Summary of Contents for Toshiba B-FV4D-GS12-QM-R

- Page 1 B-FV4D SERIES Printer Owner’s Manual B-FV4D-GS12-QM-R B-FV4D-GS12-QM-R B-FV4D-TS12-QM-R B-FV4D-TS12-QM-R ...

- Page 2 ■ Reorient or relocate the receiving antenna. ■ Increase the separation between the equipment and the receiver. ■ Connect the equipment into a different outlet on a different circuit. ■ Consult the dealer or an experience Radio/TV technician for help. This unit was tested with shielded cables on the peripheral devices. Shielded cables must be used with the unit to insure compliance. The user is cautioned that any changes or modifications not expressly approved by Toshiba TEC Corporation could void the user’s authority to operate the equipment. i ...

- Page 3 In no event shall Toshiba or anyone else involved in the creation, production, or delivery of the accompanying product (including hardware and software) be liable for any damages whatsoever (including, ...

- Page 4 Standards below are certified under the operation with the provided antenna. Do not use this product with other antennas. Europe - EU Declaration of Conformity Hereby, TOSHIBA TEC, declares that B-FV4D series are in compliance with the essential requirements and other relevant provisions of Directive 1999/5/EC.

- Page 5 CAUTION: This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) this device may not cause harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired operation. Any changes or modifications not expressly approved by the grantee of this device could void the user's authority to operate the equipment.

- Page 6 (antennes sont supérieures à 20 cm à partir du corps d'une personne). Approved Countries/Regions for use for the devices This equipment is approved to the radio standard by the specific countries/regions. Please ask TOSHIBA TEC authorized dealer or service engineer. Precaution for Use...

- Page 7 This product communicates with other devices by radio. Depending on the installation location, orientation, environment, etc., its communication performance may deteriorate or devices installed near by may be affected. Bluetooth ® devices operate within the same radio frequency range and may interfere with ®...

-

Page 8: Table Of Contents

1 Introduction ......................1 1.1 Features....................1 1.2 Unpacking ....................2 1.3 Understanding Your Printer ..............3 1.3.1 Perspective View................3 1.3.2 Back View..................4 1.3.3 Interior View ..................5 1.4 Printer Lights ..................6 1.4.1 Status Lights ...................6 1.4.2 System Mode .................7 2 Getting Started.......................8 2.1 Attaching Power ..................8 2.2 Turning On/Off the Printer..............9 2.2.1 Turn On the Printer ................9 2.2.2 Turn Off the Printer ..............10 2.3 ... - Page 9 5 Troubleshooting ....................33 5.1 Printer Issues..................33 5.2 Media Issues..................34 5.3 Other Issues ..................36 6 Specifications .......................37 6.1 Printer ....................37 6.2 Media ....................39 6.3 Bar Code....................40 6.4 Bluetooth .....................43 6.5 Electrical and Operating Environment ..........44 6.6 Physical Dimension ................44 6.7 Interfaces....................45 6.7.1 USB ....................45 6.7.2 Ethernet ..................46 6.7.3 RS‐232C ..................47 ...

-

Page 10: Introduction

1 Introduction Features 1 Introduction Thank you for purchasing a Toshiba B‐FV4D printer. This manual provides information about how to set up and operate your printer, load the media and solve common problems. 1.1 Features ■ Various Connectivity Options USB, Ethernet, RS‐232C, Centronics ■ Easy Operation One‐button design for easy control ■ High Print Resolution 203 dpi for GS models, 300 dpi for TS models ■ Fast Print Speed Max 6 inches/sec for GS models, max 4 inches/sec for TS models ■ Wireless Connection Build a wireless printing environment with Bluetooth ■ External Memory The extra USB port allows you to use a USB flash drive for storage ■... -

