Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Buchi Interface I-300 PRO

- Page 1 Interface I-300 Operation Manual...

- Page 2 CH-9230 Flawil 1 E-Mail: quality@buchi.com BUCHI reserves the right to make changes to the manual as deemed necessary in the light of experi- ence, especially with respect to structure, illustrations and technical detail. This manual is copyrighted. Information from it may not be reproduced, distributed, or used for competi- tive purposes, nor made available to third parties.

-

Page 3: Table Of Contents

BÜCHI Labortechnik AG Contents Contents About this document...................... 6 Warning notices in this document...................... 6 Symbols ............................... 6 1.2.1 Warning symbols ........................ 6 1.2.2 Mandatory directive symbols .................... 7 1.2.3 Other symbols.......................... 7 Available languages.......................... 7 Trademarks............................ 7 Safety............................ 8 Intended use ............................ 8 Use other than that intended ....................... - Page 4 Viewing the QR code ......................... 72 7.10 Generating a password........................ 74 7.11 Connecting to the distillation system with the BUCHI Rotavapor app .......... 74 7.12 Scanning the QR code with your smartphone ................... 75 7.13 Activating push notifications ...................... 76 7.14...

- Page 5 BÜCHI Labortechnik AG Contents Cleaning and servicing ..................... 80 Cleaning the casing/display ....................... 80 Performing a leak test........................ 80 Fitting GL14 cap nut with tube seal .................... 81 Checking seals .......................... 82 Calibrating AutoDest sensor ...................... 83 Calibrating the pressure sensor...................... 83 8.6.1 Offset calibration ........................

-

Page 6: About This Document

If you still have any questions after reading these operating instructions, please contact BÜCHI Labortechnik AG Customer Service. Contact details for your local agents can be found on the Internet at http://www.buchi.com. Warning notices in this document Warning notices warn you of dangers that can occur when handling the device. There are four danger levels, each identifiable by the signal word used. -

Page 7: Mandatory Directive Symbols

These operating instructions were originally produced in German and have been translated into several other languages. The translations are available on the enclosed CD or can be obtained as a PDF file via http://www.buchi.com. Trademarks Product names and registered or unregistered trademarks that are used in this instruction manual are used only for identification and remain the property of the owner in each case. -

Page 8: Safety

2 | Safety BÜCHI Labortechnik AG Safety Intended use The Interface I-300 is intended for indicating vacuum within an operating range of 0 mbar to ambient atmospheric pressure. The measurement and regulation of the vacuum is performed by means of a VacuBox. The Interface I-300 has been designed and built as an item of laboratory equipment and can be used in conjunction with the following devices: —... -

Page 9: Residual Risks

Technical modifications to the device or accessories should only be carried out with the prior written approval of BÜCHI Labortechnik AG and only by authorized BUCHI technicians. BUCHI accepts no liability whatsoever for damage arising as a result of unauthorized modifications. Operation Manual Interface I-300... -

Page 10: Product Description

3 | Product description BÜCHI Labortechnik AG Product description Description of function The Interface I-300 is designed for indicating, adjusting and controlling the complete distillation system. The Interface I-300 settings enable precise specification of the individual process parameters.For example: — Rotation speed of the evaporating flask —... -

Page 11: Rear View

BÜCHI Labortechnik AG Product description | 3 3.2.2 Rear view Fig. 2: Rear view of Interface I-300 1 LAN port 3 Locating lug for bracket 2 Standard BUCHI communication port 4 MicroSD card (not used) (COM) Operation Manual Interface I-300 11/96... -

Page 12: Vacubox (Connections)

NOTE Connecting VacuBox with R-220 Pro: If the Interface I-300 Pro and the VacuBox are operated in the Rotavapor R-220 Pro system, the following points should be noted: The external valves must always be connected to the Rotavapor R-220 Pro even if there is an alternative connection on the VacuBox. -

Page 13: Legacybox (Connections)

3.2.4 LegacyBox (connections) Connection of a LegacyBox is required whenever legacy BUCHI laboratory equip- ment is to be controlled via the Interface I-300. The LegacyBox is connected to the distillation system using a standard BUCHI communication cable and has other connection options such as an RS-485 communication port. - Page 14 3 | Product description BÜCHI Labortechnik AG Fig. 5: 8-pin MiniDin pin assignment, view of socket Symbol Description 8-pin notation Ground Ground connection for valve and 10 V output Valve Vacuum valve connection Spare 10 V output 0 – 10 V (max. 20 mA, min. 500 Ohm) Relay In Max.

