Table of Contents

Advertisement

Quick Links

VF-S

ERIES

S E R V I C E

M A N U A L

TABLE OF CONTENTS

TROUBLESHOOTING

TROUBLESHOOTING

This section is intended for use in determining the solution to a known problem. Solutions given are intended to give the

individual servicing the CNC a pattern to follow in, first, determining the problem’s source and, second, solving the problem.

The troubleshooting tips are organized in this section according to the area of the CNC that may be giving sign of a problem.

(Ex.: Out-of round circles in drilling will be found under the heading General Machine Operation - Accuracy).

If the problem you are experiencing cannot be found under the heading you expect, please try several other possible head-

ings. If the problem is still not found, contact Haas Automation for further details.

BEFORE YOU BEGIN:

USE COMMON SENSE

Many problems are easily overcome by correctly evaluating the situation. All machine operations are composed of a

program, tools, and tooling. You must look at all three before blaming one as the fault area. If a bored hole is chattering

because of an overextended boring bar, don’t expect the machine to correct the fault. Don’t suspect machine accuracy if the

vise bends the part. Don’t claim hole mis-positioning if you don’t first center-drill the hole.

FIND THE PROBLEM FIRST

Many mechanics tear into things before they understand the problem, hoping that it will appear as they go. We know this

from the fact that more than half of all warranty returned parts are in good working order. If the spindle doesn’t turn,

remember that the spindle is connected to the gear box, which is connected to the spindle motor, which is driven by the

Spindle Drive, which is connected to the I/O BOARD, which is driven by the computer. The moral here is don’t replace the

Spindle drive if the belt is broken. Find the problem first; don’t just replace the easiest part to get to.

DON’T TINKER WITH THE MACHINE

There are hundreds of parameters, wires, switches, etc., that you can change in this machine. Don’t start randomly changing

parts and parameters. Remember, there is a good chance that if you change something, you will incorrectly install it or break

something else in the process. Consider for a moment changing the processor’s board. First, you have to download all

Parameters, remove a dozen connectors, replace the board, reload and reconnect, and if you make one mistake or bend one

tiny pin it WON’T WORK. You always need to consider the risk of accidentally damaging the machine anytime you work on

it. It is cheap insurance to double-check a suspect part before physically changing it. The less work you do on the machine

the better.

1

1-15-96

96-8100

HAAS

AUTOMATION, INC.

Advertisement

Table of Contents

Summary of Contents for Haas VF-SERIES

- Page 1 (Ex.: Out-of round circles in drilling will be found under the heading General Machine Operation - Accuracy). If the problem you are experiencing cannot be found under the heading you expect, please try several other possible head- ings. If the problem is still not found, contact Haas Automation for further details. BEFORE YOU BEGIN: USE COMMON SENSE Many problems are easily overcome by correctly evaluating the situation.

- Page 2 Machine can be powered on, but turns off by itself. ´ Machine turns on, keyboard beeps, but no CRT display. ´ Any LED on Microprocessor PCB goes out (except HALT). ´ Machine turns on, CRT works, but no keyboard keys work. 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 3 S E R V I C E M A N U A L TABLE OF CONTENTS TROUBLESHOOTING 1.2 VIBRATION ´ Machine vibrates while jogging the axis with the hand wheel. ´ The machine vibrates excessively in a cut. 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 4 Bored holes do not go straight through the workpiece. ´ Machine bores holes out-of-round. ´ Bored holes are out of round or out of postion. ´ Machine mis-positions holes. ´ Machine leaves large steps when using a shell mill. 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 5 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS TROUBLESHOOTING ´ Boring depth inaccurate (VF-6) 1.4 FINISH ´ Machining yields a poor finish. 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 6 S E R V I C E M A N U A L TROUBLESHOOTING 2. SPINDLE 2.1 NOT TURNING ´ Spindle not turning. NOTE: 2.2 NOISE ´ Excessive noise coming from the spindle head area. Ø Ø Ø Ø 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 7 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS TROUBLESHOOTING 2.3 OVERHEATING NOTE: NOTE: 2.4 STALLING/LOW TORQUE 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 8 Spindle loses correct orientation. Ø 2.7 TOOLS STICKING IN TAPER ´ Tool sticking in the taper causes ATC to be pulled up; accompanied by a popping noise as the tool holder pops out of the spindle taper. NOTE: 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 9 S E R V I C E M A N U A L TABLE OF CONTENTS TROUBLESHOOTING 3. SERV O MOTORS / LEADSCREWS 3.1 NOT OPERATING ´ Servo motor is not functioning. NOTE: 3.2 NOISE NOTE: ´ Servo motor noise. 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 10 VF-S ERIES S E R V I C E M A N U A L TROUBLESHOOTING ´ Lead screw noise. NOTE: Ø ´ Noise in Z - Motion (VF-6) 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 11 3.3 ACCURACY/BACKLASH ´ Poor mill table-positioning accuracy. INITIAL PREPARATION - CHECKING X-AXIS: Fig. 3-1 Dial indicator in position to check X-axis. TOTAL DEVIATION BETWEEN THE DIAL INDICATOR AND THE CONTROL PANEL DISPLAY SHOULD NOT EXCEED .0002. 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 12 M A N U A L TROUBLESHOOTING NOTE: CHECKING Y-AXIS: Fig. 3-2 Dial indicator in position to check Y-axis. TOTAL DEVIATION BETWEEN THE DIAL INDICATOR AND THE CONTROL PANEL DISPLAY SHOULD NOT EXCEED .0002. NOTE: 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 13 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS TROUBLESHOOTING CHECKING Z-AXIS: NOTE: NOTE: Fig. 3-3 Dial indicator in position to check Z-axis. 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 14 Excessive servo motor vibration. 3.5 OVERHEATING ´ Servo motor overheating. 3.6 FOLLOWING ERROR ´ Following error alarms occur on one or more axes sporadically. ´ Z-axis motor overcurrent (VF-6) Ø Ø Ø Ø Ø Ø Ø 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 15 Tool holder sticking in the spindle taper causes the ATC to be pulled up as the spindle head is traveling up; accompanied by a popping noise as the tool holder pops out of the spindle taper. NOTE: ´ During a tool change, ATC appears to be pulled up; no popping noises. 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 16 Shuttle crashes into spindle when a tool change is commanded (tool holder is in the pocket facing the spindle head). NOTE: ´ During a tool change spindle crashes into top of the tool holder after a turret rotation. 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 17 The part or fixture on the mill table crashes into long tooling or into the ATC itself when machining. 4.3 BREAKAGE ´ ATC shuttle is broken off of the holding plate. ´ ATC extractor forks are damaged after breakage. 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 18 VF-S ERIES S E R V I C E M A N U A L TROUBLESHOOTING 4.4 NOISY OPERATION ´ ATC makes noise as the shuttle moves. NOTE: NOTE: DO NOT 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 19 Alarm 113 will be generated. ´ ATC WILL NOT RUN ´ ATC shuttle will not move; shuttle is getting power (Command a tool change and feel for power being applied to the shuttle motor). Ø NOTE: Ø NOTE: 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 20 ATC shuttle will not move; shuttle is not getting power. Ø Ø ´ ATC turret will not rotate; turret motor is getting power. ´ ATC turret will not rotate; turret motor is not getting power. Ø Ø 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 21 5. GEARBOX AND SPINDLE MOTOR NEVER 5.1 NOISE ´ Excessive or unusual noise coming from the gearbox and/or spindle motor. Ø Ø Ø 5.2 GEARS WILL NOT CHANGE ´ Machine will not execute a gear change. NOTE: 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 22 6.1 COOLANT OVERFLOW ´ Coolant pouring out of spindle head covers. ´ Excessive coolant flow out of drain line. ´ Pulsating flow through tool and drain line. 6.2 LOW COOLANT ´ Alarm 151, "Low Thru Spindle Coolant" 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 23 S E R V I C E M A N U A L TABLE OF CONTENTS TROUBLESHOOTING 6.3 COOLANT TIP WEAR ´ Coolant tip is wearing quickly and needs frequent replacement. 6.4 PRE-CHARGE FAILURE ´ Alarm 198, "Precharge Failure" NOTE: 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 24 VF-S ERIES S E R V I C E M A N U A L ALARMS 7. ALARMS Alarm number and text: Possible causes: 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 25 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS ALARMS 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 26 VF-S ERIES S E R V I C E M A N U A L ALARMS 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 27 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS ALARMS 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 28 VF-S ERIES S E R V I C E M A N U A L ALARMS 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 29 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS ALARMS 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 30 VF-S ERIES S E R V I C E M A N U A L ALARMS 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 31 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS ALARMS 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 32 VF-S ERIES S E R V I C E M A N U A L ALARMS 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 33 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS ALARMS Pn.n 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 34 VF-S ERIES S E R V I C E M A N U A L ALARMS M X Y Z A Q 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 35 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS ALARMS B C U V 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 36 VF-S ERIES S E R V I C E M A N U A L ALARMS X Y Z 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 37 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS ALARMS Onnnn 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 38 VF-S ERIES S E R V I C E M A N U A L ALARMS Onnnn 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 39 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS ALARMS 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 40 VF-S ERIES S E R V I C E M A N U A L ALARMS 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 41 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE MECHANICAL SERVICE 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 42 M A N U A L MECHANICAL SERVICE 1. HEAD COVERS REMOVAL / INSTALLATION PLEASE READ THIS SECTION IN ITS ENTIRETY BEFORE ATTEMPTING TO REMOVE OR REPLACE COVERS. REMOVAL - CAUTION! Fig. 1-1 View of VMC head covers. 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 43 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE INSTALLATION - CAUTION! 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 44 2 . TOOL RELEASE PISTON ASSEMBLY PLEASE READ THIS SECTION IN ITS ENTIRETY BEFORE ATTEMPTING TO REPLACE TOOL RELEASE PISTON ASSEMBLY. NOTE: 2.1 REMOVAL Fig. 2-1 Spindle and headstock area shown with covers removed. VF-0 will have no transmission. 96-8100 1-15-96 HAAS AUTOMATION, INC.

