalevel® MINI ® unit will change, and the bar graph might fluctuate slightly. However, the bar graph will only disappear entirely once you place the sensor on the container wall above the liquid level.

- Page 163 PORTAGAUGE® 3 OPERATING I NSTRUCTIONS Operation: Plug t he s ensor i nto t he P ortagauge® 3 , a ligning t he r ed m arks. Turn it on by pressing the ON switch Place a small amount of ultrasonic gel on to the sensor face Press the sensor face with medium pressure onto the 5mm calibration...

- Page 164 Replacement necessary when “low bat” shows on display Battery: Lever off both screw covers on bottom of unit, unscrew and replace with 9V battery Testing P ipework: F or b est r esults k eep c entral d ivision o f p robe a t 9 0 d eg t o axis ...

- Page 165 PORTAGAUGE ® USER MANUAL...

- Page 166 Contents Introduction and Key Features 1.1 What does the Portagauge ® 1.2 The Portagauge ® 1.21 The Portagauge ® 4 – Unit and Measuring Screen 1.22 The Portagauge ® 4 – Definition of Menu Items How does a Portagauge ® 4 work? Operating Instructions Introduction...

-

Page 167: Introduction And Key Features

1. Introduction and key features What does the Portagauge ® The Portagauge 4 is a portable, robust device used to accurately measure the ® thickness of a material using multiple echo, ultrasonic technology. The Portagauge 4 is ® capable of working across a large number of different applications and environments, whether this be different surface conditions, the presence of rust, small curvature surfaces or for any other maintenance and inspection requirement. -

Page 168: The Portagauge

The Portagauge ® Lemo Connector: Allows for secure Display: Color LCD fastening of the cable for display for access to the the sensor probe. Measuring screen and Menu Right Option Key: screen. Selects the option at Left Option Key: the bottom right of the Selects the option at the LCD screen bottom left of the LCD... - Page 169 Definition of Menu Items iProbe Shows that an iProbe has been connected. The probes are — automatically recognised by the gauge and all the relevant probe data is transferred to the gauge to perfectly match the probe to the gauge for optimum performance. All materials have varying velocity of sound properties and —...

-

Page 170: How Does A Portagauge ® 4 Work

4 work? How does a Portagauge ® All sound is physical vibrations which move through a material, and in the case of the sound we are used to, the vibrations move through air. Ultrasound is the same as the sound we experience, but its frequency is beyond that which humans are capable of hearing. -

Page 171: Operating Instructions

2. Operating Instructions DO NOT PROCEED BEFORE READING SECTION 1. There are two basic procedures which must be carried out when using the Portagauge ® 1. Preparation: Calibration ensures that the Portagauge ® equipment functions properly for the specific metal being tested. 2. -

Page 172: Preparation

PREPARATION Preparation for testing is simple, quick and ensures you get the most reliable and accurate results from your testing. It ensures the equipment is assembled correctly and that the appropriate probe is selected. Calibration ensures that the unit and probe work correctly for the specific metal being tested. -

Page 173: Probe Membranes

Probe Membranes All probes are fitted with protective membranes to help prolong the life of the probe. The membranes also provide a flexible interface which acts as an aid when working on rough surfaces. Membrane wear should be monitored and checked at regular intervals. -

Page 174: Calibration

Calibration The gauge should be calibrated to the type of material that is being measured. This is because ultrasound travels at different speeds in different materials. There are two methods of changing the calibration. Either adjust the velocity of sound setting according to the metal being measured, or adjust the gauge to a known thickness of metal. -

Page 175: Speed Table

Speed Table The given values are in certain cases strongly dependent on the alloy, heat treatment, manufacturing and processing and are therefore only approximate standard values. They are given here as a guide only. Material Speed – m/s Aluminium 6200 – 6360 Rolled 6420 Duraluminium... - Page 176 STEP 4: Turn on the gauge using the ON/OFF button (see page 4). Note: If a compatible probe other than an SDi probe is attached to the unit, the gauge will automatically detect this and display the message “Unrecognised Probe”. If this occurs press the “OK”...

- Page 177 Note: If the message “No Probe connected” appears, either connect a suitable probe or simply press the “OK” button to enable the navigation of the menus without a probe fitted. No measurements can be taken if a probe is not detected. The Coating Plus+ feature is automatically switched off when the unit is turned off.