Page 11: Unpacking

1 Introduction Unpacking 1.2 Unpacking Make sure all of the following items are included in your package. CD Toshiba B‐FV4D Including document and Toshiba B‐FV4D Printer Quick Installation software Guide AC Power Cord USB Cable Power Supply When you receive the printer, open the package immediately and inspect for shipping damage. If you discover any damage, contact the shipping company and file a claim. Toshiba is not responsible for any damage incurred during shipping. Save all package materials for the shipping company to inspect. Note If any item is missing, please contact your local dealer. 2 ... -

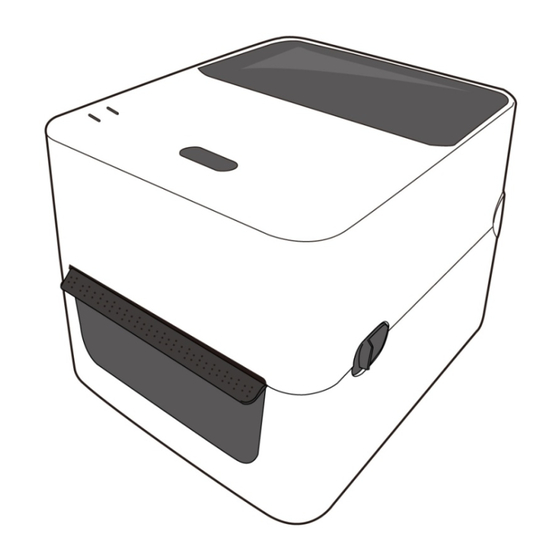

Page 12: Understanding Your Printer

1 Introduction Understanding You Printer 1.3 Understanding Your Printer 1.3.1 Perspective View 3 ... -

Page 13: Back View

1 Introduction Understanding You Printer 1.3.2 Back View Optional Interfaces 4 ... -

Page 14: Interior View

1 Introduction Understanding You Printer 1.3.3 Interior View 5 ... -

Page 15: Printer Lights

1 Introduction Printer Lights 1.4 Printer Lights There are two LED lights that show the status of your printer. 1.4.1 Status Lights Status lights help you check printer’s condition. The following tables show the blinking speed of status lights and the conditions they indicate. Symbol Blinking Speed Blinking Interval Fast 0.5 Second Medium 1 Second Slow 2 Seconds LED 1 LED 2 Description Off Off The print module is opened when the printer is turned on. Green Off In the online mode. Green Off The printer is transmitting data. Green Off In a pause state. ... -

Page 16: System Mode

1 Introduction Printer Lights 1.4.2 System Mode The system mode consists of status light color combinations. It contains a list of commands for you to select and run. To enter the system mode and run the command, do the following: 1. Turn off the printer. 2. Press and hold the FEED button, and turn on the printer. 3. Both status lights glow solid orange for a few seconds. Next, they turn to green shortly, and then turn to other colors. 4. When status lights show the color combination you need, release the FEED button immediately. 5. Press the FEED button to run the command. The following table is the command list of the system mode. LED 1 LED 2 Command Green Red Transmissive Sensor Calibration (Section 3.1) Green Orange Reflective Sensor Calibration (Section 3.1) Red Red Resetting the Printer (Section 3.3) Red Orange TPCL Auto Call Cancellation Red ... -

Page 17: Getting Started

2 Getting Started Attaching Power 2 Getting Started This chapter describes how to set up your printer. 2.1 Attaching Power 1. Make sure the power switch is set to the OFF position. 2. Insert the power supply’s connector into the printer power jack. 3. Insert the AC power cord into the power supply. 4. Plug the other end of the AC power cord into the wall socket. Important Use only power supplies listed in the user instructions. Warning Do not plug the AC power cord with wet hands, or operate the printer and the power supply in an area where they may get wet. Serious injury may result from these actions! 8 ... -

Page 18: Turning On/Off The Printer

2 Getting Started Turning On/Off the Printer 2.2 Turning On/Off the Printer When the printer is connected to a host (the computer), it is good to turn on the printer before turning on the host, and turn off the host before turning off the printer. 2.2.1 Turn On the Printer 1. To turn on the printer, turn on the Power Switch as below. The “I” is the ON position. 2. Both status lights glow solid orange for a few seconds, and then LED 2 goes out, while LED 1 turns to solid green. Note If you connect the printer to the internet or insert a USB drive before turning on the printer, it will take longer for the printer to enter the online mode (LED 1 glows solid green) after you turn it on. 9 ... -