-

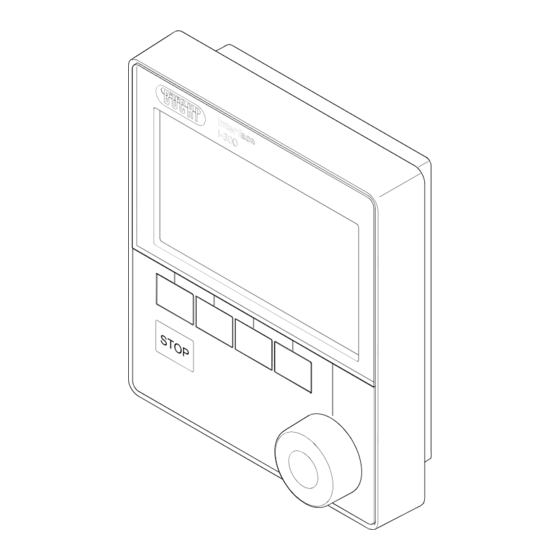

Page 15: Display (Touch-Screen)

BÜCHI Labortechnik AG Product description | 3 3.2.5 Display (touch-screen) Fig. 6: Display layout 1 Status bar 5 Current setting (e.g. vacuum) 2 Menu bar 6 Scroll bar 3 Current reading (e.g. vacuum) 7 Function activated if navigation control is pressed 4 Functions of the function buttons below (context-dependent) Operation Manual Interface I-300... -

Page 16: Type Plate

3 | Product description BÜCHI Labortechnik AG 3.2.6 Type plate The type plate is on the rear of the Interface I-300. BÜCHI Labortechnik AG CH-9230 Flawil/Switzerland Type: I-300 1000000000 Volt: 30 VDC Frequ.: Power: 3 W Built: 2014 Made in Switzerland Fig. 7: Type plate (example) 1 Company name and address 7 Year of manufacture... -

Page 17: Navigating Through The Menu System

BÜCHI Labortechnik AG Product description | 3 Navigating through the menu system 3.3.1 Main menu Highest menu level Symbol Meaning Sub-items Home page — Process control parameters Favorites — Bookmarks for fre- quently used individual starting points — Manual Operating modes —... - Page 18 3 | Product description BÜCHI Labortechnik AG 3.3.2 Operating modes Fig. 8: "Operating modes" selected on main menu of Interface I-300 The Interface I-300 distinguishes between the following operating modes for a distillation system: Operating mode Purpose Consists of Manual Carrying out distil- User-definable configuration of specified lation with manually settings for the individual process...

- Page 19 BÜCHI Labortechnik AG Product description | 3 Operating mode Purpose Consists of Drying Post-drying of con- Drying of evaporating flask contents. tents of evaporating Evaporating flask rotates in alternating flask. directions for a defined period of time. User-definable configuration of specified settings for the individual process parameters: —...

- Page 20 3 | Product description BÜCHI Labortechnik AG 3.3.3 Configuration Fig. 9: "Configuration" selected on main menu of Interface I-300 The menu item "Configuration" on the main menu of the Interface I-300 offers the fol- lowing options: Servicing "Servicing" provides access to information on seal servicing and the option of carrying out a leak test on the distillation system.

- Page 21 Network Entry of details System name DHCP: Yes/No Network addresses for "Device IP address", "Gateway", "Subnet mask", "Server IP address" BUCHI Cloud: Yes/No Delete APP con- Confirmation ques- All connections settings entered for the nection tion device are reset. Operation Manual Interface I-300...

- Page 22 3 | Product description BÜCHI Labortechnik AG Service The "Service" submenu provides options for adjusting/calibrating the connected measuring instruments. Action Option Consists of Calibrate Au- Perform calibration Calibration sequence between the two toDest sensor condenser sensors. Precondition: the two condenser sensors are at the same temperature.

- Page 23 The Interface I-300 offers a list containing a selection of the wearing parts for the BUCHI Rotavapor system. The list is divided into two columns. The left-hand column itemizes the wearing parts in alphabetical order. The right-hand column shows the order numbers for the wearing parts.

