Summary of Contents for GRIFOLS DG Spin

- Page 1 DG Spin Instrucciones de Utilización Instructions for Use Diagnostic Grifols, S.A. 3027662 07/2008 Passeig Fluvial, 24, 08150 Parets del Vallès, Barcelona - ESPAÑA Tel. [34] 935 710 400 Fax [34] 935 731 132 www.grifols.com...

- Page 2 DG spin Instructions for Use Diagnostic Grifols, S.A. Passeig Fluvial, 24 - 08150 Parets del Vallès, ESPAÑA (SPAIN)

- Page 3 PLEASE READ THESE INSTRUCTIONS FOR USE CAREFULLY BEFORE STARTING TO WORK WITH THE CENTRIFUGE DG SPIN Information about matter relating to the equipment safety can be found in the chapter 2 “Safety information”. The symbols used in these Instructions for Use are as follows: DANGER! Any kind of injure –...

- Page 4 Definitions: RESPONSIBLE AUTHORITY Individual or group responsible for the use and maintenance of the equipment and for ensuring that operators are adequately trained. OPERATOR Person operating equipment for its intended purpose. The OPERATOR should have received appropriate training for this purpose. QUALIFIED TECHNICIAN Person responsible for the installation, reparation and special maintenance of the equipment who has received specific training...

-

Page 5: Table Of Contents

3 SPECIFICATIONS OF THE CENTRIFUGE ECHNICAL SPECIFICATIONS CCESSORIES EGULATORY 4 DESCRIPTION OF THE CENTRIFUGE ENERAL DESCRIPTION OF THE CENTRIFUGE 4.1.1 Centrifugation chamber 4.1.2 DG Spin head 4.1.3 Centrifuge cover 4.1.4 Control buttons 4.1.4.1 Centrifugation starting button 4.1.4.2 Centrifugation stopping button 4.1.4.3... - Page 6 DG Spin Index ONFIGURATION OF THE EQUIPMENT 6 OPERATING PROCEDURE XECUTION OF A CENTRIFUGATION BATCH ISUALISATION OF THE CENTRIFUGATION SPEED ENTRIFUGATION STOP 7 MAINTENANCE AINTENANCE PLAN 7.1.1 Cleaning procedures 7.1.2 Decontamination of the equipment 7.1.2.1 Decontaminant liquids 8 OPERATION QUALIFICATION PROCEDURE (OQ)

-

Page 7: Introduction

DG Spin Introduction 1 INTRODUCTION IN VITRO THIS EQUIPMENT IS AN DIAGNOSTIC MEDICAL DEVIDE (IVD). These Instructions for Use, which are intended for the OPERATORS of the DG Spin incubator, contain all the information that is necessary for safely and adequately working with the instrument. -

Page 8: Safety Information

DG-Spin Safety Information 2 SAFETY INFORMATION Important safety instructions The following indications are directly related to the safety of the equipment: DANGER! Misuse of the equipment can impair the protection provided by itself. DANGER! To avoid risk of electric shock, this equipment should only be connected to a supply main with protective earth. - Page 9 DG-Spin Safety Information WARNING! This equipment only must be used by the RESPONSIBLE AUTHORITY, OPERATORS and QUALIFIED TECHNICIANS. WARNING! Electromagnetic compatibility and electrical safety tests have been performed using the cord supplied by the manufacturer. However, if it is necessary to use another cord, be sure that cord meets following...

-

Page 10: E Quipment Labelling

“Read before use”. Furthermore, before installing the equipment, the rules of 5.2 “Installation requirements” section must be read. Equipment labelling DG Spin centrifuge is labelled with the following labels: (4) Packaging label (5) Identification and Basic Technical Characteristics of the equipment label (6) Biological risk of the Centrifugation chamber. - Page 11 DG-Spin Safety Information Temperature range permitted during storage and transport Relative humidity range permitted during storage and transport European conformity (2) Identification and Basic Technical Characteristics label Label located on the rear part of the equipment containing technical information (mains tension, frequency and power) as well as the model, serial number, manufacturing date, name and address of the manufacturer and regulatory information.