Page 19: Turn Off The Printer

2 Getting Started Turning On/Off the Printer 2.2.2 Turn Off the Printer 1. Make sure LED 2 is off and LED 1 is solid green before turning off the printer. 2. To turn off the printer, turn off the Power Switch as below. The “O” is the OFF position. Caution Do not turn off the printer during data transmission. 10 ... -

Page 20: Loading Media

2 Getting Started Loading Media 2.3 Loading Media There are various types and sizes for the media roll. Load the applicable media to satisfy your need. 2.3.1 Preparing Media The inside wound and outside wound media roll can be loaded into the printer the same way. In case the media roll is dirty during shipping, handling or storage, remove the outside length of the media. It helps avoid dragging adhesive and dirty media between the printhead and platen roller. Inside Wound Outside Wound 2.3.2 Placing Media Roll 1. Open the top cover of the printer. 11 ... - Page 21 2 Getting Started Loading Media 2. Press the holder lock on the Media Roll Holders to slide them outward, and place the media roll between the holders. Make sure the print side is up, and the media roll is clamped tightly by the holders. Note The default core holder is set for 1.5‐inch inside diameter (ID). To install a 1‐inch ID media roll, use your hand or a coin to loosen two thumbscrews on both holders, turn over the core holders and secure them back. 1 inch 1.5 inch 12 ...

- Page 22 2 Getting Started Loading Media 3. Pull the media until it reaches out of the printer. Thread the media under the media guides. 4. Close the top cover. 13 ...

-

Page 23: Testing Media Feed

2 Getting Started Loading Media 2.3.3 Testing Media Feed 1. Turn on the printer, and press the FEED button to feed a label. 2. Flip the media and tear it along the edge of the top cover. 14 ... -

Page 24: Media Types

2 Getting Started Loading Media 2.3.4 Media Types Your printer supports various media types, including non‐continuous media, continuous media, and fanfold media. The following table provides details about them. Media Type Looks Like Description Non‐Continuous Non‐continuous media is the typical media for Media bar code printing. Labels and tags are made of various materials, such as paper, fabric or cardstock, and are separated by gaps, holes, notches or black marks. Many labels are self‐adhesive with liners, while some are linerless. 15 ... - Page 25 2 Getting Started Loading Media Continuous Continuous media does not have gaps, holes, Media notches or black marks. It allows you to print data anywhere on the media. A cutter may be used for splitting labels. Mostly it is used for direct thermal printing. Fanfold Media Fanfold media is in continuous form, but it can be used as non‐continuous media, because its labels are separated by folds. Some fanfold media also has black marks or liners. 16 ...

-

Page 26: Printer Operation

3 Printer Operation Media Sensor Calibration 3 Printer Operation This chapter provides information about printer operation. 3.1 Media Sensor Calibration You will want the printer to work properly before starting your print jobs. To do this, you need to calibrate the media sensor. Toshiba B‐FV4D provides transmissive and reflective sensor calibration. Take the following steps to use them. 1. Make sure the media is properly loaded, the print module is closed, and the printer’s power switch is set to the OFF position. 2. Press and hold the FEED button, and turn on the printer. 3. Both status lights glow solid orange for a few seconds. Next, they turn to green shortly, and then turn to other colors. Do one of the following to select the sensor: If you want to calibrate the transmissive sensor, when LED 1 turns to green and LED 2 turns to red, release the FEED button immediately. If you want to calibrate the reflective sensor, when LED 1 turns to green and LED 2 turns to orange, release the FEED button immediately. 4. Press the FEED button. The media calibration is complete after the printer feeds 3‐4 labels and stops. 17 ... -

Page 27: Self Test And Dump Mode

3 Printer Operation Self Test and Dump Mode 3.2 Self Test and Dump Mode The printer can run a self test to print a configuration label, which helps you understand current settings of the printer. 3.2.1 Self Test 1. Turn off the printer. 2. Press and hold the FEED button, and turn on the printer. 3. Both status lights glow solid orange for a few seconds. Next, they turn to green shortly, and then turn to other colors. When LED 1 turns to orange and LED 2 turns to green, release the FEED button. 4. Press the FEED button to print a configuration label. Your configuration label should look like this: 18 ... - Page 28 3 Printer Operation Self Test and Dump Mode 19 ...