-

Page 178: Maintenance

Never try to repair a probe or try to remove scratches from the face of the probe. This may result in further damage. Always return it to SDi for investigation and possible repair. -

Page 179: Battery Care

STEP 5: Refit the retaining ring (3) and secure it in place using the membrane key (5). STEP 6: Place a few drops of membrane oil (6) onto the face of the probe (4). Do not use too much. STEP 7: Screw the knurled ring (1) back onto the probe (4) whilst applying pressure on the membrane (2) with the thumb to expel any air from behind the membrane. -

Page 180: Battery Replacement

Battery Replacement You will need a small flathead screwdriver and three 1.5V AA batteries. STEP 1: Ensure the unit is off and turn the unit so that the front fascia faces downwards. STEP 2: Take a small, flat head screwdriver and unscrew the two screws holding down the hatch of the battery compartment. - Page 181 PORTASTEELE ® USER MANUAL...

- Page 182 Contents Introduction and Key Features What does the Portasteele ® The Portasteele ® How does a Portasteele work? ® Preparation Tablet Setup Testing Calculator Mode Calculating Mass Measurements Calculating Liquid Level Measurements Performing Calculations Database Mode Adding a New Cylinder Adding a New Folder Managing Saved Cylinders Editing Saved Cylinders...

-

Page 183: Introduction And Key Features

1. Introduction and key features What does the Portasteele ® The Portasteele ® is an application which is readily installed on a rugged, secure tablet.The Portasteele uses information input by the user, including the dimensions ® of a cylinder and its liquid level, to calculate the mass of agent contained within a cylinder. - Page 184 Portasteele ® Micro USB port: cable may be connected to charge the device or to connect to a PC to export data from the Portasteele ® application. Power Button: Powers the device on and off when held down. Ruggedized Casing: Casing designed to be hard-wearing and shock resistant with a rating of...

-

Page 185: How Does A Portasteele ® Work

How does the Portasteele work? ® The Portasteele uses measurements of the dimensions of a cylinder, such as height and circumference, to calculate the volume of the space inside a cylinder. From there it can use the value of the liquid level, also measured by the user, to find out how much of this volume is occupied by the agent inside the cylinder. -

Page 186: Preparation

2. Preparation Before using the Portasteele it is important to ensure that the tablet is set up ® correctly. Tablet Setup The tablet should be fully charged on receipt. A charger will accompany the tablet on arrival. The tablet can be charged via PC or electrical outlet and the charger is plugged into the micro-USB socket as shown on page 4. -

Page 187: Testing

Testing After the initial setup of the tablet, it should be tested to ensure that the Portasteele ® tablet is functioning properly and that calculation results are correct. Begin by launching the Portasteele ® application, which is shown by its icon on the home screen of the tablet. -

Page 188: Calculator Mode

3. Calculator Mode Calculator Mode is used to quickly input measurements for a single cylinder, and receive the calculated result for either Actual Agent Mass or Expected Liquid Level, depending on what has been input. When the application boots it will open onto its home screen. To begin carrying out calculations, select the Calculator option by tapping on the upper half of the screen as highlighted... - Page 189 Selecting the Calculator button will open up Calculator mode. Start by using the drop down menus to select the agent type. To do this, tap on the drop down arrow next to agent, which can be seen here Then select the desired agent from the drop down menu by tapping on the correct option.

- Page 190 Follow the same procedure to select the desired unit type (metric or imperial). There is a similar drop down menu which can be used to change between calculating Actual Agent Mass and calculating Expected Liquid Level, as shown here. Once these options have been selected, the measurements for the cylinder need to be entered into the calculator.

-

Page 191: Calculating Mass Measurements

Part 1 – Calculating Mass Measurements To calculate mass, the calculate type must be set to Actual Agent Mass – ensure this is correct before proceeding. The measurements which need to be inputted into the calculator are slightly different depending on the agent in question. Please ensure you refer to the correct section for the cylinder you are measuring. - Page 192 The measurements which need to be taken are: Height, this needs to be measured from the base of the cylinder to the point at • which the cylinder begins to curve, shown as in the diagram overleaf. This must be measured in centimetres for metric units and inches for imperial units. This needs to be measured to the nearest 0.1 cm or nearest 0.1 ”.

- Page 193 Cylinder The grey dashed line shows the point at which the cylinder begins to curve, it is important that measurements are correctly taken relative to this point. The red line shows the top of the cylinder, the dome height should not include any components of the valves or tubing at the top of the cylinder.

