HP 8753E User Manual

Network analyzer

Hide thumbs

Also See for HP 8753E:

- Installation and quick start manual (68 pages) ,

- Programming and command reference manual (192 pages) ,

- Service manual (612 pages)

Summary of Contents for HP HP 8753E

- Page 1 ® Advanced Test Equipment Rentals www.atecorp.com 800-404-ATEC (2832) HP 8753E Network Analyzer Supersedes October 1998 HP Rut No. 08753-90367 Printed iu USA February 1999...

- Page 2 Notice. The information contained in this document is subject to change without notice. Hewlett-Packard makes no warranty of any kind with regard to this material, including but not limited to, the implied warranties of merchantability and fitness for a particular purpose.

- Page 3 If the warranty covers repair or service to be performed at Buyer’s facility, then the service or repair will be performed at the Buyer’s facility at no charge within HP service travel areas Outside HP service travel areas, warranty service will be performed at Buyer’s facility only upon HP’s prior agreement, and Buyer shall pay HP’s round-trip travel expenses.

- Page 4 If you are sending the instrument to Hewlett-Packard for service, ship the analyzer to the nearest HP service center for repair, including a description of any failed test and any error message. Ship the analyzer, using the original or comparable anti-static packaging materials.

- Page 5 UNITED STATES Instrument Support Center Hewlett-Packard Company (800) 403-0801 EUROPEAN FIELD OPEEA!l’IONS Headquarters Hewlett-Packard S.A. Hewlett-Packard France Hewlett-Packard GmbH 1 Avenue Du Canada Hewlett-Packard Strasse 150, Route du Nantd’Avril Zone D’Activite De Courtaboeuf 1217 Meyrin Z/Geneva 61352 Bad Homburg v.d.H (41 22) 780.8111 France (49 6172) 16-O...

-

Page 6: Safety Symbols

Safety Symbols The following safety symbols are used throughout this manual. Familiarize yourself with each of the symbols and its meaning before operating this instrument. Caution Caution denotes a hazard. It calls attention to a procedure that, if not correctly performed or adhered to, would result in damage to or destruction of the instrument. -

Page 7: General Safety Considerations

(F 3A/250V). The use of other fuses or material is prohibited. Warning lb prevent electrical shock, disconnect the HP 87533 from mains before cleaning. Use a dry cloth or one slightly dampened with water to clean the external case parts. Do not attempt to clean internally. - Page 8 Caution This product is designed for use in Installation Category II and Pollution Degree 2 per IEC 1010 and 664 respectively. Caution VENTILATION REQUIREMENTS: When instaIling the product in a cabinet, the convection into and out of the product must not be restricted. The ambient temperature (outside the cabinet) must be less than the maximum operating temperature of the product by 4O C for every 100 watts dissipated in the cabinet.

- Page 9 User’s Guide Overview Chapter 1, “HP 8753E Description and Options, n describes features, functions, and available options. Chapter 2, “Making Measurements,” contains step-by-step procedures for making measurements or using particular functions. Chapter 3, “Making Mixer Measurements, n contains step-by-step procedures for making calibrated and error-corrected mixer measurements.

- Page 10 The Quick Reference Guide provides a summary of selected user features. The HEW3 Programming and Command Reference Guide provides programming information for operation of the network analyzer under HP-IB control.

- Page 11 The HP BASIC Programming Examples Guide provides a tutorial introduction using BASIC programming examples to demonstrate the remote operation of the network analyzer. The System Vertication and ‘lkst Guide provides the system verification and performance tests and the Performance Test...

- Page 12 Santa Rosa, CA 95403-I 799 Hyogo, 651-22 Japan Declares that the product: Product Name: Network Analyzer Model Number: HP 8753E Product Options: This declaration covers all options of the above product Conforms to the following Product specifications: Safety: IEC 61010-1:199O/EN 61010-I:1993 EMC:...

-

Page 13: Table Of Contents

Service and Support Options ......Differences among the HP 8753 Network Analyzers .... - Page 14 2-13 Characterizing a Duplexer ......2-14 Required Equipment ......2-14 Procedure for Characterizing a Duplexer .

- Page 15 2-63 Set Up the Lower Stopband Parameters ....2-63 Set Up the Passband Parameters ..... 2-63 Set Up the Upper Stopband Parameters .

- Page 16 LO to RF Isolation ......3-33 RF Feedthrough ......3-35 4.

- Page 17 What You Can Save to a Computer ..... 4-34 Saving an Instrument State ......4-35 Saving Measurement Results .

- Page 18 Where to Look for More Information ..... HP 8753E System Operation ......

- Page 19 IF Detection ....... Ratio Calculations ......Sampler/IF Correction .

- Page 20 Segment Menu......6-23 ......6-23 Stepped Edit List Menu .

- Page 21 6-56 Marker Function Menu ......6-56 Marker Search Menu ......6-56 6-56 .

- Page 22 Using the Instrument State Functions ..... 6-110 HP-IB Menu ....... . . 6-111 6-111 .

- Page 23 Compatible Sweep Types ......6-119 External Source Requirements ..... 6-119 6-119 Capture Range.

- Page 24 Naming Files Generated by a Sequence ....6-151 HP-GL Considerations ......6-151 6-151 Entering HP-GL Commands .

- Page 25 7-19 HP-IB ........Parallel Port ....... .

- Page 26 Verification Kit 11-2 HP 85029B 7-mm Verification Kit ..... 11-2 ......

- Page 27 HP-IB Programmingtlverview 11-16 HP-IB Operation ....... 11-16 Device Types .......

- Page 28 Example 4,851O 3-Term kequency List Cal Set F’iIe ... . Conclusion ....... . The CITIfIIe Keyword Reference .

- Page 29 HP 8753E Front Panel ............

- Page 30 2-43. Sloping Limit Lines 2-50 2-44. Example Single Points’Lk’Line : 1 : 1 1 1 1 1 1 : : : : : 1 1 1 1 1 : 1 : 2-51 2-45. Example Stimulus Offset of Limit Lines ....2-54 .

- Page 31 4-2. Printing Two Measurements ......4-3. Peripheral Connections to the Analyzer ....4-4.

- Page 32 6-77 6-52. HP 87533 functional block diagram for a 2-port error-corrected measurement system ....... . .

- Page 33 11-17 11-2. HP-IB Bus Structure ......11-3. AnaIyzer Siie Bus Concept ......

- Page 34 6-13. Gate Characteristics ......7-2. Measurement Port Characteristics (Corrected*) for HP 8753E (509) with 7-mm Test Ports .

- Page 35 9-76 9-2. Softkey Locations ........... . 11-6 .

- Page 36 Chapter 6, “Application and Operation Concepts, ’ contains explanatory-style information about many applications and analyzer operation. HP 5753E Description and Options...

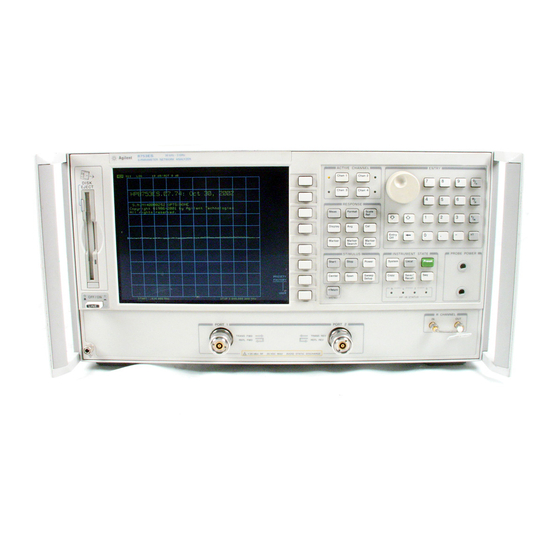

- Page 37 Analyzer Description The HP 8753E is a high performance vector network analyzer for laboratory or production measurements of reflection and transmission parameters. It integrates a high resolution synthesized RF source, an S-parameter test set, and a four-channel three-input receiver to measure and display magnitude, phase, and group delay responses of active and passive networks.

- Page 38 Power meter calibration that allows you to use an HP-IB compatible power meter to monitor and correct the analyzer’s output power at each data point. (The analyzer stores a power correction table that contains the correction values.)

-

Page 39: Hp 8753E Description And Options

If the line switch is mistakenly pushed, the instrument will be turned off, losing all settings and data that have not been saved. Figure l-l. HP 8753E Front Panel F’igure l-l shows the location of the following front panel features and key function blocks. - Page 40 The @Ki) and @iGZ) keys retain a history of the last active channel. For example, if channel 2 has been enabled after channel 3, you can go back to channel 3 without pressing [Ghan’ twice. HP 5753E Dessription and Options...

- Page 41 (Option 002) time domain transform (Option 010) HP-IB STATUS indicators are also included in this block. user preset state that can be dellned. Refer to the “Preset State and Memory Allocation” chapter for a complete listing of the instrument preset condition.

