Summary of Contents for Endress+Hauser Smartec S CLD132

-

Page 1: Operating Instructions

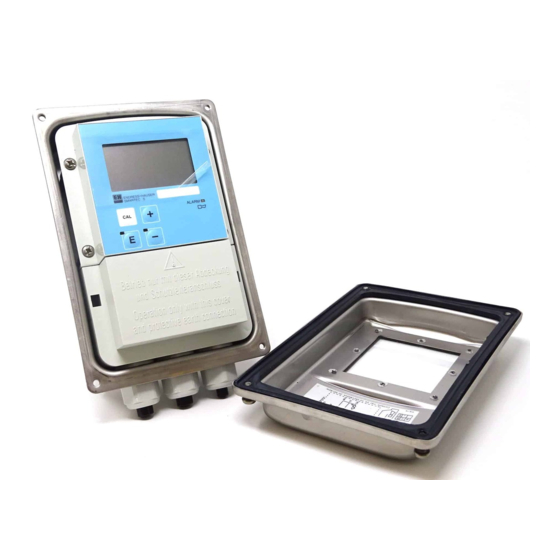

Operating Instructions Smartec S CLD132 Conductivity Measuring System BA207C/07/en/09.04 51501595 Software version 1.00 or later... - Page 2 Spare parts that can be delivered and a system overview are listed on these pages. ▼ Technical data → Page 73 Dimensions → Page 73 ff. Process conditions, weight, material ▼ Index → Page 80 ff. The index helps you to find information and important terms easily and quickly. Endress+Hauser...

-

Page 3: Table Of Contents

3.1.1 Measuring system ....9 Maintenance of Smartec S CLD132 ... . 54 Incoming acceptance, transport, storage . - Page 4 Smartec S CLD132 Technical Data....71 10.1 Input ........71 10.2 Output .

-

Page 5: Safety Instructions

Safety instructions Safety instructions Designated use Smartec S CLD132 is a field-tested and reliable transmitter used to determine the conductivity of liquid media. It is particularly suitable for use in the foodstuffs industry. Any other use than the one described here compromises the safety of persons and the entire measuring system and is, therefore, not permitted. -

Page 6: Return

Safety instructions Smartec S CLD132 Return If the transmitter has to be repaired, please return it cleaned to the sales centre responsible. Please use the original packaging, if possible. Please enclose the completed "Declaration of contamination" (copy the second last page of these Operating Instructions) with the packaging and the transportation documents. -

Page 7: Identification

0...+55 °C C07-CLD132xx-18-06-00-xx-001.eps Fig. 1: Nameplate CLD132 (example) 2.1.2 Product structure Smartec S CLD132 Version Compact version Separate transmitter, cable length 20 m / 65.62 ft Separate transmitter, cable length 5 m / 16.41 ft Separate transmitter, cable length 10 m / 32.81 ft Process connection Dairy fitting DN 50 (acc. -

Page 8: Basic Version And Function Extensions

• Relay can be configured as alarm or limit contact Scope of delivery The scope of delivery of the compact version inlcudes: • Smartec S CLD132 compact measuring system with integrated sensor • Terminal strip set • Expansion bellows (-*GE1***** versions only) •... -

Page 9: Installation

• If you have not yet installed the sensor at the measuring point, perform an Airset and install the sensor (see the Technical Information of the sensor). • Connect the sensor to the Smartec S CLD132 as described in the chapter "Electrical connection". • Connect the transmitter as described in the chapter "Electrical connection". -

Page 10: Incoming Acceptance, Transport, Storage

Installation Smartec S CLD132 Incoming acceptance, transport, storage • Make sure the packaging is undamaged! Inform the supplier about damage to the packaging. Keep the damaged packaging until the matter has been settled. • Make sure the contents are undamaged! Inform the supplier about damage to the delivery contents. -

Page 11: Cld132 Separate Version

Smartec S CLD132 Installation 3.3.2 CLD132 separate version 142 / 5.59 Ø 7 / 0.28 225 / 8.86 175 / 6.89 mm /inch C07-CLD132xx-11-06-00-en-001.EPS Fig. 5: CLD132 wall mounting with mounting plate C07-CLD132xx-11-06-00-en-002.EPS Fig. 6: CLD132 mounting on pipes (Ø 60 mm / 2.36") - Page 12 Installation Smartec S CLD132 Conductivity sensors for the separate transmitter CLS52 conductivity sensors with various process connections covering all common installation conditions are available for the separate version. Note! Perform an Airset and calibrate the sensor before sensor installation. C07-CLD132xx-11-06-00-en-003.EPS Fig.

