Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Esko Kongsberg XN IPC 2.0

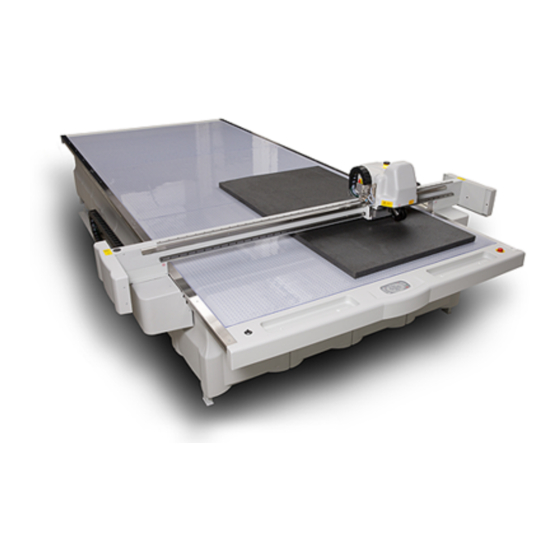

- Page 1 Kongsberg XN / iPC 2.0 User Manual 01 - 2017 | XN...

-

Page 2: Table Of Contents

Kongsberg XN / iPC 2.0 Contents 1. Preface................................. 7 2. Change Record............................8 3. Welcome..............................9 4. Using this manual........................... 10 4.1 Main Sections........................... 10 4.2 Name Styles and Symbols.......................11 4.3 Pictures and Illustrations.........................11 4.4 Local Languages..........................12 5. Safety Regulations..........................13 5.1 Introduction............................ - Page 3 Contents 6.4 Variable Blow Back...........................27 6.5 Pressurized Air system........................28 6.6 Application programs available.......................29 7. Basic Operations............................30 7.1 Power On Sequence........................30 7.2 Reset Safety System.........................31 7.3 Power Off Sequence........................31 7.4 Continue after Safety Break......................31 8. Prepare for a Job............................. 33 8.1 Introduction............................

- Page 4 Kongsberg XN / iPC 2.0 10.12.1 Vacuum Section Configuration..................53 10.12.2 Using two vacuum pumps....................55 10.13 Router Setup..........................55 10.14 Conveyor Belt Control......................... 55 10.14.1 Split Sheet Feed......................... 56 10.14.2 Sheet Feed Correction.......................56 10.15 Board Size............................. 56 11. Tool Configuration and Adjustment....................57 11.1 Introduction............................

- Page 5 Contents 12.8.12 Tool Adjustment.......................101 12.8.13 Table Top and Height Adjustment..................102 12.8.14 Miscellaneous........................103 12.8.15 LubriCool.......................... 104 12.9 Chiller 1 for MultiCUT-HP......................106 12.9.1 Introduction........................106 12.9.2 Chiller, Error Conditions....................107 12.9.3 Chiller Heater, Operation....................108 12.10 Chiller2016 for MultiCUT-HP..................... 109 12.10.1 Introduction........................109 12.10.2 Startup..........................110 12.10.3 Error Conditions.......................110 12.11 Measuring Foot..........................

- Page 6 17. Collector Basket..........................155 18. Vacuum Cleaner..........................156 18.1 Vacuum Cleaner, Zefiro....................... 156 18.1.1 How to use......................... 156 18.2 Vacuum Cleaner, High-capacity, TB ESKO.................. 158 18.2.1 How to use......................... 158 18.3 Compact Vacuum Cleaner......................160 18.3.1 How to use......................... 160 19. Install Software........................... 162 20.

-

Page 7: Preface

Kongsberg AS does not warrant, guarantee or make any representations regarding the use, or the results of the use of the system or the information contained herein. Esko-Graphics Kongsberg AS shall not be liable for any direct, indirect, consequential or incidental damages arising out of the use or inability to use the system or the information contained herein. -

Page 8: Change Record

Kongsberg XN / iPC 2.0 2. Change Record Description Date dd-mm-yy 20-05-2016 jhbe Document is updated according to iPC ver 2.0 06-09-2016 jhbe The importance of MultiCUT chuck cleaning is emphasized 18-10-2016 jhbe CorruSpeed information updated 24-10-2016 jhbe MultiCUT-HP, new chiller and information about old chiller added 15-11-2016 jhbe... -

Page 9: Welcome

Kongsberg XN / iPC 2.0 3. Welcome Welcome to the User Manual for Kongsberg XN running iPC 2.0. This manual will provide a complete and detailed description of Cutting Table functions. There is a separate user manual for i-cut Production Console (iPC). Thus, actual GUI functions will be referenced in this manual, but the complete and comprehensive description is available in the User Manual for i-cut Production Console. -

Page 10: Using This Manual

Kongsberg XN / iPC 2.0 4. Using this manual 4.1 Main Sections The manual is divided into the following Main Sections: Safety Regulations • All safety related issues are discussed. System Description • This chapter provides basic knowledge about the machine. Basic Operations •... -

Page 11: Name Styles And Symbols

Kongsberg XN / iPC 2.0 Appendices • Roll Feeder - basic information. • Vacuum Cleaner - basic information. • - Frequently Asked Questions 4.2 Name Styles and Symbols Name or style Description Pop-up dialog This is the dialog that appears when you click the Right mouse button. -

Page 12: Local Languages

Kongsberg XN / iPC 2.0 4.4 Local Languages This manual is available in a wide range of local languages. Screen pictures and illustrations remains in English language. -

Page 13: Safety Regulations

Kongsberg XN / iPC 2.0 5. Safety Regulations 5.1 Introduction The table is designed to conform to Safety Regulation standards. Nevertheless, operating the table can involve hazards if: • The operator does not follow the Operating Instructions. • The table is used for Non-intended purposes. In addition to the Safety Regulation described below, you will find safety warnings in the respective topics. -

Page 14: Requirements To Be Met By Operators

• Utilizing accessories other than those specified by Esko. Non-intended use may cause: • Health hazards and injuries. • Damage to the system. • Incorrect functionality. • Damage to work materials. Note: Esko is not liable for any damage resulting from such Non-intended use. 5.5 Danger Zones... -

Page 15: Danger Zones

Kongsberg XN / iPC 2.0 5.5.1 Danger Zones The area around the moving parts is considered to be a Danger Zone. The Danger Zone is identified by the means of a yellow / black floor marking. 5.5.2 Moving Parts, Laser Radiation and High Voltage... -

Page 16: Loose Clothing

Kongsberg XN / iPC 2.0 5.5.3 Loose Clothing While working with this machine, do not: • Use ties • Use loose necklaces • Use scarfs 5.5.4 Noise Level • Hearing Protection should be used by any personnel exposed to the noise from the machine. -

Page 17: I-Camera Strobing Light

Kongsberg XN / iPC 2.0 • Eye Protection should be used by any personnel working with MultiCUT. 5.5.6 i-Camera strobing light If your system includes i-Camera, please read this warning carefully: WARNING i-Camera is equipped with LED strobing light. The LED default frequency (10 Hz) is in a range that can cause photosensitive epileptic reactions amongst susceptible people. - Page 18 Kongsberg XN / iPC 2.0 Do not Touch Potential areas with a risk of being squeezed are marked with the Do Not Touch sign. These areas are: • Between Y carriage and rack • Between the table top and the moving traverse. •...