-

Page 24: Specifications Supplied

3 | Product description BÜCHI Labortechnik AG Specifications supplied 3.4.1 Interface I-300 Component Quantity sup- plied Interface I-300 Device bracket assembly: — Screw, M6x16 — Torx key, Tx20 — Torx key, Tx30 — Holder — Metal plate — Knurled-head screw 3.4.2 VacuBox Component... -

Page 25: Technical Data

BÜCHI Labortechnik AG Product description | 3 Technical data 3.5.1 Interface I-300 Dimensions (W x H x D) 121 x 141 x 50 mm Weight 400 g Power supply voltage 30 VDC ±5 % Power consumption Enclosure rating IP21 Approval CE/CSA 3.5.2 VacuBox... -

Page 26: Legacybox

3 | Product description BÜCHI Labortechnik AG 3.5.3 LegacyBox Dimensions (W x H x D) 50 x 167 x 28 mm Weight 200 g Power supply voltage 30 VDC ±5 % Power consumption Enclosure rating IP21 Approval CE/CSA 3.5.4 Ambient conditions Max. -

Page 27: Transport And Storage

BÜCHI Labortechnik AG Transport and storage | 4 Transport and storage Transport IMPORTANT Risk of breakage due to incorrect transportation Make sure that all parts of the device are safely packed in such a way as to prevent breakage, ideally in the original box. Avoid sharp movements during transit. -

Page 28: Installation

5 | Installation BÜCHI Labortechnik AG Installation Fitting the Interface I-300/I-300 Pro The Interface I-300/I-300 Pro can be mounted on one of the following BUCHI laboratory devices: — Rotavapor R-300 — Vacuum Pump V-300 — Rotavapor R-220 Pro Alternatively, the Interface I-300/I-300 Pro can be mounted separately on a laboratory stand, see Chapter 5.1.3 "Mounting interface unit on laboratory stand (optional... - Page 29 BÜCHI Labortechnik AG Installation | 5 Fig. 13: Fitting the holder and interface unit on the handle 1 Knurled-head screw 4 Fixing screw for holder 2 Holder for interface unit 5 Metal plate 3 Interface unit 6 Rotavapor arm and handle Position the holder (2) for the interface unit on the Rotavapor arm (6).

-

Page 30: Fitting Interface Unit On Vacuum Pump V-300

5 | Installation BÜCHI Labortechnik AG 5.1.2 Fitting interface unit on Vacuum Pump V-300 Fig. 14: Fitting interface unit on Vacuum Pump V-300 1 Interface unit 5 Casing front 2 Fixing screw for holder 6 Knurled-head screw 3 Metal plate 7 Holder 4 Rubber plug and threaded hole Tools required: —... -

Page 31: Mounting Interface Unit On Laboratory Stand (Optional Accessory)

BÜCHI Labortechnik AG Installation | 5 5.1.3 Mounting interface unit on laboratory stand (optional accessory) Fig. 15: Mounting interface unit on laboratory stand 1 Holder for interface unit 4 Knurled-head screw 2 Interface unit 5 T-screw 3 Laboratory stand The Interface I-300 can also be mounted on a laboratory stand using a holder. Position the holder (1) on the laboratory stand (3) and fix it in place using the T-screw (5). -

Page 32: Mounting Interface Unit On A Wall Bracket (Optional Accessory)

5 | Installation BÜCHI Labortechnik AG 5.1.4 Mounting interface unit on a wall bracket (optional accessory) Fig. 16: Two-piece wall bracket for interface unit 1 Front plate of wall bracket 4 Rear plate of wall bracket 2 Interface unit 5 Slot in rear plate 3 Fixing screws for interface unit 6 Lug on front plate The Interface I-300 can also be mounted directly onto a plastered or tiled wall or a... -

Page 33: Assembling The Buchi Distillation System

Connecting communication cables to interface unit The communication connections between the Interface I-300, the VacuBox and the other BUCHI laboratory equipment are established using the standard BUCHI communication cable (with green connector). The corresponding connection sockets Operation Manual Interface I-300... -

Page 34: Overview: Setting Up Communication Connections

Chiller F-3XX R-300 Interface I-300/ I-300 Pro Fig. 18: Schematic diagram of communication connections between the BUCHI laboratory equipment (example) Connect the Recirculating Chiller F-3xx to the Rotavapor R-300. Connect the Rotavapor R-300 to the VacuBox. Connect the VacuBox to the Vacuum Pump V-300/V-600. -

