Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for KLA Tencor P-16+

- Page 1 P-16+ / P-6 User’s Guide KLA-TENCOR CONFIDENTIAL Family: Profiler Product Line: Profiler P1X / PX Model: P-16+ / P-6 Software Version 7.31/7.35 MNL, USER PN- 0142530-000 AB One Technology Drive., Milpitas, CA 95035 Phone: (408) 875-3000 FAX: (408) 571-2722...

- Page 2 TRADEMARKS P-16+ / P-6 is a trademark of KLA-Tencor Corporation. All other brand and product names may be trademarks of their respective companies. KLA-TENCOR CONFIDENTIAL P-16+ / P-6 User’s Guide 0142530-000 AB 3/13/09...

- Page 3 KLA-Tencor P-16+ / P-6 User’s Guide EC COMPLIANCE At the time of printing, the P-16+ / P-6 Profiler complies with the essential requirements of the EC (Electromagnetic Compatibility) Directives listed below: EC Directives EC 89/392/EEC EC 89/336/EEC EC 93/68/EEC Machinery, Annex 1 EC 98/37/EEC Low Voltage, Annex 1 EC 73/23/EEC...

- Page 4 KLA-Tencor P-16+ / P-6 User’s Guide KLA-Tencor Confidential 0142530-000 AB 3/13/09...

-

Page 5: Table Of Contents

Table of Contents Chapter 1 Introduction & Safety ..............1-1 NSTRUMENT VERVIEW . - Page 6 KLA-Tencor P-16+ / P-6 User’s Guide Chapter 3 Scan Recipes ................3-1 NTRODUCTION .

- Page 7 KLA-Tencor P-16+ / P-6 User’s Guide Chapter 4 XY View Screen ................4-1 NTRODUCTION XY V .

- Page 8 KLA-Tencor P-16+ / P-6 User’s Guide Chapter 6 Sequence Recipe and Data ................6-1 NTRODUCTION .

- Page 9 KLA-Tencor P-16+ / P-6 User’s Guide Introduction................7-32 Activating Line Leveling .

- Page 10 KLA-Tencor P-16+ / P-6 User’s Guide Creating a 3D Stress Recipe ............. . 10-4 Adding New Substrates to the Substrate Database .

- Page 11 KLA-Tencor P-16+ / P-6 User’s Guide Chapter 13 Stylus Change Procedure ................13-1 NTRODUCTION .

- Page 12 KLA-Tencor P-16+ / P-6 User’s Guide Chapter 16 Backup and Restore Introduction................16-1 Profiler Backup Procedure .

- Page 13 List of Figures Chapter 1 Introduction & Safety Figure 1.1 Power Cord Plug Lockout/Tagout ..........1-3 Chapter 2 Basic Skills Figure 2.1 Logon Dialog...

- Page 14 KLA-Tencor P-16+ / P-6 User’s Guide Figure 3.26 Detection Variables - Feature Detection - Recipe Editor ......3-35 Figure 3.27 Scan Trace (Red) with First Derivative (Dark Blue) Overlaid on the Same Graph .

- Page 15 KLA-Tencor P-16+ / P-6 User’s Guide Figure 3.77 Recipe Information Dialog Box ..........3-100 Chapter 4 XY View Screen Figure 4.1 XY View Screen...

- Page 16 KLA-Tencor P-16+ / P-6 User’s Guide Figure 6.6 Die Grid Menu ............. . 6-7 Figure 6.7 Load Die Grid Dialog Box .

- Page 17 KLA-Tencor P-16+ / P-6 User’s Guide Figure 7.15 Parameters Menu from the Analysis Screen Menu Bar ......7-25 Figure 7.16 3D Recipe Editor .

- Page 18 KLA-Tencor P-16+ / P-6 User’s Guide Chapter 11 System Security Figure 11.1 Log On Dialog ............. 11-1 Figure 11.2 Log On Dialog at Runtime .

- Page 19 KLA-Tencor P-16+ / P-6 User’s Guide Figure 12.19 Move To Position Dialog Box ..........12-17 Figure 12.20 Teach Lowest Elevator Position Screen .

- Page 20 KLA-Tencor P-16+ / P-6 User’s Guide Figure 14.6 Choose Calibration ............14-6 Figure 14.7 Stage Configuration Parameters .

- Page 21 List of Tables Chapter 1 Introduction & Safety Chapter 2 Basic Skills Table 2.1 Profiler Program Access Icons ........... . 2-5 Table 2.2 Stylus Arm Assembly Protection .

- Page 22 KLA-Tencor P-16+ / P-6 User’s Guide Table 4.5 Actions Menu ..............4-7 Table 4.6 Sample Menu .

- Page 23 KLA-Tencor P-16+ / P-6 User’s Guide Table 7.8 Edit Menu Option ............. 7-17 Table 7.9 View Menu Options.

- Page 24 KLA-Tencor P-16+ / P-6 User’s Guide LOT-4 KLA-Tencor Confidential 0142530-000 AB Friday, March 13, 2009...

-

Page 25: Chapter 1 Introduction & Safety

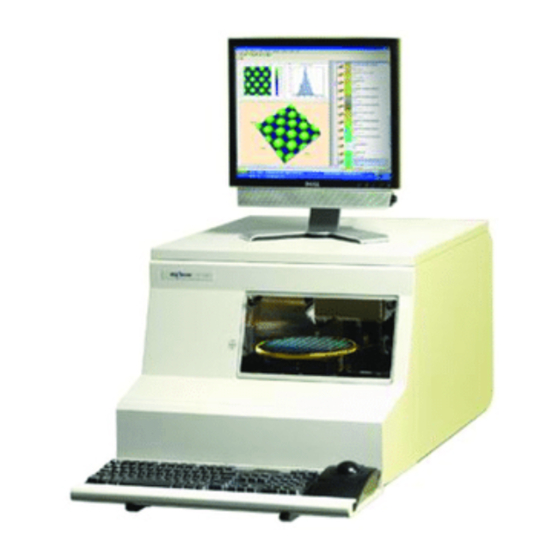

KLA-Tencor P-16+ / P-6 User’s Guide Introduction & Safety - Instrument Overview INTRODUCTION & SAFETY Chapter 1 NSTRUMENT VERVIEW The KLA-Tencor P-16+ / P-6 Profiler is a highly sensitive surface profiler that measures step height, roughness, and waviness on sample surfaces. The KLA-Tencor Profiler systems use stylus-based scanning to achieve high resolution. - Page 26 Introduction & Safety - Safety KLA-Tencor P-16+ / P-6 User’s Guide DANGER: Dangers indicate an imminently hazardous situation which, if not avoided, will result in death or serious injury. This signal word is limited to extreme situations. PINCH POINT: Pinch Point indicates a situation where the user, if not careful, could get a hand or finger pinched.

-

Page 27: Figure 1.1 Power Cord Plug Lockout/Tagout

KLA-Tencor P-16+ / P-6 User’s Guide Introduction & Safety - Safety Lockout/Tagout Procedure If the system is hardwired to facilities power, the lockout/tagout procedure is to be set by the system owner. Service personnel authorized to perform this type of lockout/tagout must be trained by the system owner in accordance with their set procedures. - Page 28 Introduction & Safety - Safety KLA-Tencor P-16+ / P-6 User’s Guide Place a padlock through one of the holes on the lockout hasp as shown in Figure 1.1, step 3. Make sure the device is secured in the closed position. Before locking the padlock, place the eyelet of an approved lockout tag over the hook of the padlock.

- Page 29 KLA-Tencor P-16+ / P-6 User’s Guide Introduction & Safety - Safety If none of the components are in motion when the door is opened, or when the interlock is tripped, the system can be activated again by closing the door or by returning the interlock to its normal operating position.

- Page 30 Introduction & Safety - Safety KLA-Tencor P-16+ / P-6 User’s Guide KLA-Tencor Confidential 0142530-000 AB 3/13/09...

-

Page 31: Chapter 2 Basic Skills

KLA-Tencor P-16+ / P-6 User’s Guide Basic Skills - Overview BASIC SKILLS Chapter 2 VERVIEW Before beginning the use of the P-16+ / P-6 Profiler system, become familiar with basic skills — such as starting and shutting down the system, and operating the system buttons, keyboard, trackball, Microsoft Windows, Profiler application, and other components RGONOMIC... -

Page 32: Powering U P The Profiler

Basic Skills - Powering Up the Profiler KLA-Tencor P-16+ / P-6 User’s Guide OWERING P THE ROFILER Introduction By powering up the computer, the system launches Windows. Power Up Procedure 1. Press the O button on the monitor to activate the monitor. 2. -

Page 33: Starting The Profiler Application

KLA-Tencor P-16+ / P-6 User’s Guide Basic Skills - Starting the Profiler Application 4. The E10 state is not being tracked by the software, so it can be left at the default value. 5. Click on Logon TARTING THE ROFILER PPLICATION Introduction The Profiler application is the interface with the P-16+/P-6 Profiler system from... -

Page 34: Figure 2.3 Profiler Catalog Screen

Basic Skills - Starting the Profiler Application KLA-Tencor P-16+ / P-6 User’s Guide 2. The system goes through its initiation at the end of which the Profiler Catalog screen appears. (See Figure 2.3.) Figure 2.3 Profiler Catalog Screen KLA-Tencor Confidential 0142530-000 AB Friday, March 13, 2009... -

Page 35: Avigating Etween Rogram Evel Creens

KLA-Tencor P-16+ / P-6 User’s Guide Basic Skills - Navigating Between Program Level Screens This is the starting point for operating the instrument. In this screen, scan and sequence recipes can be accessed for system operation. Each icon along the right side of the screen opens another application that contains the parameters or controls for a specific type of task. -