-

Page 42: Analyzer Display

The start frequency of the source in frequency domain measurements. The lower power value in power sweep. When the stimulus is in center/span mode, the center stimulus value is shown in this space. The color of the stimuhis display reflects the current active channel. HP 6753E Description and Options... - Page 43 Operation” in Chapter 6, “Application and Operation Concepts. “) Gating is on (time domain Option 010 only). (For time domain measurement procedures, refer to Chapter 2, “Making Measurements.” For time domain theory, refer to Chapter 6 “Application and Operation Concepts.“) 1-8 HP 6753E Description and Options...

- Page 44 For multiple-graticule displays, the channel information labels will be in the same relative position for each graticule. The label of the active channel is enclosed in a rectangle to differentiate it Note from inactive channels. HP 6753E Description and Options...

- Page 45 Measured Input(s). This shows the S-parameter, input, or ratio of inputs currently measured, as selected using the LMeas) key. Also indicated in this area is the current display memory status. Format. This is the display format that you selected using the (Format] key. 10.

-

Page 46: Rear Panel Features And Connectors

Power cord receptacle, with fuse. For information on replacing the fuse, refer to the Line voltage selector switch. For more information refer to the HP 87533 Network 10 ME PRECISION REFERENCE OUTPUT. (Option lD5) 10 MHZ REFERENCE ADJUST. - Page 47 Pass: TTLhigh Fail: ITLlow TEST SET INTEECONNECC. This allows you to connect an HP 8763E Option 011 analyzer to an HP 85046A/B or 85047A S-parameter test set using the interconnect cable supplied with the test set. The S-parameter test set is then fully controlled by the analyzer.

-

Page 48: Analyzer Options Available

Option lCM, Rack Mount Flange Kit Without Handles Option 1CM is a rack mount kit containing a pair of flanges and the necessary hardware to mount the instrument, with handles detached, in an equipment rack with 482.6 mm (19 inches) horizontal spacing. HP 8753E Description and Options... -

Page 49: Option Lcp, Rack Mount Flange Kit With Handles

Option lCP, Rack Mount Flange Kit With Handles Option 1CP is a rack mount kit containing a pair of flanges and the necessary hardware to mount the instrument with handles attached in an equipment rack with 482.6 mm (19 inches) spacing. -

Page 50: Differences Among The Hp 8753 Network Analyzers

Differences among the HP 8753 Network Analyzers Feature Fully integrated measurement system (built-in test s&J Auto/manual power m selecting Port power coupliug/uncoupling Internal disk drive Precision frequency reference (Option lD5) 300 kHz Frequency range - low end 300 kHz Ext. freq. range to 6 GHz (Option 006) - Page 51 300 lcHz to 3 GHz, without option 006, or 30 lcHz to 6 GHz, with Option 006 For this network analyze5 the feature is dependent on the test set being used.

-

Page 52: Where To Look For More Information

This Chapter contains the following example procedures for making measurements or using particular functions: Basic measurement sequence and example Four-Parameter Display Mode Magnitude and insertion phase response Electrical length and phase distortion Deviation from linear phase Group delay Limit testing Gain compression Measurements using the swept list mode Tuned Receiver Mode... -

Page 53: Principles Of Microwave Connector Care

This type of information is typically located in Chapter 3 of the calibration kit manuals. For additional connector care instruction, contact your local Hewlett-Packard Sales and Service Office about course numbers HP 8505OA + 24A and HP 8505OA + 24D. See the following table for quick reference tips about connector care. -

Page 54: Basic Measurement Sequence And Example

Basic Measurement Sequence and Example Basic Measurement Sequence There are five basic steps when you are making a measurement. 1. Connect the device under test and any required test equipment. Damage may result to the device under test if it is sensitive to the analyzer’s Caution default output power level. -

Page 55: Setting The Source Power

Note You could also press the @ and &TJ keys and enter the frequency range limits as start frequency and stop frequency values Setting the Source Power. You could also press ~~~~.~~~~~~~~ ~~~~~~:~,~~~~~ and select of the Note power ranges to keep the power setting within the deGned range. Setting the Measurement. -

Page 56: Step 4. Measure The Device Under Test

Caution Do not mistake the Iine switch for the disk eject button. See the figure below. If the Iine switch is mistakenly pushed, the instrument wiIi be turned off, losing ah settings and data that have not been saved. Step Measure the device under test. -

Page 57: Using The Display Functions

Using the Display Functions In some cases, you may want to view more than one measured parameter at a time. Simultaneous gain and phase measurements for example, are useful in evaluating stability in negative feedback amplifiers. You can easily make such measurements using the dual channel display. -

Page 58: Lb View The Measurement Data And Memory Trace

3. To return to a single-graticule display, press: ~~~~~~~;.,~~~~~~~,,, $8, . You can control the stimulus functions of the two channels independent of each Note Press (j) ~~~~~~~~~~ to store the current active measurement data in the memory of the active channel. The data trace is now also the memory trace. - Page 59 You can use this feature for ratio comparison of two traces, for example, measurements of gain or attenuation. 1. You must have already stored a data trace to the active channel memory, as described in “To Save a Data Trace to the Display Memory.” 2.

-

Page 60: 2-4. Example Of A Display Title

. ii i If you have a DIN keyboard attached to the analyzer, type the title you want from the keyboard. Then press (WI to enter the title into the analyzer. You can enter a title that has a maximum of 50 characters. (For more information on using a keyboard with the analyzer, refer to “Keyboards”... -

Page 62: Channel Display

The display will appear as shown in F’igure 2-5. Channel 1 is in the upper left quadrant of the display, channel 2 is in the upper right quadrant, and channel 3 is in the lower half of the display. 1 7 S s p 1 9 9 8 11:13:31 1 0 dB/ R E F -50 dB . -

Page 63: Channel Display

This enables channel 4 and the screen now displays four separate grids as shown in Figure 2-6. Channel 4 is in the lower-right quadrant of the screen. 2 S e p 1 9 9 8 14:is: 5 7 . 5 dB/ REF - 2 dB 1 0 dB/ R E F - 5 0 dB DUAL CHAN O N o f f... -

Page 64: Quick Four-Parameter Display

13. Press (Ghan] again. Observe that the LED is flashing, indicating that channel 3 is active. 14. Rotate the front panel control knob and notice that marker 2 still moves on all four channel traces. 15. To independently control the channel markers: Press (Marker) ‘~~~~~~::::.~~, set ~jQ#$JR&~~- to UNCOUPLED. -

Page 65: Required Equipment

(a 3-port device) are routed correctly. This example uses one of the following adapters to perform this function: HP 8753E Option K36 duplexer test adapter HP 8753E Option K39 3-port test adapter You must also have a set of calibration standards for performing a full 2-port calibration on your test set up. - Page 66 Note Make sure you connect the calibration standards to the Rx port of the test adapter (or a cable attached to it) for the FORWARD calibration, and the Antenna port for the REVERSE calibration. 12. When the calibration has been completed, save this state in the analyzer: 13.

-

Page 67: Duplexer Measurement

5 Au9 1 9 9 8 - 4 0 dB 1 0 dB/REF 1 0 dB/REF - 4 0 dB Ref 1: FWD T r a n s : F W D T r a n s : R E V Ref 1: REV ANALOG IN A u x I n p u t... -

Page 68: Using Analyzer Display Markers

Using Analyzer Display Markers The analyzer markers provide numerical readout of trace data. You can control the marker search, the statistical functions, and the capability for quickly changing stimulus parameters with markers, from the (jMarker) key. Markers have a stimulus value (the x-axis value in a Cartesian format) and a response value (the y-axis value in a Cartesian format). -

Page 69: Active And Inactive Markers Example

The active marker appears on the analyzer display as V. The active marker stimulus value is displayed in the active entry area. You can modify the stimulus value of the active marker, using the front panel knob or numerical keypad. All of the marker response and stimulus values are displayed in the upper right comer of the display. -

Page 70: Marker Information Moved Into The Softkey Menu Area

If marker information obscures the display traces, you can turn off the softkey menu and move the marker information off of the display traces and into the softkey menu area. Pressing the backspace key @ performs this function. This is a toggle function of the backspace key. That is, pressing @ alternately hides and restores the current softkey menu. -

Page 71: Ib Use Delta (A) Markers

4. Restore the softkey menu and move the marker information back onto the graticules: Press The display will be similar to Figure 2-11. 2 S e p 1 9 9 8 12:09: 4 3 5 dB.’ R E F - 2 dB -50 dB ‘... -

Page 72: Marker 1 As The Reference Marker Example

and move marker 2 to any position that you want to measure in reference Figure 2-12. Marker 1 as the Reference Marker Example 4. ‘Ib change the reference marker to marker 2, press: When a reference marker is tied, it does not rely on a current trace to maintain its fixed position. -

Page 73: Using The

1. To set the frequency value of a iixed marker that appears on the analyzer display, press: keypad. The marker is shown on the display as a small delta (A), smaller than the inactive marker triangles. 2. ‘RI set the response value (dl3) of a fixed marker, press: keypad. - Page 74 Using the :,~~.~:~.~~~ Key to Activate a Fixed Reference Marker Marker zero enters the position of the active marker as the A reference position. Alternatively, you can specify the fixed point with ;$$&E& .~~~;~.~~~~~~~. Marker zero is canceled by switching delta mode off. 1.