-

Page 13: Cld 132 Compact Version

Smartec S CLD132 Installation Measuring range C07-CLD132xx-05-06-00-xx-002.eps Fig. 8: CLS52 measuring range 3.3.3 CLD 132 compact version 225 / 8.86 142 / 5.59 35.5 / 1.40 ∅ 49 / 1.93 34 / 1.34 mm / inch C07-CLD132xx-11-06-00-en-004.eps Fig. 9: Dimensions of CLD132 compact version... - Page 14 Installation Smartec S CLD132 Connection variants Various process connections covering all common installation conditions are available for the compact version. The compact version is installed at the measuring point with the required process connection. C07-CLD132xx-11-06-00-en-005.eps Fig. 10: Process connections for the CLD132 compact version Note! •...

-

Page 15: Installation Instructions

Smartec S CLD132 Installation Installation instructions 3.4.1 Mounting CLD132 separate version Wall mounting For wall mounting, attach the mounting plate to the wall by drilling holes as required. Anchors and screws are to be provided by the operator. ∅ 7 / 0.28 225 / 8.86... -

Page 16: Mounting Cld132 Compact Version Or Cls52 Sensor For Separate Version

Fig. 14: Installation of CLD132 compact version When installing the Smartec S CLD132 or the sensor, make sure that the flow opening of the sensor is oriented in the flow direction of the medium. An orientation arrow on the sensor facilitates orientation (see Fig. -

Page 17: Post-Installation Check

Smartec S CLD132 Installation Sensor positioning: compact version The sensor in the compact housing must be oriented in the flow direction. If you need to reorient the sensor in relation to the housing, proceed as follows: Remove the cover. Loosen the screws of the electronics box and carefully remove the box from the housing. -

Page 18: Wiring

• Ensure that there is no voltage at the power cable before beginning the connection work. 4.1.1 Electrical connection of transmitter Proceed as follows to connect the Smartec S CLD132: 1. Loosen the 4 Phillips screws on the housing cover and remove the cover. -

Page 19: Version

Smartec S CLD132 Wiring C07-CLD132xx-04-06-04-xx-001.eps Fig. 17: Terminal assignments of cable glands on Smartec S CLD132 Separate version Compact version Plug, Pg 13.5, analog output, binary input Plug, Pg 13.5, analog output, digital input Cable gland for alarm contact, Pg 13.5 Cable gland for alarm contact, Pg 13.5... - Page 20 10-50 V ∼ – ∼ – 10-50 V C07-CLD132xx-05-06-00-xx-003.eps Fig. 19: Electrical connection of Smartec S CLD132 Signal output 1 conductivity Conductivity sensor Signal output 2 temperature Temperature sensor Auxiliary power output Alarm (contact position: no current) Binary input 2 (MRS1+2)

-

Page 21: Version

Smartec S CLD132 Wiring Connection compartment sticker 131082-4A Sensor 31 + 32 - 33 + Temp. (opt.) 34 - 85 + +15V 10mA 86 - 93 + Bin 2 94 - 81 + Bin 1 82 - ∼ – Mains ∼... -

Page 22: Post-Connection Check

Wiring Smartec S CLD132 Post-connection check After wiring up the electrical connection, carry out the following checks: Device status and specifications Remarks Are the transmitter or the cable externally damaged? Visual inspection Electrical connection Remarks Are the installed cables strain-relieved? No loops and cross-overs in the cable run? Are the signal cables correctly connected acc. -

Page 23: Operation

Note! For operation via HART or PROFIBUS PA/DP, read the corresponding chapters in the additional operating instructions: • PROFIBUS PA/DP, field communication with Smartec S CLD132, BA 213C/07/en ® • HART , field communication with Smartec S CLD132, BA 212C/07/en The following chapters describe local operation via operating keys. -

Page 24: Operating Elements

SMARTEC S ALARM – C07-CLD132xx-19-06-00-xx-001.eps Fig. 25: Operating elements of Smartec S CLD132 Liquid crystal display showing measured values and configuration data 4 operating keys for calibration and instrument configuration Field for user labeling LED indicator for alarm function 5.2.3... - Page 25 Smartec S CLD132 Operation PLUS key and MINUS key In setup mode, the PLUS and MINUS keys have the following functions: • Selection of function groups Note! To select function groups in the order given in the chapter "Instrument configuration", use the MINUS key.