Page 36: Navigation Procedure

Basic Skills - Exiting the Profiler Application KLA-Tencor P-16+ / P-6 User’s Guide Navigation Procedure Use the following procedure to navigate between screens: Click the icon of the required program screen. (See Figure 2.4.) This closes the current program screen and accesses the chosen one. This could generate a message box that inquires if changes to settings, or data are to be saved or discarded. -

Page 37: Clearing A Status Bar Message

KLA-Tencor P-16+ / P-6 User’s Guide Basic Skills - Clearing a Status Bar Message 4. A Profiler Container (message box) appears asking, “Are you sure you want to exit the Profiler?” Click to exit. NOTE: The Profiler system will initialize upon shutdown.. 5. -

Page 38: Rotecting The Tylus Rm Ssembly

Basic Skills - Protecting the Stylus Arm Assembly KLA-Tencor P-16+ / P-6 User’s Guide ROTECTING THE TYLUS SSEMBLY System Provisions for Stylus Protection The P-16+ / P-6 Profiler incorporates several design features that protect the stylus from damage. (See Table 2.2) Table 2.2 Stylus Arm Assembly Protection Protection Name... -

Page 39: Figure 2.6 Contact Scan Stylus Tip

KLA-Tencor P-16+ / P-6 User’s Guide Basic Skills - Protecting the Stylus Arm Assembly The stylus can be damaged by a shorter object if it has sharp corners or burrs that bite into the stylus tip. Figure 2.6 Contact Scan Stylus Tip Scan Direction Damage can occur with steps... -

Page 40: Loading A Sample

Basic Skills - Loading a Sample KLA-Tencor P-16+ / P-6 User’s Guide When designing custom jigs or fixtures, consider the precautions noted in this section. For instance, when designing a custom hard disk locator, its center section must be flush with the top of the disk surface. Care must be exercised when nulling where there is a hole in a jig, a vacuum hole, or a groove in a surface. -

Page 41: Figure 2.8 Xy View Screen

KLA-Tencor P-16+ / P-6 User’s Guide Basic Skills - Loading a Sample Figure 2.8 XY View Screen Menu Bar Tool Bar Step 3 Click MAN LOAD to move the stage to the door. Video Display Window Sample Navigation Window 3. Click (see Figure 2.8) in the Tool Bar to move the stage to the door. -

Page 42: Adjusting The Video Image

Basic Skills - Adjusting the Video Image KLA-Tencor P-16+ / P-6 User’s Guide DJUSTING THE IDEO MAGE Introduction The Video Controls allow the view of a particular sample surface to be optimized. The brightness and contrast can be varied for the camera. NOTE: Changing the focus can invalidate sequences that use pattern recognition because the sample image is less likely to match the stored image in the pattern recognition files. -

Page 43: Sing Ile Ame Onventions

KLA-Tencor P-16+ / P-6 User’s Guide Basic Skills - Using File Name Conventions SING ONVENTIONS Introduction Scan and sequence recipes and data can be saved, as well as graphs and video images. In the Windows OS naming convention only the following special characters are allowed: Table 2.3 Special Characters Allowed for Naming Purposes... -

Page 44: Exporting Data Graphs

Basic Skills - Exporting Data Graphs KLA-Tencor P-16+ / P-6 User’s Guide XPORTING RAPHS Introduction Data graphs are contained in the Scan Data catalog, Sequence Data catalog and in the Analysis screen when the scan data is being analyzed. 2D and 3D graphs can be exported directly from the Analysis screen during scan data analysis. -

Page 45: Figure 2.12 Data Catalog Screen For Export Of Data Or Recipes

KLA-Tencor P-16+ / P-6 User’s Guide Basic Skills - Exporting Data Graphs 2. In the Database Catalog screen, choose either the button in the tool bar. Depending on the Catalog group chosen, this displays the 2D or 3D data or recipe sets. -

Page 46: Exporting Data From The Database File Manager

Basic Skills - Exporting Data from the Database File Manager KLA-Tencor P-16+ / P-6 User’s Guide 6. Set the required variables in the dialog box. See Table 2.4 for an Save As explanation of the variables to be set. Table 2.4 Graphics Export Dialog Features Variable Description... -

Page 47: Figure 2.14 Data Catalog Screen For Export Of Data Or Recipes

KLA-Tencor P-16+ / P-6 User’s Guide Basic Skills - Exporting Data from the Database File Manager 2. Choose either the Scan Data or Sequence Data catalog button. This displays the related 2D or 3D data files in the chosen catalog. Figure 2.14 Data Catalog Screen for Export of Data or Recipes Step 1 Click 2D or 3D to display related files. - Page 48 Basic Skills - Exporting Data from the Database File Manager KLA-Tencor P-16+ / P-6 User’s Guide 2-18 KLA-Tencor Confidential 0142530-000 AB Friday, March 13, 2009...

-

Page 49: Ntroduction

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Introduction SCAN RECIPES Chapter 3 NTRODUCTION The P-16+ / P-6 Profiler system performs scans of sample surfaces using recipes that set the parameters of each scan. Each recipe can be used alone or, in conjunction with other recipes in a sequence to gather necessary data from a given sample. -

Page 50: Accessing The Scan Recipe Catalog Screen

Scan Recipes - Accessing the Scan Recipe Catalog Screen KLA-Tencor P-16+ / P-6 User’s Guide CCESSING THE ECIPE ATALOG CREEN The Catalog screen is the first screen to appear when the Profiler application is opened. The functional areas in the screen are described in Figure 3.1 and Figure 3.2. Figure 3.1 Catalog Sequence Recipe Screen The Control Button... -

Page 51: Recipe Catalog Screen

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Scan Recipe Catalog Screen Components Figure 3.2 Catalog Sequence Recipe Screen When a recipe is chosen, its name appears in this box. The current path to the set of files displayed in the List window is shown here. -

Page 52: Figure 3.3 Title Bar For Catalog Screen

Scan Recipes - Scan Recipe Catalog Screen Components KLA-Tencor P-16+ / P-6 User’s Guide Title Bar The Title Bar contains the Control menu button, the Screen Title Bar, and the Close/Minimize icons (see Figure 3.3) or the GEM Status for systems equipped with the GEM/SECS option. -

Page 53: Figure 3.4 Menu Bar For Scan Recipe Screen

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Scan Recipe Catalog Screen Components Menu Bar The following tables present the content of each drop-down menu in the Menu Bar for the screen. Scan Recipe Catalog NOTE: One or more of the menu options in a given drop-down menu might be grayed out. -

Page 54: Table 3.3 File Menu Options Description

Scan Recipes - Scan Recipe Catalog Screen Components KLA-Tencor P-16+ / P-6 User’s Guide Table 3.3 File Menu Options Description File Menu Description Starts the currently highlighted scan procedure. The screen changes to the scan START screen. In the screen depicted in Figure 3.2, it would start the recipe scan. -

Page 55: Table 3.6 Host Menu Options Description (Only Available With Gem/Secs Option)

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Scan Recipe Catalog Screen Components Table 3.6 Host Menu Options Description (Only available with GEM/SECS Option) Host Menu Description This takes the P-16+ / P-6 Profiler system offline. This is used to prevent the Go Offline system from responding to a host during a user defined operation. -

Page 56: Figure 3.5 Toolbar Icons

Scan Recipes - Scan Recipe Catalog Screen Components KLA-Tencor P-16+ / P-6 User’s Guide ToolBar The ToolBar has eight icons that work as short cuts to functions. Figure 3.5 ToolBar Icons The function of each icon is described in Table 3.10. Table 3.10 ToolBar for the Scan Recipe Catalog Screen ToolBar Icon... -

Page 57: Catalog Screen Access Buttons

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Scan Recipe Catalog Screen Components Catalog Screen Access Buttons The Catalog screen presents access to four sets of information. The Scan Recipe and the Sequence Recipe screen, provide access to the currently defined recipes available for execution in the P-16+ / P-6 Profiler system. -

Page 58: List Window

Scan Recipes - Scan Recipe Catalog Screen Components KLA-Tencor P-16+ / P-6 User’s Guide List Window List Window for Scan Recipe When the button is clicked, the List Window displays the Scan Recipe Scan Recipe information and associated function buttons. (See Figure 3.6.) Figure 3.6 Scan Recipe information in the List Window displays the currently... -

Page 59: Figure 3.7 Tool Bar Buttons

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Scan Recipe Catalog Screen Components Recipe List Window This area contains the list of scan recipes that have been created for the various types of scans used by the system. Scan Recipes are categorized into 2D Scan recipes and 3D Scan recipes. -

Page 60: System Status Message

Scan Recipes - Creating and Editing a Scan Recipe KLA-Tencor P-16+ / P-6 User’s Guide Table 3.12 Scan Recipe List Window Function Access Buttons (Continued) Function Icon Description This opens the real-time display screen and begins the scan procedure associated with the currently highlighted scan recipe. -

Page 61: Accessing The Scan Recipe Editor

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Creating and Editing a Scan Recipe Accessing the Scan Recipe Editor The actual creation of a scan recipe is performed in the Editor screen. This means that recipe creation and editing is restricted to those whose password permits access to the Recipe Editor. -

Page 62: Scan Parameter Definition Window

Scan Recipes - Creating and Editing a Scan Recipe KLA-Tencor P-16+ / P-6 User’s Guide Figure 3.9 Recipe Editor for a 2D UNTITLED Recipe The Title bar shows that the recipe name is currently and the screen UNTITLED Recipe Editor Each Parameter button displays its parameters in the Information Display... -

Page 63: Figure 3.11 2D Scan Category Parameters

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Creating and Editing a Scan Recipe button displays four categories of 2D or 3D scan Scan Parameter Definition parameters: ; and 2D Scan 3D Scan Scan Time Stylus Vertical Ranging 2D Scan Category Parameters - Scan Parameters Definition The parameters defined in this category deal with the actual mechanics of the 2D scan. - Page 64 Scan Recipes - Creating and Editing a Scan Recipe KLA-Tencor P-16+ / P-6 User’s Guide μ - This parameter sets the speed at which the scan is Scan Speed ( μ μ performed. It has a range between , with numerous 25000 options within this range displayed in its drop-down menu and is not user-definable.