-

Page 75: Key

At a preset state, the markers have the same stimuhrs values on each channel, but they can be uncoupled so that each channel has independent markers. for the display channels. Choose .~~~~~~~~ if you want the analyzer to uncouple the marker stimulus . -

Page 76: Example Of A Log Marker In Polar Format

2. Select the type of polar marker you want from the following choices: Choose ;&X#“?!&% if you want to view the magnitude and the phase of the active marker. The magnitude values appear in units and the phase values appear in degrees. active marker. -

Page 77: Lb Set Measurement Parameters Using Markers

The marker annotation tells that the complex impedance is capacitive in the bottom half of the Smith chart display and is inductive in the top half of the display. Choose .X&@I#& if you want the analyzer to show the linear magnitude and the phase of the reflection coefficient at the marker. -

Page 78: Setting The Start Frequency

Setting the Start Frequency 1. F’ress (mFctn) and turn the front panel knob, or enter a value from the front panel keypad to position the marker at the value that you want for the start frequency. the value of the active marker. 3 1 es2 588 PtHl CENTER SPAN... -

Page 79: Setting The Center Frequency

1. Press @GiFFXj and turn the front panel knob, or enter a value from the front panel keypad to position the marker at the value that you want for the center frequency. marker. Figure 2-20. Example of Setting the Center Frequency Using a Marker... -

Page 80: Setting The Frequency Span

Setting the Frequency Span You can set the span equal to the spacing between two markers. If you set the center frequency before you set the frequency span, you will have a better view of the area of interest. Turn the front panel knob, or enter a value from the front panel keypad to position the markers where you want the frequency span. -

Page 81: Setting The Display Reference Value

Setting the Display Reference Viilue 1. Press (j.GLXGFctn_) and turn the front panel knob, or enter a value from the front panel keypad to position the marker at the value that you want for the analyzer display reference value. 2. Press ~~,~~~ to change the reference value to the value of the active marker. Figure 2-22. -

Page 82: Setting The Electrical Delay

Setting the Electrical Delay This feature adds phase delay to a variation in phase versus frequency, therefore it is only applicable for ratioed inputs. 2. Press (jjFctn) and turn the front panel knob, or enter a value from the front panel keypad to position the marker at a point of interest. -

Page 83: Searching For The Maximum Amplitude

These functions place the marker at an amplitude-related point on the trace. If you switch on tracking, the analyzer searches every new trace for the target point. Searching for the Maximum Amplitude trace. Figure 2-24. Searching for the Maximum Amplitude Using a Marker Example of 232 Making Measurements... -

Page 84: Searching For The Minimum Amplitude

Searching for the Minimum Amplitude ii. i ..i ..T i . ; ; ; ..; ..s ..: : . / i . . . minimum point on the measurement trace. -

Page 85: Searching For A 'Lhrget Amplitude

Searching for a ‘beget Amplitude trace. 3. If you want to change the target amplitude value (default is -3 dB), press ~~~~~ and enter the new value from the front panel keypad. 4. If you want to search for multiple responses at the target amplitude value, press . -

Page 86: Searching For A Bandwidth

Searching for a Bandwidth The analyzer can automatically calculate and display the -3 dB bandwidth (BW:), center frequency (CENT:), Q, and loss of the device under test at the center frequency. (Q stands for “quality factor,” defined as the ratio of a circuit’s resonant frequency to its bandwidth.) These values are shown in the marker data readout. -

Page 87: Ri Calculate The Statistics Of The Measurement Data

This function calculates the mean, standard deviation, and peak-to-peak values of the section of the displayed trace between the active marker and the delta reference. If there is no delta reference, the analyzer calculates the statistics for the entire trace. 2. -

Page 88: Measuring Magnitude And Insertion Phase Response

Measuring Magnitude and Insertion Phase Response The analyzer allows you to make two different measurements simultaneously. You can make these measurements in different formats for the same parameter. For example, you could measure both the magnitude and phase of transmission. You could also measure two different parameters (Sll and S&. -

Page 89: Measuring Insertion Phase Response

4. Reconnect your test device. 5. lb better view the measurement trace, press: . . . , . , . _ . , . . , . , . / ../ ..6. -

Page 90: Phase Samples

The phase response shown in F’igure 2-32 is undersampled; that is, there is more than HO0 phase delay between frequency points If the A4 2 HO”, incorrect phase and delay information may result. Figure 2-32 shows an example of phase samples being with A+ less than MO0 and greater than MOO. -

Page 91: Measuring Electrical Length And Phase Distortion

Measuring Electrical Length and Phase Distortion Electrical Length The analyzer mathematically implements a function similar to the mechanical “line stretchers” of earlier analyzers. This feature simulates a variable length lossless transmission line, which you can add to or remove from the analyzer’s receiver input to compensate for interconnecting cables, etc. -

Page 92: Linearly Changing Phase

3. Substitute a thru for the device and perform a response calibration by pressing: Reconnect your test device. 5. To better view the measurement trace, press: Notice that in Figure 2-34 the SAW filter under test has considerable phase shift within only a 2 MHz span. -

Page 93: Measuring Phase Distortion

8. Press (-Ref) ~~~~~~~~~~ ad turn the front panel knob to increase me ele&ricd length until you achieve the best flat line, as shown in Figure 2-35. The measurement value that the analyzer displays represents the electrical length of your device relative to the speed of light in free space. -

Page 94: Group Delay

Follow the procedure in “Measuring Electrical Length.” ..To use the marker statistics to measure the maximum peak-to-peak deviation from linear phase, press: M a r k e r F c t n ~~.:~~~~~~ ,f!@@ Activate and adjust the electrical delay to obtain a minimum peak-to-peak value. Note It is possible to use delta markers to measure peak-to-peak deviation in only one portion of the trace, see “lb Calculate the Statistics of the Measurement... -

Page 95: Group Delay Example Measurement

3. lb activate a marker to measure the group delay at a particular frequency, press: Figure 2-37. Group Delay Example Measurement Group delay measurements may require a specific aperture (AF’) or frequency spacing between measurement points The phase shift between two adjacent frequency points must be less than 4. - Page 96 5. lb increase the effective group delay aperture, by increasing the number of measurement points over which the analyzer calculates the group delay, press: As the aperture is increased the “smoothness” of the trace improves markedly, but at the expense of measurement detail. Figure 2-39.

-

Page 97: Setting Up The Measurement Parameters

Limit testing is a measurement technique that compares measurement data to constraints that you define. Depending on the results of this comparison, the analyzer will indicate if your device either passes or fails the test. Limit testing is implemented by creating individual flat, sloping, and single point limit lines on the analyzer display. -

Page 98: Creating Flat Limit Lines

4. Reconnect your test device. 5. To better view the measurement trace, press: S c a l e R e f ... ;:: /,,,,, i ....1 :$?&% : Creating Flat Limit Lines In this example procedure, the following flat Iimit Iine values are set: Frequency Range .............. - Page 99 5. To terminate the flat line segment by establishing a single point limit, press: Figure 2-41 shows the flat limit lines that you have just created with the following parameters: stimulus from 127 MHz to 140 MHz upper limit of -21 dB lower limit of -27 dB Figure 2-41.

-

Page 100: Creatingaslopinglimitline

Figure 2-42. Example Flat Limit Lines Creating a Sloping Limit Line This example procedure shows you how to make limits that test the shape factor of a SAW Frequency Bange ..............Power Range 144 MHz to 146 MHz ............To establish the start frequency and limits for a sloping limit line that tests the low side of the filter, press: Making Measurements 249... -

Page 101: Sloping Limit Lines

... . . i xi ..i ..the l?lter, press: You could use this type of limit to test the shape factor of a ITIter. Figure 2-43. -

Page 102: Creating Single Point Limits

Creating Single Point Limits In this example procedure, the following limits are set: from -23 dB to -28.5 dB at 141 MHz from -23 dB to -28.5 dB at 126.5 MHz Figure 2-44. Example Single Points Limit Line Making Measurements 2-51... -

Page 103: Editing Limit Segments

Editing Limit Segments This example shows you how to edit the upper limit of a limit line. 1. To access the limits menu and activate the limit lines, press: 2. symbol (>) on the analyzer display to the segment you wish to modify, press: 3. -

Page 104: Reviewing The Limit Line Segments

1. To access the limits menu and activate the limit lines, press: Reviewing the Limit Line Segments The limit table data that you have previously entered is shown on the analyzer display. 2. To verify that each segment in your limits table is correct, review the entries by pressing: 3. -

Page 105: Offsetting Limit Lines

Offsetting Limit Lines The limit offset functions allow you to adjust the limit lines to the frequency and output level of your device. For example, you could apply the stimulus offset feature for testing tunable This example shows you the offset feature and the limit test failure indications that can appear on the analyzer display. -

Page 106: Measuring Gain Compression

Measuring Gain Compression Gain compression occurs when the input power of an amplifier is increased to a level that reduces the gain of the amplifier and causes a nonlinear increase in output power. The point at which the gain is reduced by 1 dB is called the 1 dB compression point. The gain compression will vary with frequency, so it is necessary to find the worst case point of gain compression in the frequency band. - Page 107 b. To uncouple the channel stimulus so that the channel power will be uncoupled, press: This will allow you to separately increase the power for channel 2 and channel 1, so that you can observe the gain compression on channel 2 while channel 1 remains unchanged.