-

Page 26: Local Operation

Operation Smartec S CLD132 Local operation 5.3.1 Operating concept Operating modes Measuring mode: standard mode of operation, displaying current measured values Setup mode Calibration mode: access to all execution of calibration routine configuration settings Code The function groups are selected with the PLUS or MINUS key. - Page 27 Smartec S CLD132 Operation Menu structure The configuration and calibration functions are arranged in a menu structure by function groups. The function groups are selected in the setup mode with the PLUS and MINUS keys. The ENTER key is used to move from one function to the next within a function group.

-

Page 28: Commissioning

C111 top to the bottom and from the left to the right. C07-CLD132xx-13-06-00-xx-005.eps Fig. 29: Function coding For a detailed description of the function groups available on the Smartec S CLD132 see the chapter "Instrument configuration". Endress+Hauser... -

Page 29: Endress+Hauser

Smartec S CLD132 Commissioning Factory settings When the instrument is switched on for the first time, the factory settings are in effect. The following table provides an overview of all major settings. Please refer to the description of the individual functions in the chapter "Instrument configuration"... -

Page 30: Quick Setup

Commissioning Smartec S CLD132 Quick setup After switching the transmitter on, configure the major functions required for accurate measurement. The following section gives you an example for a basic configuration. Input Selection or range Display (factory setting bold) 1. Press the ENTER key. - Page 31 Smartec S CLD132 Commissioning Input Selection or range Display (factory setting bold) 14. In A6, press the ENTER key to confirm the factory setting. 1.000 If your wall distance is smaller than 15 mm / 0.59", 0.10 ... 1 ... 5.00 refer to the chapters 3.3.1 and 6.4.14 for information...

-

Page 32: Endress+Hauser

Commissioning Smartec S CLD132 Input Selection or range Display (factory setting bold) 26. In O2, select the linear characteristic. lin = linear (1) Confirm your selection by pressing ENTER. sim = simulation (2) Sel.Type 27. In O211, select the current range for your output, e.g. -

Page 33: Instrument Configuration

Smartec S CLD132 Commissioning Instrument configuration The following sections give a detailed description of all Smartec S CLD132 functions. 6.4.1 Setup 1 (conductivity, concentration) In the SETUP 1 function group, you can change the operating mode and the sensor settings. -

Page 34: Setup 2 (Temperature)

Commissioning Smartec S CLD132 6.4.2 Setup 2 (temperature) The temperature compensation only needs to be performed in the conductivity mode (selection in field A1). The temperature coefficient specifies the change in conductivity per degree of temperature change. It depends on the chemical composition of the medium and the temperature itself. - Page 35 Smartec S CLD132 Commissioning k( ) C07-CLD132xx-05-06-00-xx-011.eps Fig. 33: Determination of temperature coefficient Required data Calculated α values Use the following formula to calculate the α values for the temperatures occurring in your process: κ κ (T) - (T ) α...

-

Page 36: Current Outputs

Commissioning Smartec S CLD132 Coding Field Selection or range Display Info (factory settings bold) ° 25.0 Enter process 25 °C Only if B1 = fixed. temperature -10.0 ... 150.0 °C This value can only be specified in °C. ProcTemp. Display temperature Display and entry of real °... -

Page 37: Alarm

Smartec S CLD132 Commissioning Coding Field Selection or range Display Info (factory settings bold) Enter the measured value corresponding to Cond: 2000 mS/cm 20 mA value: the maximum current value (20 mA) at the mS/cm 2000 Conc: 99.99 % O213... -

Page 38: Check

Commissioning Smartec S CLD132 Coding Field Selection or range Display Info (factory settings bold) Select the errors that are to trigger an alarm signal. The errors are selected via the error number. Select error Please refer to the table in chapter 9.2 "System 1 ... -

Page 39: Relay Configuration

(Error no.: E152) 6.4.6 Relay configuration For Smartec S CLD132 equipped with remote parameter set switching (measuring range switching), there are three options for configuring the relay (selection in field R1): • Alarm The relay closes the contact 41/42 (voltage-free, safe state) if an alarm condition according to chapter 9.2 occurs and if the setting in the “Alarm contact”... - Page 40 Commissioning Smartec S CLD132 C07-CLD132xx-05-06-00-xx-008.eps Fig. 35: Relation of switch-on and switch-off points and pickup and dropout delays Switch-on point > switch-off point: Max. function Switch-on point Switch-on point < switch-off point: Min. function Switch-off point Contact ON Contact OFF...