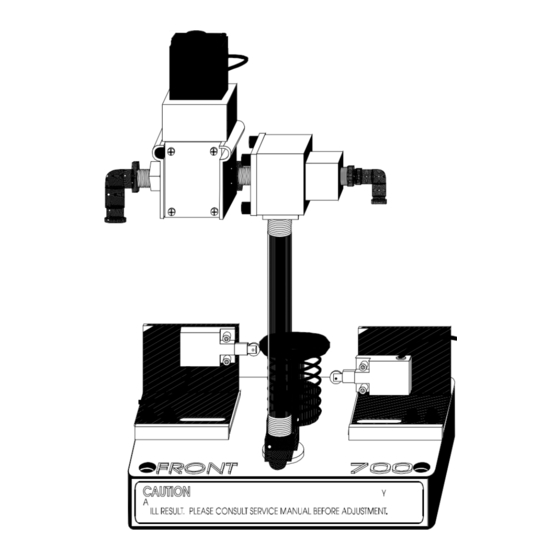

- Page 45 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE Fig. 2-2 Tool release piston with solenoid valve. Fig. 2-3 Mounting location for tool release piston assembly 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 46 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE 2.2 INSTALLATION 2.3 SETTING PRE-CHARGE NOTE: Fig. 2-4 Air pressure regulator adjustment knob. 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 47 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE CAUTION! 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 48 M A N U A L MECHANICAL SERVICE 3. BELT ASSEMBLY PLEASE READ THIS SECTION IN ITS ENTIRETY BEFORE ATTEMPTING TO REPLACE THE DRIVE BELT. 3.1 BELT REMOVAL NOTE: Fig. 3-1 Spindle head casting disconnect points 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 49 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE Fig. 3-2 Head casting area showing belt location NOTE: 3.2 BELT INSTALLATION NOTE: NOTE: NOTE: 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 50 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE 3.3 TENSION ADJUSTMENT NOTE: VF-1, VF-2, VF-3, VF-4: VF-0: 96-8100 1-15-96 HAAS AUTOMATION, INC.

