Table of Contents

Summary of Contents for enware AQUABLEND 2500

- Page 1 AQUABLEND 2500 25MM THERMOSTATIC MIXING VALVE For use in Australia Part No. IS127 I00045_Aug _16 Call 1300 369 273 www.enware.com Enware Australia Pty Limited 9 Endeavour Rd Caringbah NSW 2229 Australia Ph: +61 2 8556 4000 Fax: +61 2 8556 4055...

-

Page 3: Table Of Contents

Preparation of this publication which has been issued for guidance only. No liability can be accepted for any consequences which may arise as a result of its application. Enware = trade mark of Enware Australia Pty Limited - A.C.N. 003 988 314 Aquablend TMV’s are exclusively manufactured for Enware Australia Pty Limited by... -

Page 4: Introduction

Aquablend 2500 Thermostatic Mixing Valve Introduction The ENWARE AQUABLEND 2500 Thermostatic Mixing Valve is a high performance Thermostatic Mixing Valve suitable for a wide range of applications. The valve is designed to comply with AS4032 - Thermostatic Mixing Valves. The mixing valve has the following features: •... -

Page 5: Warranty

ENWARE to be so defective will be replaced as set out below. If the valve is sold by a party other than ENWARE then it is sold by that seller as principal and the seller has no authority from ENWARE to give any additional warranty on behalf of ENWARE. - Page 6 Warranty Exclusions: Replacement work will be carried out as set out in the ENWARE Warranty above, but the following exclusions may cause the warranty to become void, and may incur a service charge including cost of parts where: 6.

-

Page 7: Safety

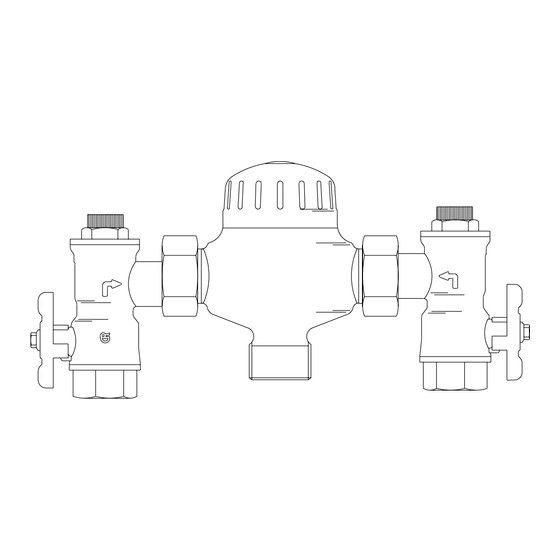

The ENWARE AQUABLEND 2500 Thermostatic Mixing Valve is also available without inlet fittings as an option. The schematics and dimensions of these valves with their corresponding order codes are shown in below. -

Page 8: Physical Description

Physical Description Figure 1.2 located below shows a general arrangement drawing of the ENWARE AQUABLEND 2500 Thermostatic Mixing Valve showing the method of operation. Hot and cold water is supplied to each side of the valve respectively. The hot water enters through a port below the piston, the cold water enters above the piston. -

Page 9: Recommended Pressures & Temperatures

Aquablend 2500 Thermostatic Mixing Valve Recommended Pressures & Temperatures MIXED OUTLET TEMPERATURE Temperature Adjustment Range 35°-50°Celsius INLET TEMPERATURES Cold Supply Minimum 5° Celsius Maximum 30° Celsius Hot Supply Minimum 55° Celsius Maximum 90° Celsius Hot to Mix Temperatures Differential for Stable Minimum 10°... -

Page 10: Flow Sizing Graph

Aquablend 2500 Thermostatic Mixing Valve Flow Sizing Graph The ENWARE AQUABLEND 2500 Thermostatic Mixing Valve is suitable for many applications. The Headloss Characteristic for Mixed Outlet Flowrate versus Balanced Inlet Pressure is shown Graph 2.1 below. It is important that the valve is not oversized for its intended application. -

Page 11: Technical Description

Aquablend 2500 Thermostatic Mixing Valve Technical Description LOCK NUT & TOP COVER CARTRIDGE COMPLETE (PART No. ATMS304) (PART No. ATMS3002) ALLEN KEY (SUPPLIED) LOWER TOP CAP (PART No. ATMS309) & 2 CARTRIDGE THERMOSTATIC ELEMENT O-RINGS* (PART No. ATMS306) MIXED WATER... -

Page 12: Installation

The ENWARE AQUABLEND 2500 must be installed by a licensed plumber, or where applicable, a licensed plumber who has undertaken T.A.F.E. training in Thermostatic Mixing Valves. - Page 13 The inlet fittings supplied with each TMV will ensure this requirement is met. If the ENWARE AQUABLEND 2500 Thermostatic Mixing Valve is to be installed without the supplied inlet control valves then it will be necessary to install a separate isolating valve, non- return valve and strainer to both inlets to the valve.