Page 35: Overview: Setting Up Coolant Tubing Connections

Installation | 5 5.2.3 Overview: setting up coolant tubing connections The tubing connections between the various items of BUCHI laboratory equipment form a sealed circulation system. The starting and finishing point is always the recirculating chiller (F-3xx). Below is an example of the tubing connections between the laboratory apparatus. -

Page 36: Overview: Setting Up Vacuum Tubing Connections

5.2.4 Overview: setting up vacuum tubing connections The vacuum tubing connections in a typical BUCHI distillation system lead from the Rotavapor R-300 via a Woulff bottle to the Vacuum Pump V-300/V-600. The vacuum is measured by means of the VacuBox, which is also connected to the Woulff bottle. -

Page 37: Connecting Autodest Sensor To Vapor Temperature Sensor (Optional Accessory)

BÜCHI Labortechnik AG Installation | 5 Connecting AutoDest sensor to vapor temperature sensor (optional accessory) The Interface I-300 offers a program for carrying out an automatic distillation process (see Chapter 6.2.6 "Performing automatic distillation", page 57). Automatic distilla- tion requires connection of an AutoDest sensor to the Rotavapor R-300. The Au- toDest sensor is connected to the inlet and outlet of the cooling condenser and con- tinuously measures the following temperatures: —... - Page 38 5 | Installation BÜCHI Labortechnik AG Connect two tubes between the AutoDest sensor (2) and the cooling condenser (4). When doing so pay attention to the direction of flow of the coolant. The arrows on the AutoDest sensor indicate the direction of flow. NOTE The distance between the AutoDest sensor and the cooling condenser should not be more than...

-

Page 39: Connecting Foam Sensor (Optional Accessory)

BÜCHI Labortechnik AG Installation | 5 Connecting foam sensor (optional accessory) The foam sensor uses infra-red to measure the level of foam formation inside the evaporating flask and initiates one or more short venting bursts to combat the foam. When de-foaming is active, it is indicated by the symbol on the status bar of the Interface I-300/I-300 Pro. -

Page 40: Connecting Valve Unit For External Vacuum

I-300 Pro. Connect the remote interface unit to the interface unit on the Rotavapor using the standard BUCHI communication port (COM). Use a standard BUCHI communication cable to do so. 40/96... -

Page 41: Operation

BÜCHI Labortechnik AG Operation | 6 Operation Navigating the menu The I-300 Pro offers the fundamental option of navigating the menu either by using the function buttons and the navigation control or by means of the touch-screen func- tionality of the display. The touch-screen functions can be operated using laboratory gloves. -

Page 42: Entering Parameter Settings

6 | Operation BÜCHI Labortechnik AG 6.1.2 Entering parameter settings The Interface I-300 offers the facility for manually setting various parameters. The parameters are shown on the home screen of the interface unit. Rotating the navigation control selects each parameter in turn. The currently selected parameter is highlighted in green. - Page 43 BÜCHI Labortechnik AG Operation | 6 Fig. 28: Options for the setting Press the navigation control to choose SAVE and save the selected option. Operation Manual Interface I-300 43/96...

-

Page 44: Performing Distillation

6 | Operation BÜCHI Labortechnik AG Performing distillation The Interface I-300 offers the following options for performing distillation: — Manuall For performing manual distillation, see Chapter 6.2.3 "Performing manual distillation", page 47. — Timer For performing timer-controlled distillation, see Chapter 6.2.4 "Performing timer-controlled distillation", page 50. —... -

Page 45: Overview: Typical Distillation Sequence

BÜCHI Labortechnik AG Operation | 6 6.2.1 Overview: typical distillation sequence Proper performance of a distillation process typically requires the following steps in the order indicated. NOTE The steps listed below in "Starting distillation" and "Stopping distillation" can also be pre-programmed via the interface unit, see Chapter 3.3.3 "Configuration", page 20. -

Page 46: Basic Functions

6 | Operation BÜCHI Labortechnik AG 6.2.2 Basic functions Venting during distillation There is the possibility to briefly venting the system while distillation is in progress. To briefly vent the system while distillation is in progress, press and hold the AERATE function button until the desired pressure is reached. -