-

Page 51: Spindle Assembly

S E R V I C E M A N U A L MECHANICAL SERVICE 4. SPINDLE ASSEMBLY PLEASE READ THIS SECTION IN ITS ENTIRETY BEFORE ATTEMPTING TO REPLACE SPINDLE. IMPORTANT! NOTE: 4.1 SPINDLE CARTRIDGE REMOVAL NOTE: 1-15-96 96-8100 HAAS AUTOMATION, INC. - Page 52 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE Fig. 4-1 Position wood block under spindle. 4.2 SPINDLE CARTRIDGE INSTALLATION Fig. 4-2 Spindle cartridge. 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 53 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE Fig. 4-3 Underside view of spindle cartridge. Fig. 4-4 Spindle cartridge alignment. Do not force it! CAUTION! 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 54 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE WARNING! NOTE: 4.3 DRAWBAR REPLACEMENT NOTE: REMOVAL - INSTALLATION - CAUTION! NOTE: 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 55 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE CAUTION! 4.4 SPINDLE SWEEP ADJUSTMENT NOTE: 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 56 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE Fig. 4-5 Spindle sweep area. 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 57 MACHINED ALUMINUM BLOCK (2" x 4" x 4") 6" FLEXIBLE RULER or .020" SHIM 1" DIA. PIPE (APPROX. 1' LONG) 5.1 TOOL CLAMP/UNCLAMP SWITCH ADJUSTMENT - INITIAL PREPARATION Fig. 5-1 Placement of aluminum block under spindle. NOTE: 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 58 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE CAUTION! 5.2 SETTING DRAWBAR HEIGHT 5.3 SHIM WASHERS NOTE: Fig. 5-2 Tool release piston assembly 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 59 M A N U A L MECHANICAL SERVICE 5.4 ADJUSTMENT OF SWITCHES - LOWER (UNCLAMP) SWITCH Fig. 5-3 Tool release piston assembly. THIS ADJUSTMENT IS VERY IMPORTANT FOR PROPER TOOL CHANGER OPERATION, AND MUST BE PROPERLY SET! 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 60 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE UPPER (CLAMP) SWITCH - CAUTION! Fig. 5-4 Placement of shim before checking switch adjustment. Ø Ø 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 61 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE Fig. 5-5 Push piston down to hold shim in place. 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 62 M A N U A L MECHANICAL SERVICE 6. SPINDLE ORIENTATION PLEASE READ THIS SECTION IN ITS ENTIRETY BEFORE ATTEMPTING TO ORIENT THE SPINDLE. 6.1 SPINDLE ORIENTATION Fig. 6-1 Top view of spindle orientation components. 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 63 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE Fig. 6-2 VF-0 motor with orient ring location. NOTE: NOTE: 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 64 M A N U A L MECHANICAL SERVICE 7. SETTING PARAMETER 64 (TOOL CHANGE OFFSET) PLEASE READ THIS SECTION IN ITS ENTIRETY BEFORE ATTEMPTING TO SET PARAMETER 64. NOTE: Fig. 7-1 Checking tool offset reference. 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 65 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE Fig.7-2 Screen showing calculator. NOTE: 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 66 S E R V I C E M A N U A L MECHANICAL SERVICE 8. SPINDLE MOTOR & TRANSMISSION PLEASE READ THIS SECTION IN ITS ENTIRETY BEFORE ATTEMPTING TO REMOVE OR REPLACE TRANSMISSION. NOTE: 8.1 MOTOR REMOVAL (VF-0) NOTE: 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 67 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE Figure 8-1 VF-0 with lifting eyeholes. 8.2 INSTALLATION (VF-0) NOTE: 8.3 HOIST PRE-ASSEMBLY 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 68 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE Fig. 8-2 Support base/mast support assembly. Fig. 8-3 Exploded view of boom modification plate components. 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 69 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE Fig. 8-4 Mounting cable guide and pulley wheel to boom. NOTE: 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 70 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE Fig. 8-5 View of transmission lift fixture. 8.4 TRANSMISSION REMOVAL NOTE: 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 71 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE Fig. 8-6 Solenoid bracket with all lines connected. CAUTION! Fig. 8-7 Support base/mast support assembly location. 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 72 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE Fig. 8-8 Mounting boom assembly to mast. Fig. 8-9 Fully assembled hoist in position 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 73 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE Fig. 8-10 Lifting position for VF-1 through 4. 8.5 TRANSMISSION INSTALLATION Ø Ø Ø NOTE: 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 74 Ø NOTE: NOTE: 9. AXIS MOTOR REMOVAL / INSTALLATION READ THIS SECTION IN PLEASE ITS ENTIRETY BEFORE ATTEMPTING TO REMOVE OR REPLACE THE MOTORS. 9.1 X-AXIS MOTOR REMOVAL - Fig. 9-1 X-axis motor and components. 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 75 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE INSTALLATION - Fig. 9-2 Motor coupling components. 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 76 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE 9.2 Y-AXIS MOTOR REMOVAL - Fig. 9-3 Y-axis motor and components. REMOVING OILER AND AIR REGULATOR PANEL - 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 77 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE CAUTION! Fig. 9-4 Lubricator/air regulator panel. INSTALLATION - 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 78 S E R V I C E M A N U A L MECHANICAL SERVICE 9.3 Z-AXIS MOTOR REMOVAL - ALWAYS BLOCK THE HYDRAULIC CYLINDER WITH SHAFT STOP BLOCK BEFORE SERVICING ANY Z-AXIS COMPONENTS. NOTE: 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 79 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 80 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE Fig. 9-5 Z-axis motor and components 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 81 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE Fig. 9-6 Z-axis motor and components for machines equipped with hydraulic counterbalance. INSTALLATION - 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 82 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE 9.4 COUPLING REPLACEMENT NOTE: NOTE: Fig. 9-7 Motor coupling. 10. LEAD SCREW REMOVAL AND INSTALLATION 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 83 PLEASE READ THIS SECTION IN ITS ENTIRETY BEFORE ATTEMPTING TO REMOVE OR REPLACE THE LEAD SCREWS. IMPORTANT NOTICE ! ! ! TOOLS REQUIRED: SPANNER WRENCH 2" x 4" WOOD BLOCK (21"-23 ½" L) PRE-LOAD FIXTURE BLUE LOCTITE 10.1 X-AXIS LEAD SCREW REMOVAL - Fig. 10-1 X-axis lead screw and components. 