-

Page 19: Safety Devices

Kongsberg XN / iPC 2.0 5.7 Safety devices 5.7.1 Overview Device no Description Main Power Switch Emergency Stop Button Warning Lamp / Status Lamp Photo cell supervision, Dynaguard Traverse Stop Switches, Dynaguard 5.7.2 Emergency Stop Button Switch positions: - Emergency Stop is switched OFF. - Emergency Stop is switched ON;... -

Page 20: Warning Lamp On Top Of Y Carriage

Kongsberg XN / iPC 2.0 Note: Activating the Emergency Stop Button does not provide a guarantee against injury! Due to the high kinetic energy of moving parts, do not underestimate Stop Distance of traverse, Y carriage and Tool Head. 5.7.3 Warning Lamp on top of Y Carriage Light is Description Servo Power is off... -

Page 21: Protective Equipment

3. Observe that Servo Power is switched on, 4. Press Start to continue. 5.8 Protective equipment For the operator(s), Esko recommends the following Protective Equipment: Close-fitting clothes to avoid being caught by the beam or the tool head which can cause injuries. - Page 22 Kongsberg XN / iPC 2.0 Beneath traverse end The low part of the traverse ends is un- protected. Actions: • Children are not supposed to be in the machine area. • Do not work or stay beneath the traverse while the machine is working. Y-carriage The top of the Y-carriage is un-protected in all four directions.

- Page 23 Kongsberg XN / iPC 2.0 The DynaGuard Safety System photo cell beam c will stop the movement when hit. When the Feeder Paws are mounted, the distance between beam c and the mechanics is reduced. Actions: • Stay out of this area while the machine is working.

-

Page 24: System Description

Kongsberg XN / iPC 2.0 6. System Description 6.1 Naming conventions XN with front cover. XN with Revolving Work Station and Conveyor belt 1 Table Top 7 Front cover including Operator Panel 2 Traverse 8 Main Power on/off switch 3 Y carriage 9 Traverse Safety Stop switches (DynaGuard) 4 Tools 10 Operator Station/Operator Panel... -

Page 25: Main Power Switch

Kongsberg XN / iPC 2.0 Axes X - X-axis X1 - X1 end of traverse Y - Y-axis X2 - X2 end of traverse Z - Z axis The arrows indicates positive moving direction. 6.2 Main Power Switch Switch positions: - the Main Power to the machine is switched OFF. -

Page 26: Operators Panel

Kongsberg XN / iPC 2.0 6.3 Operators Panel Power On Mains Power on/off indication. Servo Power On Servo Power on/off control. Start Press this button to Start Operation. Pause / Safety System Reset Press this button to Pause Operation and Reset Safety System. Vacuum On/Off Press this button to switch Vacuum On/Off. -

Page 27: Variable Blow Back

Kongsberg XN / iPC 2.0 Move to Table Zero Press this button, then the Start button, to move the tool head to Selected Reference Point. The Table Zero Mode is automatically selected at Power on. The system remains in the Table Zero Mode until Table Zero movement is completed. -

Page 28: Pressurized Air System

Kongsberg XN / iPC 2.0 For conveyor belt:: The Blow Back function creates an air pillow below the conveyor belt in order to reduce belt friction. For material handling: The Blow Back function creates an air pillow below the material in order to ease handling. Variable Blow Back - adjust the air flow to a suitable level for the actual material. -

Page 29: Application Programs Available

Kongsberg XN / iPC 2.0 The Air Pressure should be adjusted to minimum 6 bar (6 kg/cm2, 6*105 Pa). Recommended pressure level is 7 bar (7 kg/cm2, 7*105 Pa). Where to find Air Pressure Regulator 6.6 Application programs available After installation of iPC, the following application programs are available Control program for the Cutting Table. -

Page 30: Basic Operations

Kongsberg XN / iPC 2.0 7. Basic Operations Keep away from Moving Parts during operation. Do not lean on Racks, Guide Ways or Traverse during operation, as this may cause personal injury. Before starting any operation, make sure that: • The Table is free from obstructions •... -

Page 31: Reset Safety System

Kongsberg XN / iPC 2.0 Table Zero Sequence Press Start pushbutton to complete the Table Zero Sequence. The machine will move to the Selected Reference Point. The table is now ready for operation. 7.2 Reset Safety System Press Pause to Reset Safety System. 7.3 Power Off Sequence Follow these steps to power down the system: Servo Power... - Page 32 Kongsberg XN / iPC 2.0 Reset the Safety System by pressing the Pause pushbutton. The Warning Lamp on top of the Y carriage should be on without flashing. Observe that Servo Power is switched on, Press Start to continue.

-

Page 33: Prepare For A Job

Kongsberg XN / iPC 2.0 8. Prepare for a Job 8.1 Introduction Keep away from Moving Parts during operation. Do not lean on Racks, Guide Ways or Traverse during operation, as this may cause personal injury. Before starting any operation, make sure that: •... -

Page 34: Production Setup

Kongsberg XN / iPC 2.0 8.4 Production Setup Opened Job->Production Setup. Verify correct Production Setup: • Number of Copies • Accuracy/Speed Prioritization • Select Reference Point and Job Position • Step and Repeat • Registration • Material Handling • Tool Head Parking 8.5 Speed Setting Opened Job->Production Setup->Quality. -

Page 35: Job Execution

Kongsberg XN / iPC 2.0 Proper selection is important to achieve the best possible material hold down. 8.8 Job Execution Before execution, check this: Verify that Opened Job is ready for production. Verify that the Table View display of the Job is reasonable. Press Pause to reset Safety System. -

Page 36: Make A Pen Plot

Kongsberg XN / iPC 2.0 Ensure the vacuum cleaner container is prepared for the actual job. Empty the container regularly. Note: Milling Jobs should be executed in High Quality mode. 8.10 Make a Pen Plot Follow the procedure for how to prepare for and execute a job. Ensure the Ballpoint Pen is clean and ready to use. - Page 37 Kongsberg XN / iPC 2.0 Menu Bar->Machine->Adjust Tool Height Machine Panel Toolbar->Tool Height • A wizard dialog appears. • Follow the instructions in the wizard to complete calibration. Measure all tools, started from Operators panel, procedure • Press the Pause button for more than 2 sec. •...

- Page 38 Kongsberg XN / iPC 2.0 • Press the Measure Tool button. • A wizard dialog appears. • Follow the instructions in the wizard to complete calibration. • Height Settings Current setting: The automatically measured height value. •...

- Page 39 Kongsberg XN / iPC 2.0 All Measuring Pad operations are cancelled by: • Press Close in the active dialog. • Press Pause on Operators Panel...