-

Page 65: Figure 3.13 Scan Trace Comparison - Large Vs. Small Stylus Radius

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Creating and Editing a Scan Recipe Figure 3.13 illustrates the impact of stylus radius in generating a scan trace.. Figure 3.13 Scan Trace Comparison - Large vs. Small Stylus Radius Scan Direction Stylus A with large radius. -

Page 66: Figure 3.14 Data Collection When Using A Large Radius Stylus

Scan Recipes - Creating and Editing a Scan Recipe KLA-Tencor P-16+ / P-6 User’s Guide Figure 3.14 Data Collection When Using a Large Radius Stylus Stylus Path A (large radius stylus) - Stylus Path A (large radius stylus) - Low Frequency Data Collection High Frequency Data Collection Low and High Frequency Data Traces are nearly the same since a large radius... -

Page 67: Figure 3.15 Data Collection When Using A Small Radius Stylus

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Creating and Editing a Scan Recipe Figure 3.15 Data Collection When Using a Small Radius Stylus Stylus Path B (small radius stylus) - Stylus Path B (small radius stylus) - Low Frequency Data Collection Medium Frequency Data Collection Stylus Path B (small radius stylus) - High Frequency Data Collection As the Data Points get closer (higher frequency), the Data Trace... - Page 68 Scan Recipes - Creating and Editing a Scan Recipe KLA-Tencor P-16+ / P-6 User’s Guide - This is a 2D option that allows the user to repeat a single Multi-Scan Average scan up to 10 times so that the scan data can be averaged by the number of scans performed.

-

Page 69: Table 3.13 Show Position Options

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Creating and Editing a Scan Recipe Table 3.13 Show Position Options Option Description Graphic Representation Start setting is used in the Video portion of the XY Start Click here to position Start view screen to position the start of the scan at the intersection of the Video screen crosshairs. -

Page 70: Figure 3.17 Teach Scan Length, From The 2D Scan Teach Button

Scan Recipes - Creating and Editing a Scan Recipe KLA-Tencor P-16+ / P-6 User’s Guide Figure 3.17 Teach Scan Length, from the 2D Scan Teach Button With the feature in the field of view, click in the appropriate reference point (start, center, or end) for the scan. -

Page 71: Figure 3.18 3D Scan Parameters

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Creating and Editing a Scan Recipe Table 3.14 3D Scan Parameters Summary (Continued) Parameter Setting 2D, 3D or Both Description and Location Multi-Scan Average The number of single identical scans which are performed and used to create a scan data set that represents the average of the scans. -

Page 72: Figure 3.19 Traces - Scan Perimeter With Traces

Scan Recipes - Creating and Editing a Scan Recipe KLA-Tencor P-16+ / P-6 User’s Guide Traces This assigns the number of scans that are made in the X-direction across the Y Scan direction. In Figure 3.19, the number in the variable box would be 8. -

Page 73: Table 3.15 Show Position Options

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Creating and Editing a Scan Recipe Automatic Parameter Adjustment: - In general, a connection exists in the software such that, when certain parameters are changed, other parameters are readjusted to accommodate the changes. The adjustments occur between the Y Scan Size Traces parameters. -

Page 74: Figure 3.20 Scan Time - Scan Parameters Definition

Scan Recipes - Creating and Editing a Scan Recipe KLA-Tencor P-16+ / P-6 User’s Guide Scan Time Parameters (2D and 3D) - Scan Parameters Definition parameters box displays time and data point values, broken down into Scan Time general components. (See Figure 3.20.) No values can be set or defined in this portion of the screen. -

Page 75: Figure 3.21 Stylus Parameters (2D And 3D)

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Creating and Editing a Scan Recipe ] + move time = For 2D and 3D X Scan Size Scan speed Individual Traces (s) - This is the total time that it takes to complete the set of scans Total (hr:min:s) defined in the scan recipe section, 3D Scan... -

Page 76: Table 3.16 Stylus Force Ranges For The Different Head Configurations

Scan Recipes - Creating and Editing a Scan Recipe KLA-Tencor P-16+ / P-6 User’s Guide Changing the setting: Applied Force Table 3.16 Stylus Force Ranges for the Different Head Configurations MicroHead V LF MicroHead V SR MicroHead V XR 0.05-50 mg 0.5-50 mg 0.5-50 mg 1. -

Page 77: Table 3.17 Range And Resolution Scan Parameters For The Microhead V Lf Head

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Creating and Editing a Scan Recipe Range/Resolution This parameter sets the maximum size limit of the features that can be scanned in each given range, and the minimum feature size that can be resolved (positively detected). -

Page 78: Figure 3.22 Vertical Ranging - Profile Types

Scan Recipes - Creating and Editing a Scan Recipe KLA-Tencor P-16+ / P-6 User’s Guide If, in the course of a scan, the upper limit of any one of the ranges is reached, the Saturated Data Points system aborts the scan and a message is issued reporting that there are too many saturation data points. -

Page 79: Feature Detection (Only For 2D Scans)

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Creating and Editing a Scan Recipe Table 3.20 Profile Types (Continued) Profile Type Range Description 131 μm 131 μm scans features ≈ 100 μm down from the scan’s starting point. 327 μm 1000 μm 327 μm scans features ≈... -

Page 80: Figure 3.23 Feature Detection - Recipe Editor

Scan Recipes - Creating and Editing a Scan Recipe KLA-Tencor P-16+ / P-6 User’s Guide Accessing the Feature Detection parameters: In the click the button. (See Figure 3.23.) For Recipe Editor, Feature Detection information on how to display the , see Accessing the Scan Recipe Recipe Editor Editor on page 13. -

Page 81: Figure 3.24 Feature Detection Point Locations On A Step

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Creating and Editing a Scan Recipe Feature This parameter allows the user to choose between six different features that can be detected and identified during a scan. Figure 3.24 Feature Detection Point Locations on a Step Example of a Step feature UpEdge DownEdge... -

Page 82: Table 3.21 Feature Detection Descriptions (See Figure 3.24 And Figure 3.25.)

Scan Recipes - Creating and Editing a Scan Recipe KLA-Tencor P-16+ / P-6 User’s Guide Table 3.21 Feature Detection Descriptions (See Figure 3.24 and Figure 3.25.) Feature Description None No feature detection is being used. UpEdge At the trailing edge of a feature rise, it is the point at which the trace begins the plateau. -

Page 83: Detection Variables - Feature Detection - Recipe Editor

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Creating and Editing a Scan Recipe For Up Edge, Up Base, Down edge, Down Base, Convex, and Concave: Feature Number If there are multiple edges detected in the scan, provides a way to Feature Number select a specific edge for detection. - Page 84 Scan Recipes - Creating and Editing a Scan Recipe KLA-Tencor P-16+ / P-6 User’s Guide Min. Plateau Width Minimum Plateau Width defines the minimum horizontal distance between rising and falling edges (or falling and rising edges). This parameter is useful to differentiate between features of similar shape, but different width.

-

Page 85: Scan Trace (Red) With First Derivative (Dark Blue) Overlaid On The Same Graph

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Creating and Editing a Scan Recipe Figure 3.27 Scan Trace (Red) with First Derivative (Dark Blue) Overlaid on the Same Graph Deriviative without filtering does not produce clear inflection points at the rising and falling edges. -

Page 86: Filters And Cursors

Scan Recipes - Creating and Editing a Scan Recipe KLA-Tencor P-16+ / P-6 User’s Guide Filters and Cursors Filters Two filters are available for removing noise from scan data, either as the scan is taking place, or after the scan occurs but before the data is saved. The oldest filter is the RC Filter. -

Page 87: Figure 3.29 Cursor Parameters - Recipe Editor

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Creating and Editing a Scan Recipe 2. Click the desired value or type in the desired value. Long Wavelength Cutoff NOTE: The availability of cutoffs is dependent on the scan speed. The systems prevents the accidental entry of a long wavelength cutoff that is shorter than the currently selected short wavelength cutoff or the value of the analog cutoff. -

Page 88: Analysis Screen With Trace In Need Of Leveling

Scan Recipes - Creating and Editing a Scan Recipe KLA-Tencor P-16+ / P-6 User’s Guide Figure 3.30 Analysis Screen with Trace in Need of Leveling The Leveling Cursors are the top set The Measurement Cursors are the bottom set. The trace is shown running from the top left to the bottom right of the screen. -

Page 89: Figure 3.31 Cursor Boundary Setting On Unleveled Trace

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Creating and Editing a Scan Recipe b. Click and hold the mouse button while using the track ball to drag the boundary into position for leveling the scan. Release the mouse button when the boundary is correctly positioned. -

Page 90: Setting Measurement Cursors

Scan Recipes - Creating and Editing a Scan Recipe KLA-Tencor P-16+ / P-6 User’s Guide 1. It is important to set the measurement cursors to accurately measure the desired feature. In Figure 3.32 the left cursor is set on the sample surface with the cursor borders positioned to measure a relatively flat trace segment. -

Page 91: Cursor Parameters - Recipe Editor

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Creating and Editing a Scan Recipe b. As the track ball cursor approaches one of the active cursors, the cursor header changes to appear indented and the track ball cursor appears as a double arrow as shown in Figure 3.6. -

Page 92: Measurement Cursors - Relative To Feature Detection

Scan Recipes - Creating and Editing a Scan Recipe KLA-Tencor P-16+ / P-6 User’s Guide Relative to Feature Detected When there is a check ( ) in its checkbox, the cursor limits are set relative to the feature that is defined in the parameters window in the Feature Detection Recipe... - Page 93 KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Creating and Editing a Scan Recipe Median Filter for 2D and 3D Data This filter can be chosen as part of the recipe to help filter out spikes from environmental noise and particulate contamination. A median filter can be turned on before the scan, allowing the system to filter the data before the first viewing.