-

Page 41: Temperature Compensation With Table

Smartec S CLD132 Commissioning Coding Field Selection or range Display Info (factory settings bold) Enter dropout delay 0 ... 2000 s Off Delay auto auto This selection can only be made if limit has Select simulation manual been selected in R1. -

Page 42: Concentration Measurement

6.4.8 Concentration measurement The Smartec S CLD132 transmitter can convert conductivity values to concentration values. For this, set the operating mode to Concentration measurement (see field A1). You must enter the basic data to which the concentration calculation should refer. For the most common substances, the required data is already saved in your device. - Page 43 Smartec S CLD132 Commissioning κ κ C07-CLD132xx-05-06-00-xx-012.eps Fig. 36: Measured data for variable process temperatures (example) κ Conductivity Measuring point Concentration Measuring range Temperature κ κ ma x ma x C07-CLD132xx-05-06-00-xx-015.epsB Fig. 37: Measured data for a constant process temperature (example) κ...

- Page 44 Commissioning Smartec S CLD132 • Enter the values in the order of increasing concentration (see the following example). mS/cm °C Coding Field Selection or range Display Info (factory settings bold) Settings for concentration measurement. Four Function group fixed and four editable concentration fields are CONCENTRATION stored in this function group.

-

Page 45: Service

Smartec S CLD132 Commissioning Coding Field Selection or range Display Info (factory settings bold) mS/cm Enter uncompensated 0.0 mS/cm conductivity 0.0 ... 9999 mS/cm conduct. Enter concentration 0.00 % value for K6 0.00 ... 99.99 % concentr. °C Enter temperature 0.0 °C... -

Page 46: E+H Service

Commissioning Smartec S CLD132 Coding Field Selection or range Display Info (factory settings bold) Manual hold Man.HOLD Enter hold dwell 10 s period 0 ... 999 s Cont.Time Enter SW upgrade Entering an incorrect code returns you to the release code of measurement menu. -

Page 47: Interfaces

Smartec S CLD132 Commissioning Coding Field Selection or range Display Info (factory settings bold) E111 E111: Version of transmitter software xx.xx E121 Software version is E111 E121-141: Version of module firmware (if E131 displayed available) E141 SW-Vers. E112 xx.xx E122... -

Page 48: Determining The Temperature Coefficient

MRS) You can order the remote parameter set switching via binary inputs directly as an option of your Smartec S CLD132 (see "Product structure") or you can retrofit a standard transmitter with the MRS function extension (see the chapter "Accessories"). - Page 49 Smartec S CLD132 Commissioning Assignment of binary inputs The Smartec S CLD132 transmitter has 2 binary inputs. They can be defined in field M1 as follows: Assignment of field M1 Assignment of binary inputs M1 = 0 MRS not active. The binary input 1 can be used for external hold.

- Page 50 Commissioning Smartec S CLD132 Coding Field Selection or range Display Info (factory settings bold) cond. cond = conductivity The operating mode can be individually Select operating mode conc = concentration defined for each parameter set. Oper.Mode NaOH NaOH, H2SO4, H3PO4, HNO3 Select medium Only available if M4 = conc.

-

Page 51: Calibration

Smartec S CLD132 Commissioning 6.4.14 Calibration To access the "Calibration" function group, press the CAL key. This function group is used to calibrate the transmitter. Two different types of calibration are possible: • Calibration by measurement in a calibration solution of a known conductivity. - Page 52 Commissioning Smartec S CLD132 Coding Field Selection or range Display Info (factory settings bold) If C113 = E xxx, then only no or new. Store calibration C114 C114 If new, return to C. results? If yes/no, return to “Measurement”. Store...