-

Page 40: How To Procedures, Advanced

Kongsberg XN / iPC 2.0 9. How To Procedures, Advanced 9.1 Cutting Thick Materials When preparing materials with thickness between 45 – 50 mm (1¾ - 2 in.), the following rules apply: • No Camera operations are available. • Disable Measure Material Thickness. •... -

Page 41: Multi Pass Milling

Kongsberg XN / iPC 2.0 9.3 Multi Pass Milling Opened Job->Layers->Edit Layer Menu Bar->Layer->Edit Layer 1. pass 2. pass 3. pass - mill through and clean the path Multi Pass Milling is beneficial if you want to mill through a material where the thickness is bigger than the router bit diameter. -

Page 42: Work With Different Reference Point Settings

Kongsberg XN / iPC 2.0 A typical use of Reverse Operation is when you want to add a crease line on the front side of a material that you normally prepare from the rear side. Reverse Operation is available by modifications of the actual Layer. This function requires that the table is equipped with left and right rulers. - Page 43 Kongsberg XN / iPC 2.0 Introduction In User Manual for i-cut Production Console, general information about MultiZone Production is available. In this chapter, more machine-specific issues are described. MZP Panel Each work zone is equipped with a panel that makes it possible to run the complete MultiZone Production sequence from the table.

-

Page 44: Multizone, Workflow

Kongsberg XN / iPC 2.0 MultiZones The illustration shows the most actual zones available for MultiZone Production Limitations The last section of a multizone table is somewhat smaller than the first one(s). As a consequence, the work area available for MultiZone Production is determined by the size of the last section. - Page 45 Kongsberg XN / iPC 2.0 - Recommended material flow direction. - Attention Area. During operation in one zone, parts of the traverse will move into the other zone (photo cell beams, traverse end cover). To ensure a continous workflow, the operator should be very careful inside the Attention Area, not to trigger the safety system by his body or by material in and out.

-

Page 46: System Setup

Kongsberg XN / iPC 2.0 10. System Setup 10.1 Introduction This chapter will explain functions and parameters that are important for the XN system to run properly. It is a supplement to the information available from the User Manual for i-cut Production Console. -

Page 47: Adjust X1 To X2 Angle

Kongsberg XN / iPC 2.0 Conveyor Belt Control Board Size 10.2 Adjust X1 to X2 Angle Machine Connection->Machine Configuration->Installation_>Adjust X1 to X2 Angle Use this wizard to obtain correct angle between X axis and Y axis. Typical use is after maintenance or repair. Procedure: 1. -

Page 48: Set Ruler Position

Kongsberg XN / iPC 2.0 10.4 Set Ruler Position Machine Connection->Machine Configuration->Installation_>Set Ruler Position Follow instructions from the wizard. If your table is equipped with Rulers, please complete the wizard for left and right ruler. For the table to operate properly an exact registration of the Ruler Positions is necessary. This is a one time job, but it can be necessary to repeat the procedure if mechanical maintenance has been carried out on the table or traverse. -

Page 49: Map Table Top Surface

Kongsberg XN / iPC 2.0 10.6 Map Table Top Surface Machine Connection->Machine Configuration->Installation_>Map Table Top Surface To assure correct Cutting Depth, the surface of the Table Top is measured in order to create a map. It is recommended to execute this function if the Cutting Mat is worn out and after the Cutting Mat has been replaced. - Page 50 Kongsberg XN / iPC 2.0 The Main Reference Point position The Main Reference Point is a fixed position on the Cutting Table marked as a cross of drilled holes. The User Defined Reference Points are all specified relative to the Main Reference Point. Thus, moving the Main Reference Point will move these reference points as well.

-

Page 51: Table Speed

Kongsberg XN / iPC 2.0 Position the Laser Pointer in the position where you want your Panel Reference Point. Press the Set Reference Point button on Operators Panel. The Panel Reference Point is set to current Laser Pointer Position Rulers and Reference Points The Ruler System ensures an easy and correct positioning of the material on the table. -

Page 52: Jog Settings

Kongsberg XN / iPC 2.0 Opened Job->Production Setup->Quality Here you specify if this is a High Quality Job or High Speed Job. 10.9 Table Acceleration Menu Bar->Advanced->Configure Tools...->Acceleration This is the default value for each tool when Layers are created. Note: Acceleration can be reduced to a % value of the maximum acceleration available. -

Page 53: Set Table Top Reference

Kongsberg XN / iPC 2.0 10.11 Set Table Top Reference Menu Bar->Machine->Set Table Top Reference Follow instructions from the wizard. Machine Connection->Machine Configuration->Installation_>Table Top Reference Follow instructions from the wizard. Machine Panel Toolbar->Table Top Reference Use this function to complete a Tool Height Reference calibration. The Tool Height is measured in current position and the reference to the table top surface is updated. - Page 54 Kongsberg XN / iPC 2.0 This is a dialog where the Vacuum Section Configuration for the actual machine is specified. This setup is a one-time job as long as the Vacuum Section Solution on the machine remains un-changed. The setup should correspond to the actual hardware. The selected setup will determine which Vacuum Section Configuration that will be available in the User Interface.

-

Page 55: Using Two Vacuum Pumps

Kongsberg XN / iPC 2.0 Machine Zone Configuration Vacuum Configuration XN46 XN48 10.12.2 Using two vacuum pumps Machine Connection->Machine Configuration->HW Configuration->2 Vacuum Pumps Enable this parameter if your machine is equipped with two vacuum pumps (option). Note: When running two vacuum pumps, the start of the second pump is slightly delayed. 10.13 Router Setup Machine Connection->Machine Configuration->HW Configuration->Router Setup From the Router Setup dialog, maintain the following parameters:... -

Page 56: Split Sheet Feed

Kongsberg XN / iPC 2.0 Specify if the machine is equipped with Conveyor Belt. 10.14.1 Split Sheet Feed Sheet in Load Position Sheet Load, step 1 Sheet Load, step 2 In some occasions, the sheet unloaded from the cutting table can trigger the photo cell safety system. -

Page 57: Tool Configuration And Adjustment

Kongsberg XN / iPC 2.0 11. Tool Configuration and Adjustment 11.1 Introduction Machine Connection->Tool Configuration The Tool Configuration dialog is used for all tool settings and adjustments. 11.2 Adjust Active Tool From the Adjust Selected Tool – dialog, all Tool Adjustment Wizards are executed. The following procedures are general descriptions of how to adjust the tools. -

Page 58: Tool Height Calibration

Kongsberg XN / iPC 2.0 We recommend using a sheet of Folding Carton material, 5-6 mm / 0.2 inch, when executing the adjustments. Note: All tools need to be adjusted in the position they will be used. Before any adjustment, complete a Table Top Reference function: Menu Bar->Machine->Set Table Top Reference Machine Panel Toolbar->Table Top Reference 11.3 Tool Height Calibration... - Page 59 Kongsberg XN / iPC 2.0 Lag Setting Lag – lag value. This is the distance from the rotation center to the back of the Knife Blade. Enter the value as measured or as found using the Lag test, see below. Width –...