-

Page 94: Figure 3.36 Median Filter Application In Glitch Removal

Scan Recipes - Creating and Editing a Scan Recipe KLA-Tencor P-16+ / P-6 User’s Guide Figure 3.36 Median Filter Application in Glitch Removal BEFORE APPLICATION 1 x 3 point median filter AFTER APPLICATION before and after application Notice how much smoother the 1 x 7 filter (below) made the scan than that of the 1 x 3 filter (above). -

Page 95: Figure 3.37 2D And 3D Median Filter Options

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Creating and Editing a Scan Recipe 3. Click to display the Filters and Cursors parameters. Filters/Cursors 4. Click the menu-arrow for either the 2D or 3D Median Filter to display the options. -

Page 96: Filters Cursors Menu For A 3D Recipe

Scan Recipes - Creating and Editing a Scan Recipe KLA-Tencor P-16+ / P-6 User’s Guide Apply Filter The Apply Filter option is enabled by default. This means that the filter is applied to every 3D scan that meets the parameters described in the Y Lead Screw Filter Constraints. -

Page 97: Figure 3.39 3D Measurement Cursor Box

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Creating and Editing a Scan Recipe 3D Measurement Cursor The 3D measurement cursor is used to isolate an area of the scan, from which the measurements designated in the recipe for inclusion in the Analysis data (such as some of the parameters in General Parameters on page 51 and Roughness and Waviness Parameters on page 55), can be reported. -

Page 98: Figure 3.40 Recipe Editor - Choosing 3D Cursors

Scan Recipes - Creating and Editing a Scan Recipe KLA-Tencor P-16+ / P-6 User’s Guide Figure 3.40 Recipe Editor - Choosing 3D Cursors To open the 3D Cursors window, click Filters Cursors. Click to put a check in the check box to activate the X Start Level. -

Page 99: Unit Output

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Creating and Editing a Scan Recipe Unit Output Unit Output is designed to give the user an opportunity to determine units of output for the parameters calculated and to set automatic crossover values for unit changes. The options here let the user choose the units for the 2D graphical display through the recipe that is used to generate the scan. -

Page 100: Figure 3.42 General Parameters - Recipe Editor

Scan Recipes - Creating and Editing a Scan Recipe KLA-Tencor P-16+ / P-6 User’s Guide Figure 3.42 General Parameters - Recipe Editor To display the General Parameters options in the Information Display window of the Recipe Editor, click the General Parameters The 3D options are button. -

Page 101: Table 3.22 2D General Parameters

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Creating and Editing a Scan Recipe Each parameter is discussed below. (See Figure 3.42.) Table 3.22 2D General Parameters Parameter Description Step Height (StpHt) The difference in height between the left and right measurement cursors positions. - Page 102 Scan Recipes - Creating and Editing a Scan Recipe KLA-Tencor P-16+ / P-6 User’s Guide Table 3.22 2D General Parameters (Continued) Parameter Description Peak (Pp) Maximum Z value, measured relative to the leveled reference line, between the left and right measurement cursors. Valley (Pv) Minimum Z value, measured relative to the leveled reference line, between the left and right measurement cursors.

-

Page 103: Roughness And Waviness Parameters

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Creating and Editing a Scan Recipe Either one or both calculation options can be used. If both are used, two sets of calculations are performed and presented in the Analysis screen. Table 3.23 3D General Parameters Parameter... -

Page 104: Figure 3.43 Waviness Vs. Roughness

Scan Recipes - Creating and Editing a Scan Recipe KLA-Tencor P-16+ / P-6 User’s Guide For applications where the user is unsure of a specific long wavelength cutoff, use the μ general rule of 1/5 the scan length. This means that for a scan of 50 m, the cutoff μ... -

Page 105: Figure 3.45 Recipe Editor Showing 2D And 3D Roughness/Waviness Parameters

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Creating and Editing a Scan Recipe Figure 3.45 shows the Recipe Editor with the Roughness and Waviness parameters in the Information Display window. Figure 3.45 Recipe Editor Showing 2D and 3D Roughness/Waviness Parameters 0142530-000 AB KLA-Tencor Confidential 3-57... -

Page 106: Table 3.24 2D Roughness Parameters

Scan Recipes - Creating and Editing a Scan Recipe KLA-Tencor P-16+ / P-6 User’s Guide 2D Roughness Parameters Each of the roughness parameters available in the option 2D Roughness Parameters box are described in Table 3.24 on page 3-58. (For more information Roughness, see the Introduction to Roughness and Waviness Parameters on page 3-55.) Table 3.24 2D Roughness Parameters... - Page 107 KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Creating and Editing a Scan Recipe Table 3.24 2D Roughness Parameters (Continued) Parameter Description Roughness Height (R The difference in height in the roughness profile between the left and right cursor positions. Analogous to the Height data that always appears in the Summary box of the Analysis window.

-

Page 108: Table 3.25 2D Waviness Parameters

Scan Recipes - Creating and Editing a Scan Recipe KLA-Tencor P-16+ / P-6 User’s Guide 2D Waviness Parameters Table 3.25 2D Waviness Parameters Parameter Description Average (W This is the arithmetic average deviation of the absolute values of the waviness profile from the mean line or centerline also known as centerline average waviness). -

Page 109: Figure 3.46 3D Roughness Parameters

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Creating and Editing a Scan Recipe Figure 3.46 3D Roughness Parameters Either or both of the options for each parameter can be chosen. Each parameter option can be calculated in two different ways: With this checkbox selected, the parameter are calculated using data Full Scale: from the entire scan. - Page 110 Scan Recipes - Creating and Editing a Scan Recipe KLA-Tencor P-16+ / P-6 User’s Guide Table 3.26 3D Roughness Parameters (Continued) Parameter Description Kurtosis (S A measure of the peakedness or sharpness of the surface height distribution. It characterizes the spread of the height distribution.

-

Page 111: Bearing Ratio And Cutting Depth

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Creating and Editing a Scan Recipe Bearing Ratio and Cutting Depth Access the Bearing Ratio and Cutting Depth Information Display window by clicking the Bearing Ration/Cutting Depth button in the Recipe Editor. (See Figure 3.47.) Figure 3.47 Bearing Ration and Cutting Depth Parameters Bearing Ratio (t... -

Page 112: Figure 3.48 2D Bearing Ratio

Scan Recipes - Creating and Editing a Scan Recipe KLA-Tencor P-16+ / P-6 User’s Guide 1. The option exists to create three 2D bearing ratio parameters. Click in up to three empty checkboxes to put a check ( ) in them and activate their variable boxes. -

Page 113: Figure 3.50 Cutting Depth

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Creating and Editing a Scan Recipe 1. The option exists to create three 2D cutting depth parameters. Click in up to three empty checkboxes to put a check ( ) in them and activate their variable boxes. - Page 114 Scan Recipes - Creating and Editing a Scan Recipe KLA-Tencor P-16+ / P-6 User’s Guide 4. The is the distance down from the top of the highest point in the scan. To Depth set or change the , double-click the current variable and type in the Depth Depth...

-

Page 115: High Spot Count And Peak Count

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Creating and Editing a Scan Recipe High Spot Count and Peak Count Access the High Spot Count and Peak Count Display Window by clicking the High button in the Recipe Editor. (See Figure 3.51.) Spot Count/Peak Count Figure 3.51 Bearing Ratio and Cutting Depth Parameters... -

Page 116: Figure 3.52 High Spot Count

Scan Recipes - Creating and Editing a Scan Recipe KLA-Tencor P-16+ / P-6 User’s Guide Projecting through means that the profile curve first climbs above the reference line and then falls below it. Thus, if the profile rises above the reference line, descends without falling below it, then rises again, multiple peaks are not identified. -

Page 117: Figure 3.53 Peak Count

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Creating and Editing a Scan Recipe 4. The is the distance up from the lowest point of the roughness trace. In Height most scans, this value is compared to High Spot Count (HSC) so this height must be identical to the Height High Spot Count (HSC) -

Page 118: Histogram Leveling And Depth Analysis

Scan Recipes - Creating and Editing a Scan Recipe KLA-Tencor P-16+ / P-6 User’s Guide 2D Mean Spacing Sm (1/PC) Mean Peak spacing is the mean value of the local peak spacing of the profile within the sampling length. The peaks for Peak Count are defined by the (bandwidth) Band parameter from the Peak Count (PC) window. - Page 119 KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Creating and Editing a Scan Recipe Leveling Reference The system offers the following data planes to choose from for leveling the scan data: Most Populous Plane Highest Plane Lowest Plane All Data Planes The leveling takes place based upon the data points identified in one of the three data distribution planes identified above.