-

Page 12: R Ead Before Use

DG-Spin Safety Information (3) Biological risk level Located on the lateral part of the Centrifugation chamber, it indicates and warns of the biohazard caused by possible remaining substances deposited on the surface. Read before use Use the equipment only for the purposes described in the Instructions for Use. -

Page 13: Specifications Of The Centrifuge

DG Spin Specifications of the Centrifuge 3 SPECIFICATIONS OF THE CENTRIFUGE Technical specifications MODEL DG spin DG Gel cards LOAD CAPACITY DG SPIN HEAD Removable and interchangeable DG Gel cards CENTRIFUGATION Pre-programmed. Those required for CONDITIONS CENTRIFUGATION 990 rpm ± 10 rpm (128.1 g ± 1.0 %) -

Page 14: A Ccessories

DG Spin Specifications of the Centrifuge WEIGHT (KG) Approximately 15 kg WORK CONDITIONS Indoor use Temperature: 15ºC to 40ºC Maximum relative humidity non 80 % condensing: Maximum altitude: 3000 m Mains supply ±10 % of nominal voltage maximum voltage fluctuations:... -

Page 15: R Egulatory

DG Spin Specifications of the Centrifuge Regulatory DG Spin centrifuge comforms to the requeriments of: In Vitro EU Directive 98/79/EC on “ Diagnostic Medical Devices”. EU Directive 2002/96/EC on “Waste electrical and electronic equipment". -

Page 16: Description Of The Centrifuge

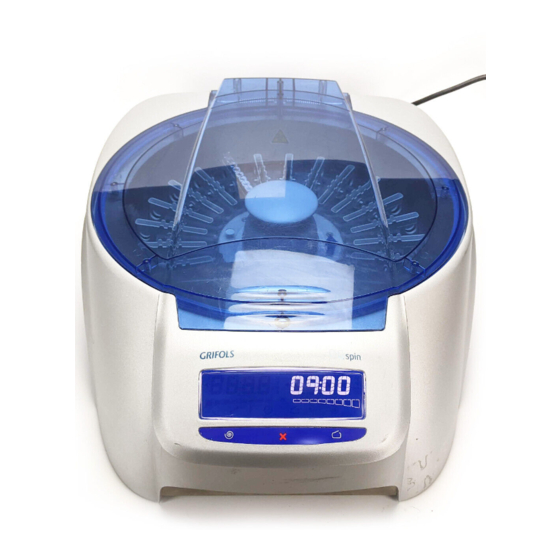

DG Spin Description of the Centrifuge 4 DESCRIPTION OF THE CENTRIFUGE General description of the centrifuge DG Spin Figure 1 and Figure 2 show, respectively a front and rear image of the centrifuge. DG Spin Figure 1: General view of the... -

Page 17: Centrifugation Chamber

DG Spin Description of the Centrifuge DG Spin Figure 2 : Rear view of the centrifuge (6) Main switch (7) Fuses housing (8) Mains cord connection (9) Security ring housing (10) Connection to a computer (for exclusive use of the authorised Technical Service) 4.1.1... -

Page 18: Dg Spin Head

DG Spin Description of the Centrifuge (1) Centrifugation chamber DG Spin (2) Lean axle and Crosshead of Head (3) Motor protective cover The Centrifugation chamber also has a protective cover (Ref. (3), Figure 3) that protects the motor. DG Spin 4.1.2... -

Page 19: Centrifuge Cover

DG Spin Description of the Centrifuge 4.1.3 Centrifuge cover DG Spin centrifuge has a safety transparent cover (Ref. (3), Figure 1) with a hinge and an electromagnetic safety closure. 4.1.4 Control buttons DG Spin centrifuge has three buttons (Ref.(4), Figure 1) for control of centrifugation. -

Page 20: Remaining Centrifugation Time Information

DG Spin Description of the Centrifuge Figure 6 : Display (1) Centrifugation speed information (2) Timer information (3) Centrifugation speed units (4) Warnings area 4.1.5.1 Remaining centrifugation time information In normal mode, the Display shows on the right, the time remaining up to end of centrifugation of the batch by means of a digital counter (Ref. -

Page 21: Units

DG Spin Description of the Centrifuge 4.1.5.2 Units DG Spin centrifuge informs the OPERATOR of the centrifugation speed in rpm or in g. To change the configuration that appears on the screen consult section 5.5 “Configuration of the equipment”. 4.1.5.3 Warnings area This is located on the left lower part of the Display (Ref. - Page 22 DG Spin Description of the Centrifuge DG Spin During normal use of the centrifuge, ensure that the ring is protected by the aforementioned lid. WARNING! Before use the Security ring, check that the DG Spin centrifuge is unplugged and the Head is not moving.