-

Page 29: Dump Mode

3 Printer Operation Resetting Your Printer 3.2.2 Dump Mode The printer will enter the Dump mode after running a self test. In this mode, characters are printed in hexadecimal codes, allowing users and engineers to debug the system. To return to the online mode: ■ Turn off the printer, and turn it on again. 3.3 Resetting Your Printer By resetting your printer, you can return your printer to the state it was in when you receive it. This can help you solve some problems caused by settings changed during the printing. Do the following to reset your printer: 1. Turn off the printer. 2. Press and hold the FEED button, and turn on the printer. 3. Both status lights glow solid orange for a few seconds. Next, they turn to green shortly, and then turn to other colors. When both lights turn to red, release the FEED button immediately. 4. Press and hold the FEED button for 3 seconds and release it. Both status lights blink red three times, and turn to solid orange for a few seconds. After the printer is reset, LED 2 goes out while LED 1 turns to solid green. Important In step 4, if you do not hold the FEED button long enough, LED 2 will blink orange three times while LED 1 goes out. It means the printer is not reset. 20 ... -

Page 30: Media Sensing

3 Printer Operation Media Sensing 3.4 Media Sensing B‐FV4D printers offer two types of media sensor: transmissive and reflective. They are used for detecting specific media types. 3.4.1 Transmissive Sensor The transmissive sensor is fixed and placed near the center of the printhead. It is used for detecting gaps across the entire width of the label. Single Column 21 ... -

Page 31: Reflective Sensor

3 Printer Operation Media Sensing 3.4.2 Reflective Sensor The reflective sensor is movable within the entire width of the media. It detects gaps, notches and black marks not located at the center of the media. Multi Columns Notch Black Mark Flip the media so the black‐mark side is facing down to align with the sensor. 22 ... -

Page 32: Wireless Connection (Optional)

3 Printer Operation Wireless Connection (Optional) 3.5 Wireless Connection (Optional) Printers which have built‐in Wi‐Fi or Bluetooth are able to connect to the internet in a more flexible way. You can transmit data to your printers in any location within the range of the access point or Bluetooth. 3.5.1 Bluetooth Before you use Bluetooth to connect your printer, make sure your computer or device has a built‐in Bluetooth adapter. If your computer doesn’t have it, get an adapter and plug it into the USB port. The Bluetooth setup screen may vary depending on your computer or device. In this article, we use a Windows XP computer as an example. Do the following to set up a Bluetooth connection for your printer: 1. Click the Bluetooth icon in the notification area (system tray). 2. In the Bluetooth Devices dialog box, click Add. 23 ... - Page 33 3 Printer Operation Wireless Connection (Optional) 3. In the Add Bluetooth Device Wizard dialog box, select the My device is set up and ready to be found check box, and click Next. 24 ...

- Page 34 3 Printer Operation Wireless Connection (Optional) 4. Click TOSHIBA B‐FV4, and click Next. 5. Click Let me choose my own passkey. The default key is 0000. After entering the key, click Next. 25 ...

- Page 35 3 Printer Operation Wireless Connection (Optional) 6. The computer will try to connect the printer. If it succeeds, you’ll see the successful message. Take a note of the outgoing COM port and click Finish. Note If you forget the port number, in the Bluetooth Devices dialog box, click the COM Ports tab to see the virtual COM port assigned to the printer. 7. Use any third‐party application to transmit data to the printer, such as 26 ...