-

Page 120: Figure 3.55 Histogram Leveling Parameters

Scan Recipes - Creating and Editing a Scan Recipe KLA-Tencor P-16+ / P-6 User’s Guide Figure 3.55 Histogram Leveling Parameters In Figure 3.60, Scan A shows that the major distribution of points lie clearly in Z Min, Z Mid, and Z Max. The histogram of this distribution would be clearly presented in three ranges. -

Page 121: Histograms Of Scans A And B

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Creating and Editing a Scan Recipe Figure 3.56 Histograms of Scans A and B Scan A Bin Number Z Min Z Mid Z Max Lowest Plane Most Populous Plane Highest Plane Scan B Bin Number Z Min... -

Page 122: Figure 3.58 Flat Surface Scan Of A Single Object

Scan Recipes - Creating and Editing a Scan Recipe KLA-Tencor P-16+ / P-6 User’s Guide Leveling Reference Three reference planes exist, from which one must be chosen to level the scan. Two of the planes are easy to understand and use; the Highest Plane and Lowest Plane. Highest Plane –... -

Page 123: Figure 3.59 Most Populous Plane Trace Variation

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Creating and Editing a Scan Recipe The scan illustrated in Figure 3.59 would not be an acceptable candidate for Most Populous Plane. This scan has four traces that would give different data sets depending on which trace was used to level the scan. -

Page 124: Histogram Depth

Scan Recipes - Histogram Depth KLA-Tencor P-16+ / P-6 User’s Guide Figure 3.60 Histogram of a Scan Z Max Z Mid Z Min Bin Number Z Min Z Mid Z Max Lowest Plane (Mode) Most Populous Plane (Mode) Highest Plane (Mode) In the Histograms, the different planes (modes) are color coded for easy reference and identification. -

Page 125: Cmp Analysis

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - CMP Analysis Figure 3.61 Histogram Depth CMP A NALYSIS Introduction CMP (Chemical Mechanical Polishing) processes are used on a variety of different surface compositions. In general, the analysis of CMP surface scans centers around three structures: arrays, lines, and pads. -

Page 126: Figure 3.62 Cmp Analysis - Lines Or Array

Scan Recipes - CMP Analysis KLA-Tencor P-16+ / P-6 User’s Guide Figure 3.62 CMP Analysis - Lines or Array 3-78 KLA-Tencor Confidential 0142530-000 AB 3/13/09... -

Page 127: Figure 3.63 Cmp Analysis - Pads

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - CMP Analysis Figure 3.63 CMP Analysis - PADS 0142530-000 AB KLA-Tencor Confidential 3-79 3/13/09... -

Page 128: Arrays

Scan Recipes - CMP Analysis KLA-Tencor P-16+ / P-6 User’s Guide Arrays For the purposes of this analysis, “array” is defined as an array of contacts or vias (plugs). The contacts or vias are usually a metal like tungsten or copper which typically have polish rates higher than that of the surrounding array oxide. -

Page 129: Figure 3.65 Er And Cr

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - CMP Analysis The “erosion region” (ER) is found by determining the minimum and maximum slopes in the profile. The “calculations region” (CR) is defined as some fraction of the ER. Figure 3.65 ER and CR Curve A Curve B Determine the local maxima within the CR. -

Page 130: Lines

Scan Recipes - CMP Analysis KLA-Tencor P-16+ / P-6 User’s Guide Lines For the purposes of this analysis, “lines” is defined as an intermittent distribution of metal and oxide lines. The metal line are usually a soft metal like aluminum or copper which typically have polish rates higher than that of the surrounding array oxide. -

Page 131: Pads

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - CMP Analysis Determine the vertical range of data within the CR. Determine the local maxima within the CR using a window of variable size. The size of the window is roughly equivalent to the pitch of the lines. -

Page 132: Feature Find

Scan Recipes - Feature Find KLA-Tencor P-16+ / P-6 User’s Guide Using the PADS Analysis Routine This routine is designed to perform analysis on both 2D and 3D Profiler data. The same set of input parameters are used for 2D and 3D data belonging to a single recipe, e.g., 2D slices from a 3D data set. -

Page 133: Figure 3.68 Feature Find Parameter Definition

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Feature Find recipe and then clicking the Define button. If the option Model Feature is selected the recipe editor selections will change slightly to display different options. Table 3.27 contains a short description of the recipe parameters. Each parameter is discussed in detail as well. -

Page 134: Search For: Trench / Line

Scan Recipes - Feature Find KLA-Tencor P-16+ / P-6 User’s Guide Table 3.27 Feature Find Recipe Parameters (Continued) Parameter Setting Sensor or Oval, Description Sample Trench or Model X Scan Size (μm) Both X direction scan size of the feature find scan Traces Both This is the maximum number of x direction scans... -

Page 135: Figure 3.69 Trench / Line Features

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Feature Find process continues until a feature is found or until all x scan lines have been attempted. If no x scan lines find a feature, then the Feature Find scan failed. If during any of the x scan lines a feature is found that meets the requirements, the remaining x scans are canceled and the found coordinate becomes the Feature Find offset, which is the center point of the measurement scan. -

Page 136: Search For Model Feature

Scan Recipes - Feature Find KLA-Tencor P-16+ / P-6 User’s Guide Figure 3.70 Trench / Line Scan Search For Model Feature Model Feature definition is for features that are not easily defined as a rectangle or line. These features can be of irregular shape, an edge, or attempting to find a feature at the edge of an array for repeatability testing, as shown in Figure 3.71. -

Page 137: Figure 3.71 Edge Of An Array Of 5 Μm Lines

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Feature Find Figure 3.71 Edge of an Array of 5 µm Lines Scan data is saved as model, such as the model shown below. This model is for the edge of the array, with the top two lines including the 5 m lines and μ... -

Page 138: Figure 3.73 Model Feature Scan

Scan Recipes - Feature Find KLA-Tencor P-16+ / P-6 User’s Guide Example: Model Feature Search for the Edge of an Array of 5µm Lines ♦ Four x scans are performed, lines one through four, from Bottom to Top, to build a scan size equal to the number of lines as the model size. ♦... -

Page 139: Search Patterns: Center Outward, Top To Bottom

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Feature Find Search Patterns: Center Outward, Top to Bottom, or Bottom to Top There are three different search patterns that can be used in combination with any of the search types. All of the search patterns can be used with sensor or sample stage measurements. -

Page 140: Y Spacing (Μm)

Scan Recipes - Feature Find KLA-Tencor P-16+ / P-6 User’s Guide recipe, the number of Traces is limited to 2000. When setting up a sensor stage recipe, the allowable number of Traces is limited to 200 and is also limited by the recipe y size, and Feature Find Y Spacing and any offsets, with the total summing to less than the 90 µm scan size limitation for the sensor stage. -

Page 141: Failure Option: Save Search Data, Skip Current Scan, Or Scan At Center

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Feature Find Failure Option: Save Search Data, Skip Current Scan, or Scan at Center The choice of Failure Option depends on the preference of the user and the purpose of the Feature Find scan. When running a recipe with a Feature Find scan in a sequence recipe, if the option to Save Search Data is selected, after the Feature Find fails, it will save the x scan search data in the sequence data set and proceed to the next measurement site. -

Page 142: Feature Characteristics: Feature Down Or Feature Up

Scan Recipes - Feature Find KLA-Tencor P-16+ / P-6 User’s Guide Figure 3.74 5µm Lines Measurement Pattern Feature Characteristics: Feature Down or Feature Up When using the Oval / Rectangle and Trench / Line search types the user must define the physical characteristics of the feature. Feature Down or Feature Up defines if the feature is below or above the sample surface. -

Page 143: Model

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Feature Find filter size for the Feature Find scan. So if the tolerance is set too large, then a large filter can be applied which will affect the scan and Feature Find search performance. -

Page 144: Matching Methods: Edge Base Or Depth Base

Scan Recipes - Feature Find KLA-Tencor P-16+ / P-6 User’s Guide Figure 3.75 Feature Find Definition for Model Feature Matching Methods: Edge Base or Depth Base Edge Based matching method is the setting for most applications. It used the x and y edges of features in the model and compares it to the Feature Find scan data. -

Page 145: Matching Scores

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Feature Find Figure 3.76 Dual Damascene Example for Model Feature using Depth Based Matching Matching Scores The Matching Scores function in the way as the scores for sequence recipe pattern recognition. As each Feature Find scan line completes, a pattern recognition score is given that shows how well the model matches the scan data. -

Page 146: Reference Point (Μm)

Scan Recipes - Feature Find KLA-Tencor P-16+ / P-6 User’s Guide NOTE: The Model Feature pattern recognition scores will be shown on the status bar during the Feature Find scan. When optimizing the recipe, these scores should be noted to ensure that the High and Low matching scores are set properly. -

Page 147: Table 3.28 Diagnostic Options

KLA-Tencor P-16+ / P-6 User’s Guide Scan Recipes - Feature Find Diagnostic Options Listed below are options located in the Diagnostic options window. Table 3.28 Diagnostic Options Option Description No Motion Scan During the scan, data is collected but the stage does not move. -

Page 148: Entering Comments

Scan Recipes - Feature Find KLA-Tencor P-16+ / P-6 User’s Guide Entering Comments Introduction This feature is designed for recording important comments about the recipe. The only field that is active for user input is the Comments: field. The other fields are automatically set by the system to reflect the specific recipe. -

Page 149: Chapter 4 Xy View Screen

KLA-Tencor P-16+ / P-6 User’s Guide XY View Screen - Introduction XY VIEW SCREEN Chapter 4 NTRODUCTION The name XY View comes from the function of the screen itself, which is for viewing the sample surface, and positioning a scan. The XY View screen also provides other tools required to set up and perform a scan. - Page 150 XY View Screen - Starting the XY View Application KLA-Tencor P-16+ / P-6 User’s Guide XY View Menu Bar The Menu Bar contains the majority of the available screen function commands. Each function is explained in detail in this section. KLA-Tencor Confidential 0142530-000 AB 3/13/09...