- Page 194 NOVEC 1230 The measurements which need to be taken are: Fill Weight, this is the mass of agent with which the cylinder was originally filled, • and should be printed on the side of the cylinder. This must be measured in kilogrammes for metric units and pounds for imperial units.

- Page 195 NOVEC 1230 Cylinder The grey dashed lines shows the points at which the cylinder begins to curve, it is important that measurements are taken correctly relative to these points. The red line shows the top of the cylinder, the dome height should not include any components of the valves or tubing at the top of the cylinder.

- Page 196 FM-200 The measurements which need to be taken are: Height, this needs to be measured from the base of the cylinder to the point at • which the cylinder begins to curve, shown as in the diagram overleaf. This must be measured in centimetres for metric units and inches for imperial units. This needs to be measured to the nearest 0.1 cm or nearest 0.1 ”.

- Page 197 FM-200 Cylinder The grey dashed lines shows the points at which the cylinder begins to curve, it is important that measurements are taken correctly relative to these points. The red line shows the top of the cylinder, the dome height should not include any components of the valves or tubing at the top of the cylinder.

-

Page 198: Calculating Liquid Level Measurements

Part 2 – Calculating Liquid Level Measurements To calculate liquid level, the calculate type must be set to Expected Liquid Level – ensure this is correct before proceeding. The measurements which need to be inputted into the calculator are slightly different depending on the agent in question. Please ensure you refer to the correct section for the cylinder you are measuring. - Page 199 The measurements which need to be taken are: Actual Agent Mass, this is the mass of agent with which the cylinder was • originally filled, and should be printed on the side of the cylinder. This must be measured in kilogrammes for metric units and pounds for imperial units. This needs to be measured to the nearest 0.1 kg or nearest 1 lb.

- Page 200 Cylinder The grey dashed line shows the point at which the cylinder begins to curve, it is important that measurements are taken correctly relative to this point. The red line shows the top of the cylinder, the dome height should not include any components of the valves or tubing at the top of the cylinder.

- Page 201 NOVEC 1230 The measurements which need to be taken are: Fill Weight, this is the mass of agent with which the cylinder was originally filled, • and should be printed on the side of the cylinder. This must be measured in kilogrammes for metric units and pounds for imperial units.

- Page 202 NOVEC 1230 Cylinder The grey dashed lines shows the points at which the cylinder begins to curve, it is important that measurements are taken correctly relative to these points. The red line shows the top of the cylinder, the dome height should not include any components of the valves or tubing at the top of the cylinder.

- Page 203 FM-200 The measurements which need to be taken are: Actual Agent Mass, this is the mass of agent with which the cylinder was • originally filled, and should be printed on the side of the cylinder. This must be measured in kilogrammes for metric units and pounds for imperial units. This needs to be measured to the nearest 0.1 kg or nearest 1 lb.

- Page 204 FM-200 Cylinder The grey dashed lines shows the points at which the cylinder begins to curve, it is important that measurements are taken correctly relative to these points. The red line shows the top of the cylinder, the dome height should not include any components of the valves or tubing at the top of the cylinder.

-

Page 205: Performing Calculations

Performing Calculations Once all the necessary measurements have been taken to calculate either mass or liquid level, they can inputted into the calculator. To input measurements, tap in the space above the line next to the corresponding measurement value to be entered.This will bring up the on-screen keyboard, which can then be used to input the measured value. - Page 206 Once all the measurements have been correctly inputted into the calculator, close the keyboard and tap the ‘Calculate’ below the input boxes. If something has been input incorrectly, an error message will appear at the bottom of the screen, detailing what it is that must be changed for the inputs to be valid.

-

Page 207: Database Mode

4. Database Mode Cylinder Database The application also has the ability to create and organize records of cylinder dimensions and calculation results. This means that when cylinders are tested again, the record of their dimensions can be simply opened in the app, rather than having to measure all the cylinders each time they are tested. -

Page 208: Adding A New Cylinder

Adding a New Cylinder to the Database The first time the database is loaded, it will contain only a single example cylinder. New saved cylinders for as many different cylinder types and dimensions as is needed can be added and stored in the database for later use. To add a new cylinder to the database, start by clicking the + button in the bottom right, as shown here. - Page 209 The New Cylinder creation screen is very similar to the Calculator Mode as detailed on page 8.The specifications and dimensions of the new cylinder should be input in exactly the same way as in Calculator Mode, the only differences being that the new cylinder being created must be given a unique name to identify it in the database, and that no measured liquid level or mass needs to be inputted, since no calculation is being performed at this stage.