- Page 36 3 Printer Operation Wireless Connection (Optional) Hyper Terminal. When you set up a connection in Hyper Terminal, choose the COM port you obtained in the previous step, so you can use Bluetooth to communicate with the printer. 27 ...

-

Page 37: Maintenance

4 Maintenance Cleaning 4 Maintenance This chapter describes routine cleaning procedure. 4.1 Cleaning To maintain print quality and prolong the printer’s life, you need to perform some routine maintenance. Daily maintenance should be done for high volume printing, and weekly for low volume printing. Caution Always turn off the printer before cleaning. 4.1.1 Printhead It is essential to keep printhead clean if you want the best print quality. We strongly recommend that you clean the printhead when you load a new media roll. If the printer is operated in critical environment, or the print quality declines, you need to clean the printhead more frequently. Keep in mind these things before you clean: ■ Keep the water away in case of corrosion on heating elements. ■ If you just finish printing, wait until the printhead cools down. ■ Do not touch the printhead with bare hands or hard objects. Cleaning steps: 1. Moisten a soft cloth or a cotton swab with ethyl alcohol. 2. Gently wipe the printhead in one direction. That is, wipe it only from left to right or vice versa. Do not wipe back‐and‐forth, in case dust or dirt attaches to the printhead again. 28 ... -

Page 38: Media Housing

4 Maintenance Cleaning Important Printhead warranty becomes void if printhead’s serial number is removed, altered, defected, or made illegible, under every circumstance. 4.1.2 Media Housing Use a soft cloth to clean the dust, dirt or debris built up on the Media Roll Holders, Media Guides and media path. 1. Moisten a soft cloth with ethyl alcohol. 2. Wipe the Media Roll Holders to clean dust. 3. Wipe the Media Guides to clean dust and dirt. 4. Wipe the media path to clean paper debris. 29 ... -

Page 39: Sensor

4 Maintenance Cleaning 4.1.3 Sensor Media sensors may not be able to detect the media correctly if it becomes dirty. 1. Moisten a soft cloth or a cotton swab with absolute ethyl alcohol. 2. Gently brush sensors to remove the dust away. 3. Use a dry cloth to clean the residue. 30 ... -

Page 40: Platen Roller

4 Maintenance Cleaning 4.1.4 Platen Roller The platen roller is also important for print quality. Dirty platen roller may damage the printhead. Clean the platen roller right away if the adhesive, dirt or dust accumulates on it. 1. Moisten a soft cloth with absolute ethyl alcohol. 2. Gently wipe the platen roller to remove the dust and adhesive. 31 ... -

Page 41: Replacing Rtc Battery (Optional)

4 Maintenance Replacing RTC Battery (Optional) 4.2 Replacing RTC Battery (Optional) If your printer has a built‐in real‐time clock (RTC), you will find the RTC battery on the main board. The RTC battery keeps the RTC running when the printer is turned off, so the RTC can keep track of the current time. You can check the RTC battery from the status lights. If the RTC battery is low or out, you need to replace it with a new one. Take the following steps to replace your RTC battery: 1. Turn on the printer. 2. Locate the battery on the main board. 3. Remove the old coin battery and install a new one. 4. Turn off the printer. Caution Risk of explosion if battery is replaced by an incorrect type. Dispose of used batteries according to the instructions. ... -

Page 42: Troubleshooting

5 Troubleshooting Printer Issues 5 Troubleshooting This chapter provides the information about printer problems and solutions. 5.1 Printer Issues The printer won’t turn on ■ Did you attach the AC power cord? ■ Make sure the power supply’s connector is inserted into the printer power jack. ■ Check the power connection from the wall socket to the printer. Test the power cord and the socket with other electrical devices. ■ Disconnect the printer from the wall socket, and connect it again. The printer turns itself off ■ Turn on the printer again. ■ Make sure the power supply’s connector and the power cord are properly plugged. ■ Make sure the power supply and the power cord are not damaged. ■ Use the applicable power supply. ■ If the printer keeps turning itself off, check the socket and make sure it has enough power for the printer. The printer does not feed the media out ■ The media is not loaded correctly. See Section 2.3, “Loading Media” to reload the media. ■ If there is a paper jam, clear it. 33 ... -

