Horton C2150 Setup & Troubleshooting

For series 2000, 2000b, 2001 & 2003 electric slide door operators

Hide thumbs

Also See for C2150:

- Setup instructions (12 pages) ,

- Setup instructions & troubleshooting (15 pages) ,

- Setup instructions & troubleshooting (20 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Horton C2150

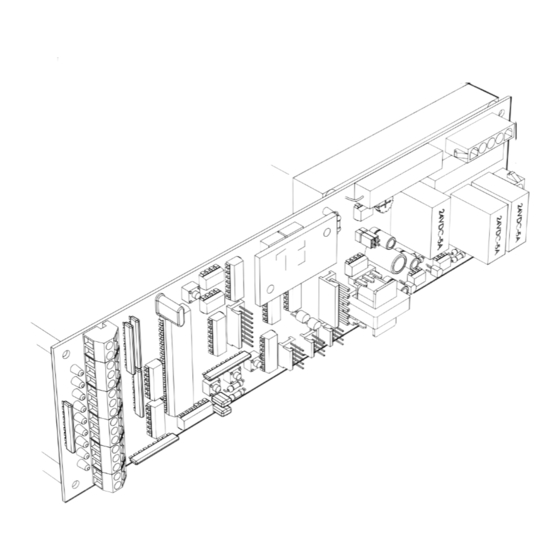

- Page 1 C2150 Control with Version 10 Software for Series 2000, 2000B, 2001 & 2003 Electric Slide Door Operators SETUP INSTRUCTIONS & TROUBLESHOOTING To be used with either G200, G2001, G230, G230T, G205 or G20B Installation Instructions A U T O M A T I C S 2.0466d...

-

Page 2: Table Of Contents

23. Encoder test points…………………………………………………………..H210.12 BELT DRIVE or LINEAR DRIVE 24. Power failure units…………………………………………………….…..…H210.13 APPENDIX A. In case of difficulty (Trouble shooting the C2150)……………………….H202.14 B. Linear drive function test……………………………………………………H202.15 B1. Belt drive function test……………….…………..………………….………H202.15 C. Code displays …………………………………………..………….……..H202.16 C2. Code displays, foot notes and short cuts…… ………………………..….H202.17 D. - Page 3 H210.1 2.0468d 05/08...

-

Page 4: C2150 Initialization (Learn Cycle)

+100 LOCK -If the above cycle check is OK and there are no parameters to be changed or an autolock to setup, this concludes the C2150 initialization. 4th Step -Checking door cycle IF THERE IS ANY DIFFICULITY SEE APPENDIX A When the toggle switch is on, the DOWN button acts as an actuation device. -

Page 5: Adjusting Parameters (Procedure For Changing Preset Parameters)

4 reserved parameters -Set the reversing sensitivity as required using R10. Do not leave this adjustment at minimum. Horton recommends setting *Time delay is 2-8, 10, 12, 14, 16, 18, 20, 25, 30, & 60 seconds the sensitivity so the door will reverse at 28 ft.lb. or less. -

Page 6: Actuation Features

During initialization the control clears all ports and the solenoid becomes inactive. (Yellow) FAIL SECURE The C2150 looks to see if there is a contact at the lock port CN4 and if the yellow lock monitor LED Double click = off or on is off. -

Page 7: Setting Lock Parameters

7. SETTING LOCK PARAMETERS Auto lock circuit board To set up the lock parameters on the C2150 turn off the toggle circuit or double click the -When the solenoid initially energizes there SET button. Use the UP / DOWN buttons to locate dL & L1. -

Page 8: Micro Switch Diagnostics

-Missing codes, or codes that appear in improper order, indicate a problem with a switch assembly or a defective switch lace, or possibly the C2150. Mount the partial open switch at the -A blank display means that the door is in mid-stroke (no switches are tripped). -

Page 9: Belt Drives

BELT DRIVE 13. C2150 INITIALIZATION (learn cycle) 4th Step - Close stop RESET 1st Step - Power up -The display should indicate FC (for first run - Finding +100 Be sure the toggle circuit is complete and apply Close stop) The door should fully close at slow speed. -

Page 10: C2150 Initialization (Learn Cycle) Cont

The chart (following) shows the position of the door and the display code for each position. Inspect the unit for smooth operation, free of binds and excessive noise. -Close cUshion +100 The following cycles are carried out automatically by the C2150 control -The display starts with: +100 -The display returns to:... -