-

Page 23: Installation

DG Spin Installation 5 INSTALLATION Action upon delivery This equipment may be installed directly by the OPERATOR or RESPONSIBLE AUTHORITY. Installation requirements The requirements for the place where the equipment is to be installed are as follows: If the equipment has been stored in environmental conditions different from work conditions, it should be kept for at least one hour under environmental work conditions before being plugged in. -

Page 24: U Npacking The Equipment

DG Spin Installation Unpacking the equipment Once the appropriate place is selected for installation, unpack the equipment according to the following instructions: • Open the upper part of the box. • Remove all protections and accessories. • Remove the protection bag and place the equipment in the chosen position. -

Page 25: Configuration Of The Equipment

DG Spin Installation • DG Spin Wait for 30 seconds and verify that the Head has stopped and the Display again shows the pre-established centrifugation time. DG Spin centrifuge is supplied with a conformity certificate stating that the centrifugation speed (990 rpm) has been verified using instruments calibrated by DG Spin accredited entities. - Page 26 DG Spin Installation • Press to modify the value to the required level. • Once the required level has been selected, press to move onto the next parameter. The Display will automatically show the following configuration menu: Selection of centrifugation speed units.

- Page 27 DG Spin Installation NOTE: To save the modification of any parameter (volume, units, date and time) it is necessary to keep pressed down until the indicator emits the long and continuous acoustic signal. Otherwise, the OPERATOR will leave the Configuration mode without recording the...

-

Page 28: Operating Procedure

DG Spin Operating Procedure 6 OPERATING PROCEDURE CAUTION! DG Spin Do not use the centrifuge if it does not work correctly or has been damaged. Execution of a centrifugation batch DG Spin To correctly use the centrifuge the following instructions should be followed: •... - Page 29 DG Spin Operating Procedure CAUTION! The direction of centrifugation is important to standardise the work and make centrifugation conditions of the cards uniform. DG Gel Consequently, place the cards in such a way that the bar code coincides with the barcode symbolised in the Card holder as shown by Figure 8.

-

Page 30: Visualisation Of The Centrifugation Speed

DG Spin Operating Procedure WARNING! Centrifugation heads different to those specified should not be used as they may cause deterioration and malfunction of the instrument. • DG Spin Once the cards have been distributed in the Head, place it inside the centrifuge. -

Page 31: Centrifugation Stop

DG Spin Operating Procedure Figure 9: Centrifugation speed information on the Display (1) Centrifugation speed or force (2) Timer information Centrifugation stop If, for some reason it is necessary to stop the centrifugation before the established DG Spin time is finished, should be keep pressed down for a few seconds. - Page 32 DG Spin Operating Procedure WARNING! If centrifugation is stopped, the cards should be invalidated. Reliable results can only be obtained if the cards are subject to a complete and continuous centrifugation, only once.

-

Page 33: Maintenance

QUALIFIED TECHNICIAN should be noted in the "Maintenance services carried out" register included at the end of these Instructions for Use. Technical assistance may be provided by your supplier or other Technical Services authorised by Diagnostic Grifols, S.A. DANGER! During... -

Page 34: Cleaning Procedures

DG Spin Maintenance WARNING! Before the cleaning and decontamination procedures, all samples and cards should be removed from inside the equipment. WARNING! The cleaning processes of the equipment surfaces should be carried out with the equipment unplugged from mains. 7.1.1... -

Page 35: Decontamination Of The Equipment

DG Spin Maintenance 7.1.2 Decontamination of the equipment DANGER! Any part of the equipment that could come into contact with blood, serum samples or any other biological liquid should be treated as potentially contaminant. In order to prevent any risk of infection, it is important to carry out decontamination of the instrument before performing certain operations. -

Page 36: Decontaminant Liquids

DG Spin Maintenance WARNING! Before using any cleaning or decontamination product different to those recommended by the manufacturer, the RESPONSIBLE AUTHORITY should verify with the manufacturer that the methods proposed will not damage the equipment. NOTE: The procedures described above do not... -

Page 37: Operation Qualification Procedure (Oq)

DG Spin Procedure for Qualification of the Operation (OQ) 8 OPERATION QUALIFICATION PROCEDURE (OQ) DG Spin centrifuge has two non-adjustable independent time basis controlled by the centrifuges program itself. Given that the speed has been calibrated by the manufacturer, if no function alarm is activated (see sections 12.1 and 12.2), it is... -