Page 43: Media Issues

Media Issues 5.2 Media Issues The media is out ■ Load a new media roll. The paper is jammed ■ Open the printer and clear the jammed paper. ■ Make sure the paper is held properly by the Media Guides. The printing position is not correct ■ Did you use the correct media type for printing? ■ The media is not loaded correctly. See Section 2.3, “Loading Media” to reload the media. ■ The media sensor needs to be calibrated. See Section 3.1, “Media Sensor Calibration” to calibrate the sensor. ■ The media sensor is dirty. Clean the media sensor. Nothing is printed ■ The media is not loaded correctly. See Section 2.3, “Loading Media” to reload the media. ■ The print data might not be sent successfully. Make sure the interface is set correctly in the printer driver, and send the print data again. The print quality is poor ■ The printhead is dirty. Clean the printhead. ■ The platen roller is dirty. Clean the platen roller. ■ Adjust the print darkness, or lower the print speed. ■ The media is incompatible for the printer. Use Toshiba‐approved media roll instead. 34 ... - Page 44 5 Troubleshooting Media Issues 35 ...

-

Page 45: Other Issues

5 Troubleshooting Other Issues 5.3 Other Issues There are broken lines in the printed label ■ The printhead is dirty. Clean the printhead. An error occurred when writing data to the USB memory ■ Did you insert the USB drive? ■ Make sure the USB drive is plugged tightly into the port. ■ The USB drive might be broken. Replace it with another one. The printer is unable to save files due to insufficient USB memory ■ Delete the files on your USB drive to free some space, or replace your USB drive with an empty one. The cutter is experiencing issues ■ If there is a paper jam, clear it. ■ The cutter has become loose. Fix the cutter in position and tighten it. ■ The cutter blade is not sharp anymore. Replace your cutter with a new one. The printhead temperature is extremely high ■ The printhead temperature is controlled by the printer. If it is extremely high, the printer will stop printing automatically, until the printhead is cool down. After that, the printer will resume printing automatically, if there is any unfinished print job. The printhead is broken ■ Contact your local dealer for assistance. 36 ... -

Page 46: Specifications

6 Specifications Printer 6 Specifications This chapter provides specifications for the printer. 6.1 Printer B‐FV4D‐GSXX‐QM‐R B‐FV4D‐TSXX‐QM‐R Model B‐FV4D‐TSXX‐CN‐R B‐FV4D‐GSXX‐CN‐R Print method Direct Thermal Resolution 203 dpi (8 dots/mm) 300 dpi (12 dots/mm) Media Centered Alignment Standard: Continuous mode, Tear‐off mode Operation Mode Optional: Cutter mode, Peeler mode Media Sensor: Gap Sensor (Transmissive, Fixed) Sensor I‐Mark Sensor (Reflective, Movable) Head Open Switch 2, 3, 4, 5, 6 inches/sec 2, 3, 4 inches/sec (50.8, 76.2, 101.6, 127, 152.4 Print Speed (50.8, 76.2, 101.6 mm/sec) mm/sec) ... - Page 47 6 Specifications Printer Standard Memory (SDRAM): 32 MB External USB: Max 16 GB Memory Panel 2 LED, 1 Button LED: Red and Green (Various Combinations: Orange) LED LED: Red and Green (Various Combinations: Orange) Standard: See the TEC Command Reference Font Extended: Download with B‐FV Setting Tool 38 ...