-

Page 14: Commissioning Of The Valve

Aquablend 2500 Thermostatic Mixing Valve Figure 3.1 Schematic Installation Diagram Commissioning Of The Valve Upon completion of the installation, the valve should be tested and commissioned as per the procedure outlined below or as specified by the local authority. The entire procedure should be read through thoroughly prior to the commissioning of the valve. - Page 15 Aquablend 2500 Thermostatic Mixing Valve • Ensure all outlets that will be serviced by the valve have adequate warning signs posted to ensure that no outlet is used during commissioning. • Open the cold supply line to the valve, then open the hot supply line, ensuring there are no leaks.

- Page 16 Aquablend 2500 Thermostatic Mixing Valve REMOVE THE LOCKNUT & TOP COVER WITH A FLAT BED SCREWDRIVER ALLEN KEY SUPPLIED COLD Figure 3.2 Increasing and Decreasing Mixed Water Temperature Shut Down Test • Now that the mixing valve has been set & locked it’s necessary to perform a shut down check.

-

Page 17: Maintenance And Servicing

Annual Maintenance Procedure Every 12 months the ENWARE AQUABLEND 2500 should be serviced and cleaned. The external surface of the valve should be given a light wipedown. The valve & surrounding area should be inspected for leaks or water damage and action taken if required. - Page 18 Aquablend 2500 Thermostatic Mixing Valve white plastic cover will expose the mixed water temperature adjuster, a set of octagonal wrenching flats & 2 wrenching flats. Using the 2 wrenching flats only, undo the cartridge & remove from the valve body, as per Figure 4.2. Thoroughly clean the...

- Page 19 Aquablend 2500 Thermostatic Mixing Valve Remove the mixed water temperature adjuster mechanism by rotating clockwise. Refer to the exploded view on page 9 Remove the o-ring from the Piston Assembly, the o-ring from the Mixed Water Temperature Adjuster, and the 3 Cartridge o-rings from the Seat Shell and Lower Top Cap.

-

Page 20: Fault Finding

Aquablend 2500 Thermostatic Mixing Valve Fault Finding FAULT / CAUSE RECTIFICATION SYMPTOM The desired • Hot and cold • Refit the valve with Hot/ mixed water supplies are fitted Cold supplies fitted to the temperature to the wrong correct connections. - Page 21 Aquablend 2500 Thermostatic Mixing Valve FAULT / CAUSE RECTIFICATION SYMPTOM Either full hot • Valve is incorrectly • Adjust mix temperature or cold flowing set. between 35 - 50°C as from outlet • Hot/Cold water required. fixture has migrated to •...

-

Page 22: Spare Parts

Aquablend 2500 Thermostatic Mixing Valve FAULT / CAUSE RECTIFICATION SYMPTOM Hot water flows Non-return valves. Replace non-return into the cold valves (ATMS312). water system or vice versa. Valve is noisy. Water velocity above Reduce water velocity. velocity requirements of AS3500.1, 3.4... - Page 23 Aquablend 2500 Thermostatic Mixing Valve Enware Thermostatic Mixing Valve Commissioning Report For Thermostatic Mixing Valves use a separate sheet for each valve Establishment Address Phone No Contact Work Order Date Make & Model of Hot Water Unit Pressure Pressure Hot Water Cold Water ˚C...

- Page 24 Aquablend 2500 Thermostatic Mixing Valve Test results (complete table on following page) Valve considered satisfactory for use YES/NO If NO, state reason and action taken It is hereby certified that all the commissioning work has been carried out by the undersigned in accordance with local plumbing...

- Page 25 Aquablend 2500 Thermostatic Mixing Valve Test results Valve location/building Room or area designation Work Order No Warm Name/type/ Flow rate of design Temp of warm water water size & location warm water (L/sec) °C outlet of outlet fixture 1 outlet ** All req.

- Page 26 Aquablend 2500 Thermostatic Mixing Valve Enware Thermostatic Mixing Valve Servicing Report For Thermostatic Mixing Valves use a separate sheet for each valve Establishment Address Phone No Contact Date Work Order No. Make & Model of Hot Water Unit Model No:...

- Page 27 Aquablend 2500 Thermostatic Mixing Valve It is hereby certified that all the commissioning work has been carried out by the undersigned in accordance with local plumbing requirements for Thermostatic Mixing Valves Lic/Cert No Signature Licensed Plumber Business name of Plumbing...

- Page 28 Call 1300 369 273 www.enware.com Enware Australia Pty Limited 9 Endeavour Rd Caringbah NSW 2229 Australia Ph: +61 2 8556 4000 Fax: +61 2 8556 4055...

Need help?

Do you have a question about the AQUABLEND 2500 and is the answer not in the manual?

Questions and answers