-

Page 60: Rotation Adjustment (For Rotating Tools)

Kongsberg XN / iPC 2.0 Circle Lag Circle quality is determined by a parameter called Circle Lag. The parameter value will vary depending upon the actual material. Therefore, the adjustment is located in the Job Setup dialog. 11.5 Rotation Adjustment (for Rotating tools) Optimal Angular Offset may vary with different material strength and thickness. -

Page 61: Center Offset Adjustment

Kongsberg XN / iPC 2.0 10.Note how the knife enters into the material. 11.Press Tool Override Down once more to lift the Tool again. 12.If knife enters exact into the cut, the angle is correct; select Finish to exit. 13.If seen in the cutting direction, the knife enters to the left of the cut, the Angular Offset Value should be decreased. -

Page 62: Manual Adjustment Of Center Offset And Angle

Kongsberg XN / iPC 2.0 10.Press Tool Override Down once more to lower the Tool, and Jog the same distance back. 11.Press Tool Override Down once more to lift the Tool. 12.The two cuts should follow exactly the same path. 13.If exact, the Center Offset is correct, select Finish to exit. -

Page 63: Maintain Tool List (More

Kongsberg XN / iPC 2.0 The Laser Pointer is the reference: 1. Place an appropriate test material on the table, and switch Vacuum On. 2. Select the Tool to be adjusted. 3. Press Adjust Active Tool to enter the Wizard Selection Dialog. 4. - Page 64 Kongsberg XN / iPC 2.0 • Add new Tools • Add tools that fails during Automatic Tool Detection The Tool is added to the Tool List.

-

Page 65: Tooling System

Kongsberg XN / iPC 2.0 12. Tooling System Knife Blades are extremely sharp. Take care when handling Knife Tools. Laser Radiation. Do not stare into beam! The tool head is equipped with a class II laser pointer. Emitted laser power < 1 mW. 12.1 Tool handling and care All tools are precision instruments and should be treated as such to ensure proper operation. -

Page 66: Tool Heads Available, Overview

Kongsberg XN / iPC 2.0 Motor cable and connector When disconnecting the motor cable, use the plug. 12.3 Tool Heads available, overview FlexiHead FlexiHead is a Multi-purpose Tool Head prepared for the following tools: Bevel Knife KissCut Knife Psaligraphy Knife Crease Tool Knife Tool Reciprocating Knife... -

Page 67: Tool Head Mount / Dismount

Kongsberg XN / iPC 2.0 MultiCut-HP MultiCUT-HP is a special purpose tool head, which can be equipped as follows: • Two general tool positions prepared for the standard FlexiHead tools. • Milling tool equipped with a high speed milling spindle. 12.4 Tool Head mount / dismount >>... - Page 68 Kongsberg XN / iPC 2.0 Tool Head Description 1. Tool positions 1, 2, 3 with locking knobs 2. Outlet for Reciprocating Knife motor 3. Laser pointer 4. Measuring foot / material hold down foot. Has 3 functions: a. Measure the thickness of the material on the table b.

-

Page 69: Powerhead

Kongsberg XN / iPC 2.0 Tool Rotation Adjust tool angle tangential to moving direction Center Offset Adjust tool sideways until centered Tool Offset Adjust offset to Laser Pointer. 12.6 PowerHead Tool Head Description 1. Tool position 1 (FlexiHead tool insert) 2. -

Page 70: Ø150 Mm Crease Wheel

Kongsberg XN / iPC 2.0 Tool Rotation Adjust tool angle tangential to moving direction Center Offset Adjust tool sideways until centered Tool Offset Adjust offset to Laser Pointer. Tool Configuration. For more information about how to run the adjustment wizards, see 12.6.1 ø150 mm Crease Wheel This Crease Wheel has the equivalent of 50kg [110lb.] of down-pressure. -

Page 71: Perforation Wheel Ø60 Mm

Kongsberg XN / iPC 2.0 The Crease Adapter allows 26 mm (1 in.) crease wheels to be used in the Heavy Duty crease tool position. The tool is adjusted and operates as an ordinary crease tool. 12.6.3 Perforation Wheel ø60 mm Use Perforation Wheel to prepare perforation lines at high speed. - Page 72 Kongsberg XN / iPC 2.0 Ensure the path is clean. Fix cover properly. Push / pull the perforation wheel in / out from the adapter. Tool Adjustment For this tool, complete the following adjustments: Adjustment Description Tool Height Measured automatically, possible to add an Offset Value. Lag Setting The Lag value depends upon the Blade Adapter.

-

Page 73: Hd Knife Tool

Kongsberg XN / iPC 2.0 For more information about how to run the Adjustment Wizards, see the Tool Configuration chapter 12.6.4 HD Knife Tool The HD Knife Tool is inserted in the HD crease tool position. The tool is adjusted and operates as an ordinary knife tool. - Page 74 Kongsberg XN / iPC 2.0 V-notch Knife mounted on a Heavy-Duty Unit. How to insert / remove V-notch Knife Turn the V-notch Knife (A) correctly to fit the Both latch pins are used for the V-notch Knife. alignment pin (B). How to replace a Knife Blade This picture shows how the Knife Blade is 1.

- Page 75 Kongsberg XN / iPC 2.0 3. Insert a new Knife Blade and make sure that it is aligned with the alignment pins in the tool head. 4. Mount the new tool. 5. Select Option->Tool Configuration ->Adjust Active Tool->Tool Height Calibration wizard, to assure correct height of the new knife. ...

- Page 76 Kongsberg XN / iPC 2.0 How to set the depth of the V-notch Knife 1. The default depth of the V-notch Knife is cut through the entire material. 2. Define the depth of the V-notch cut in the dialog. 3. Normally the cut should extend down to just above the bottom liner closest. How to set the width of the V-notch cut From the dialog, modify the default width.

- Page 77 Kongsberg XN / iPC 2.0 Double Cut This is the default mode if neither Single Cut nor Triple Cut are enabled. Triple Cut Function Set from Opened Job->Edit Layer To ensure proper folding of rigid materials, use this function to remove material from the middle of the cut.

-

Page 78: Foamhead

Kongsberg XN / iPC 2.0 If you prepare a material for folding, the following rules applies: • Adjust the cutting depth to just above the bottom liner. • Adjust the cutting width (W) by the adjustment parameter dW. Nominally, the width of the cut has to be increased by dW = - 2 x bottom liner thickness. - Page 79 Kongsberg XN / iPC 2.0 Tool Adjustments, FoamHead Tool Height Correct tool height relative to table top Lag Setting Default lag value for the long foam knife is 4.5mm/0,18" Tool Rotation Adjust tool angle tangential to moving direction Center Offset Adjust tool sideways until centered Tool Offset Adjust offset to Laser Pointer.