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 84 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE Fig. 10-2 Lead screw assembly. NOTE: CAUTION: INSTALLATION - CAUTION: 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 85 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE Fig. 10-3 Install lead screw from right side. Fig. 10-4 Bearing sleeve mounting location. ® CAUTION: 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 86 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE Ø Ø Ø Ø 10.2 Y-AXIS LEAD SCREW REMOVAL - Fig. 10-5 Y-axis lead screw and components 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 87 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE CAUTION: Fig. 10-6 Pull lead screw forward around bearing support,... 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 88 ...push back into the machine, then pull out forward. INSTALLATION - CAUTION! NOTE: DO NOT SKIP STEPS 7-10. THESE STEPS ENSURE THE LEAD SCREW IS INSTALLED AND RUNS PARALLEL AND FLAT TO THE LINEAR GUIDES AND THE SADDLE. Ø 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 89 10.3 Z-AXIS LEAD SCREW REMOVAL - WARNING! ALWAYS BLOCK THE HYDRAULIC CYLINDER WITH SHAFT STOP BLOCK. DO NOT MOVE THE SPINDLE DURING LEAD SCREW SERVICE. USE EXTREME CAUTION! DO NOT DAMAGE THE THREADS ON THE LEAD SCREW. 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 90 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE Fig. 10-7 Z-axis lead screw and components. INSTALLATION - 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 91 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE CAUTION: Fig. 10-8 Reinstalling the lead screw. NOTE: 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 92 11. BEARING SLEEVE REMOVAL AND INSTALLATION Please read this section in its entirety before attempting to remove or replace the bearing sleeve. TOOLS REQUIRED: SPANNER WRENCH WOOD BLOCK (16" L) PRE-LOAD FIXTURE 11.1 X-AXIS BEARING SLEEVE REMOVAL - 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 93 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE Fig. 11-1 X-axis lead screw and components. NOTE: CAUTION! INSTALLATION - CAUTION! 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 94 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE Fig 11-2 Lead screw assembly NOTE: Ø Ø Ø Ø 11.2 Y-AXIS BEARING SLEEVE REMOVAL - 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 95 S E R V I C E M A N U A L MECHANICAL SERVICE CAUTION: INSTALLATION - NOTE: 11.3 Z-AXIS BEARING SLEEVE REMOVAL - WARNING! ALWAYS BLOCK THE HYDRAULIC CYLINDER WITH SHAFT SROP BLOCK BEFORE SERVICING ANY Z-AXIS COMPONENTS. 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 96 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE NOTE: Fig. 11-3 Z-axis bearing sleeve. NOTE: 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 97 M A N U A L MECHANICAL SERVICE CAUTION! INSTALLATION - CAUTION! NOTE: 12. AUTOMATIC TOOL CHANGER TOOLS REQUIRED: ½" DRIVE RATCHET HYDRAULIC JACK 10" EXTENSION (½" DRIVE) DIAL CALIPER 1-2-3 BLOCK CARDBOARD LEVEL, STARRET #98 TWO-JAW PULLER 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 98 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE 12.1 CARRIAGE CASTING REPLACEMENT NOTE: NOTE: NOTE: 12.2 ROLLER BOLT REPLACEMENT CAUTION! NOTE: 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 99 ERIES S E R V I C E M A N U A L MECHANICAL SERVICE 12.3 AUTOMATIC TOOL CHANGER (ATC) ALIGNMENT NOTE: Fig. 12-1 Underside showing centering measurements. NOTE: 12.4 SHUTTLE STROKE ADJUSTMENT - 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 100 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE Fig. 12-2 Automatic Tool Changer - Mechanical Assembly (Side View) 12.5 EXTRACTOR FORK REPLACEMENT NOTE: NOTE 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 101 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE Fig. 12-3 Automatic Tool Changer - Mechanical Assembly (Top View) DO NOT OVER-TORQUE! 12.6 SLIDING COVER REPLACEMENT NOTE: 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 102 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE NOTE: 12.7 SHUTTLE MOTOR REMOVAL- Fig. 12-4 Wiring harness for shuttle motor. 12.8 SHUTTLE MOTOR INSTALLATION - 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 103 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE Fig. 12-5 Front view of holding plate showing FHCS location. ® ® 12.9 TURRET MOTOR REMOVAL - 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 104 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE Fig. 12-6 Carriage casting with cover removed. NOTE: INSTALLATION - 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 105 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 106 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE Fig. 12-7 Required spacing for Geneva driver. 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 107 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE NOTE: 12.10 GENEVA STAR REPLACEMENT NOTE: 12.11 ATC TRAP DOOR REPLACEMENT NOTE: 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 108 S E R V I C E M A N U A L MECHANICAL SERVICE 13. GRID OFFSET CALCULATION PLEASE READ THIS SECTION IN ITS ENTIRETY BEFORE ATTEMPTING TO SET THE GRID OFFSET. GUIDELINES - SETTING THE OFFSET - NOTE: 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 109 14. ENCLOSURE REPLACEMENT PLEASE READ THIS SECTION IN ITS ENTIRETY BEFORE ATTEMPTING TO REPLACE THE DOORS OR WINDOWS. TOOLS REQUIRED: TRIM INSTALLATION TOOL (DULL-EDGED KNIFE OR CAULKING SPATULA) 14.1 DOOR REPLACEMENT CAUTION! REMOVAL - INSTALLATION - 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 110 S E R V I C E M A N U A L MECHANICAL SERVICE Ø Ø Fig. 14-1 Roller/roller guide assembly DOOR ADJUSTMENTS - Ø Ø Ø Fig. 14-2 View of vertical gap between front doors. Ø 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 111 M A N U A L MECHANICAL SERVICE Fig. 14-3 View of gap between front of door and front panel flange. SWITCH ADJUSTMENT - Ø NOTE: Ø 14.2 WINDOW REPLACEMENT REMOVAL - Fig. 14-4 Cross-section of window seal. 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 112 Pressure tank with manifold assembly, prefilled with (2) Quarts DTE-25 Hydraulic Oil. Hydraulic cylinder with hose attached (if necessary). 15.1 HYDRAULIC TANK REPLACEMENT REMOVAL - CAUTION! NOTE: DO NOT LOWER SPINDLE ONTO BLOCK. NOTE: INSTALLATION - 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 113 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE Ø NOTE: Ø Ø 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 114 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE Fig. 15-1 Hydraulic Counterbalance view. NOTE: 15.2 HYDRAULIC CYLINDER REPLACEMENT Removal - NOTE: INSTALLATION NOTE: 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 115 S E R V I C E M A N U A L MECHANICAL SERVICE DO NOT power up the machine Fig. 15-2 Hydraulic Cylinder Rod Installation. G28, G54, Z-14. 