- Page 108 14. To set the CW frequency before going into the power sweep mode, press: 16. Enter the start and stop power levels for the sweep. Now channel 1 is displaying a gain compression curve. (Do not pay attention to channel 2 at this time.) 17.

-

Page 109: Gain Compression Using Power Sweep

2 dB/ REF 1 9 0 1 dB I og 1 3 2 dBm I og MRG 5 dB/ R E F 0 dB 7 . 6 4 7 4 1 dB comd 1 .OOO 000 MHz S T O P 0 . -

Page 110: Measuring Gain And Reverse Isolation Simultaneously

Measuring Gain and Reverse Isolation Simultaneously Since an amplifier will have high gain in the forward direction and high isolation in the reverse direction, the gain (E&l) will be much greater than the reverse isolation (SH.). Therefore, the power you apply to the input of the amplifier for the forward measurement (SZl) should be considerably lower than the power you apply to the output for the reverse measurement saturated. -

Page 111: Gain And Reverse Isolation

Note the calibration. However, the analyzer compensates for nominal power changes you make during a measurement, so that the error correction still remains approximately valid. In these cases, the Cor annunciator will change to CA. START 1 . 0 0 0 0 0 0 MHz S T O P 1 0 0 0 000 0 0 0 MHz Figure 2-49. -

Page 112: Measurements Using The Swept List Mode

Measurements Using the Swept List Mode When using a list frequency sweep, the HP 8753E has the ability to sweep arbitrary frequency segments, each containing a list of frequency points. Two different list frequency sweep modes can be selected: In this mode, the source steps to each defined frequency point, Stepped List Mode stopping while data is taken. -

Page 113: Observe The Characteristics Of The Filter

Observe the Characteristics of the Filter Figure 2-51. Characteristics of a Filter needed to avoid overdriving the next stage of the DUT (if that stage contains an amplifier) or the network analyzer receiver. characteristic, the dynamic range of the system will have to be maximized. This can be done by increasing the incident power and narrowing the IF bandwidth. -

Page 114: Set Up The Lower Stopband Parameters

Set Up the Lower Stopband Parameters 3. lb set up the segment for the lower stopband, press 4. ‘Ib maximize the dynamic range in the stopband (increasing the incident power and narrowing the IF bandwidth), press 6. ‘RI specify a lower power level for the passband, press . -

Page 115: Calibrate And Measure

8. Tbmaximiz e the dynamic range in the stopband (increasing the incident power and narrowing the IF bandwidth), press: . . . , . : . : . : ..< : ; . . , : , : : : : : : . y . . : . . . : . : . . : : . < Calibrate and Measure Remove the DUT and perform a full two-port calibration. -

Page 116: Filter Measurement Using Swept List Mode

Filter Measurement Using Linear Sweep (Power: 0 dBm/lF BW: 3700 Hz) SEGMENT I SEGMENT 3 Power: +I 0 dBm Power: +lO dBm IF BW: 1000 Hz IF BW: 300 Hz Power: -10 dBm IF BW: 3700 Hz Figure 2-53. Filter Measurement Using Swept List Mode Making Measurements 245... -

Page 117: Measurements Using The Tuned Receiver Mode

Measurements Using the Tuned Receiver Mode In the tuned receiver mode, the analyzer’s receiver operates independently of any signal source. This mode is not phase-locked and functions in all sweep types. The analyzer tunes the receiver to a synthesized CW input signal at a precisely specified frequency. All phase lock routines are bypassed, increasing sweep speed significantly. -

Page 118: External Source Requirements

External Source Requirements An analyzer in tuned receiver mode can receive input signals into PORT 1, PORT 2, or R CHANNEL IN. Input power range specifications are provided in Chapter 7, ( L Specifications and Measurement Uncertainties. n Making Measurements 247... -

Page 119: Test Sequencing

Test sequencing allows you to automate repetitive tasks. As you make a measurement, the analyzer memorizes the keystrokes. Later you can repeat the entire sequence by pressing a single key. Because the sequence is defined with normal measurement keystrokes, you do not need additional programming expertise. -

Page 120: Creating A Sequence

Creating a Sequence 1. ‘lb enter the sequence creation mode, press: As shown in F’igure 2-55, a list of instructions appear on the analyzer display to help you create or edit a sequence. Figure 2-55. ‘l&t Sequencing Help Instructions 2. ‘RI select a sequence position in which to store your sequence, press: This choice selects sequence position #l. -

Page 121: Running A Sequence

3. To create a test sequence, enter the parameters for the measurement that you wish to make. For this example, a SAW filter measurement is set up with the following parameters: The above keystrokes will create a displayed list as shown: Start of Sequence RECALLPRSTSTATE LOG MAG... -

Page 122: Editing A Sequence

Editing a Sequence Deleting Commands 1. To enter the creation/editing mode, press: 2. ‘Ib select the particular test sequence you wish to modify (sequence 1 in this example), press: . . , . ; .., . . , . , / _ . , . . , . 3. -

Page 123: Modifying A Command

Modifying a Command 1. To enter the creation/editing mode, press: 2. To select the particular test sequence you wish to modify, (sequence 1 in this example), press: ..i i i ..A . . v . : . w The following list is the commands entered in “Creating a Sequence.’... -

Page 124: Changing The Sequence Title

Changing the Sequence Title If you are storing sequences on a disk, you should replace the default titles (SEQl, SEQ2 . . . ). To select a sequence that you want to retitle, press: ..~ . ~ ~ ~ . ~ . ~ ~ ~ . “ . ~ ~ ~ ~ ~ . ~ ~ ..: : ~ ~ ~ . . . The analyzer shows the available title characters. -

Page 125: Storing A Sequence On A Disk

Storing a Sequence on a Disk 1. To format a disk, refer to Chapter 4, “Printing, Plotting, and Saving Measurement Results.” 2. To save a sequence to the internal disk, press: ....: . ..:: i: The disk drive access light should turn on briefly. -

Page 126: Loading A Sequence From Disk

Loading a Sequence from Disk For this procedure to work, the desired file must exist on the disk in the analyzer drive. 1. To view the first six sequences on the disk, press: If the desired sequence is not among the Rrst six files, press: :: . -

Page 127: Cascading Multiple Example Sequences

Cascading Multiple Example Sequences By cascading test sequences, you can create subprograms for a larger test sequence. You can also cascade sequences to extend the length of test sequences to greater than 200 lines In this example, you are shown two sequences that have been cascaded. You can do this by having the last command in sequence 1 call sequence position 2, regardless of the sequence title. -

Page 128: Loop Counter Example Sequence

Loop Counter Example Sequence This example shows you the basic steps necessary for constructing a looping structure within a test sequence. A typical application of this loop counter structure is for repeating a specific measurement as you step through a series of CW frequencies or dc bias levels For an example application, see “Fixed IF Mixer Measurements”... -

Page 129: Generating Files In A Loop Counter Example Sequence

Generating Files in a Loop Counter Example Sequence This example shows how to increment the names of tiles that are generated by a sequence with a loop structure. Start of Sequence LOOP COUNTER 7 xl INTERNAL DISK DATA ONLY DO SEQUENCE SEQUENCE 2... -

Page 130: Limit Test Example Sequence

Start of Sequence FILE NAME PLOT NAME SINGLE SAVE FILE 0 PLOT DECR LOOP COUNTER IF LOOP COUNTER 0 THEN DO SEQUENCE 2 Sequence 1 initializes the loop counter and calls sequence 2. Sequence 2 repeats until the loop counter reaches 0. It takes a single sweep, saves the data file and plots the display. The data file names generated by this sequence will be: through The plot llle names generated by this sequence will be:... - Page 131 This will create a displayed list for sequence 1, as shown: Start of Sequence RECALL FlEG 1 IF LIMIT TEST PASS THEN DO IF LIMIT TEST FAIL THEN DO 2. lb create a sequence that stores the measurement data for a device that has passed the limit test, press: This will create a displayed list for sequence 2, as shown: Start of Sequence...