Page 47: Performing Manual Distillation

BÜCHI Labortechnik AG Operation | 6 To stop all apparatus immediately, press the red STOP button (emergency stop). 6.2.3 Performing manual distillation In "Manual" operating mode (manual distillation), the distillation process can be controlled by manually setting the individual process parameters. CAUTION Risk of personal injury and property damage from unexpected equipment behavior... - Page 48 6 | Operation BÜCHI Labortechnik AG Parameters and readings Equipment possibly required — Actual reading and specified setting Heating Bath B-301/B-305 for heating bath temperature — Actual reading and specified setting Recirculating Chiller F-3xx for cooling temperature — Actual reading for vapor temperature AutoDest sensor or vapor temperature sensor —...

- Page 49 BÜCHI Labortechnik AG Operation | 6 Editing parameters during manual distillation There is the facility for changing individual parameter settings while distillation is in progress. Precondition: R Distillation process has been started. Select the parameter that is to be adjusted while distillation is in progress, see Chapter 6.1 "Navigating the menu", page 41.

-

Page 50: Performing Timer-Controlled Distillation

6 | Operation BÜCHI Labortechnik AG 6.2.4 Performing timer-controlled distillation In "Timer" mode, a distillation process with a predefined duration is started. CAUTION Risk of personal injury and property damage from unexpected equipment behavior Always carefully check the pre-programmed settings before every distillation process. - Page 51 BÜCHI Labortechnik AG Operation | 6 Parameters and readings Equipment possibly required — Actual reading and specified setting Recirculating Chiller F-3xx for cooling temperature — Actual reading for vapor temperature AutoDest sensor or vapor temperature sensor — Actual reading and specified setting for duration of distillation (timer) Parameters and readings Equipment possibly required...

- Page 52 6 | Operation BÜCHI Labortechnik AG Fig. 38: Editing parameters while distillation is in progress Enter the new setting for the timer. While the parameters are being edited, the distillation process continues running in the background (identifiable by the symbol on the status bar). Fig. 39: Saving edited parameter settings After the parameters have been altered, the timer jumps to the new setting and starts counting down the time from the beginning.

-

Page 53: Drying The System After Distillation ("Continuous Pumping")

BÜCHI Labortechnik AG Operation | 6 6.2.5 Drying the system after distillation ("Continuous pumping") In "Continuous pumping" mode, the system continues running in "idling" mode to dry out the vessels and tubing after a distillation process has finished. NOTE In "Continuous pumping" mode, the settings for manual or timer-controlled distillation are ignored. - Page 54 6 | Operation BÜCHI Labortechnik AG Fig. 42: "Continuous pumping" screen NOTE In "Continuous pumping" mode, only the following parameters can be edited: Rota- tion (rotation speed of the evaporating flask), Heating bath (temperature) and Recir- culating chiller (temperature). Those processes cannot be started via the interface unit and instead have to be started manually on the equipment concerned.

- Page 55 BÜCHI Labortechnik AG Operation | 6 Fig. 43: Continuous pumping for drying the system started To edit individual process parameters (e.g. rotation) while drying is in progress, select and edit the parameter concerned in each case. To stop the drying process, press the function button STOP. In this operating mode, the following parameters and readings are available: Parameters and readings Equipment possibly required...

- Page 56 6 | Operation BÜCHI Labortechnik AG Parameters and readings Equipment possibly required — Actual reading and specified setting Recirculating Chiller F-3xx for cooling temperature — Actual reading for vapor temperature AutoDest sensor or vapor temperature sensor — Actual reading for lift NOTE The pressure (vacuum) cannot be altered.

-

Page 57: Performing Automatic Distillation

BÜCHI Labortechnik AG Operation | 6 6.2.6 Performing automatic distillation Automatic distillation requires the use of an AutoDest sensor. The AutoDest sensor is connected to the VacuBox (see Chapter 5.3 "Connecting AutoDest sensor to vapor temperature sensor (optional accessory)", page 37) and measures the inlet and outlet temperature of the coolant and the vapor temperature at the cooling condenser.From those three readings, the system calculates the parameter settings required for optimum distillation. - Page 58 6 | Operation BÜCHI Labortechnik AG Parameters and readings Equipment possibly required Specified setting for vacuum VacuBox (e.g. with Vacuum Pump V-300/V-600) Actual reading for current pressure in distillation system Actual reading and specified setting for Rotavapor R-300 rotation speed (evaporating flask) Actual reading and specified setting for Heating Bath B-301/B-305 heating bath temperature...