-

Page 80: Multicut-Hp

Kongsberg XN / iPC 2.0 Loosen the fixing screw, replace the Knife Blade and fix it again. When not in use, protect the Knife Blade using the handle. Disable Material Thickness Measurement Opened Job->Production Setup->Material Handling For the Foam Knife Tool, the Disable Material Thickness Measurement function is available. Use this function if •... -

Page 81: Introduction

Kongsberg XN / iPC 2.0 12.8.1 Introduction MultiCut-HP MultiCUT-HP is a special purpose tool head, which can be equipped as follows: • Two general tool positions prepared for the standard FlexiHead tools. • Milling tool equipped with a high speed milling spindle. Spindle motor Power rating (max) 3 kW... -

Page 82: Tool Head Description

Kongsberg XN / iPC 2.0 MultiCUT-HP chucks Different chucks are available from http:// www.esko.com/en/store/kongsberg-bits-blades/ Replacing a chuck Replacing a chuck is described in detail in Chuck Change and Cleaning on page 96. This chapter is included just to remind you how important it is to use the Chuck Changing... - Page 83 Kongsberg XN / iPC 2.0 Tool Head Description MultiCUT-HP 1. Tool position 1 (FlexiHead tool insert) 2. Tool position 2 (FlexiHead tool insert) 3. Laser pointer 4. Tool position 3 5. Measuring foot / material hold down foot 6. Electrical connection, router spindle motor 7.

- Page 84 Kongsberg XN / iPC 2.0 Note: To protect the chuck from damage and the spindle from contamination, do not close the chuck over time without a dummy bit inserted. Never start the spindle without a bit / dummy bit in the Chuck. 5.

- Page 85 Kongsberg XN / iPC 2.0 The suction tube is fixed to the suction house. When MultiCUT-HP is not in use, the suction tube and the water tubes are fixed to the traverse as shown here. Chiller / MultiCUT-HP start up time Depending upon the environmental temperature, the Chiller needs some start-up time after Power On before it is ready to operate.

-

Page 86: Safety Issues

Kongsberg XN / iPC 2.0 Procedure: 1. Loosen lock screw (a). 2. Adjust suction house to desired height. Spindle RPM limitations Running 8 mm bits at a high RPM rate can generate vibrations and excessive wear. Using Milling Bits with extended length at high RPM can also be dangerous. Therefore, using long Milling Bits is subject to an automatic RPM reduction. - Page 87 Kongsberg XN / iPC 2.0 • Follow the Vacuum Cleaner filling level carefully. • Empty the container before the level reach the inlet position (indicated in red). Suction House Always, when executing a job, let the Suction House float on top of the material. In addition to chip removal, the house reduces the risk of being hit by small work pieces or by a broken Router Bit.

-

Page 88: Precautions

Kongsberg XN / iPC 2.0 Be aware that it is normal that the MultiCUT/MultiCUT-HP appears to be hot during operation. Clean surface Keep the table and material surface clean, free from obstacles. 12.8.4 Precautions Spindle motor power consumption supervision Machine Panel->Spindle Power The MultiCUT-HP spindle is prepared for continuous operation between 0 –... - Page 89 Kongsberg XN / iPC 2.0 Keep distance d small For best performance and minimum wear, do not let the bit stick out more than necessary. Use bits with short cutting lengths for thin materials. Chuck Open/Close valve operation Never operate the Chuck Open/Close valve while the spindle is running.

- Page 90 Kongsberg XN / iPC 2.0 Maintain bit clamping Un-proper bit clamping may cause the bit to slip in the chuck and damage the Table Top. 1. Keep the bit shaft clean. 2. Avoid greasy fingers. 3. Clean the bit shaft with acetone if necessary, but use only dry cotton tips on the chuck.

-

Page 91: Routing Advice

Kongsberg XN / iPC 2.0 Empty vacuum cleaner in time 1. Do not leave the machine running if the Vacuum Cleaner can be over-filled. This might cause damage. 2. Be aware the risk of suction tube clogging. 12.8.5 Routing Advice Milling bits For thin materials, use bits with short cutting length. - Page 92 Kongsberg XN / iPC 2.0 For best performance and minimum wear, do not let the bit stick out more than necessary . Never use higher RPM than recommended by the bit supplier. Special care should be taken when using bits with cutting diameter larger than shank diameter.

- Page 93 Kongsberg XN / iPC 2.0 Acrylic or Multi Purpose bits 1. Acrylic Bits (A) are polished, extra sharp for acrylic, wood etc. 2. Multi Purpose Bits (MP) have a higher wear resistance, and are suitable for aluface, plastics, MDF, plywood, wood etc. Multi Purpose Bits can be identified by a small tooth at the tip (left hand bit on the picture).

-

Page 94: Cleaner Device

Kongsberg XN / iPC 2.0 2. Cover unused table area to increase Vacuum Hold Down Level. 3. Use Wash-Out functions instead of creating small waste parts. Using other tools in combination with the MultiCUT-HP It might be necessary to reduce the acceleration in order to achieve an optimal Cutting Quality when combining a heavy tool head with high quality cutting tools. - Page 95 Kongsberg XN / iPC 2.0 Lock the house in its up position. Observe that the Router Bit is not rotating. Use a cloth to hold the bit. Move the Chuck Open/Close lever down to open the Chuck. Put the bit in a proper storage container. Insert a new Router Bit.

-

Page 96: Chuck Change And Cleaning

Kongsberg XN / iPC 2.0 Regularly, perform a Chuck cleaning, following the dedicated procedure; Chuck Change and Cleaning on page 96. Note: Never use Compressed Air for cleaning. If a bit is stuck If a Milling Bit is stuck in the chuck, the probable cause is low air pressure. To release a Milling Bit from the chuck, a pressure of 7 bar is required. - Page 97 Kongsberg XN / iPC 2.0 Place the Tool Head on the table. Open the chuck and remove any bit. Note: Never apply Compressed Air for cleaning. Apply the 17 mm key to hold the Spindle Rotor. Note: Do not turn the rotor when Chuck is in open position.

- Page 98 Kongsberg XN / iPC 2.0 Hold the rotor with the 17 mm key and unscrew the chuck using the Chuck Tool. Note: If you can not move the chuck with the Chuck Tool, a 12 mm key might be used, together with a dummy bit, to unscrew the chuck.

- Page 99 Torque up the chuck by hand, using the Chuck Tool with a Dummy Bit. Hold the rotor with the 17 mm key. Close the chuck on a Dummy Bit. Chuck Maintenance Kits are available in the Esko Store on www.esko.com.