-

Page 53: Communication Interfaces

Smartec S CLD132 Commissioning Coding Field Selection or range Display Info (factory settings bold) Airs = Airset (1) Calibration with InstF Cellc = cell constant (2) C1 (3) sensor adaptation for InstF = installation Sensor calibration with compensation of wall... -

Page 54: Maintenance

• For your own safety, use only original spare parts. Original parts will guarantee functionality, accuracy and reliability after repairs. Note! Please contact your Endress+Hauser representative if you have any questions. You can also send your queries to the Endress+Hauser Service Organisation via the Internet: www.endress.com Maintenance of Smartec S CLD132 7.1.1... -

Page 55: Special Case: Replacement Of Central Module

– Monitoring functions – Interface parameters Dismantle the instrument as described in the chapter "Dismantling Smartec S CLD132". Refer to the part number of the central module to determine whether the new module has the same part number as the old one. -

Page 56: Maintenance Of Measuring System

Maintenance Smartec S CLD132 Maintenance of measuring system 7.2.1 Cleaning conductivity sensors Inductive sensors are less sensitive to soiling than conventional conductive sensors since there is no galvanic contact with the medium. However, dirt may collect in the measuring opening (making it narrower), which changes the cell constant. -

Page 57: Instrument Check By Medium Simulation

Smartec S CLD132 Maintenance 7.2.3 Instrument check by medium simulation The inductive sensor cannot be simulated. However, the overall system comprising the CLD132 and inductive sensor can be checked using equivalent resistances. Note the cell constant ( k = 5.9 for CLS52). -

Page 58: Checking Line Extension And Junction Box

Maintenance Smartec S CLD132 7.2.4 Checking line extension and junction box • Use the methods described in chapters "Checking inductive conductivity sensors" and "Instrument check by medium simulation" to perform a quick functional check from the conductivity sensor to the measuring instrument via an extension. -

Page 59: Accessories

Inductive conductivity sensor with fast response time and hygienic design; with integrated temperature sensor. Order according to product structure, see Technical Information TI 167C/07/en. One Indumax H CLS52 is included in the Smartec S CLD132 scope of delivery. Extension cable ❑Extension cable CLK5 for inductive conductivity sensors, for extension via the VBM junction box, sold by the metre;... -

Page 60: Post Mounting Kit

Accessories Smartec S CLD132 Post mounting kit ❑Mounting kit for installation of Smartec S CLD132 on horizontal or vertical pipes and posts (max. Ø 60 mm / 2.36"), material stainless steel 1.4301; order no.: 50062121 C07-CLD132xx-00-06-06-001.eps Fig. 40: Mounting kit for installing CLD132 separate version on posts or pipes Software upgrade ❑Software upgrade... -

Page 61: Troubleshooting

Optoscope, see chapter "Service equipment not match hardware (central module) Optoscope"). E002 4. If problem persists, return instrument to your local Endress+Hauser sales agency for repair or replace instrument. Download error Download must not access locked functions (e.g. E003 temperature table in basic version). -

Page 62: Process-Specific Errors

Troubleshooting Smartec S CLD132 Error no. Display Tests and / or measures Alarm contact Error current Factory User Factory User E063 Below current output range 1 Check measured value and current output assignment (function group O). E064 Current output range 1 exceeded... - Page 63 Smartec S CLD132 Troubleshooting Error Possible cause Tests and / or remedial measures Equipment, spare parts, personnel Short circuit / moisture in sensor Check sensor. See chapter "Checking inductive conductivity sensors". Short circuit in cable or junction box Check cable and junction box.

- Page 64 Troubleshooting Smartec S CLD132 Error Possible cause Tests and / or remedial measures Equipment, spare parts, personnel Relay configured for alarm Activate limit contactor. See field R1. Pickup delay setting too long Shorten pickup delay. See field R4. Limit contact does not work "Hold"...

-

Page 65: Instrument-Specific Errors

"Spare parts". active Power supply unit defective Replace power supply unit using correct On-site diagnosis by Endress+Hauser Service variant. (test module required) Central module LSCH / LSCP defective Replace central module using correct On-site diagnosis by E+H Service (test variant. - Page 66 Troubleshooting Smartec S CLD132 Error Possible cause Tests and / or remedial measures Equipment, spare parts, personnel Ribbon cable or transmitter module not Reinsert transmitter module, use additional Refer to exploded view in chapter "Spare Display shows measured properly installed fastening screw M3 if necessary.