-

Page 151: Table 4.1 View Menu Description

KLA-Tencor P-16+ / P-6 User’s Guide XY View Screen - Starting the XY View Application View Menu Table 4.1 View Menu Description View Menu Description Focus Using the current magnification setting, this button causes the system to focus on the sample that is on the stage at the same time that the stylus is nulled on the sample surface. -

Page 152: Table 4.2 Die Grid Menu

XY View Screen - Starting the XY View Application KLA-Tencor P-16+ / P-6 User’s Guide Die Grid Menu (Optional Feature with Pattern Recognition Option, P-16+ Only) Table 4.2 Die Grid Menu Die Grid Menu Description Load… Displays the dialog box used to load a die grid pattern. -

Page 153: Figure 4.2 Move Extents Dialog Box

KLA-Tencor P-16+ / P-6 User’s Guide XY View Screen - Starting the XY View Application Move Menu Table 4.3 Move Menu Move Menu Description Slow – Sets the XY stage to move in the slowest, or smallest increment, speed as defined in the Move Extents Medium –... -

Page 154: Table 4.4 Direction Menu

XY View Screen - Starting the XY View Application KLA-Tencor P-16+ / P-6 User’s Guide Direction Menu Table 4.4 Direction Menu Direction Menu Description Up – Moves the stage in the +Y direction away from the front door by one increment (as defined in for the set speed) per Move Speeds... -

Page 155: Table 4.5 Actions Menu

KLA-Tencor P-16+ / P-6 User’s Guide XY View Screen - Starting the XY View Application Actions Menu Table 4.5 Actions Menu Actions Menu Description Start Scan Starts the scan process. View Scan Changes to the View Scan window. Sample Menu Table 4.6 Sample Menu Sample Menu... -

Page 156: Figure 4.4 Distance Dialog Box

XY View Screen - Starting the XY View Application KLA-Tencor P-16+ / P-6 User’s Guide Stylus Menu Table 4.8 Stylus Menu Stylus Menu Description Drop/Lift (Applicable to P/16+ only) Causes the stylus to pivot up. A check mark is visible while it is in the UP position. Click it to release it back to its normal scanning position Distance…... -

Page 157: Setting The Magnification

The system has an optical zoom function that allows the operator to view the sample surface at different magnifications for feature identification and scan placement. If the system has Pattern Recognition operating (P-16+only), zooming in and out could prevent the system from performing accurately because the recognition function also takes into consideration the size of the image as well as its shape. -

Page 158: Changing The Magnification

XY View Screen - Setting the Magnification KLA-Tencor P-16+ / P-6 User’s Guide Changing the Magnification Click the to change the magnification. Each click changes the ZOOM IN ZOOM OUT magnification level in or out by a small amount. (Alternative: In the Menu bar click to display its menu. -

Page 159: Focusing The View

KLA-Tencor P-16+ / P-6 User’s Guide XY View Screen - Focusing the View 3. Ensure that the zoom position in the dialog box field agrees with the Zoom Zoom in the screen display. (See Figure 4.6.) Position 4. Click the check box. -

Page 160: P-16+ Microhead Measurement Head

XY View Screen - Focusing the View KLA-Tencor P-16+ / P-6 User’s Guide 3. Open the measurement chamber door and then the head door. (See Figure 4.7.) Figure 4.7 P-16+ MicroHead Measurement Head. Top Panel Stylus Protection Plate Camera Status Indicators Stylus Wrench Optics... -

Page 161: Positioning The Scan Site

KLA-Tencor P-16+ / P-6 User’s Guide XY View Screen - Positioning the Scan Site 6. If the side view requires focusing, use the Side-View Focus knob to focus the side view. (See Figure 4.8) Figure 4.8 P-16+ Focusing the Optics (Dual-View Optics). Side-View Focus Knob (P-16+ Only) -

Page 162: Figure 4.9 Coordinate System Of The Kla-Tencor Profiler Stage

XY View Screen - Positioning the Scan Site KLA-Tencor P-16+ / P-6 User’s Guide Figure 4.9 shows the stage coordinate system (SEMI Standard M20-92) used by the Profiler. The X and Y coordinates relative to the center of the measurement area are displayed in the current stage coordinate area of the XY View window. -

Page 163: Figure 4.10 Xy View Screen Tool Bar

KLA-Tencor P-16+ / P-6 User’s Guide XY View Screen - Positioning the Scan Site Table 4.10 Locating a Scan Site Movement Required Movement Method Move in increments Arrow Buttons Positioning – Click the Fast , or buttons (move extents) to change Medium Slow across the sample using... -

Page 164: Using Die Grid Navigation (Optional Feature , P-16+ Only )

XY View Screen - Using Die Grid Navigation (Optional Feature, P-16+ only) KLA-Tencor P-16+ / P-6 User’s Guide 3. Click the button to null the stylus on the sample and confirm the Stylus Drop-Lift scan position. Figure 4.11 XY View Screen Video Display Window Sample Navigation Window... -

Page 165: Figure 4.12 Teach Die Grid Screen With Loaded Die Grid

KLA-Tencor P-16+ / P-6 User’s Guide XY View Screen - Using Die Grid Navigation (Optional Feature, P-16+ only) Figure 4.12 Teach Die Grid Screen with Loaded Die Grid Current : The die Die Scan Position currently being scanned is highlighted. Die Grid Navigation Window: This is a representation of the current die grid loaded in the... -

Page 166: Creating A Die Grid

XY View Screen - Using Die Grid Navigation (Optional Feature, P-16+ only) KLA-Tencor P-16+ / P-6 User’s Guide In making it more convenient to position scans on a wafer, Die Grid Navigation provides the following options: Mask out the dies that are not to be measured. Masked dies appear blacked out on the Die Grid Navigation Window, providing visual reference points. -

Page 167: Figure 4.13 Scan Catalog Screen

KLA-Tencor P-16+ / P-6 User’s Guide XY View Screen - Using Die Grid Navigation (Optional Feature, P-16+ only) Figure 4.13 Scan Catalog Screen Step 1 Click the Scan Recipe button to open the list of available Step 2 Click the Die Grid icon to initiate the Teach... -

Page 168: Figure 4.15 Teach Die Grid Screen

XY View Screen - Using Die Grid Navigation (Optional Feature, P-16+ only) KLA-Tencor P-16+ / P-6 User’s Guide 3. Click to continue with the procedure. (See Figure 4.14.) 4. In the screen, the procedure is prompted from the message Teach Die Grid display area at the bottom left of the screen. -

Page 169: Figure 4.16 Teach Die Grid - Teach First Position

KLA-Tencor P-16+ / P-6 User’s Guide XY View Screen - Using Die Grid Navigation (Optional Feature, P-16+ only) 10. Click when all variables are correct. Figure 4.16 Teach Die Grid - Teach First Position Step 11 The graphic represents a single die. The thick gray border is the area between the various dies on the wafer. -

Page 170: Figure 4.17 Teach Die Grid - Teach Feature

XY View Screen - Using Die Grid Navigation (Optional Feature, P-16+ only) KLA-Tencor P-16+ / P-6 User’s Guide Figure 4.17 Teach Die Grid - Teach Feature Step 12 Use the arrow buttons to locate a distinct feature. Use the click and drag procedure to draw a box around the feature. -

Page 171: Figure 4.18 Teach Die Grid - Lower Right Corner

KLA-Tencor P-16+ / P-6 User’s Guide XY View Screen - Using Die Grid Navigation (Optional Feature, P-16+ only) 14. After making any required adjustments, click If the die width and height were not entered, the instrument continues to the third position in the Teach Die Grid sequence: Figure 4.18 Teach Die Grid - Lower Right Corner Step 15 Use the arrow buttons... -

Page 172: Figure 4.19 Teach Die Grid - With Feature In Navigation Window

XY View Screen - Using Die Grid Navigation (Optional Feature, P-16+ only) KLA-Tencor P-16+ / P-6 User’s Guide Figure 4.19 Teach Die Grid - With Feature in Navigation Window The feature appears in the navigation window, above the text explaining the current system activity. -

Page 173: Loading A Die Grid (Turning On Die Grid Navigation) For A Single Scan

KLA-Tencor P-16+ / P-6 User’s Guide XY View Screen - Using Die Grid Navigation (Optional Feature, P-16+ only) At the bottom of the die grid navigation window is a representation of the die grid, which appears as a bounded white rectangle. The taught feature is pictured a small bounded box appearing in its relative position in the die. -

Page 174: Figure 4.21 Sequence Editor With Die Grid Menu

XY View Screen - Using Die Grid Navigation (Optional Feature, P-16+ only) KLA-Tencor P-16+ / P-6 User’s Guide Figure 4.21 Sequence Editor with Die Grid Menu Step 2 Click to display its Grid menu. Step 3 Click to display Load... the Load Die Grid dialog box. -

Page 175: Figure 4.22 Load Sequence Die Grid

KLA-Tencor P-16+ / P-6 User’s Guide XY View Screen - Using Die Grid Navigation (Optional Feature, P-16+ only) 4. In the dialog box, double-click the name of the die grid to be used. Load Die Grid This displays die grid name in the File Name display box. Figure 4.22 Load Sequence Die Grid Step 4 To choose a die grid to... -

Page 176: Clearing A Die Grid (Turn Off Die Grid Navigation)

XY View Screen - Using Die Grid Navigation (Optional Feature, P-16+ only) KLA-Tencor P-16+ / P-6 User’s Guide Clearing a Die Grid (Turn OFF Die Grid Navigation) 1. Go to the window. Teach Scan 2. Click the menu, and select . -

Page 177: Displaying Grid Numbers In The Die Grid Navigation Window

KLA-Tencor P-16+ / P-6 User’s Guide XY View Screen - Aligning the Sample Displaying Grid Numbers in the Die Grid Navigation Window From a window, click , then click (See Teach Scan Site Die Grid Display Numbers Figure 4.23.)click If the numbers are too small to see, increase the size of the Die Grid Navigation Window by clicking and dragging the window’s vertical separator bar to the left. -

Page 178: Figure 4.24 Setting Alignment Angle

XY View Screen - Aligning the Sample KLA-Tencor P-16+ / P-6 User’s Guide 4. Click in the tool bar to display its menu. In the menu, click View Align Sample This sets up the procedure which aligns the XY axis of the Alignment Sample screen with the chosen feature. -

Page 179: Figure 4.25 Move Menu

KLA-Tencor P-16+ / P-6 User’s Guide XY View Screen - Aligning the Sample 2. Use the theta movement arrows in the tool bar (in conjunction with the other arrow buttons as necessary) to rotate the chosen feature until it aligns with the X-axis on the XY view screen. - Page 180 XY View Screen - Aligning the Sample KLA-Tencor P-16+ / P-6 User’s Guide 4-32 KLA-Tencor Confidential 0142530-000 AB 3/13/09...