-

Page 100: Bit Slipping, Chuck Change

2. Bit vibrations. When replacing the chuck, follow instructions in Chuck Change and Clean. New chucks are available from Esko store. 12.8.10 Bit Length and Position Keep distance d small. For best performance and minimum wear, do not let the bit stick out more than necessary. -

Page 101: False Air Valve

Kongsberg XN / iPC 2.0 Maximum balancing length g is 12 mm/0.5 inches. 12.8.11 False Air valve MultiCUT is equipped with a False Air Valve. When milling small parts, use the False Air Valve to reduce the suction force. 12.8.12 Tool Adjustment For FlexiHead tool positions, complete relevant adjustments as described for FlexiHead. -

Page 102: Table Top And Height Adjustment

Kongsberg XN / iPC 2.0 12.8.13 Table Top and Height Adjustment The following rules apply when adjusting MultiCUT/MultiCUT-HP T = Cutting table, C = Cutting underlay Map Table Top function is carried out on top of the Cutting underlay. U = Milling underlay ... -

Page 103: Miscellaneous

Kongsberg XN / iPC 2.0 A stiff milling underlay (S) on top of the cutting underlay: If the thickness of the milling underlay (S) is > 5 mm (0.2 inch), the underlay is supposed to be more or less stiff. One typical milling underlay material is MDF, ... -

Page 104: Lubricool

Kongsberg XN / iPC 2.0 Set “bit size” to 65 mm (2.5 inch). Hint: • Make a file name that reflect the size used. • Prepare Layer Setup with low spindle speed, zero depth, and maximum feed. • Insert the Dummy Bit into the chuck. •... - Page 105 Kongsberg XN / iPC 2.0 How to use LubriCool is on when the Vacuum Cleaner is For materials where lubrication is not suitable, use the ON/OFF switch on the LubriCool Control Unit to switch off lubrication. Inspection Opening When the LubriCool unit is on, you can see light in the control relays inside the unit.

-

Page 106: Chiller 1 For Multicut-Hp

Kongsberg XN / iPC 2.0 Proper cleaning is crucial for correct operation. • Release locker A and remove the nozzle unit. • Use vacuum cleaner to clean MultiCUT-HP suction house. • Use vacuum cleaner to clean the nozzle unit. 12.9 Chiller 1 for MultiCUT-HP 12.9.1 Introduction... -

Page 107: Chiller, Error Conditions

Kongsberg XN / iPC 2.0 Flow Measurement During operation, check the water flow level displayed on the chiller meter. For proper operation, the flow level should be > 1,0 l/min. 12.9.2 Chiller, Error Conditions One common error signal is routed from the Chiller system to the inverter and further into the control system. -

Page 108: Chiller Heater, Operation

Kongsberg XN / iPC 2.0 12.9.3 Chiller Heater, Operation Notes: 1. The Chiller Heater is optional. 2. The Chiller Heater must be filled with water before connecting mains. 3. The Chiller Heater is correctly configured when shipped from the factory. Normally, there is no need for modifications. -

Page 109: Chiller2016 For Multicut-Hp

Kongsberg XN / iPC 2.0 Programs available Program Temperature range Temperature range Hysteresis from ( to ( Frost protection Factory Setting Correct factory setting is Program = 5 and temperature = 26 oC (Chiller with heater). 12.10 Chiller2016 for MultiCUT-HP 12.10.1 Introduction Specifications Dimensions... -

Page 110: Startup

Kongsberg XN / iPC 2.0 12.10.2 Startup Ensure the following pre-requisites are in place for correct startup: • Note: Never start the chiller without liquid. • Signal cable (to inverter) is connected to the chiller unit. • Chiller fluid level should be MAX. If not, fill with fresh water. •... -

Page 111: Measuring Foot

Kongsberg XN / iPC 2.0 During normal operation, the cooling medium temperature is displayed. If any chiller failure occurs: • Alarm signal is generated. • Chiller will stop. • Look at the chiller display to see the real reason for the problem: Code Description Water level or water flow too low. -

Page 112: Laser Pointer

Kongsberg XN / iPC 2.0 Note: In Q1/2017, the strong springs used earlier were replaced by a set of softer springs, in order to avoid the foot scratching the material surface. If needed, a set of strong springs, together with a replacement procedure, is available in the tool kit included in the shipment. -

Page 113: X-Pad

Kongsberg XN / iPC 2.0 12.13 X-Pad 12.13.1 X-Pad Calibration Note: Remove any cup or cover surrounding the tool tip during this procedure. As a consequence, take care. In order to work properly, the X-Pad itself must be calibrated. The following tools are applicable when the calibration procedure is carried out: •... -

Page 114: Tool Depth And X-Pad

Kongsberg XN / iPC 2.0 12.13.2 Tool Depth and X-Pad Be aware how X-Pad is working; it is the tool tip that is measured. Depending upon the actual tool, it might be necessary to add depth in order to achieve cut or drill hole through the material. -

Page 115: Tool Inserts

Kongsberg XN / iPC 2.0 13. Tool inserts Knife Blades are extremely sharp. Take care when handling Knife Tools. 13.1 Ball Point Pen The Ball Point Pen tool is available for pen drawing. Tool pressure is adjustable by a knob on top of the tool. -

Page 116: Bevel Knife

Kongsberg XN / iPC 2.0 Parameter Description Tool Offset Adjust offset relative to laser pointer. For more information about how to run the adjustment wizards, see Tool Configuration. 13.2 Bevel Knife Bevel Knife is a special-purpose tool for 45 degree angled cuts. Lag = 3.5 mm / 0.14 in. -

Page 117: Bevel Knife U20

Kongsberg XN / iPC 2.0 About tool adjustment For the Bevel Knife, we recommend the manual procedures for tool rotation and centre offset adjustment. Use a thin Folding Carton material when adjusting tool rotation and centre offset. Remember that you should look at the bottom side of the material for correct alignment. The adjustments depend upon the actual material due to weight, structure and thickness. - Page 118 Kongsberg XN / iPC 2.0 Braille Tool, how to add spheres 1. Keep the tool in upright position during this process. 2. Remove the cap and the plunger. 3. Pour spheres into the tool. 4. Insert the plunger and the cap. Shake the tool lightly. 5.

- Page 119 Kongsberg XN / iPC 2.0 Braille Tool milling bit The supplied milling bit is heavily unbalanced and should not be run faster than 20.000 RPM to avoid excessive wear to the milling spindle! This also means that you should not use this bit when warming up the milling spindle as the warm up sequence exceeds 20.000rpm.

- Page 120 Kongsberg XN / iPC 2.0 Braille Tool should be defined with the following parameters enabled: • Velocity Z (max speed) • Z-axis Depth (0) • Drill holes (on) Preparing Layers for Braille Tool Opened Job->Layers->Edit Layers When making braille signage, you need two identical Layers with the braille pattern, one for milling holes and one for inserting braille spheres.

- Page 121 Kongsberg XN / iPC 2.0 Spindle RPM Spindle RPM is material dependent and may require experimentation. The values shown in the illustration are suitable for 3mm Dibond. Drill holes Drill holes check box should be enabled. Layer: Braille Tool Z-axis Depth Z-axis depth should initially be set to the material thickness.