-

Page 132: Measuring Swept Harmonics (Option 002 Only)

Measuring Swept Harmonics (Option 002 Only) The analyzer has the unique capability of measuring swept second and third harmonics as a function of frequency in a real-time manner. Figure 2-56 displays the absolute power of the fundamental and second harmonic in dBm. Figure 2-57 shows the second harmonic’s power level relative to the fundamental power in dBc Follow the steps listed below to perform these measurements. -

Page 133: Nd Harmonic Power Level In Dbc

I og MRG S dB/ R E F 0 dB 7 . 6 7 4 2 CHZ START 1 6 . 0 0 0 0 0 0 MHz STOP 1 0 0 0 . 0 0 0 0 0 0 MHz Figure 2-57. -

Page 134: Measuring A Device In The Time Domain (Option 010 Only)

Measuring a Device in the Time Domain (Option 010 Only) The HP 8753E Option 010 allows you to measure the time domain response of a device. Time domain analysis is useful for isolating a device problem in time or in distance. Time and distance are related by the velocity factor of your device under test. -

Page 135: Time Domain Transmission Example Measurement

2. ‘lb choose the measurement parameters, press: 3. Substitute a thru for the device under test and perform a frequency response correction. Refer to “Calibrating the Analyzer,” located at the beginning of this Chapter, for a detailed procedure. 4. Reconnect your device under test. 5. - Page 136 8. To access the gate function menu, press: To set the gate parameters, by entering the marker value, press: center gate marker. “T” As shown in Figure 2-60, only response from the main path is displayed. You may remove the displayed response from inside the gate markers by Note pressing ;Sga:’...

- Page 137 Gate spfm Gate Span Minimum -68 dB Normal -57 dB Wide fO.l dB -70 dB I NOTE: With 1601 frequency points, gating is available only in the bandpass mode. The passband ripple and sidelobe levels are descriptive of the gate shape. The cutoff time is the time between the stop time (-6 dB on the filter skirt) and the peak of the first sidelobe, and is equal on the left and right side skirts of the hlter.

-

Page 138: Gating Effects In A Frequency Domain Example Measurement

Figure 2-62. Gating Effects in a Frequency Domain Example Measurement Making Measurements 2-87... -

Page 139: Reflection Response In Time Domain

Reflection Response in Time Domain The time domain response of a reflection measurement is often compared with the time domain reflectometry (TDR) measurements. Like the TDR, the analyzer measures the size of the reflections versus time (or distance). Unlike the TDR, the time domain capability of the analyzer allows you to choose the frequency range over which you would like to make the measurement. -

Page 140: Device Response In The Frequency Domain

4. To better view the measurement trace, press: ..complex ripple pattern is caused by reflections from the adapters interacting with each other. By transforming this data to the time domain, you can determine the magnitude of the reflections versus distance along the cable. -

Page 141: Device Response In The Time Domain

7. To enter the relative velocity of the cable under test, press: and enter a velocity factor for your cable under test. Most cables have a relative velocity of 0.66 (for polyethylene dielectrics) or 0.7 Note (for teflon dielectrics). If you would like the markers to read actual one-way distance rather than return trip distance, enter one-half the actual velocity factor. -

Page 142: Non-Coaxial Measurements

Non-coaxial Measurements The capability of making non-coaxial measurements is available with the HP 8753 family of analyzers with TRL* (thru-reflect-line) or LRM* (line-reflect-match) calibration. For in-depth information on TRL*/LRM* calibration, refer to Chapter 6, “Application and Operation Concepts. n Non-coaxial, on-wafer measurements present a unique set of challenges for error correction in the analyzer: of isolation between the input and the output. -

Page 143: Making Mixer Measurements

This chapter contains information and example procedures on the following topics: Measurement considerations ..Reducing the effect of spurious responses Eliminating unwanted mixing and leakage signals How RF and IF are dellned Frequency offset mode operation Differences between internal and external R channel inputs Power meter calibration Conversion loss using the frequency offset mode High dynamic range swept RF/IF conversion loss... -

Page 144: Measurement Considerations

Measurement Considerations into consideration: ..Reducing the Effect of Spurious Responses Eliminating Unwanted Mixing and Leakage Signals Analyzer Operation How RF and IF Are Defined Frequency Offset Mode Operation Differences Between Internal and External R channel Inputs Rower Meter Calibration Minimizing Source and Load Mismatches When characterizing linear devices, you can use vector accuracy enhancement to... -

Page 145: Up Converter Port Connections

In a down converter measurement where the ~~~,~~~~~~ softkey is selected, the notation on the analyzer’s setup diagram indicates that the analyzer’s source frequency is labeled RF, connecting to the mixer RF port, and the analyzer’s receiver frequency is labeled IF, connecting to the mixer IF port. -

Page 146: Frequency Offset Mode Operation

Frequency Offset Mode Operation Frequency offset measurements do not begin until all of the frequency offset mode parameters are set. These include the following: Start and Stop IF Frequencies Up Converter / Down Converter The LO frequency for frequency offset mode must be set to the same value as the external LO source. - Page 147 Figure 3-3. B Channel External Connection 4. Measure the output power in the R channel by pressing: Observe the 13 to 16 dR offset in measured power. The actual input power level to the R channel input must be 0 dBm or less, -10 dRm typical, to avoid receiver saturation effects The minimum signal level must be greater than -35 dBm to provide sufficient signal for operation of the phaselock loop.

-

Page 148: Power Meter Calibration

Power Meter Calibration Mixer transmission measurements are generally configured as follows: measured output power (watts) /set input power (Watts) measured output power (d&n) - set input power (dBm) For this reason, the set input power must be accurately controlled in order to ensure measurement accuracy. -

Page 149: Conversion Loss Using The Frequency Offset Mode

Conversion Loss Using the Frequency Offset Mode Conversion loss is the measure of efficiency of a mixer. It is the ratio of side-band IF power to RF signal power, and is usually expressed in dB. (‘lb express ratios in dR, denominator must be subtracted from the dBm power in the numerator.) The mixer translates the incoming signal, (RF), to a replica, (IF), displaced in frequency by the local oscillator, (Lo>. -

Page 151: Connections For A One-Sweep Power Meter Calibration For Mixer Measurements

11. lb perform a one sweep power meter calibration over the IF frequency range at 0 dBm, press: Note Because power meter calibration requires a longer sweep time,...yyou may want to reduce the number of points before pressing ~~~;~~~~. After the power meter calibration is finished, return the number of points to its originaI Once completed, the display should read 0 dBm. -

Page 152: Diagram Of Measurement Frequencies

15. To select the converter type and a high-side Lo measurement configuration, press: Notice in this high-side LO, down conversion configuration, the analyzer’s source is actuahy sweeping backwards, as shown in Figure 3-7. The measurement setup diagram is shown in Figure 3-8. -

Page 153: Conversion Loss Example Measurement

18. ‘lb view the conversion loss in the best vertical resolution, press: Figure 3-9. Conversion Loss Example Measurement In this measurement, you set the input power and measured the output power. Figure 3-9 shows the absolute loss through the mixer versus mixer output frequency. If the mixer under test contained built-in amplification, then the measurement results would have shown conversion gain. -

Page 154: High Dynamic Range Swept Rf/If Conversion Loss

High Dynamic Range Swept RF/IF Conversion Loss The HP 8753E’s frequency offset mode enables the testing of high dynamic range frequency converters (mixers), by tuning the analyzer’s high dynamic range receiver above or below its source, by a fixed offset. This capability allows the complete measurement of both pass and reject band mixer characteristics. -

Page 155: Connections For Broad Band Power Meter Calibration

A N A L Y Z E R P O W E R M E T E R Figure 3-10. Connections for Broad Band Power Meter Calibration 4. Select the HP 8753E as the system controller: 5. Set the power meter’s address: 8. Perform a... - Page 156 9. Connect the measurement equipment as shown in Figure 3-11. Figure 3-11. Connections for Eeceiver Calibration Set the following analyzer parameters: Once completed, the analyzer should display 0 deem. Make the connections shown in Figure 3-12. Set the Lo source to the desired CW frequency and power level. For this example the values are as follows: CW frequency = 1500 MHz source power = 13 dBm...

-

Page 157: Connections For A High Dynamic Range Swept If Conversion Loss Measurement

N E T W O R K A N A L Y Z E R Figure 3-12. Connections for a High Dynamic Range Swept IF Conversion Loss Measurement 14. To set the frequency offset mode LO frequency, press: 15. To select the converter type and low-side Lo measurement configuration, press: In this low-side Lo, down converter measurement, the analyzer’s source frequency range determined from the following equation: receiver frequency range (100 - 1000 MHz) + Lo frequency (1500 MHz) = 1.6-2.5 GHz... -

Page 158: 3-13. Example Of Swept If Conversion Loss Measurement

START 100 000 000 MHZ STOP 1 000 000 ocin MHZ Figure 3-13. Example of Swept IF Conversion Loss Measurement Making Mixer Measurements... -

Page 159: Fixed If Mixer Measurements

1. Make the following connections as shown in Figure 3-14. Set the HP-IB address of the external RF source to 19 and the external Ix) source to 21. Confirm that the external sources are configured to receive commands in the SCPI programming language and that their output power is switched on. -

Page 160: Connections For A Response Calibration

REFERENCE REFERENCE 10 dB 6 dB EXTERNAL EXTERNAL RF SOURCE LO SOURCE Figure 3-14. Connections for a Response Calibration 4. Press the following keys on the analyzer to create sequence 1: Note keyboard may be used for convenience. Performing a Response Calibration . - Page 161 Mixer the User to to the l&t Set Initializing a Loop Counter Value to 26 Addressing and Conflguring the Two Sources ....i i i .