-

Page 181: Chapter 5 View Scan Window

KLA-Tencor P-16+ / P-6 User’s Guide View Scan Window - 2D Screen Function VIEW SCAN WINDOW Chapter 5 2D S CREEN UNCTION appears while a scan is being run. It allows the user to observe View Scan Window the progress of the scan and to adjust scan parameters in the various screens for optimum scan results. -

Page 182: 2D Scan Information Field

View Scan Window - 2D Screen Function KLA-Tencor P-16+ / P-6 User’s Guide Two columns of information are presented in the lower left quadrant of the 2D scan screen (Figure 5.1) and three columns in the 2D sequence screen. 2D Scan Information Field Figure 5.2 2D Scan Window - Scan Information Field Scan Location... -

Page 183: Scan Information Field - 2D Sequence Recipe Column

KLA-Tencor P-16+ / P-6 User’s Guide View Scan Window - 2D Screen Function Scan Information Field - 2D Sequence Recipe Column Figure 5.3 2D Scan Window - Scan Information Field Sequence Scan Location Information information column. Scan Recipe information column. 2D Sequence Column The first column in the Scan Information field is the column. -

Page 184: Real Time Scan Trace Window

View Scan Window - 2D Screen Function KLA-Tencor P-16+ / P-6 User’s Guide Real Time Scan Trace Window This window presents a real time trace of the scan. (See Figure 5.4.) A 2D scan can be set up for multi-scan averaging which causes the system to scan the same location as many times as the set parameter requires. -

Page 185: 2D View Scan Screen Menu Bar

KLA-Tencor P-16+ / P-6 User’s Guide View Scan Window - 2D Screen Function Table 5.4 2D View Scan Window Tool Bar Buttons Button Description XY View Screen Icon – Changes to view the XY View screen. Analysis Screen Icon – Changes screens to view the Analysis screen. -

Page 186: Table 5.5 2D View Scan Screen - File Menu

View Scan Window - 2D Screen Function KLA-Tencor P-16+ / P-6 User’s Guide Table 5.5 2D View Scan Screen - File Menu File Menu Description of Menu Items Oscilloscope – Not available with P-series systems. XY View – Returns to the XY View screen. If the scan was stopped in the View Scan screen, and the File/XY View menu item was used to toggle to the XY view screen, the scan start position can be... -

Page 187: Table 5.7 2D View Scan Screen - Image Menu

KLA-Tencor P-16+ / P-6 User’s Guide View Scan Window - 2D Screen Function Table 5.7 2D View Scan Screen - Image Menu Image Menu Description of Menu Items The image menu is only available for HRP systems equipt with a high resolution sensor stage. The image controls then allow the user to adjust the 3D scan location and parameters within the range of the sensor stage without lifting the stylus. -

Page 188: Table 5.11 2D View Scan Screen - Pan Menu

View Scan Window - 2D Screen Function KLA-Tencor P-16+ / P-6 User’s Guide Table 5.11 2D View Scan Screen - Pan Menu Pan Menu Description of Menu Items The pan menu is only available for HRP systems equipt with a high resolution sensor stage. The pan controls then allow the user to adjust the 2D scan location within the range of the sensor stage without lifting the stylus. -

Page 189: Screen Unction

KLA-Tencor P-16+ / P-6 User’s Guide View Scan Window - 3D Screen Function 3D S CREEN UNCTION The function of the 3D View Scan screen is similar to that of the 2D screen. Some additions to the screen are made to facilitate 3D analysis and operator monitoring of the scan process. -

Page 190: 3D Scan Information Field

View Scan Window - 3D Screen Function KLA-Tencor P-16+ / P-6 User’s Guide Figure 5.7 3D View Scan Screen During a Scan Sequence When performing a sequence, the Sequence information is added to the information set. 3D Scan Information Field Figure 5.8 3D Scan Window - Scan Information Field The only parameter in this... -

Page 191: Scan Information Field - 3D Sequence Recipe Column

KLA-Tencor P-16+ / P-6 User’s Guide View Scan Window - 3D Screen Function 3D Location Column The second column in the Scan Information field is the Location column. It contains the coordinates and orientation of the scan starting point. Table 5.12 presents a brief description of each parameter. -

Page 192: 3D View Scan Screen Menu Bar

View Scan Window - 3D Screen Function KLA-Tencor P-16+ / P-6 User’s Guide 3D View Scan Screen Menu Bar The menu bar contains those functions that are related to the activities required in the View Scan Screen. Some of the functions are duplicated in the tool bar. (See Figure 5.10.) Some menus such as the 3D View Scan Screen - Trace, Mode, Image and Debug menus, are similar to the 2D View Scan Screens. -

Page 193: Video Image

KLA-Tencor P-16+ / P-6 User’s Guide View Scan Window - 3D Screen Function Table 5.16 3D View Scan Screen - Scan Menu Scan Menu Description of Menu Items Start – Sequences: The sequence is terminated when the STOP button is clicked. There is no opportunity to use this menu item. -

Page 194: Real Time Scan Window

View Scan Window - 3D Screen Function KLA-Tencor P-16+ / P-6 User’s Guide Real Time Scan Window In a 3D scan each subsequent scan’s trace is presented in the 3D Top View display. (See Figure 5.11.) At the end of the scan the system presents the results in the 3D Analysis screen. -

Page 195: Scan Site Image Display

KLA-Tencor P-16+ / P-6 User’s Guide View Scan Window - Aborting A Scan If the wafer is not characterized by a die grid, or the die map is not loaded, the scan sites appear as colored dots at the scan location. The color code is the same as that of the wafer having a die grid map. - Page 196 View Scan Window - Aborting A Scan KLA-Tencor P-16+ / P-6 User’s Guide 5-16 KLA-Tencor Confidential 0142530-000 AB 3/13/09...

-

Page 197: Introduction

KLA-Tencor P-16+ / P-6 User’s Guide Sequence Recipe and Data - Introduction SEQUENCE RECIPE AND DATA Chapter 6 NTRODUCTION Limited Sequence Recipe and Data applications are now standard on the P-16+/P-6. However, the capability of the Sequence application can be greatly extended using the 1000- site sequence option. -

Page 198: Figure 6.1 Sequence Editor Screen

Sequence Recipe and Data - Starting the Sequence Editor Application KLA-Tencor P-16+ / P-6 User’s Guide TARTING THE EQUENCE DITOR PPLICATION 1. In the Catalog screen, if it is not already active, click the Sequence Recipe button. 2. Select a Sequence recipe to be edited. 3. -

Page 199: Sequence Recipe Catalog Screen

KLA-Tencor P-16+ / P-6 User’s Guide Sequence Recipe and Data - Creating a Sequence Recipe 2. To load a sample, click in the menu bar at the top of the screen to display Sample its menu. (See Figure 6.2.) Figure 6.2 Sequence Recipe Catalog Screen Step 2 Click in the... -

Page 200: Figure 6.3 Scan Sequence Catalog

Sequence Recipe and Data - Creating a Sequence Recipe KLA-Tencor P-16+ / P-6 User’s Guide 8. After the door is closed, click in the menu bar, then on . The End: OPTIONAL Manual Sample Manual Load Wafer Load Procedure stage moves back under the measurement head. Figure 6.3 Scan Sequence Catalog Step 9 Click the Sequence... -

Page 201: Sequence Editor For New Recipe With Pattern Recognition

KLA-Tencor P-16+ / P-6 User’s Guide Sequence Recipe and Data - Creating a Sequence Recipe Figure 6.4 Sequence Editor for NEW Recipe with Pattern Recognition Step 11 Click then Sequence to display the Save Save As dialog box for saving and naming the sequence. -

Page 202: Figure 6.5 Options Section In The Sequence Editor (Optional Feature, P-16+ Only)

Sequence Recipe and Data - Creating a Sequence Recipe KLA-Tencor P-16+ / P-6 User’s Guide 2. Click (See Figure 6.5.) Pattern Recog. Deskew… Figure 6.5 Options Section in the Sequence Editor (Optional feature, P-16+ only) Step 1 Click the menu arrow for its menu. -

Page 203: Figure 6.6 Die Grid Menu

KLA-Tencor P-16+ / P-6 User’s Guide Sequence Recipe and Data - Creating a Sequence Recipe 4. In the menu bar, click to display its menu. (See Figure 6.6.) If Die Grid Die Grid is grayed out in the menu bar, the Safe Area might be incorrect. Set the Safe Area in the Configuration screen to the size of the wafer being used. -

Page 204: Figure 6.8 Sequence Editor

Sequence Recipe and Data - Creating a Sequence Recipe KLA-Tencor P-16+ / P-6 User’s Guide 8. A warning message box appears warning that adding the die grid to the recipe changes the base angle and can invalidate deskew and measurements sites. Since this is a new recipe and the site have yet to be determined, click . -

Page 205: Pattern Rec. Deskew Teach: Site 1 Screen

KLA-Tencor P-16+ / P-6 User’s Guide Sequence Recipe and Data - Creating a Sequence Recipe 12. The screen is displayed. Click a die in the Pattern Rec. Deskew Teach: Site 1 upper left quadrant of the sample navigation grid. the dark (blue on the screen) rectangle has been chosen in Figure 6.10. -