-

Page 59: Drying The Product

Rotavapor R-300 rotates in alternating directions at defined intervals (e.g. 5 seconds). NOTE Drying not available with R-220 Pro: The operating mode "Drying" is not available if the Interface I-300 Pro is operated with the Rotavapor R-220 Pro. Navigation path ➔... - Page 60 6 | Operation BÜCHI Labortechnik AG 5 The display shows the home screen with the symbol for automatic drying in the status bar. NOTE Timer and rotation interval: the timer sets the duration of the complete drying process. The rotation interval specifies the period of time that the evaporating flask rotates in each direction.

- Page 61 BÜCHI Labortechnik AG Operation | 6 Parameters and readings Equipment possibly required — Actual reading for lift Rotavapor R-300 Display of lift position is not available for Rotavapor R-220 Pro. Operation Manual Interface I-300 61/96...

-

Page 62: Using The Solvent Library

6 | Operation BÜCHI Labortechnik AG Using the solvent library The Interface I-300 has an internal solvent library. Stored in that library are the most common solvents together with an algorithm in each case. Based on the chemical properties of the solvent, the algorithm calculates and dynamically sets the ideal vacuum according to the current readings for heating bath and coolant temperature. - Page 63 BÜCHI Labortechnik AG Operation | 6 To start a distillation process directly from the solvent library, press the function button START. To apply the settings for the selected solvent and return to the interface unit home screen, press OK. On the home screen, the settings for the individual process parameters can be edited.

-

Page 64: Activating Eco Mode

6 | Operation BÜCHI Labortechnik AG Activating eco mode The Interface I-300 offers an "eco mode" option for saving energy if the distillation system remains inactive for a predefined period of time. In eco mode, the distillation system shuts down the activity of the heating bath and recirculating chiller after a defined delay period so that: —... -

Page 65: Setting Hysteresis

The hysteresis setting is only relevant if the distillation system is not being operated with a BUCHI Vacuum Pump V-300 but with a different make of pump or with a laboratory vacuum supply, and is controlled by means of a valve. -

Page 66: Creating Favorites

6 | Operation BÜCHI Labortechnik AG Creating favorites The Interface I-300 offers the facility for saving individual functions and settings as favorites (bookmarks). Fig. 55: Submenu "Favorites" Clicking on any of the saved favorites takes you directly to the screen concerned. Fig. 56: Example of frequently used screen showing function button "Add to favorites"... -

Page 67: Mobile Connection

BÜCHI Labortechnik AG Mobile connection | 7 Mobile connection Setting up BUCHI Connect Solution The BUCHI Connect Solution is an IT solution for mobile monitoring of distillation processes. BÜCHI Cloud Fig. 57: BUCHI Connect scenario using distillation system, smartphone, cloud and server The BUCHI Connect Solution allows distillation processes to be tracked and analyzed from a smartphone or tablet while in progress. -

Page 68: Components Of The Buchi Connect Solution

Viewing the QR code. See Chapter 7.9 "Viewing the QR code", page 72. Starting the BUCHI Rotavapor app and adding a new system. See Chapter 7.11 "Connecting to the distillation system with the BUCHI Rotavapor app", page 74. Scanning the QR code with your smartphone. -

Page 69: Connecting Interface Unit To The Lan

BÜCHI Labortechnik AG Mobile connection | 7 In order to use the BUCHI Cloud a DNS server must be configured on the inter- face unit. NOTE If there is no DNS server available, the BUCHI Cloud connection must be configured by entering the IP address. - Page 70 7 | Mobile connection BÜCHI Labortechnik AG Data transmission via the LAN interface to the server Category Frequency System data: Every time connection is established — Serial number of interface unit — System name of interface unit — Interface unit model (I-300 or I-300 Pro) —...