- Page 162 Start of Sequence RECALL PRST STATE SYSTEM CONTROLLER TUNED RECEIVER NUMBER OF POINTS DONE DONE LIST FREQ TITLE PERIPHERAL HPIB ADDR TITLE TITLE TO PERIPHERAL CALIBRATE: RESPONSE CAL STANDARD TITLE CONNECT MIXER PAUSE LOOP COUNTER SCALE/DIV REFERENCE POSITION REFERENCE VALUE MANUAL TRG ON POINT TITLE TITLE...

-

Page 163: Sequence 2 Setup

TITLE FREQ:MODECW;CW 6OOMHZ;:FREQ:CW:STEP 100MHZ DO SEQUENCE Sequence 2 Setup The following sequence makes a series of measurements until all 26 CW measurements are made and the loop counter value is equal to zero. This sequence includes: taking data incrementing the source frequencies labeling the screen 1. -

Page 164: Connections For A Conversion Loss Using The Tuned Receiver Mode

../ . . % ..following sequence commands: Start of Sequence MANUALTRG ONPOINT TITLE PERIPHERAL HPIB ADDR PERIPHERAL HPIB ADDR DECR LOOP COUNTER TITLE MEASUREMENT COMPLETED 2. -

Page 165: Example Fixed If Mixer Measurement

S T A R T 1 0 0 . 0 0 0 000 MHZ S T A R T 1 0 0 . 0 0 0 000 MHZ S T O P 1 0 0 . 0 0 0 000 M H Z S T O P 1 0 0 . -

Page 166: Phase Or Group Delay Measurements

= 13 dRm Initialize the analyzer by pressing Q%+. From the front panel of the HP 8753E, set the desired receiver frequency and source output power by pressing: Connect the instruments as shown in Figure 3-17, placing a broadband “calibration” mixer... - Page 167 550 MHz LOW PASS FILTER 10 d8 10 dB REFERENCE CALIBRATION MIXER MIXER CONVERTER EXTERNAL LO SOURCE Figure 3-17. Counections for a Group Delay Measurement 5. To set the frequency offset mode LO frequency from the analyzer, press: 6. To select the converter type and a high-side LO measurement configuration, press: 7.

-

Page 168: Group Delay Measurement Example

8. To make a response error-correction, press: 9. Replace the “calibration” mixer with the device under test. If measuring group delay, set the delay equal to the “calibration” mixer delay (for example -0.6 ns) by pressing: 10. Scale the data for best vertical resolution. SPAN .lOO 000 000 GHz -CENTER .300 000 000 GHz Figure 3-18. -

Page 169: Amplitude And Phase Tracking

Amplitude and Phase Tracking Using the same measurement setup as in “Phase or Group Delay Measurements,” you can determine how well two mixers track each other in terms of amplitude and phase. 1. Repeat steps 1 through 8 of the previous “Group Delay Measurements” section with the following exception: In step 7, select w $&I2 . -

Page 170: Conversion Compression Using The Frequency Offset Mode

Conversion Compression Using the Frequency Offset Mode Conversion compression is a measure of the maximum RF input signal level, where the mixer provides linear operation. The conversion loss is the ratio of the IF output level to the RF input level. -

Page 171: Connections For The First Portion Of Conversion Compression Measurement

Caution connector saver for R CHANNEL IN. NETWORK ANALYZER Figure 3-20. Connections for the First Portion of Conversion Compression Measurement 5. lb view the absolute input power to the analyzer’s R channel, press: 6. To store a trace of the receiver power versus the source power into memory and view data/memory, press: This removes the loss between the output of the mixer and the input to the receiver, and provides a linear power sweep for use in subsequent measurements... -

Page 172: Connections For The Second Portion Of Conversion Compression Measurement

Caution To prevent connector damage, use an adapter (HP part number 1250-1462) as a connector saver for R CHANNEL IN. NETWORK ANALYZER MIXER UNDER TEST 3 dB EXTERNAL LO SOURCE Figure 3-21. Connections for the Second Portion of Conversion Compression Measurement 8. -

Page 173: Measurement Setup Diagram Shown On Analyzer Display

The measurements setup diagram is shown in Figure 3-22. FREO OFFS NETWORK ANALYZER ON off MENU DOWN CONVERTER CONVERTER RF > LO RF < LO VIEW MEASURE RETURN CW. 200 MHz CW: BOO MHz 600 MHz 13 dBm Figure 3-22. Measurement Setup Diagram Shown on Analyzer Display 11. -

Page 174: Example Swept Power Conversion Compression Measurement

Figure 3-23. Example Swept Power Conversion Compression Measurement Making Mixer Measurements... -

Page 175: Isolation Example Measurements

Isolation Example Measurements Isolation is the measure of signal leakage in a mixer. Feedthrough is specificalIy the forward signal leakage to the IF port. High isolation means that the amount of leakage or feedthrough between the mixer’s ports is very small. Isolation measurements do not use the frequency offset mode. -

Page 176: Connections For A Mixer Isolation Measurement

A full 2 port calibration will increase the accuracy of isolation measurements. Note Refer to Chapter 5, “Optinking Measurement Results.” 6. Make the connections as shown in Figure 3-26. NETWORK ANALYZER LOAD Figure 3-26. Connections for a Mixer Isolation Measurement 7. -

Page 177: Rf Feedthrough

Figure 3-27. Example Mixer ID to RF Isolation Measurement RF Feedthrough The procedure and equipment configuration necessary for this measurement are very similar to those above, with the addition of an external source to drive the mixer’s LC port as we measure the mixer’s RF feedthrough. -

Page 178: Connections For A Response Calibration

N E T W O R K A N A L Y Z E R Figure 3-28. Connections for a Response Calibration Make the connections as shown in Figure NETWORK ANALYZER SOURCE Figure 3-29. Connections for a Mixer RF Feedthrough Measurement 8. -

Page 179: Example Mixer Rf Feedthrough Measurement

Figure 3-30. Example Mixer RF Feedthrough Measurement You can measure the IF to RF isolation in a similar manner, but with the following modifications: Use the analyzer source as the IF signal drive. View the leakage signal at the RF port. Making Mixer Measurements 3-37... -

Page 180: Printing, Plotting, And Saving Measurement Results

Printing, Plotting, and Saving Measurement Results This chapter contains instructions for the following tasks: •I Defining a print function Plotting a measurement to disk Outputting plot hles from a PC to a plotter Outputting plot files from a PC to an HPGL compatible printer Plotting Multiple Measurements per page from disk Titling the displayed measurement Aborting a print or plot process... -

Page 181: Where To Look For More Information

Chapter 2, “Making Measurements, n contains step-by-step procedures for making measurements or using particular functions. corresponding HP-IB commands. Chapter 11, “Compatible Peripherals,” lists measurement and system accessories, and other applicable equipment compatible with the analyzers An HP-IB programming overview is also included. -

Page 182: Printing Or Plotting Your Measurement Results

Printing or Plotting Your Measurement Results You can print your measurement results to the following peripherals: printers with parallel interfaces You can plot your measurement results to the following peripherals: HPGL compatible printers with parallel interfaces Refer to the “Compatible Peripherals” chapter for a list of recommended peripherals. All copy coniiguration settings are stored in non-volatile memory. - Page 183 ..<..: ..: : : •I #$!‘#j#@ (for use with the HP DeskJet 540 and DeskJet 85OC) Note If your DeskJet printer does not support the 100 dpi rastg~,,,tg~at and your 3. Select one of the following printer interfaces: a.

-

Page 184: Deiining A Print Function

. Choose :&$& if your printer has a serial (RS-232) interface, and then configure the print ..: . . . ; ..~ : : . . : ~ .., ~ . , . , . : . : . : . function as follows: b. -

Page 185: Printing One Measurement Per Page

If Yim Are Using a Color Printer 2. If you want to modify the print colors, select the print element and then choose an available color. Note You can set all the print elements to black to create a hardcopy in black and white. -

Page 186: Printing Multiple Measurements Per Page

Printing Multiple Measurements Per Page 1. Configure and define the print function, as explained in “Conliguring a Print Function” and “Defining a Print Function” located earlier in this chapter.., _ i..: ..I.::.:. .:::<c ,.,., 4. - Page 188 Enter the HP-IB address of the printer (default is 01), followed by @). the HP-IB bus. c. Press LLocal) and :#N!@&&$ ,,CQ#&&$ if there is an external controller connected to the HP-IB bus. the print function as follows: . . . : ..*.i;l i ..A . . s ..