50% Rapid NOTE: Ø Ø Ø 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 116 16. THROUGH THE SPINDLE COOLANT SYSTEM TOOLS REQUIRED: 0-15 PSI gauge 0-160 PSI gauge 16.1 TOOL RELEASE PISTON ASSEMBLY - TSC PLEASE READ THIS SECTION IN ITS ENTIRETY BEFORE ATTEMPTING TO REPLACE TOOL RELEASE PISTON ASSEMBLY. REMOVAL- INSTALLATION- NOTE: 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 117 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE NOTE: NOTE: 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 118 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 119 VF-S ERIES S E R V I C E M A N U A L MECHANICAL SERVICE 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 120 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS ELECTRICAL SERVICE ELECTRICAL SERVICE 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 121 M A N U A L ELECTRICAL SERVICE 1. SOLENOIDS PLEASE READ THIS SECTION IN ITS ENTIRETY BEFORE ATTEMPTING TO REPLACE ANY SOLENOID ASSEM- BLIES. 1.1 AIR SOLENOID ASSEMBLY REMOVAL: Fig. 1-1 Air solenoid assembly. 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 122 S E R V I C E M A N U A L TABLE OF CONTENTS ELECTRICAL SERVICE INSTALLATION: 1.2 TOOL RELEASE PISTON ASSEMBLY AIR SOLENOID Fig. 1-2 Tool release piston assembly with air solenoid assembly. 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 123 S E R V I C E M A N U A L ELECTRICAL SERVICE 1.3 SPINDLE LUBE AIR SOLENOID Fig. 1-3 Front side of lube/air panel. Fig. 1-4 Top view of spindle lube/air solenoid assembly. 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 124 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS ELECTRICAL SERVICE Fig. 1-5 Top view of spindle lube/air solenoid assembly. 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 125 M A N U A L ELECTRICAL SERVICE 2. LINE VOLTAGE ADJUSTMENTS PLEASE READ THIS SECTION IN ITS ENTIRETY BEFORE ATTEMPTING TO ADJUST THE LINE VOLTAGE. TOOLS REQUIRED: LARGE FLAT TIP SCREWDRIVER DIGITAL VOLTMETER ADJUSTING VOLTAGE NOTE: CAUTION! WARNING! 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 126 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS ELECTRICAL SERVICE Fig. 2-1 Power lines; hookup location. NOTE: NOTE: Fig. 2-2 Transformer connections. CAUTION! 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 127 401 to 425 left center 452 to 480 left side 244 to 260 left side Fig. 2-3 Transformers with 195-210V (left) and 452-480V( right) range. Fig. 2-4 Measure voltage here. problems, call the factory. Ø 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 128 PLEASE READ THIS SECTION IN ITS ENTIRETY BEFORE ATTEMPTING TO REPLACE ANY FUSES. 3.1 OVERVOLTAGE FUSES WARNING! Fig. 3-1 Unscrew the three screws to open the cabinet door. (Newer control cabninets may require a key) CAUTION! 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 129 VF-S ERIES S E R V I C E M A N U A L ELECTRICAL SERVICE 3.2 OPERATOR'S LAMP FUSE Fig. 3-3 Power supply board; fuse locations. 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 130 M A N U A L TABLE OF CONTENTS ELECTRICAL SERVICE 3.3 SERVO DRIVER & SDIST FUSES FUSE FUSES AXIS AXIS AXIS AXIS R15 R11 F1 & F2 FUSE FUSES Fig 3-4 Servo Drive Assembly; fuse locations 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 131 M A N U A L ELECTRICAL SERVICE 4. PCB REPLACEMENT PLEASE READ THIS SECTION IN ITS ENTIRETY BEFORE ATTEMPTING TO REPLACE ANY PCB 'S. 4.1 MICROPROCESSOR, VIDEO, MOTIF & KEYBOARD NOTE: WARNING! MOTIF BOARD - NOTE: 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 132 690 / P9 X DRIVE SIGNAL 610 / P2 SP ENCODER OUTPUT HOME SENSORS 990/ 1000 / P20 ADDRESS BUSS DATA BUSS 860 / P15 LOW VOLTAGE Fig. 4-1 Motor Interface board. VIDEO BOARD AND KEYBOARD - 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 133 M A N U A L ELECTRICAL SERVICE RS422 FLOPPY DRIVE FLOPPY POWER 700 / P3 KEYBOARD INFO SPARE VIDEO 760 / P13 ADDRESS BUSS P4 DATA BUSS P5 LOW VOLTAGE Fig. 4-2 Video board. NOTE: PROCESSOR BOARD - 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 134 TABLE OF CONTENTS ELECTRICAL SERVICE EXT. BAT. JUMPER HALT SERIAL SERIAL PORT 2 PORT 1 850A ADDRESS BUSS DATA BUSS VOLTAGE Fig. 4-3 Processor board. 4.2 SERVO DRIVER & SDIST WARNING! SDIST BOARD - NOTE: 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 135 Z DRIVER LOW VOLTAGE 590 / P3 REGEN 920 / P10 RESISTORS A DRIVER LOW VOLTAGE 600 / P4 860A / P5 12VDC FAN / P7 Fig. 4-4 SDIST board. NOTE: SERVO DRIVER BOARDS - 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 136 X-610 / P3 Z-590 / P1 Y-620 / P3 A-600 / P1 DRIVE SIGNAL Z-630 / P3 A-640 / P3 AXIS AXIS AXIS AXIS DRIVE MOTOR (SIDE VIEW) Fig. 4-5 Servo DRIVER boards. NOTE: 4.3 I/O BOARD 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 137 SP M FAN 319/ K210/ K111/ 200/ RED/GRN 140/ HTC/ 230VAC FOR / 160 CHIP CONVEYOR COOLANT SPIGOT MOTOR CHIP CONVEYOR MOTOR Fig. 4-6 I/O board. 4.4 POWER & LOW VOLTAGE SUPPLY POWER BOARD - 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 138 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS ELECTRICAL SERVICE NOTE: 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 139 SERIAL PORT 2 (-12V) 860A/P17 910/P7 800A/P14 70/P15 12VAC/OP LAMP 230VAC/K1 CONTACTORS SPARE 115VAC OUT 115VAC CB/SOLENOID 230VAC/COOLANT PUMP +12V OP LAMP TO SWITCH I/O +12V 115VAC/T1 Fig. 4-7 Power Distribution (POWER) board. LOW VOLTAGE POWER SUPPLY - 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 140 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS ELECTRICAL SERVICE 4.5 RS-232 DB25 NOTE: Fig. 4-8 RS-232 DB25 board. 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 141 S E R V I C E M A N U A L ELECTRICAL SERVICE 5. FRONT PANEL PLEASE READ THIS SECTION IN ITS ENTIRETY BEFORE ATTEMPTING TO REPLACE ANY COMPONENT OF THE CONTROL PANEL. 5.1 CRT ASSEMBLY REPLACEMENT CAUTION! 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 142 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS ELECTRICAL SERVICE Fig. 5-1 Interior of control panel (rear). 5.2 JOG HANDLE REPLACEMENT 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 143 VF-S ERIES S E R V I C E M A N U A L ELECTRICAL SERVICE Fig. 5-2 Jog handle encoder. Fig. 5-3 Jog Handle removal 5.3 SWITCH REPLACEMENT NOTE: 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 144 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS ELECTRICAL SERVICE NOTE: 5.4 SPINDLE LOAD METER REPLACEMENT 5.5 KEYPAD REPLACEMENT 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 145 VF-S ERIES S E R V I C E M A N U A L ELECTRICAL SERVICE Fig. 5-4 Keypad installation. 4.6 KEYBOARD INTERFACE 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 146 KEYBOARD PCB TO KEYBOARD 1010/ 730/ SPEAKER METER START/HOLD METER ADJUST Fig. 5-5 Keyboard Interface 6. SPINDLE ENCODER REPLACEMENT PLEASE READ THIS SECTION IN ITS ENTIRETY BEFORE ATTEMPTING TO REMOVE OR REPLACE ENCODER. REMOVAL - 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 147 VF-S ERIES S E R V I C E M A N U A L ELECTRICAL SERVICE INSTALLATION - Fig. 6-1 Spindle encoder installation (VF-1/VF-2). 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 148 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS ELECTRICAL SERVICE 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 149 VF-S ERIES S E R V I C E M A N U A L TECHNICAL REFERENCE TECHNICAL REFERENCE SECTION 96-8100 1-15-96...