-

Page 71: Enabling Interface Unit For Access To Buchi Cloud

Enabling interface unit for access to BUCHI Cloud Navigation path ➔ Configuration ➔ Settings ➔ Network➔ BUCHI Cloud Navigate to the "Network" screen and select the menu item "BUCHI Cloud", see Chapter 6.1 "Navigating the menu", page 41. Select the option "Yes". -

Page 72: Assigning Ip Addresses

7 | Mobile connection BÜCHI Labortechnik AG Fig. 59: Enabling interface unit for access to BUCHI Cloud Assigning IP addresses Navigation path ➔ Configuration ➔ Settings ➔ Network➔ DHCP Navigate to the "Network" screen and select the menu item "DHCP", see Chapter 6.1 "Navigating the menu", page 41. - Page 73 BÜCHI Labortechnik AG Mobile connection | 7 Fig. 61: Selecting "Connection QR code" from the submenu "Settings" Navigate to the "Settings" screen and select the menu item "Connection QR code", see Chapter 6.1 "Navigating the menu", page 41. 5 The display shows a QR code. Scanning the QR code using the Rotavapor app allows the mobile device to connect to the distillation system.

-

Page 74: Generating A Password

5 The display shows the password for connecting to the current distillation system. 7.11 Connecting to the distillation system with the BUCHI Rotavapor Start the BUCHI Rotavapor app.The app automatically connects to the BUCHI Cloud. Generate and view the QR code on the interface unit of the distillation system concerned. -

Page 75: Scanning The Qr Code With Your Smartphone

Precondition: R The interface unit shows the QR code for the distillation system concerned. Start the BUCHI Rotavapor app on your smartphone or tablet. Swipe the screen to scroll to the "List" page. Tap the (+) sign in the top left corner. -

Page 76: Activating Push Notifications

7.13 Activating push notifications The BUCHI Rotavapor app offers a series of optional push notifications that are automatically sent to the smartphone or tablet while a distillation process is running in order to keep the user up to date with the current status of distillation. -

Page 77: Remotely Retrieving Process Data

BÜCHI Labortechnik AG Mobile connection | 7 7.14 Remotely retrieving process data In the BUCHI Rotavapor app you can retrieve the general data for the distillation process currently running. Fig. 65: Start screen of BUCHI Rotavapor app Precondition: R BUCHI Rotavapor app is connected to the distillation system. - Page 78 BÜCHI Labortechnik AG Fig. 66: BUCHI Rotavapor app display while a process is running NOTE If the distillation system is equipped with an Interface I-300 Pro then, in addition to the parameter data, a progression graph can be displayed for the following parameters: —...

-

Page 79: Optional Function: Setting Up A Local Server

7.15 Optional function: setting up a local server As an alternative to the public BUCHI cloud, there is also the possibility of installing the server software within the local network. In that case, the local network operator must define the server IP address. Those details are entered on the interface unit for establishing the connection. -

Page 80: Cleaning And Servicing

Any servicing and repair work which involves opening up the casing may only be carried out by BUCHI service technicians. Use only genuine BUCHI consumables and spare parts in order to ensure correct operation of the device and preserve the warranty. -

Page 81: Fitting Gl14 Cap Nut With Tube Seal

BÜCHI Labortechnik AG Cleaning and servicing | 8 Fitting GL14 cap nut with tube seal Fig. 70: Fitting GL14 cap nut with tube seal (example shows VacuBox) 1 Tube seal 3 Tubing 2 GL14 cap nut Insert the tube seal (1) in the GL14 cap nut (2) ensuring it is straight. NOTICE! Risk of damaging tube seal. -

Page 82: Checking Seals

8 | Cleaning and servicing BÜCHI Labortechnik AG Checking seals Seals are wearing parts. They have to be regularly inspected, cleaned and, if necessary, replaced. The life of a seal depends on how much it is used and how well it is looked after. -

Page 83: Calibrating Autodest Sensor

Press the navigation control to choose OK and confirm the calibration offset. Calibrating the pressure sensor The pressure sensor is calibrated at the factory by BUCHI prior to delivery. However, it can be recalibrated with the aid of an external reference pressure gauge at any time. -

Page 84: Offset Calibration

8 | Cleaning and servicing BÜCHI Labortechnik AG 8.6.1 Offset calibration An offset has to be specified if the pressure indicated on the interface unit differs from the pressure indicated by an external reference pressure gauge. The difference between the two figures is referred to as the offset. The offset applies to the entire pressure range. -