-

Page 210: Adding A New Folder

Adding a New Folder to the Database In addition to adding cylinders to the database, new folders and sub-folders can also be created.Within every folder, new cylinders and sub-folders can be created, allowing cylinders to easily be organized. To add a new folder to the database, start by clicking the + button in the bottom right, as shown here. - Page 211 A dialog will now pop up to name this new folder. Simply click in the input box to bring up the on-screen keyboard, and use it to enter a unique name for this new folder. Selecting the Create button will then add this new folder to the database.Alternatively, select the Cancel button to abandon creating this new folder.

-

Page 212: Managing Saved Cylinders

Managing Saved Cylinders The first time the database is loaded, it will contain only a single example cylinder. Saved cylinders can be managed from their drop down ribbon, located to the left of the cylinder image. The first time the database is loaded, it will contain only a single example cylinder. -

Page 213: Editing Saved Cylinders

Editing Saved Cylinders The first cylinder management option of the drop down ribbon allows the saved dimensions and information of a cylinder to be edited. Start by clicking on the first item in the drop down ribbon as shown here.This will bring up the cylinder editing screen. -

Page 214: Exporting Saved Cylinders

Exporting Saved Cylinders The second cylinder management option of the drop down ribbon allows the saved dimensions and information of a cylinder to be exported via email. Start by clicking on the second item in the drop down ribbon as shown here.This will bring up the email client if an email account has already been setup, otherwise it will prompt you to do so. -

Page 215: Deleting Saved Cylinders

Deleting Saved Cylinders The final cylinder management option of the drop down ribbon allows a cylinder to be completely removed from the database. Start by clicking on the third item in the drop down ribbon as shown here.This will then prompt the application to check that you really wish to delete the selected cylinder. -

Page 216: Navigating The Database

Navigating the Database After creating new folders, they can be opened and dealt with in the same way as the home folder. When the database first opens it will be in its home folder. Clicking on a folder will open the selected folder and navigate into this sub-folder. - Page 217 To navigate upwards in the file system, use the back button or the back arrow in the top left of the screen in order to navigate a single level upwards. In order words, this means you will be navigating into the folder containing the current folder you are within. Navigating upwards within the home folder will save and close the database.

-

Page 218: Performing Calculations On Saved Cylinders

Performing Calculations on Saved Cylinders After creating saved cylinders, calculations can be performed using this cylinder information. To perform a calculation on a cylinder, simply click on the selected cylinder.This will open up the saved cylinder calculator. This saved cylinder calculator is very similar to Calculator mode as detailed on page 8, except that the only 2 inputs which can be altered are Temperature and either Actual Liquid Level or Actual Agent Mass,... - Page 219 Once all the measurements have been correctly inputted into the calculator, close the keyboard and tap the ‘Calculate’ below the input boxes, in the same way as for Calculator mode, as detailed on page 26. Also in the same way as in Calculator mode, if something has been input incorrectly, an error message will appear.

- Page 220 Managing Calculation Records After storing cylinder calculation results, they can be viewed, managed and exported from Database Records. To open up Database Records, simply click the Records icon as seen here. The Database Records organize calculation results by cylinder, as can be seen here.To view the results for a certain cylinder, simply click on the selected cylinder’s name.This will open up a drop down list of results.

- Page 221 Opening up the records for a cylinder will show all of the stored records for that cylinder, organized by how new the record is, as seen here. A record can be removed by clicking the delete icon, as shown here.This will permanently remove the selected result from the records.

- Page 222 It is also possible to remove every record for every cylinder in Database Records, by clicking the Clear All button, as shown here.

- Page 223 Exporting Calculation Records It is possible to export all of the calculation results stored in Database Records via email with a single click. Start by clicking the Export All button, as shown here. This will bring up the email client if an email account has already been setup, otherwise it will prompt you to do so.

-

Page 224: Maintenance

5. Maintenance Basic maintenance of the tablet involves simple procedures such as recharging the battery. Any major maintenance is carried out by the technical team. Please contact service@sdifire.com for any queries. - Page 225 PORTAMONITOR® USER MANUAL...

- Page 226 1. Layout...

- Page 227 The sensing face can be degreased as necessary using a mild detergent. Do not use aggressive chemicals. 3.2. Service and Calibration SDi recommends that the BEARING INDICATOR is serviced, checked and calibrated regularly through an authorized SDi service provider. The recommended recalibration period is 12 months.