- Page 150 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS TECHNICAL REFERENCE 1. TOOL CHANGER 1 4 7 1-15-96 96-8100...

- Page 151 VF-S ERIES S E R V I C E M A N U A L TECHNICAL REFERENCE 1.1 TOOL CHANGER LUBRICATION 1.2 SHUTTLE IN/OUT MOTOR NOTE: This motor should never be disassembled 1.3 TURRET ROTATION MOTOR NOTE: This motor should never be disassembled. 96-8100 1-15-96...

- Page 152 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS TECHNICAL REFERENCE 2. TOOL CLAMP/UNCLAMP 2.1 TOOL CLAMP/UNCLAMP AIR SOLENOIDS 2.2 TOOL CLAMP/UNCLAMP SENSE SWITCHES 2.3 REMOTE TOOL UNCLAMP SWITCH 1 4 9 1-15-96 96-8100...

- Page 153 VF-S ERIES S E R V I C E M A N U A L TECHNICAL REFERENCE 3. SPINDLE OPERATION 3.1 SPINDLE ORIENTATION 3.2 SPINDLE ORIENTATION LUBRICATION 3.3 SPINDLE ORIENTATION AIR SOLENOID 3.4 SPINDLE ORIENTATION SEQUENCE 96-8100 1-15-96...

- Page 154 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS TECHNICAL REFERENCE 4. SERVOS BRUSH / BRUSHLESS 4.1 SERVO ENCODERS (BRUSH) 4.2 SERVO CHARACTERISTICS (BRUSH) 1 5 1 1-15-96 96-8100...

- Page 155 VF-S ERIES S E R V I C E M A N U A L TECHNICAL REFERENCE 4.3 SERVO DRIVE ASSEMBLY (BRUSH) 4.4 160 VOLT DC POWER SUPPLY (BRUSH) 4.5 SERVO COOLING FAN (BRUSH) 96-8100 1-15-96...

- Page 156 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS TECHNICAL REFERENCE 4.6 SERVO DISTRIBUTION PCB (SDIST) 4.7 SERVO DRIVE PCB’S (DRIVER) NOTE: REFER TO THE PCB AND CABLE LOCATION SECTION FOR BOARD DIAGRAMS. 1 5 3 1-15-96 96-8100...

- Page 157 VF-S ERIES S E R V I C E M A N U A L TECHNICAL REFERENCE 4.8 SERVO ENCODERS (BRUSHLESS) 96-8100 1-15-96...

- Page 158 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS TECHNICAL REFERENCE 4.9 SERVO CHARACTERISTICS (BRUSHLESS) 4.10 SERVO AMPLIFIERS (BRUSHLESS) NOTE: REFER TO PCB AND CABLE LOCATION SECTION FOR BOARD DIAGRAMS. 1 5 5 1-15-96 96-8100...

- Page 159 VF-S ERIES S E R V I C E M A N U A L TECHNICAL REFERENCE 5. INPUT/OUTPUT ASSEMBLY NOTE: REFER TO THE PCB AND CABLE LOCATION SECTION FOR BOARD DIAGRAMS. 96-8100 1-15-96...

- Page 160 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS TECHNICAL REFERENCE 1 5 7 1-15-96 96-8100...

- Page 161 VF-S ERIES S E R V I C E M A N U A L TECHNICAL REFERENCE 6. TWO-SPEED GEAR TRANSMISSION VF-1/2/3/4/6 6.1 GEAR BOX LUBRICATION 6.2 GEAR BOX AIR SOLENOIDS 6.3 GEAR BOX SENSE SWITCHES 6.4 GEAR CHANGE SEQUENCE 96-8100 1-15-96...

-

Page 162: Control Panel

VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS TECHNICAL REFERENCE 7. CONTROL PANEL 7.1 JOG HANDLE 7.2 POWER ON/OFF SWITCHES 7.3 SPINDLE LOAD METER 7.4 EMERGENCY STOP SWITCH 1 5 9 1-15-96 96-8100... - Page 163 VF-S ERIES S E R V I C E M A N U A L TECHNICAL REFERENCE 7.5 KEYBOARD BEEPER 8. MICROPROCESSOR ASSEMBLY 8.1 MICROPROCESSOR PCB (68ECO30) +5V logic power supply is present. (Normally On) HALT Processor halted in catastrophic fault. (Normally Off) Power-on-reset complete.

- Page 164 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS TECHNICAL REFERENCE CRT/VIDEO Initialization complete. (Normally On) Program signature found in memory.(Normally On) Program running without fault exception.(Normally On) 8.2 MEMORY RETENTION BATTERY 8.3 VIDEO KEYBOARD PCB WITH FLOPPY 1 6 1 1-15-96...

- Page 165 VF-S ERIES S E R V I C E M A N U A L TECHNICAL REFERENCE 8.4 MOTOR INTERFACE PCB (MOTIF) NOTE: REFER TO PCB AND CABLE LOCATION SECTION FOR BOARD DIAGRAMS. 8.5 MOTOR CONTROLLER (MOCON) BRUSHLESS NOTE: REFER TO PCB AND CABLE LOCATION SECTION FOR BOARD DIAGRAMS. 96-8100 1-15-96...

- Page 166 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS TECHNICAL REFERENCE 1 6 3 1-15-96 96-8100...

- Page 167 VF-S ERIES S E R V I C E M A N U A L TECHNICAL REFERENCE 9. SPINDLE DRIVE ASSEMBLY 10. RESISTOR ASSEMBLY 10.1 SPINDLE DRIVE REGEN RESISTOR 10.2 SERVO DRIVE REGEN RESISTOR 10.3 OVERHEAT SENSE SWITCH 96-8100 1-15-96...

- Page 168 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS TECHNICAL REFERENCE 11. POWER SUPPLY ASSEMBLY 11.1 MAIN CIRCUIT BREAKER CB1 TO LVPS/P20 FROM LVPS/P19 230VAC/T4 190-260VAC INPUT PRI-SEC/T5 ....290 / P19 -12V 860/P13...

- Page 169 VF-S ERIES S E R V I C E M A N U A L TECHNICAL REFERENCE 11.4 POWER PCB (POWER) 11.5 POWER-UP LOW VOLTAGE CONTROL TRANSFORMER (T5) 11.6 SECONDARY CIRCUIT BREAKERS 96-8100 1-15-96...

- Page 170 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS TECHNICAL REFERENCE 11.7 OPERATOR’S LAMP TRANSFORMER 1 6 7 1-15-96 96-8100...