-

Page 48: Media

6 Specifications Media 6.2 Media Properties Description Media Size Continuous Mode Length: 8 mm ~ 997 mm Width: 22.4 mm ~ 115 mm (including liner 25.4 ~ 118 mm) Tear‐Off Mode Length: 30 mm ~ 997 mm Width: 22.4 mm ~ 115 mm (including liner 25.4 ~ 118 mm) Peel‐Off Mode Length: 35 mm ~ 150.4 mm Width: 22.4 mm ~ 115 mm (including liner 25.4 ~ 118 mm) Cut Mode Length: 35 mm ~ 993 mm Width: 22.4 mm ~ 115 mm (including liner 25.4 ~ 118 mm) Max Roll Diameter Size: 127 mm (5 inches) Max Roll Diameter Size for External Media Stand: 203.2 mm (8 inches) Media Type Direct Thermal Label Direct Thermal Tag Roll Paper (Inside Wound or Outside Wound) Fanfold Paper 39 ... -

Page 49: Bar Code

6 Specifications Bar Code 6.3 Bar Code Programming Language TPCL Non‐TPCL One Dimensional Bar JAN8/EAN8 UPC‐A Code JAN13/EAN13 UPC‐E UPC‐E JAN/EAN EAN13+2 digits CODE39 EAN13+5 digits CODE93 CODE128 (with auto code CODE128 selection) GS1‐128 (UCC/EAN128) CODE128 (without auto CODABAR (NW‐7) code selection) ITF CODE93 Industrial 2of5 UPC‐E+2 digits MSI UPC‐E+5 digits UPC add‐on code EAN8+2 digits POSTNET EAN8+5 digits GS1 DataBar UPC‐A ... - Page 50 6 Specifications Bar Code Programming Language TPCL Non‐TPCL MaxiCode MaxiCode Composite Symbol GS1 DataBar (Truncated) EAN‐13 Composite GS1 DataBar Stacked (CC‐A/CC‐B) GS1 DataBar Stacked EAN‐8 Composite Omnidirectional (CC‐A/CC‐B) GS1 DataBar Limited UPC‐A Composite GS1 DataBar Expanded (CC‐A/CC‐B) GS1 DataBar Expanded UPC‐E Composite Stacked (CC‐A/CC‐B) UPC‐A GS1 DataBar Composite UPC‐E (CC‐A/CC‐B) EAN‐13 GS1 DataBar Truncated EAN‐8 Composite (CC‐A/CC‐B) UCC/EAN‐128 with CC‐A GS1 DataBar Stacked or CC‐B Composite (CC‐A/CC‐B) UCC/EAN‐128 with CC‐C ...

- Page 51 6 Specifications Bar Code 42 ...

-

Page 52: Bluetooth

6 Specifications Bluetooth 6.4 Bluetooth Properties Bluetooth I/F Standard Bluetooth 2.1 + EDR or later Enable Device B‐FV4 Series Operating Temperature 41°F (5°C) ~ 104°F (40°C) Storage Temperature ‐4°F (‐20°C) ~ 140°F (60°C) Operating Humidity 25 ~ 85 % Non‐condensing R.H Storage Humidity 10 ~ 90 % Non‐condensing R.H Connection Form Only one‐to‐one connection is supported. Support Profile Serial Port Profile (SPP) PIN code is supported. Class of Radio Transmission CLASS 2 Transmission Method Bi‐directional (Half‐duplex) Flow Control Credit based flow control Operating Mode Slave Mode Transmission Distance 3 m (360 degrees) SR Mode in Page/Inquiry Scanning R1 Scan Interval 1.28 sec. Scan Window 22.5 msec. RF Frequency Range ... -

Page 53: Electrical And Operating Environment

6 Specifications Electrical and Operating Environment 6.5 Electrical and Operating Environment Properties Range Power Supply Voltage: AC 100 V ~ 240 V ± 10 % (full range) Frequency: 50 Hz ‐ 60 Hz ± 5 % Power Consumption 90 W Temperature Operating: 5 °C ~ 40 °C Storage: ‐40 °C ~ 60 °C Humidity Operating: 25 %RH ~ 85 %RH (non‐condensing) Storage: 10 %RH ~ 90 %RH (non‐condensing) 6.6 Physical Dimension Dimension Size and Weight Size W 183.5 mm x D 225.5 mm x H 165.9 mm Weight Approx. 1.75 kg (excluding media and options) or less 44 ... -