Page 206: Deskew Options Dialog Box

Sequence Recipe and Data - Creating a Sequence Recipe KLA-Tencor P-16+ / P-6 User’s Guide 18. Deskew Options set the number of groping Layers, set the maximum and Begin: Setting Deskew Options minimum percentage match for identification of a feature, and offer the ability to turn on or off Deskew Twice and Image Processing options. -

Page 207: Figure 6.12 Data Options

KLA-Tencor P-16+ / P-6 User’s Guide Sequence Recipe and Data - Creating a Sequence Recipe 24. If desired, click to put a check in the check box for Perform Deskew Twice to to enable it. (See “Perform Deskew Twice to Align Theta” in Table Align Theta 6.12 on page 6-45.) 25. -

Page 208: Sequence Editor Set Up For New Recipe

Sequence Recipe and Data - Creating a Sequence Recipe KLA-Tencor P-16+ / P-6 User’s Guide 3. Save the Sequence by clicking on to display its menu, then on Sequence Save Figure 6.13 Sequence Editor Set Up for New Recipe The Sequence Editor comes up with no recipes listed. -

Page 209: Figure 6.14 Sequence Editor - Teach Scan Location

KLA-Tencor P-16+ / P-6 User’s Guide Sequence Recipe and Data - Creating a Sequence Recipe 5. In the , click a scan recipe in the sequence. It highlights when Begin: Teach Scan Sequence Editor Location chosen. (See Figure 6.14.) Figure 6.14 Sequence Editor - Teach Scan Location Step 5 Click a scan recipe so that it... -

Page 210: Teach Location For First Recipe Scan

Sequence Recipe and Data - Creating a Sequence Recipe KLA-Tencor P-16+ / P-6 User’s Guide Figure 6.15 Teach Location for First Recipe Scan Step 8 The Teach Location screen displays the sample surface under low magnification. Position the scan path across the chosen feature. -

Page 211: Figure 6.16 Sequence Editor

KLA-Tencor P-16+ / P-6 User’s Guide Sequence Recipe and Data - Creating a Sequence Recipe Figure 6.16 Sequence Editor This scan sequence uses two recipes. Both have the scan locations taught as indicated by the X, Y, and Theta coordinates. 11. -

Page 212: Figure 6.17 Sequence Editor With Die Grid Menu

Sequence Recipe and Data - Creating a Sequence Recipe KLA-Tencor P-16+ / P-6 User’s Guide 4. Click (See Figure 6.17.) Associate Dies... Figure 6.17 Sequence Editor with Die Grid Menu Step 3 Click in the Die Grid menu bar to display its menu. Step 4 Click Associate Dies... -

Page 213: Figure 6.18 Xy View With Sequence Scan Sites

KLA-Tencor P-16+ / P-6 User’s Guide Sequence Recipe and Data - Creating a Sequence Recipe Figure 6.18 XY View with Sequence Scan Sites Step 5 The original die being scanned is the number one die. Click in each successive rectangle representing a die that is to be added to the sequence using the die number one scan. -

Page 214: Figure 6.20 Sequence Editor With New Scan Sites

Sequence Recipe and Data - Creating a Sequence Recipe KLA-Tencor P-16+ / P-6 User’s Guide When is clicked, the Sequence Editor is displayed with the additional sites in the Sequence Recipe. Notice that each new site has the coordinates of the scan location for that die. In the illustration Figure 6.20, two sets of new sites have been added, one for additional dies using the scan named FIRST, and one for dies using the scan named SECOND. -

Page 215: Table 6.1 Sequence Editor Window Buttons

KLA-Tencor P-16+ / P-6 User’s Guide Sequence Recipe and Data - Sequence Editor Window Features d. When the last site is verified, the screen reverts back to the Sequence End: Auto Verify Editor. Save the Sequence by clicking on File and Save Save As e. -

Page 216: Table 6.2 Sequence List Buttons

Sequence Recipe and Data - Sequence Editor Window Features KLA-Tencor P-16+ / P-6 User’s Guide Table 6.2 Sequence List Buttons Button Description Adds the selected Scan recipe into the sequence. After highlighting an existing site in the Sequence list, clicking this button changes the Scan recipe for the site to whatever is highlighted in the catalog. -

Page 217: Table 6.4 Site Buttons

KLA-Tencor P-16+ / P-6 User’s Guide Sequence Recipe and Data - Sequence Editor Window Features Table 6.4 Site Buttons Button Description Goes to the XY view so a measurement site can be chosen based on a location observed on the screen. Goes to the XY view so a pattern can be taught for pattern recognition. -

Page 218: Sequence Editor - Sequence Menu

Sequence Recipe and Data - Sequence Editor Window Features KLA-Tencor P-16+ / P-6 User’s Guide Displaying the Sequence Information Dialog Box The Sequence Information dialog box displays the title, author, date and time of creation (or modification) of the sequence. It also provides a text box for annotations. 1. -

Page 219: Sequence Editor - Mode Menu

KLA-Tencor P-16+ / P-6 User’s Guide Sequence Recipe and Data - Editing the Options Field in the Sequence Editor ← or → until the 3. Click in the field, or press text Comments Comments box is highlighted. 4. Enter the text of the information which needs to be passed from one operator to the other. -

Page 220: Table 6.5 Mode Drop-Down Menu Options

Sequence Recipe and Data - Editing the Options Field in the Sequence Editor KLA-Tencor P-16+ / P-6 User’s Guide Set Deskew Mode Click the drop-down menu (see Figure 6.23), and select the from the following Mode modes. (See Table 6.5) Sequence NOTE: Pattern Rec. -

Page 221: Figure 6.24 Sequence Editor

KLA-Tencor P-16+ / P-6 User’s Guide Sequence Recipe and Data - Editing the Options Field in the Sequence Editor 2. Click the button to choose options for data collection that automatically Begin: Set Data Options Data execute upon sequence completion. Figure 6.24 Sequence Editor Step 2 Click the Data... -

Page 222: Table 6.8 Export Options

Sequence Recipe and Data - Editing the Options Field in the Sequence Editor KLA-Tencor P-16+ / P-6 User’s Guide 1. Choose an option from the Save, Export, and Print options. (See Table 6.7.) Table 6.7 Save and Export Options Feature Description None Saves or exports no data. -

Page 223: Figure 6.26 Sequence Editor

KLA-Tencor P-16+ / P-6 User’s Guide Sequence Recipe and Data - Editing the Options Field in the Sequence Editor Teaching the Base Angle (P-16+ Only) The Base Angle is an offset angle relative to the orientation of the sample’s pattern. It is used to align scans with the wafer geometry. -

Page 224: R Unning A S Equence

Sequence Recipe and Data - Running a Sequence KLA-Tencor P-16+ / P-6 User’s Guide to steps 4. and 5.: To align the current sample surface with the ALTERNATIVE screen crosshair, use the principles described in BEGIN Align Sample Procedure on page 13-15. Use a horizontal feature on the sample surface in place of the dotted line on the ProCal Wafer described in the procedure. -

Page 225: Figure 6.27 Queue Editor

KLA-Tencor P-16+ / P-6 User’s Guide Sequence Recipe and Data - Queue 2. This will open the Queue Editor that allows the user to add sequences to the queue as shown in Fig. 6.27. Figure 6.27 Queue Editor 3. The user can add sequences to the queue by navigating to the correct sequence in the sequence recipe database on the left and then clicking on Add. -

Page 226: Figure 6.28 Runtime View With The Sequence Queue

Sequence Recipe and Data - Queue KLA-Tencor P-16+ / P-6 User’s Guide 9. Alternatively, the user can start the queue without saving the changes for instances when this collection of sequence recipes will not be repeated in the future. Adding Sequence Recipes to the Queue at Runtime After a sequence recipe, queue, or batch has been started, the user can modify the queue while the sequences are being executed. -

Page 227: Correlation Scan Sequence

KLA-Tencor P-16+ / P-6 User’s Guide Sequence Recipe and Data - Correlation Scans ORRELATION CANS Scans are correlated when a long scan is performed first, then small scans are performed in the same general location. Correlation scanning combines local area scans with macroscopic scans so that discrete features can be related to global surface planarity. -

Page 228: Viewing The Correlation Scan Data

Sequence Recipe and Data - Correlation Scans KLA-Tencor P-16+ / P-6 User’s Guide 7. Teach the long scan position. a. Press the button. Teach LOC b. Go to the location and click it. To accept the location, click in the dialog box that appears. -

Page 229: Figure 6.30 Correlation Sub-Scan Window

KLA-Tencor P-16+ / P-6 User’s Guide Sequence Recipe and Data - Viewing Saved Sequence Data 4. Click to display the window. Correlation Scan The Correlation Scan window appears, showing the long scan trace and thumbnail callouts of each of its sub-scans positioned on the long scan (see Figure 6.30). -

Page 230: Calculating Combined Sequence Statistics

Sequence Recipe and Data - Using Multi Analysis In Sequence KLA-Tencor P-16+ / P-6 User’s Guide 3. Click the button. Recover Calculating Combined Sequence Statistics Values from different sequence sets can be combined into one, and used to calculate the standard deviation, mean, and so forth. The computer accesses stored data from selected data sets in the Sequence Data catalog and recalculates them. -

Page 231: Viewing Multi Analysis Results

KLA-Tencor P-16+ / P-6 User’s Guide Sequence Recipe and Data - Using Multi Analysis In Sequence a. Click its name in the list b. Click recipe to change any parameters and filter settings. Cursor Edit positions can only be changed by entering them numerically. c. -

Page 232: Figure 6.31

Sequence Recipe and Data - Viewing Sequence Data KLA-Tencor P-16+ / P-6 User’s Guide IEWING EQUENCE Viewing Wafer Summary Data The Sequence Parameter Data window displays the detailed results of each site scanned in the sequence. 1. Go to the menu in the window, and select File... -

Page 233: Figure 6.32