- Page 171 VF-S ERIES S E R V I C E M A N U A L TECHNICAL REFERENCE 12. POWER TRANSFORMER ASSEMBLY (T1) Fig. 12-1 Polyphase bank transformer. 12.1 PRIMARY CONNECTION TO T1 12.2 VOLTAGE SELECTION TAPS 12.3 SECONDARY CONNECTION TO T1 12.4 OPTIONAL 480 TRANSFORMER 96-8100 1-15-96...

- Page 172 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS TECHNICAL REFERENCE 13. FUSES FUSE NAME TYPE RATING VOLTAGE LOCATION (amps) ½ 250V POWER pcb, upper right ½ 250V “ “ ½ 250V “...

- Page 173 VF-S ERIES S E R V I C E M A N U A L TECHNICAL REFERENCE 14.2 M-FIN DISCRETE INPUT 14.3 TURNING M FUNCTIONS ON AND OFF 15. LUBRICATION PUMP 15.1 LOW LUBRICATION AND LOW PRESSURE SENSE SWITCHES 96-8100 1-15-96...

-

Page 174: Limit Switches

VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS TECHNICAL REFERENCE 16. SWITCHES 16.1 LAMP ON/OFF SWITCH 16.2 DOOR OPEN SENSE SWITCH 16.3 LIMIT SWITCHES NOTE: There are fourteen (14) limit switches located on the VMC, and some are difficult to reach. - Page 175 VF-S ERIES S E R V I C E M A N U A L TECHNICAL REFERENCE DOOR HOLD SWITCHES WHAT CAN GO WRONG WITH LIMIT SWITCHES? TOOL CHANGER POSITION SWITCHES GENEVA WHEEL POSITION MARK 96-8100 1-15-96...

- Page 176 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS TECHNICAL REFERENCE TOOL #1 SENSE SWITCH SHUTTLE IN/OUT SWITCHES TRANSMISSION HIGH/LOW GEAR POSITION SWITCHES NOTE: 1 7 3 1-15-96 96-8100...

- Page 177 VF-S ERIES S E R V I C E M A N U A L TECHNICAL REFERENCE 17. HYDRAULIC COUNTERBALANCE 18. LUBRICATION SYSTEM 19. DIAGNOSTIC DATA POWER FAILURE ALARM 96-8100 1-15-96...

- Page 178 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS TECHNICAL REFERENCE DISCRETE INPUTS Name Description Name Description DISCRETE OUTPUTS Name Description Name Description 1 7 5 1-15-96 96-8100...

- Page 179 VF-S ERIES S E R V I C E M A N U A L TECHNICAL REFERENCE INPUTS 2 Name Description Name Description ANALOG DATA Name Description 96-8100 1-15-96...

- Page 180 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS TECHNICAL REFERENCE 1 7 7 1-15-96 96-8100...

- Page 181 VF-S ERIES S E R V I C E M A N U A L PARAMETERS 20. PARAMETERS PARAMETER LIST Future Option - Not Yet Implemented) 96-8100 1-15-96...

- Page 182 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS PARAMETERS 2000 x 4 x 25.4 / 6 = 33867 20.0 x 33867 = 677340 1-15-96 96-8100...

- Page 183 VF-S ERIES S E R V I C E M A N U A L PARAMETERS 2000 x 4 = 8000 96-8100 1-15-96...

- Page 184 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS PARAMETERS 1-15-96 96-8100...

- Page 185 VF-S ERIES S E R V I C E M A N U A L PARAMETERS 96-8100 1-15-96...

- Page 186 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS PARAMETERS 1-15-96 96-8100...

- Page 187 VF-S ERIES S E R V I C E M A N U A L PARAMETERS 4.6 x 33867 = 155788 96-8100 1-15-96...

- Page 188 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS PARAMETERS 1-15-96 96-8100...

- Page 189 VF-S ERIES S E R V I C E M A N U A L PARAMETERS 1200000 x 0.075 = 90000 steps/second 96-8100 1-15-96...

- Page 190 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS PARAMETERS 1-15-96 96-8100...

- Page 191 VF-S ERIES S E R V I C E M A N U A L PARAMETERS 96-8100 1-15-96...

- Page 192 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS PARAMETERS 1-15-96 96-8100...

- Page 193 VF-S ERIES S E R V I C E M A N U A L PARAMETERS 96-8100 1-15-96...

- Page 194 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS PARAMETERS 1-15-96 96-8100...

- Page 195 VF-S ERIES S E R V I C E M A N U A L PARAMETERS 96-8100 1-15-96...

- Page 196 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS PARAMETERS 4.6 x 33867 = 155788 4.6 x 33867 = 155788 4.6 x 33867 = 155788 4.6 x 33867 = 155788 1-15-96 96-8100...

- Page 197 VF-S ERIES S E R V I C E M A N U A L PARAMETERS 96-8100 1-15-96...

- Page 198 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS PARAMETERS 1-15-96 96-8100...

- Page 199 VF-S ERIES S E R V I C E M A N U A L PARAMETERS 20.1 Lead Screw Compensation 96-8100 1-15-96...

- Page 200 FOR THE VF-SERIES MILL The following is a list of required regular maintenance for the HAAS VF Series Vertical Machining Centers. Listed are the frequency of service, capacities, and type of fluids required. These required specifications must be followed in order to keep your machine in good working order and protect your warranty.

- Page 201 ERIES S E R V I C E M A N U A L ELECTRICAL SERVICE LUBRICATION CHART FOR THE VF-SERIES MILL LOCATION Under the control panel at the rear of Above the spindle head Side of machine the machine DESCRIPTION Piston pump with 30-minute cycle time.