Page 54: Interfaces

B‐FV700‐BLTH‐QM‐R 6.7 Interfaces This section provides information about IO port specifications for the printer. 6.7.1 USB There are two common USB connectors. Typically, type A is found on hosts and hubs; type B is found on devices and hubs. The figure below shows their pinouts. Type A Type B Pin Signal Description 1 VBUS +5V 2 D‐ Differential data signaling pair ‐ 3 D+ Differential data signaling pair + 4 Ground Ground ‐ 45 ‐ ... -

Page 55: Ethernet

B‐FV700‐BLTH‐QM‐R 6.7.2 Ethernet The Ethernet uses RJ‐45 cable, which is 8P8C (8‐Position 8‐Contact). The figure below shows its pinout. 1 2 3 4 5 6 7 8 Pin Signal 1 Transmit+ 2 Transmit‐ 3 Receive+ 4 Reserved 5 Reserved 6 Receive‐ 7 Reserved 8 Reserved ‐ 46 ‐ ... -

Page 56: Rs-232C

B‐FV700‐BLTH‐QM‐R 6.7.3 RS232C The RS‐232C on the printer is DB9 female. It transmits data bit by bit in asynchronous start‐stop mode. The figure below shows its pinout. Pin Signal Description 1 +5V Provide 5V Power 2 TxD Transmit 3 RxD Receive 4 CTS Clear to Send 5 GND Ground 6 RTS Request to Send 7 NC No Connection 8 RTS Request to Send 9 NC No Connection Host (DB9) Printer (DB9) ... -

Page 57: Centronics

B‐FV700‐BLTH‐QM‐R 6.7.4 Centronics The 36‐pin Centronics on the printer uses parallel communication, and complies with IEEE 1284 compatibility mode (also called SPP, Standard Parallel Port). The figure below shows its pinout. Pin Signal Direction Signal Pin Signal Direction Signal 1 To Printer DATA•STB 19 Ground TWISTED PAIR GND (PIN1) 2 To Printer Data 1 20 Ground ... - Page 58 B‐FV700‐BLTH‐QM‐R Installation Manual for the B‐FV704D‐BLTH‐QM‐R Bluetooth Interface WARNING! Carefully read and follow all the instructions in this manual. Failure to do so could create safety hazards such as fire or electric shocks. Instructions in this manual must be followed when installing option kits or adding cables to ...

- Page 59 B‐FV700‐BLTH‐QM‐R Bluetooth Interface (1 pc.) M‐3 P‐Tite Screw (2 pcs.) Installation Manual (1 copy) RF Certification Label ‐ 50 ‐ ...

- Page 60 6 Specifications Interfaces 3. INSTALLATION PROCEDURE 1) Turn off the printer power, disconnect the power plug from the AC outlet, and disconnect the AC adapter from the printer. 2) Place the printer on the soft cloth to prevent scratching the surface of the printer, and remove the 4 screws provided at the Bottom Cover. 3) Remove the Bottom Cover by removing the 6 connectors from the main board. Connectors to be detached ...

- Page 61 6 Specifications Interfaces 4) Remove the Printer Cover. Printer Cover 5) Secure the Bluetooth Interface with the 2 screws provided (M‐3 P‐Tite screws). Harnesses Note: When securing the interface, prevent the two harnesses from being trapped between the interface board and the printer frame.

- Page 62 6 Specifications Interfaces 6) Attach the Printer Cover. Printer Cover Note: When fitting the Printer Cover, prevent the harness from being trapped between the covers. 7) Connect the harness connector to the connector “J15” (black) on the main board. Connector “J15” (black) ...

- Page 63 Be sure not to cover the contents described on the rating label when the RF Certification Label is attached to the upper right corner. 11) Close the Top Cover. The installation is now completed. © 2015 TOSHIBA TEC CORPORATION All Rights Reserved 1‐11‐1, Osaki, Shinagawa‐ku, Tokyo 141‐8562, JAPAN ‐ 54 ‐ ...

Need help?

Do you have a question about the B-FV4D-GS12-QM-R and is the answer not in the manual?

Questions and answers