Page 11: Adjusting Parameters (Procedure For Changing Preset Parameters)

-Set the reversing sensitivity as required using R10. Do not Check Point in inches 90% of total stroke leave this adjustment at minimum. Horton recommends setting Partial Open stroke in inches the sensitivity so the door will reverse at 28 ft.lb. or less. -

Page 12: Actuation Features

(Yellow) See diagram 2 page H202.16 FAIL SECURE The C2150 looks to see if there is a contact at the lock port CN4 and if the yellow lock monitor LED Double click = off or on is off. Press and hold = data save If the yellow LED is off... -

Page 13: Setting Lock Parameters

BELT DRIVE 17. SETTING LOCK PARAMETERS To set up the lock parameters on the C2150 turn off the toggle circuit or double click the -When the solenoid initially energizes there SET button. Use the UP / DOWN buttons to locate dL & L1. -

Page 14: Encoder Error Codes

Each segment of 4 for a total of 8 segments should appear. No segment should be skipped. There are no serviceable elements on the C5600-1. If anything occurs other than the description shown above the C2150 will get improper If the encoder fails replace the entire unit. DO NOT REMOVE COVER... -

Page 15: Power Failure Units

Fail reset Failure -If the batteries test fails during daytime operation it wil go to full open position (as per 1.2 amp hours European standard) and stay open.The C2150 display will flash bF until the failure is Yellow corrected. Test -To maintain security,battery failures are ignored in the night mode,but the failure is stored on the units circuit board. -

Page 16: In Case Of Difficulty (Trouble Shooting The C2150)

-If the fuse does not blow,reconnect the power harness at CN7 and attempt to operate the door with the motor unplugged. -If the fuse blows now, replace the C2150 control (first check motor as shown in appendix C). -If the fuse does not blow, plug the motor in and try again. -

Page 17: Linear Drive Function Test

BELT DRIVE 2000 LINEAR DRIVE APPENDIX B LINEAR DRIVE FUNCTION TEST APPENDIX B1 BELT DRIVE FUNCTION TEST RESET -Press and hold RESET -Manually move the door to mid stroke -Press and hold DOWN and SET DOWN -Release RESET RESET -Press and hold RESET DOWN -Hold DOWN and SET until Ft appears (note: version number will appear first) -

Page 18: Code Displays

APPENDIX C CODE DISPLAYS Codes are arranged in alphanumeric order (NOTE: D = Display, P = Parameter, E = Error) DISPLAY MEANING TYPE VERSION CODE Control is braking - door always brakes when opening. Close braking can be turned on at the [b parameter 2.00 Control has failed - must be replaced 2.00... - Page 19 Autolock has failed to unlock (see sect 8) 2.00 2.00 When this is turned on it tells the software not to wait for the lock monitor but try to open after a brief delay. Rarely used, only for non Horton locks FOOT NOTES: SHORT CUTS...

-

Page 20: Motor Test

-Place OHM meter in range to measure : Motor connection plug 10 to 50 ½ analog Rx1 range to the C2150 Terminals R200 ½ digital. 1 thru 15 BLK (pin 1) -

Page 21: Actuating And Control Switch Connections

H202.19 DIAGRAM 1 ACTUATING and CONTROL SWITCH CONNECTIONS INTERIOR +24VDC (BLK) 1 +24VDC ACTUATING SIGNAL (RED) 2 INTERIOR SW. SENSOR 3 EXTERIOR SW COM (WHT) [See Lower Right for Sensors] 4 COMMON EXTERIOR +24VDC (BLK) 5 +24VDC ACTUATING 6 SAFTY BEAM SIGNAL (GRN) SENSOR 7 COMMON... -

Page 22: Typical Wiring For Beams And Switches

Drill #10 & csk for #10 screw Receiver Press down release 1.38" and insert wire & shield shield Locate the beam C437 A/B amplifier as close to the C2150 as possible C2150 C2150 wire Wiring connections Typical Single slide Typical Bi-part... - Page 23 A U T O M A T I C S A Division of Overhead Door Corporation, A Sanwa Shutter Company Form H210, SEPTEMBER 2007, printed in U.S.A. Horton Automatics reserves the right to improve the product and change its specifications without notice. 2.0488d...

Need help?

Do you have a question about the C2150 and is the answer not in the manual?

Questions and answers