-

Page 189: If You Are Plotting To A Pen Plotter

Choose ~~~~~~~~~~~~~~. if your plotter has an HP-IB interface, and then conllgure the plot function as follows: a. Enter the HP-IB address of the plotter (default is 05), followed by (ZJ the plot function as follows: until the correct function appears. -

Page 190: If You Are Plotting To A Disk Drive

If You Are Plotting to a Disk Drive Caution Do not mistake the line switch for the disk eject button. See the llgure below. If the line switch is mistakenly pushed, the instrument will be turned off, losing all settings and data that have not been saved. D I S K E J E C T B U T T O N L L I N E S W I T C H ’... -

Page 191: Defining A Plot Function

Defining a Plot Function Note The plot definition is set to default values whenever the power is cycled. However, you can save the plot definition by saving the instrument state. Choosing Display Elements 2. Choose which of the following measurement display elements that you want to appear on your plot: q Choose ~~~~,~~~~~~~~ if you wmt the measurement data trace to appear on your p1ot. -

Page 192: Selecting Pen Numbers And Colors

Note Selecting Pen Numbers and Colors example, press :,~~~~~~~~~~ and then modify the pen number. The pen number selects the color if you are plotting to an HPGLIB compatible color printer. Press Ixl) after each modification. Note The following color assignments are valid for HPGL/Z compatible color printers only. -

Page 193: Selecting Line Types

Selecting Line Types q Select .!!+@!xiA.~ . . . > . . h . . . ~ ...., . . : . : .., . ; : vi ; , , , , , . . ; . . . : . . : : . . + : < . : s . > : . I::.. new line type (see F’igure 4-5), followed by @. -

Page 194: Choosing Scale

Choosing Scale 6. press ~&&&&& mtd the selection appears that you want... . i..i ..; . . ; . ; ..A . . w; ...i. i includes space for all display annotations such as marker values and stimulus values. -

Page 195: Plotting One Measurement Per Page Using A Pen Plotter

Marker Plotting One Measurement Per Page Using a Pen Plotter 1. Configure and define the plot, as explained in “Configuring a Plot Function” and “Defining a Plot Function” located earlier in this chapter. OUTPUT COMPLETED appears. 4-16 Printing, Plotting, and Saving Measurement Results... -

Page 196: Plotting Multiple Measurements Per Page Using A Pen Plotter

Plotting Multiple Measurements Per Page Using a Pen Plotter 1. Configure and dehne the plot, as explained in “Configuring a Plot Function” and “DeGning a Plot Function” located earlier in this chapter. 3. Choose the quadrant where you want your displayed measurement to appear on the hardcopy. - Page 197 Printing, Plotting, and Saving Measurement Results...

-

Page 198: Plotting A Measurement To Disk

Plotting a Measurement to Disk The plot llles that you generate from the analyzer, contain the HPGL representation of the measurement display. The files will not contain any setup or formfeed commands. 1. Configure the analyzer to plot to disk. Press The analyzer assigns the first available default lilename for the displayed directory. - Page 199 However, this program is for use with LIF formatted disks and is written in HP BASIC. To View Plot Files on a PC Plot files can be viewed and manipulated on a PC using a word processor or graphics presentation program.

-

Page 200: Usingamipr0

Using AmiPro 1. Prom the FILE pull-down menu, select IMPORT PICTURE. 2. In the dialog box, change the file Type selection to HPGL. This automatically changes the Note The network analyzer does not use the sutllx *. PIT, so you may want to change the flename filter to * . -

Page 201: Using Freelance

Using Freelance 1. From the FILE pull-down menu, select IMPORT. Set the file type in the dialog box to HGL. Note The network analyzer does not use the sulllx *.HGL, so you may want to change the tllename filter to *. * or some other pattern that will allow you to locate the llles you wish to import. -

Page 202: Outputting Plot Files From A Pc To An Hpgl Compatible Printer

Outputting Plot Files from a PC to an HPGL Compatible Printer To output the plot files to an HPGL compatible printer, you can use the HPGL initialization sequence linked in a series as follows: hpglinit. Step 1. Store the HPGL initialization sequence a hle named exithpgl. -

Page 203: Step 2. Store The Exit Hpgl Mode And Form Feed Sequence

Step 2. Store the exit HPGL mode and form feed sequence. 1. Create a test file by typing in each character as shown in the left hand column of l%ble 4-7. Do not insert spaces or linefeeds. 2. Name the file exithpgl. Command Remark Step 3. -

Page 204: Outputting Multiple Plots To A Siie Page Using A Printer

Outputting Multiple Plots to a Single Page Using a Printer Refer to the “Plotting Multiple Measurements Per Page Using a Disk Drive, n located earlier in this chapter, for the naming conventions for plot files that you want printed on the same page. You can use the following batch file to automate the plot hle printing. -

Page 205: Plotting Multiple Measurements Per Page From Disk

The following procedures show you how to store plot files on a LIF formatted disk. A naming convention is used so you can later run an HP BASIC program on an external controller that will output the flies to the following peripherals:... - Page 206 6. Define the next measurement plot that you will be saving to disk. saved. 8. Press cm) and turn the front panel knob to highlight the name of the hle that you just saved.., i,,;; , , , . , . , . , . , . , . , . , . , , . , , , . . , . , . , , . , _ _ : . x . x ; ; . : .,,i//,,,_,,i,, ; ; : , , , , ; ; , . , ; , : : : : : . ; : . : . ; : . : . : . : . : . ~ ~ , , , , . , . :::>,.- to the B character.

-

Page 207: Plot Quadrants

1. Deilne the plot, as explained in “Defining the Plot Function” located earlier in this chapter. 3. Choose the quadrant where you want your displayed measurement to appear on the hardcopy. The selected quadrant appears in the brackets under S$Ig#IJlJ&. . -

Page 208: Titling The Displayed Measurement

Titling the Displayed Measurement You can create a title that is printed or plotted with your measurement result. 1. press I-) ~$&#@~ /&&$ to access the title menu..: ; : : . . . A : ..i ..: . ~ ..; ; ; ; ; . . . 3. -

Page 209: Abortingaprintorplotprocess

You can set a clock, and then activate it, if you want the time and date to appear on your hardcopies......,.. ;..: Aborting a Print or Plot Process 1. - Page 210 3. Repeat the previous two steps until you have created hardcopies for all the desired pages of listed values. If you are printing the list of measurement data points, each page contains 30 lines of data. The number of pages is determined by the number of measurement points that you have selected under the LMenu) key.

-

Page 211: Solving Problems With Printing Or Plotting

Make sure that the analyzer address setting for the peripheral corresponds to the actual HP-IB address of the peripheral. The procedure is explained earlier in this chapter. Make sure that the analyzer is in system controller mode, by pressing m the analyzer must be in the pass control mode. -

Page 212: Saving And Recalling Instrument States

Saving and Recalling Instrument States Places Where Ybu Can Save analyzer internal memory floppy disk using the analyzer’s internal disk drive floppy disk using an external disk drive What You Can Save to the Analyzer’s Internal Memory The number of registers that the analyzer allows you to save depends on the size of associated error-correction sets, and memory traces. -

Page 213: What You Can Save To A Computer

Instrument states can be saved to and recalled from an external computer (system controller) using HP-IB mnemonics. For more information about the specific analyzer settings that can be saved, refer to the output commands located in the “Command Reference” chapter of the HP 8753E Network Analyzer Programmer’s... -

Page 214: Saving An Instrument State

@. where you want to store the instrument state llle. d. Enter the HP-IB address of the peripheral, if the default address is incorrect (default = 00). Follow the entry by pressing @. e. Press 1Local) and select one of the following: . -

Page 215: Saving Measurement Results

The analyzer stores data in arrays along the processing flow of numerical data, from IF detection to display. These arrays are points in the flow path where data is accessible, usually via HP-IB. You can choose from three different arrays which vary in modification flexibility when they are recalled. -

Page 216: Data Processing Flow Diagram

Measurement,” located earlier in this chapter. Choose one of the following disk drives: a. Connect an external disk drive to the analyzer’s HP-IB connector, and coniigure as follows: ... . / ... . . i. i ..~ ..~ ... . ~ ; ; .._ ‘ ; , .., ..; ; z ... A ..A . . . i i / ..A . . . w . - Page 217 Press m and select one of the following: peripheral access operations. q Choose :~~~~~~~~ to allow yowself to control the analyzer Over HP-IB and also ..a allows the analyzer to take or pass control. 4 . press (--) :~~:~~-~~~~~~~~~~ .

-

Page 218: Ascii Data Formats

ASCII Data Formats CITIFile (Common Instrumentation Transfer and Interchange flle) is an ASCII data format that is useful when exchanging data between different computers and instruments. CITIhles are always saved when the ASCII format has been selected as shown below: . - Page 219 The template for component data fiIes is as follows: ! comment line <data line> . . . where indicates that ah following on this Iine is a comment indicates that entries following on this Iine are parameters that are being specified frequency units...