-

Page 67: Spare Parts

Smartec S CLD132 Troubleshooting Spare parts Spare parts are to be ordered from your sales centre responsible. Specify the order numbers listed in the chapter "Spare parts kits". To be on the safe side, you should always specify the following data with your spare part orders: •... -

Page 68: Exploded View

Smartec S CLD132 9.5.1 Exploded view C07-CLD132xx-09-06-06-en-001.eps The exploded view drawing shows all components and spare parts of Smartec S CLD132. Use the position numbers to find the spare parts designation and their order number in the following section. Endress+Hauser... -

Page 69: Spare Part Kits

Smartec S CLD132 Troubleshooting 9.5.2 Spare part kits Item Kit designation Name Function/content Order number Housing bottom, separate Bottom assembly 51501574 Housing bottom, compact Bottom assembly 51501576 Post mounting kit 1 pair of post mounting parts 50062121 Housing cover Cover with accessories... -

Page 70: Return

Troubleshooting Smartec S CLD132 Item Kit designation Name Function/content Order number Cable entry kit Conduit Cable glands, plugs, Goretex filter 51502283 Screw and gasket kit All screws and gaskets 51501596 Protection cover kit Protection cover for connection 51502382 compartment Return If the transmitter has to be repaired, please return it cleaned to the sales centre responsible. -

Page 71: Technical Data

Smartec S CLD132 Technical Data Technical Data 10.1 Input Measured variables Conductivity Concentration Temperature Measuring range Conductivity: recommended range: 100 µS/cm ... 2000 mS/cm (uncompensated) Concentration – NaOH: 0 ... 15 % – HNO 0 ... 25 % – H 0 ... -

Page 72: Power Supply

–10 ... +70 °C / 14 ... 158 °F (separate version) –10 ... +55 °C / 14 ... 131 °F (compact version) (see Fig. 41 "Permissible temperature ranges of Smartec S CLD132") Storage temperature –25 ... +70 °C / -13 ... 158 °F Electromagnetic compatibility Interference emission and interference resistance acc. -

Page 73: Mechanical Construction

Smartec S CLD132 Technical Data 10.6 Mechanical construction Design, dimensions Separate transmitter with mounting L x W x D: 225 x 142 x 109 mm / plate: 8.86 x 5.59 x 4.29" Compact transmitter MV1, CS1, L x W x D: 225 x 142 x 242 mm / GE1, SMS versions: 8.86 x 5.59 x 9.53"... - Page 74 Technical Data Smartec S CLD132 Permissible temperature ranges of Smartec S CLD132 [°F] [°F] [° C] –10 –5 [° C] Medium temperature C07-CLD132xx-05-06-00-en-013.eps Fig. 41: Permissible temperature ranges of Smartec S CLD132 CLS52 sensor with separate version Compact version short-term for sterilisation (< 30 min) Pressure-temperature load curve of CLS52 sensor C07-CLS52xxx-05-05-00-en-001.eps...

-

Page 75: Chemical Durability Of Cls52 Sensor

Indumax H CLS52, Technical Information TI 167C/07/en Order no.: 50086110 PROFIBUS PA/DP, Field communication with Smartec S Order no.: 51502194 CLD132, Operating Instructions BA 213C/07/en ® HART , Field communication with Smartec S CLD132, Order no.: 51502192 Operating Instructions BA 212C/07/en Endress+Hauser... -

Page 76: Appendix

Appendix Smartec S CLD132 Appendix Operating matrix C07-CLD132xx-13-06-00-en-001.eps Endress+Hauser... - Page 77 Smartec S CLD132 Appendix C07-CLD132xx-13-06-00-en-002.eps Endress+Hauser...

- Page 78 Appendix Smartec S CLD132 C07-CLD132xx-13-06-00-en-003.eps Endress+Hauser...

- Page 79 Smartec S CLD132 Appendix C07-CLD132xx-13-06-00-en-004.eps Endress+Hauser...

-

Page 80: Index

Connection compartment sticker ....21 Smartec S CLD132 ......54 Connection diagram . - Page 81 Smartec S CLD132 Product structure ....... . 7 Quick setup........30 Relay configuration .

- Page 82 Smartec S CLD132 Endress+Hauser...

- Page 84 www.endress.com/worldwide BA207C/07/en/09.04 Printed in Germany / FM+SGML 6.0 / DT 51501595...

Need help?

Do you have a question about the Smartec S CLD132 and is the answer not in the manual?

Questions and answers