-

Page 122: Corruspeed Knife

Kongsberg XN / iPC 2.0 Keep other graphics than Braille in separate layers. 13.5 CorruSpeed Knife Note: iPC version 2.0 or higher is required to run this tool. CorruSpeed Knife tool is made especially for cutting corrugated materials. Maximum material thickness: 7 mm/0.28 in. -

Page 123: Tool Adjustment

Kongsberg XN / iPC 2.0 C - scale indicating actual pressure. For optimal performance, the foot pressure must be adapted to each material. Run some test cuts to find the best combination of knife tip exposure and foot pressure. Start with foot pressure = 5 and test with different knife tip exposures. By this, you can find and save settings that are optimal for each type of material. -

Page 124: Crease Tool

Kongsberg XN / iPC 2.0 13.6 Crease Tool Crease Tool The Crease Tool is a multipurpose tool allowing a wide range of creasing wheels. Lag is nominal 0 mm. Replace crease wheel Push the wheel into position 13.6.1 Tool adjustment For this tool, complete the following adjustments: Parameter Description... -

Page 125: Crease Tool, 60 Mm

Kongsberg XN / iPC 2.0 13.7 Crease Tool, 60 mm Use the ø60 mm Crease Tool to avoid cracking the liner. Lag is nominal 0 mm. The crease wheel is attached to the tool after it has been mounted in the Tool Head. Note: When working with thin materials, avoid crease close to the Ruler. -

Page 126: Drill Tools

Kongsberg XN / iPC 2.0 For more information about how to run the adjustment wizards, see Tool Configuration. 13.8 Drill tools 13.8.1 Flexi Drill Tool How to replace a drill bit Push the drill bit towards the bottom of the Chuck. -

Page 127: Reboard Drill Tool

Kongsberg XN / iPC 2.0 13.8.2 Reboard Drill Tool Reboard Drill Tool is a tool insert for a standard XL tool position. This drill tool is for use in re-board and other paper - based materials. The tool is prepared for drill bits 0.5 –... -

Page 128: Tool Adjustment

Kongsberg XN / iPC 2.0 13.8.4 Tool Adjustment For this tool, complete the following adjustments: Parameter Description Tool Height The tool tip should touch the material surface. Tool Offset Adjust offset relative to laser pointer. For more information about how to run the adjustment wizards, see Tool Configuration. -

Page 129: Ink Tool

Kongsberg XN / iPC 2.0 Lag adjustments for Foam Knife The lag for the Foam Knife tool should be 2.5mm (0.1") How to replace a Knife Blade Static Knife. Follow instructions for 13.10 Ink Tool Two ink tool models are available; Liquid Ink Tool and Fibertip Tool. Lag is nominal 0 mm. -

Page 130: Fibertip Tool

Kongsberg XN / iPC 2.0 Ink tool assembly 13.10.2 Fibertip Tool Fibertip Tool is for ink drawing. The tool is prepared for Staedtler Lumocolor insert. Fibertip tool assembly 13.10.3 Tool adjustment For this tool, complete the following adjustments:... -

Page 131: Kisscut

Kongsberg XN / iPC 2.0 Parameter Description Tool Height The tool tip should touch the material surface. Lag Setting The knife lag depends upon the actual knife blade adapter and knife blade. Tool Rotation Adjust tool angle tangential to moving direction. Center Offset Adjust tool sideways until centered. - Page 132 Kongsberg XN / iPC 2.0 Replace Knife Blade This figure shows how the Knife Blade is fixed A special hand tool is available as an aid when inside the KissCut knife tool. replacing knives. Use this hand tool when removing and inserting knives into the tool. The friction between the Alignment Pin A and the Knife Blade keeps the blade in place.

-

Page 133: Microcut

Kongsberg XN / iPC 2.0 Foot solution Normally, the KissCut knife tool is used without the foot mounted. When the foot is mounted, the cutting depth d is controlled by the adjustable screw S. For this tool, complete the following adjustments: Parameter Description Lag Setting... - Page 134 Kongsberg XN / iPC 2.0 How to set Cutting Depth • When inserting a new Knife Blade, align the tip of the knife with the sliding sleeve and zero the depth meter (A). • Then adjust the micrometer screw (Starret micrometer (218)) until desired depth is displayed (B).

-

Page 135: Psaligraphy Knife

Kongsberg XN / iPC 2.0 For more information about how to run the adjustment wizards, see Tool Configuration. 13.13 Psaligraphy Knife Note: iPC version 2.0 or higher is required to run this tool. Psaligraphy Knife is a tool for cutting of fine details in paper and folding carton. -

Page 136: Rbi 90-16 (Rigid Board Insert)

Kongsberg XN / iPC 2.0 Parameter Description Lag Setting The knife lag depends upon the actual knife blade adapter and knife blade. Tool Rotation Adjust tool angle tangential to moving direction. Center Offset Adjust tool sideways until centered. Tool Offset Adjust offset relative to Laser Pointer. -

Page 137: Reciprocating Knife

Kongsberg XN / iPC 2.0 Parameter Description Tool Rotation Adjust tool angle tangential to moving direction. Center Offset Adjust tool sideways until centered. Tool Offset Adjust offset relative to laser pointer. For more information about how to run the adjustment wizards, see Tool Configuration. -

Page 138: Tool Adjustment

Kongsberg XN / iPC 2.0 Replace Knife Blade Pull out the electrical connection. Note: Pull using the connector, not just the cable. Remove the foot by pulling the foot straight out. Loosen the screw A and replace the knife. Ensure the knife has correct position relative to the screw. -

Page 139: Rigid Material Knife

Kongsberg XN / iPC 2.0 13.16 Rigid Material Knife Insert / remove knife blade Ensure the blade is correctly aligned. Use a 3 mm Allen Key to fix / loosen the knife blade. After a blade change, the tool depth should be checked again. Tool Adjustment Use the standard adjustment wizards when adjusting the knife. -

Page 140: Rotacut

Kongsberg XN / iPC 2.0 13.17 RotaCut RotaCut is a special tool for cutting light materials, as thin fabric. Maximum cutting depth is 2 mm / 0.07 inch. Note: Due to the characteristics of this knife tool, some restrictions apply to the use of it: •... - Page 141 Kongsberg XN / iPC 2.0 Be careful, though, not to adjust the cutting depth too deep into the cutting underlay (figure at left). U - cutting underlay M - material D - X/Y moving direction For more information about how to run the adjustment wizards, see Tool Configuration.

- Page 142 Kongsberg XN / iPC 2.0 Push the foot into position. A self-locking mechanism ensures the foot is kept in place. Note: Be careful not to hit the sharp knife. Layer Setup for RotaCut Correct setting of Lag- and Width - values are shown.

-

Page 143: Static Knife

Kongsberg XN / iPC 2.0 13.18 Static Knife Static Knife is a multipurpose tool allowing a wide range of Knife Blades. Lag, nominal value is 0-3 mm. Insert Knife Blade After a blade change, the tool depth should be checked again. -

Page 144: Tool Adjustment

Kongsberg XN / iPC 2.0 Knife direction The locking screw will always point towards the The locking screw will always point towards the cutting direction cutting direction 13.18.1 Tool adjustment For this tool, complete the following adjustments: Parameter Description Tool Height The tool tip should touch the material surface. - Page 145 Kongsberg XN / iPC 2.0 How to mount VI45 Knife Tool Remove the knife adapter from the tool and Position the tool adapter onto the shaft. insert the upper part into the tool position. Observe Alignment Pin orientation. Keep the knife adapter in this position while you turn the tool shaft…...