-

Page 220: Re-Saving An Instrument State

Re-Saving an Instrument State If you re-save a Gle, the analyzer overwrites the existing file contents. Note You cannot re-save a file that contains data only. You must create a new file. Press the QD &) keys or the front panel knob to highl&ht the name of the file that you want to delete. -

Page 221: Renamingafile

Renaming a File 2. Choose from the following storage devices: q .~~~~~~~~~ the file that you want to rename. 5. Turn the front panel knob to point to each character of the new filenam~,,,,,p~~ssing an incorrect character. After you have selected all the characters in the new fllename, press Note Renaming ties may also be done by using the optional external keyboard. -

Page 222: Formatting A Disk

If the external disk is a hard disk, make sure that the disk volume number is set correctly. If the disk drive is an older HP 9122, it may not recognize the newer high density disks. Substitute the disk drive. -

Page 223: Optimizing Measurement Results

Optimizing Measurement Results This chapter describes techniques and analyzer functions that help you achieve the best measurement results. The following topics are included in this chapter: Increasing measurement accuracy Interconnecting cables Reference plane and port extensions Measurement error-correction One-port reflection correction Full two-port correction Modifying calibration kit standards Power meter measurement calibration... -

Page 224: Where To Look For More Information

Where to Look for More Information Additional information about many of the topics discussed in this chapter is located in the following areas: measurements or using particular functions. Chapter 4, “Printing, Plotting, and Saving Measurement Results,” contains instructions for saving to disk or to the analyzer internal memory, and printing and plotting displayed measurements. -

Page 225: Frequency Drift

Refer to the HP 8753E Service Guide for the measurement verification procedure. Reference Plane and Port Extensions Use the port extension feature to compensate for the phase shift of an extended measurement reference plane, due to such additions as cables, adapters, and Bxtures, after completing an error-correction procedure (or when there is no active correction). -

Page 226: Measurement Error-Correction

Measurement Error-Correction The accuracy of network analysis is greatly influenced by factors external to the network analyzer. Components of the measurement setup, such as interconnecting cables and adapters, introduce variations in magnitude and phase that can mask the actual response of the device under test. -

Page 227: Error-Correction Stimulus State

Corresponding Errors Carmeted Measurement Transmission or reflection Frequency response. Thru for transmission, open Response measurement when the highest or short for reflection. accuracy is not required. Response & isolation Transmission of high insertion loss Frequency response plus Same as response plus devices or reflection of high return isolation in transmission or isolation standard. -

Page 228: Calibration Standards

Calibration Standards The quality of the error-correction is limited by two factors: (1) the difference between the model of the calibration standards and the actual electrical characteristics of those standards, and (2) the condition of the calibration standards. lb make the highest quality measurement calibration, follow the suggestions below: Inspect the calibration standards Clean the calibration standards,... - Page 229 Note State of the instrument can be yd@.ued so that in@polated ..“..” _ . . . interpolated error correction. Optimizing Measurement Results 5-7...

-

Page 230: Procedures For Error-Correcting Your Measurements

Procedures for Error-Correcting Your Measurements This section has example procedures or information on the following topics: frequency response correction frequency response and isolation correction one-port reflection correction full two-port correction modifying calibration kit standards power meter measurement calibration procedure Note If you are making measurements on uncoupled measurement channels, you must make a correction for each channel. -

Page 231: Frequency Response Error-Corrections

Frequency Response Error-Corrections You can remove the frequency response of the test setup for the following measurements: reflection measurements combined reflection and transmission measurements Response Error-Correction for Reflection Measurements 1. Press w). 2. Select the type of measurement you want to make. If you want to make a reflection measurement on PORT 1 (in the forward direction, Sil), leave the instrument default setting. -

Page 232: Measurement

NETWORK ANALYZER TEST POPT CABLES SHORT OPEN SHORT OPEN FOR S, 1 RESPONSE Figure 5-1. Standard Connections for Response Error-Correction for Reflection Measurement To measure the standard when the displayed trace has settled, press: If the calibration kit you selected has a choice between male and female calibration standards, remember to select the sex that applies to the test port and not the standard. -

Page 233: Response Error-Correction For Transmission Measurements

Response Error-Correction for Transmission Measurements 1. Press LPresetJ. 2. Select the type of measurement you want to make. If you want to make a transmission measurement in the forward direction (&), press: If you want to make a transmission measurement in the reverse direction (&a), press: 3. -

Page 234: Receiver Calibration

Note use an open or short standard for a transmission response correction, Note You can save or store the measurement correction to use for later measurements. Refer to the ‘Printing, Plotting, and Saving Measurement Results” chapter for procedures. 7. This completes the response correction for transmission measurements. You can connect and measure your device under test. - Page 235 Note You can save or store the measurement correction to use for later measurements. Refer to the “Printing, Plotting, and Saving Measurement Results” chapter for procedures. 7. This completes the receiver calibration for transmission measurements. You can connect and measure your device under test. Note The accuracy of the receiver calibration will be nearly the same as the test port power accuracy;...

-

Page 236: Frequency Response And Isolation Error-Corrections

Frequency Response and Isolation Error-Corrections removes frequency response of the test setup removes isolation in transmission measurements You can make a response and isolation correction for the following measurements: combined reflection and transmission measurements Response and Isolation Error-Correction for Reflection Measurements Although you can perform a response and isolation correction for reflection measurements, Hewlett-Packard recommends that you perform an S1l one-port error-correction;... -

Page 237: Standard Connections For A Response And Isolation Error-Correction For Transmission Measurements

NETWORK ANALYZER F O R S,, R E S P O N S E F O R S22 R E S P O N S E SHORT OPEN F O R L O A D LOAD Figure 5-4. Standard Connections for a Response and Isolation Error-Correction for Reflection Measurements 8. -

Page 238: Response And Isolation Error-Correction For Transmission Measurements

Response and Isolation Error-Correction for Transmission Measurements This procedure is intended for measurements that have a measurement range of greater than 1. Press IpresetJ. 2. Select the type of measurement you want to make. If you want to make a transmission measurement in the forward direction (&I), press: If you want to make a transmission measurement in the reverse direction (E&2), press: 3. -

Page 239: Standard Connections For A Response And Isolation Error-Correction For Reflection Measurements

FOR RESPONSE FOR ISOLATION POSSIBLE ADAPTERS LOAD LOAD Figure 5-5. Standard Connections for a Response and Isolation Error-Correction for Transmission Measurements Note If you will be measuring highly reflective devices, such as filters, use the test device, connected to the reference plane and terminated with a load, for the isolation standard. -

Page 240: One-Port Reflection Error-Correction

One-Port Reflection Error-Correction removes source match errors of the test setup You can perform a l-port correction for either an S11 or an S22 measurement. The only difference between the two procedures is the measurement parameter that you select. Note This is the recommended error-correction process for all reflection measurements, when full two-port correction is not used. -

Page 241: Standard Connections For A One Port Reflection Error-Correction

NETWORK ANALYZER OPEN SHORT LOAG OPEN SHORT LOAD FOR S,, FOP Sz2 Figure 5-6. Standard Connections for a One Port Reflection Error-Correction 8. To measure the standard, when the displayed trace has settled, press: Note If the calibration kit that you selected has a choice between male or female calibration standards, remember to select the sex that applies to the test port and not the standard. - Page 242 Note You can save or store the error-correction to use for later measurements. Refer to the “Printing, Plotting, and Saving Measurement Results” chapter for procedures. 14. This completes the one-port correction for reflection measurements. You can connect and measure your device under test. Optimizing Measurement Results...

-

Page 243: Full Two-Port Error-Correction

Full Two-Port Error-Correction removes directivity errors of the test setup in forward and reverse directions removes source match errors of the test setup in forward and reverse directions removes isolation errors of the test setup in forward and reverse directions (optional) removes frequency response of the test setup in forward and reverse directions Note This is the most accurate error-correction procedure. - Page 244 6. To measure the standard, when the displayed trace has settled, press: WAIT -, MEXWFlING CAL STANDARD analyzer displays during the standard measurement. The analyzer underlines the @!?Zl& softkey after it measures the standard. 7. Disconnect the open, and connect a short circuit to PORT 1. 8.

-

Page 246: Trl Error-Correction

The HP 8753E analyzer has the capability of making calibrations using the TRL*/LRM* method. You must have a TRL calibration kit defined and saved in the :$&$%@$.T.. as shown in ....) “Modifying Calibration Kit Standards, n located later in this section. -

Page 247: Trm Error-Correction

Connect a load to PORT 2, and press: Connect the load to PORT 1, and press: You may repeat any of the steps above. There is no requirement to go in the order of steps. When the analyzer detects that you have made all the necessary measurements, the . - Page 248 trace settleq,,),,press the softkey corresponding to the load used. If a sliding load is used, press ~~~~~~~~:: to access the Sliding Load menu. Position the slide and press When all the appropriate load measurements are complete, the load data is measured and Repeat the previous TRM load measurement steps for PORT 2.

- Page 250 Default Standard Type Staadard Number short (m) broadband load sliding load short (f) 5. Press the underlined softkey. For example, if you selected (iJ (xl) in the previous step, Note “type” of standard. 6. This step applies only to the open. Go to the next step if you selected any other standard. analyzer front panel to change the value.

-

Page 251: Definitions