Page 38: Procedure For Qualification Of Centrifugation Speed

DG Spin Procedure for Qualification of the Operation (OQ) NOTE: It is advisable regular calibration of 1 year or that recommended by the manufacturer of the tachometer if its calibration validity period is lower than 1 year. Procedure for qualification of centrifugation speed... -

Page 39: Procedure For Qualification Of The Out-Of-Balance Control System

DG Spin Procedure for Qualification of the Operation (OQ) • Verify that the tachometer speed marked is within the speed range defined in 3.1 “Technical specifications”. • Furthermore, verify that the speed shown by the Display when pressed, although is not exactly the same than the tachometer speed, is also within the speed range defined in 3.1 “Technical specifications”. - Page 40 DG Spin Procedure for Qualification of the Operation (OQ) • Verify that centrifugation is stopped and that the out-of-balance indicator ( ) is activated in the Warning area of the Display during centrifugation NOTE: The centrifugation stop enables ensuring DG Spin...

-

Page 41: Transport And Storage

DG Spin Transport and Storage 9 TRANSPORT AND STORAGE WARNING! The equipment must be decontaminated before being transported and/or stored. DG Spin If the centrifuge has to be stored for a long period of time, it is recommendable to pack it as for transportation. -

Page 42: Disposal Of The Equipment

DG Spin Disposal of the Equipment 10 DISPOSAL OF THE EQUIPMENT DG Spin To dispose of the centrifuge it should be completely cleaned and decontaminated and all remains of samples and reagents eliminated. Once this is done, it should be sent to an authorised centre for the processing of electronic waste. -

Page 43: Warranty

Damages caused by incorrect handling including that carried out by technical personnel not authorised by Diagnostic Grifols, S.A. Parts of plastic or rubber as well as enamel and paints that have deteriorated due to knocks or usage except in the case of a manufacture defect. -

Page 44: Resolution Of Incidences

DG Spin Resolution of Incidences 12 RESOLUTION OF INCIDENCES DG Spin During normal functioning of the centrifuge certain warnings and incidences may appear that the OPERATOR can resolve without the assistance of the specialised Technical Service. 12.1 Warnings or incidences... - Page 45 DG Spin Resolution of Incidences timer shows by flashing, the value indicated at that moment. power stopped centrifugation batch. The time shows by flashing, the value indicated at that time and will emit some short sounds. Press any button to stop the Acoustic alarm and leave the timer prepared for a new centrifugation batch.

- Page 46 DG Spin Resolution of Incidences Contact the Technical If the centrifuge detects any alteration in its Service function that cannot be resolved by the OPERATOR, the corresponding luminous indicator is activated. In this case, switch off the centrifuge and restart again. If the warning persists contact the Technical Service.

-

Page 47: Error Messages

DG Spin Resolution of Incidences as described in section 4.1.6 ”Security ring”. Restart again and if the error is detected again, contact the Technical Service. 12.2 Error messages Apart from the alerts and errors mentioned, the equipment may detect other error conditions. - Page 48 DG Spin Resolution of Incidences If after a complete centrifugation batch the Cover has not been opened to remove the cards already centrifuged and the button is pressed again to start a new centrifugation batch, the system emits some short sounds and the Open cover alarm flashes.

-

Page 49: Maintenance Services Carried Out

DG Therm Servicios de Mantenimiento Realizados / Maintenance Services Carried out SERVICIOS DE MANTENIMIENTO REALIZADOS MAINTENANCE SERVICES CARRIED OUT Modelo: Nº de Serie: Fecha de Instalación: Model: Serial Number: Installation date: TÉCNICO/AUTORIDAD FECHA ACCIÓN REALIZADA TÉCNICO/OPERADOR RESPONSABLE DATE WORK CARRIED OUT TECHNICIAN/OPERATOR TECHNICIAN/RESPONSIBLE AUTHORITHY... - Page 50 DG Therm Servicios de Mantenimiento Realizados / Maintenance Services Carried out Modelo: Nº de Serie: Fecha de Instalación: Model: Serial Number: Installation date: TÉCNICO/AUTORIDAD FECHA ACCIÓN REALIZADA TÉCNICO/OPERADOR RESPONSABLE DATE WORK CARRIED OUT TECHNICIAN/OPERATOR TECHNICIAN/RESPONSIBLE AUTHORITHY...

Need help?

Do you have a question about the DG Spin and is the answer not in the manual?

Questions and answers