Page 85: Loading Factory Calibration

BÜCHI Labortechnik AG Cleaning and servicing | 8 In the second stage, use the function buttons to increase/ decrease the vacuum in the system until the pressure shown on the reference gauge is within ±10 mbar of the specified setting. Enter the pressure indicated by the reference pressure gauge. Repeat the process for all subsequent stages. -

Page 86: Help With Faults

(for terminal vacuums greater than 700 mbar, set to automatic hysteresis; see Manual mode). Valve does not Valve body is dirty. Contact BUCHI Customer switch over Service. Valve lead not plugged in. Plug in valve lead. Vacuum is not Back-evaporation from the re-... -

Page 87: Error Messages

The addresses of the official BUCHI Customer Service offices can be found on the BUCHI website at: www.buchi.com. If you have any questions regarding technical issues or faults, please contact those offices. -

Page 88: Taking Out Of Service And Disposal

10 | Taking out of service and disposal BÜCHI Labortechnik AG Taking out of service and disposal 10.1 Taking out of service Switch off the Interface I-300 and disconnect it from the mains power supply. Remove all tubing and communication cables from the device. 10.2 Disposal The operator is responsible for proper disposal of the Interface. -

Page 89: Appendix

BÜCHI Labortechnik AG Appendix | 11 Appendix 11.1 Solvent table Solvent Formula Molar Evaporation en- Boiling Density in Vacuum in mass in g/ ergy in J/g point in °C g/cm mbar for at 1013 40 °C boil- mbar ing point Acetone 58.1 0.790 n-pentanol... - Page 90 11 | Appendix BÜCHI Labortechnik AG Solvent Formula Molar Evaporation en- Boiling Density in Vacuum in mass in g/ ergy in J/g point in °C g/cm mbar for at 1013 40 °C boil- mbar ing point Tetrachloroethene 165.8 1.623 THF (tetrahydrofu- 72.1 –...

-

Page 91: Spare Parts And Accessories

Appendix | 11 11.2 Spare parts and accessories Use only genuine BUCHI consumables and spare parts in order to ensure correct, safe and reliable operation of the system. NOTE Any modifications of spare parts or assemblies are only allowed with the prior written permission of BUCHI. -

Page 92: Wear Parts

Valve unit. Incl. Woulff bottle, 125mL, P+G, holder 11061887 Magnetic valve. Meant to be used with the Interface I-300/I-300 Pro. For operation with non-BUCHI vacuum pumps or house vacuum. Vapor temperature sensor. Incl. cap nut, seal GL14 11060707 Measures the vapor temperature inside the system. Meant to be used with the Interface I-300/I-300 Pro. -

Page 93: Spare Parts

BÜCHI Labortechnik AG Appendix | 11 11.2.3 Spare parts Seals Set. For Woulff bottle/valve unit 045544 Content: O-ring (048406, 5pcs), O-ring (047169, 5pcs). Set. For Woulff bottle/valve unit 045545 Content: O-ring (048406, 5pcs), O-ring (047169, 5pcs), spare parts for valve unit (047258), seal (047165). Further spare parts Holder. -

Page 94: Health And Safety Approval

11 | Appendix BÜCHI Labortechnik AG 11.3 Health and safety approval To guarantee the health and safety of our staff and to comply with the law and the regulations for handling hazardous materials, for the purposes of health and safety at work and safe disposal of waste, no products may be sent back to BÜCHI Labortechnik AG or repaired unless we have received the declaration below, completed and signed. -

Page 95: Health And Safety

BÜCHI Labortechnik AG Appendix | 11 11.4 Health and safety Declaration regarding the safety, hazards and safe disposal of waste To guarantee the health and safety of our staff and to comply with the law and the regulations for handling hazardous materials, regarding health and safety at work, and to comply with safety regulations, health and safety requirements and require- ments for safe disposal of waste such as chemical waste, chemical residues or solvents, the form below must be fully completed and signed whenever devices or... - Page 96 T +55 19 3849 1201 F +66 2 862 08 54 F +971 4 313 2861 F +55 19 3849 2907 bacc@buchi.com middleeast@buchi.com latinoamerica@buchi.com www.buchi.com/th-th www.buchi.com www.buchi.com/es-es We are represented by more than 100 distribution partners worldwide. Find your local representative at: www.buchi.com...

Need help?

Do you have a question about the Interface I-300 PRO and is the answer not in the manual?

Questions and answers