- Page 146 Kongsberg XN / iPC 2.0 About tool adjustment For the VI45 Knife Tool, we recommend the manual procedures for tool rotation and centre offset adjustment. Use a thin Folding Carton material when adjusting tool rotation and centre offset. Remember that you should look at the bottom side of the material for correct alignment.

-

Page 147: Maintenance

Kongsberg XN / iPC 2.0 14. Maintenance More information about maintenance is available in the Maintenance Manual. Warning Main Power should be switched off before cleaning is carried out. 14.1 Daily maintenance • Inspect the equipment in order to prevent any irregularities. •... -

Page 148: Fuse Replacement

Kongsberg XN / iPC 2.0 15. Fuse replacement Before starting the Fuse Replacement procedure: • Switch Power Off using the Main Power Switch • Remove the Main Power plug from the wall socket 15.1 MPU fuses MPU Location Note: MPU location is model dependent. All fuses are located on the rear side of the Main Power Unit (MPU). -

Page 149: X1 Fuses

Kongsberg XN / iPC 2.0 Fuse Details Fuse location 115V 230V F1 and F2, line fuses T 10A 250V (5x20 mm) T 5A 250V (5x20 mm) F24, +24V fuse T 6,3A 250V (5x20 mm) T 6,3A 250V (5x20 mm) F48, 48V Servo power fuse T 15A 250V (5x20 mm) T 15A 250V (5x20 mm) 15.2 X1 fuses... -

Page 150: Y/Z Fuses

Kongsberg XN / iPC 2.0 Fuse Location 1 – 6/12A amplifier X2. Procedure 1. Remove X2 cover. 2. Check the X2 fuse with ohm - meter. If blown, replace with a new, identical fuse. 3. Replace covers. 4. Insert main power cable into the wall socket and turn main power ON. Fuse Details T 8A 250V 1 1/4 x 1/4 in. -

Page 151: Tool Rotation/Reciprocating Knife Fuses

Kongsberg XN / iPC 2.0 Procedure 1. Remove Y cover. 2. Check the Y and Z fuse with ohm - meter. If blown, replace with a new, identical fuse. 3. Replace covers. 4. Insert main power cable into the wall socket and turn main power ON. Fuse Details Name Fuse... - Page 152 Kongsberg XN / iPC 2.0 Remove the on/off button Remove cover (4 screws) Fuse location Pull out the fuse holder Turn the fuse holder 90 deg. Now you have easy access to the fuse. 1 - Spare fuse 2 - Fuse in action Fuse: T 1A 250V (5x20 mm)

-

Page 153: Heater For Chiller Fuse

Kongsberg XN / iPC 2.0 15.7 Heater for Chiller Fuse Heater Fuse Location The Fuse is available inside the connector cover. Fuse details F - 4A 250V T 5x20mm Slow Blow (42448944) 15.8 Chiller2016 Fuse replacement Fuses are located on the PCB inside the Chiller unit. -

Page 154: Roll Feeder

Kongsberg XN / iPC 2.0 16. Roll Feeder A – Bracket Position Pin (push the center button to release the lock). B – Roll Holder Bracket. C – Brake Position Locker. D – Roller Brake. E – Brake Tension adjustment. Turn clockwise to increase tension. To adapt to different roll sizes, three Roll Holder Positions are prepared. -

Page 155: Collector Basket

Kongsberg XN / iPC 2.0 17. Collector Basket The unit is placed in the unload end of the conveyor belt (front of table). The unit is prepared for rigid pieces up till 200x200 mm / 8x8 in, or flexible materials. Maximum load weight is 30 kg / 65 lbs. -

Page 156: Vacuum Cleaner

Kongsberg XN / iPC 2.0 18. Vacuum Cleaner 18.1 Vacuum Cleaner, Zefiro 18.1.1 How to use Filter Shaking Filter Shaking is important in order to maintain a good Vacuum Cleaner performance. Filter Shaking is best operated every time before use and after prolonged operation. ... - Page 157 Kongsberg XN / iPC 2.0 Note: You can use the container with or without Plastic Bag. Use Plastic Bag in Material Container Parts needed: Steel ring and plastic bag Fix the Plastic Bag to the ring in this way Ring and Plastic Bag ready for the container Fold/fix the Plastic Bag around the container...

-

Page 158: Vacuum Cleaner, High-Capacity, Tb Esko

Container with Plastic Bag ready for operation Detailed information about how to operate the Vacuum Cleaner is available in the Zefiro 75 Operators and maintenance manual. 18.2 Vacuum Cleaner, High-capacity, TB ESKO 18.2.1 How to use Introduction 1 – Filter Chamber 2 –... - Page 159 Kongsberg XN / iPC 2.0 Filter Shaking Filter Shaking is important in order to maintain a good Vacuum Cleaner performance. Filter Shaking is best operated every time before use and after prolonged operation. Note: This operation must be performed only when the Vacuum Cleaner is switched off and the motor has stopped.

-

Page 160: Compact Vacuum Cleaner

Kongsberg XN / iPC 2.0 Shake the filter well before emptying the Fix the Plastic Bag to the steel bar. container. Plastic Bag with bar ready for container. Fold/fix the Plastic Bag around the container. Container with Plastic Bag ready for operation. - Page 161 Kongsberg XN / iPC 2.0 1. Suction tube inlet 2. Container fixture 3. Filter unit locking mechanism 4. Motor 5. Filter unit How to empty container 1. Ensure vacuum cleaner motor is off. 2. Remove the suction tube (1). 3. Release the container (3). 4.

-

Page 162: Install Software

Kongsberg XN / iPC 2.0 19. Install Software For information about software installation, see the Installation Manual for the actual machine. Available on the Documentation DVD. -

Page 163: Frequently Asked Questions

Are all transmitters pointing correctly to their receiver? Check if the red light is shining on the receiver. If necessary, adjust by bending the transmitter/receiver holder During start up: X1/X2/Y servo error This is probably caused by a defect in an amplifier board. Please contact Esko for technical support During start up: X1/X2/Y fuse error Check the fuse of the motor If problem persists, it is likely to be the amplifier board malfunctioning. -

Page 164: Ipc

Check all connections of the milling spindle: at tool head, inside cover X1 and at the inverter Check serial connection between inverter and PC: connection OK? COM port changed lately? If problem still persists, contact Esko 2 or 3 tools are working at the same time Check your compressed air, make sure you have 7 bar Check compressed air connection at the head. - Page 165 Kongsberg XN / iPC 2.0 If there was a software update recently, check if the firmware on the machine and iPC are of the same version Check the serial connection between PC and MCU Check the connection at the emergency button...

Need help?

Do you have a question about the Kongsberg XN IPC 2.0 and is the answer not in the manual?

Questions and answers