- Page 202 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS CABLE LOCATIONS PCB'S CABLE LOCATIONS BOARD DIAGRAMS 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 203 SERIAL PORT 1 (-12V) 860A/P31 90/P8 800/P30 930/P6 SERIAL PORT 2 (-12V) 860A/P17 910/P7 800A/P14 70/P15 SPARE 12VAC/OP LAMP 230VAC/K1 CONTACTORS 115VAC OUT 115VAC CB/SOLENOID +12V 230VAC/COOLANT PUMP 115VAC/T1 OP LAMP TO SWITCH I/O +12V POWER PCB 32-5010 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 204 èTO: POWER ——- 12VAC/OP LAMP èTO: OPERATORS LAMP ——- 860A +12VDC èTO: POWER ——- ——- 115VAC IN èTO: T1 - SECONDARY ——- ——- 115VAC OUT èTO: POWER ON/OFF 740 POWER ON/OFF èTO: ON/OFF SWITCH ——- 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 205 S E R V I C E M A N U A L CABLE LOCATIONS EXT. BAT. JUMPER HALT SERIAL SERIAL PORT 2 PORT 1 850A ADDRESS BUSS DATA BUSS VOLTAGE MICRO PROCESSOR PCB 32-3090 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 206 POWER SUPPLY PCB ——- EXTERNAL BATTERY è TO: (EXT. BATTERY) ——- PORT 1 8 5 0 SERIAL PORT #1 è TO: SERIAL PORT #1 ——- PORT 2 850A SERIAL PORT #2 è TO: SERIAL PORT #2 ——- 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 207 AUTO OFF COOLANT SPIGOT SW Y160 / P27 Y160 / 300 SP M FAN K210/ 200/ RED/GRN 140/ 319/ K111/ HTC/ 230VAC FOR / 160 CHIP CONVEYOR COOLANT SPIGOT MOTOR CHIP CONVEYOR MOTOR I/O PCB 32-3080 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 208 è TO: 5 3 0 MOTIF PCB è TO: A161 SPARE ——- è TO: 1 8 0 COOLANT TANK ——- è TO: SERVO BRK (EXTERNAL) ——- è TO: ——- RED/GREEN LTS ——- è TO: 940A ——- 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 209 1060 / P13 GND FAULT Z DRIVER LOW VOLTAGE 590 / P3 REGEN 920 / P10 RESISTORS A DRIVER LOW VOLTAGE 600 / P4 860A / P5 12VDC FAN / P7 SERVO DISTRIBUTION PCB 32-5020 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 210 è TO: 9 7 0 OV V I/O PCB 1060 GND FAULT è T O : I/O PCB 115VAC FROM T1 è T O : ——- 160VDC TO AMPS. è T O : SERVO DRIVERS 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 211 Y-580 / P1 X-610 / P3 Z-590 / P1 Y-620 / P3 A-600 / P1 DRIVE SIGNAL Z-630 / P3 A-640 / P3 AXIS AXIS AXIS AXIS DRIVE MOTOR (SIDE VIEW) SERVO DRIVER PCB’s 32-4070 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 212 A AXIS è TO: 6 0 0 LOW VOLTAGE SDIST PCB è TO: ——- MOTOR DRIVE A SERVO MOTOR ——- è TO: 6 4 0 X DRIVE SIGNAL MOTIF PCB è TO: ——- +160VDC SDIST PCB 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 213 620 / P3 SIGNAL 690 / P9 A ENCODER OUTPUT X DRIVE SIGNAL 610 / P2 SP ENCODER OUTPUT HOME SENSORS 990/ 1000 / P20 ADDRESS BUSS DATA BUSS 860 / P15 LOW VOLTAGE MOTIF PCB 32-4020 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 214 SP. ENCODER OUTPUT SPINDLE ENCODER ——- è TO: 1020 SP. TEMP SPINDLE ——- è TO: 730B SP. DRIVE LOAD SPINDLE DRIVE ——- è TO: 9 9 0 HOME SENSORS X, Y & Z LIMIT SW. ——- 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 215 M A N U A L CABLE LOCATIONS RS422 FLOPPY DRIVE FLOPPY POWER 700 / P3 KEYBOARD INFO SPARE VIDEO 760 / P13 ADDRESS BUSS P4 DATA BUSS P5 LOW VOLTAGE VIDEO & KEYBOARD PCB 32-3201 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 216 FLOPPY DR. POWER FLOPPY DRIVE ——- è TO: ——- SPARE è TO: ——- FLOPPY DR. SIGNAL FLOPPY DRIVE ——- è TO: 7 6 0 VIDEO SIGNAL ——- è TO: ——- RS422 B è TO: ——- RS422 A 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 217 A ENCODER OUTPUT 690 / P9 Y DRIVE 620 / P3 SIGNAL B ENCODER OUTPUT 690B X DRIVE 610 / P2 SIGNAL 860 / P15 ADDRESS BUSS DATA BUSS LOW VOLTAGE MOCON PCB 32-4023 C 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 218 SP. ENCODER OUTPUT SPINDLE ENCODER ——- è TO: 9 8 0 VOLTAGE MONITOR è TO: 730B SP. DRIVE LOAD SPINDLE DRIVE ——- è TO: 9 9 0 HOME SENSORS X, Y & Z LIMIT ——- 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 219 M A N U A L CABLE LOCATIONS SERVO DRIVE SIGNAL (FROM MOCON) 12V FAIL FAULT PWR ON LOW VOLTAGE (INPUT) CAUTION HIGH VOLTAGE HAAS BRUSHLESS SERVO AMPLIFIER TO SERVO MOTOR - HV 320VDC (FROM SPINDLE DRIVE) FUSE OPEN BRUSHLESS SERVO AMPLIFIER...

- Page 220 L. V. POWER SUPPLY ——- è TO: TB A, B, C ——- MOTOR DRIVE X SERVO MOTOR ——- è TO: 6 4 0 X DRIVE SIGNAL MOCON PCB è TO: TB -HV +HV ——- 320VDC SPINDLE DRIVE ——- 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 221 VF-S ERIES S E R V I C E M A N U A L CABLE LOCATIONS CABLE LOCATION DIAGRAM 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 222 VF-S ERIES S E R V I C E M A N U A L TABLE OF CONTENTS CABLE LOCATIONS 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 223 115 VAC FROM TRANSFORMER T1 91/U STEPPED-DOWN 115 VAC (FROM XFRMER T1) #12 92/V STEPPED-DOWN 115 VAC (FROM XFRMER T1) #12 93/W STEPPED-DOWN 115 VAC (FROM XFRMER T1) #12 115 VAC TO CRT - SHIELD +2 LEG 1 #16 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 224 PHASE B 230VAC PHASE C 230VAC AUTO OFF FUNCTION - SHIELD +2 RELAY 1-7 COMMON (C7) ; AUTO OFF RELAY 1-7 N.O. COOLANT SPIGOT DETENT SWITCH SIGNAL COMMON UNCLAMP FROM SPINDLE HEAD TO IOASM INPUT 25 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 225 LEG 1 115VAC FUSED AT 3 A #18 LEG 2 115VAC FUSED AT 3 A #18 310 SOLENOIDS OUTPUT TO HORIZONTAL PALLET CHANGER 115VAC COMMON UNSCREW SCREW DB DOWN PALLET UP PALLET CW PALLET CCW 320 SWITCH INPUTS FROM HORIZONTAL PALLET CHANGER 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 226 A-AXIS FUSED MOTOR POWER + (P4-E) A-AXIS FUSED MOTOR POWER - (P4-F) OVERTEMP SENSOR FROM SPINDLE MOTOR - SHIELD +2 OVERTEMP WIRE 1 #20 (N.C.) OVERTEMP WIRE 2 #20 RELAY CARD 1 DRIVE CABLE - 16 WIRE RIBBON #24 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 227 Z AXIS DRIVER CONTROL CABLE - SHIELD +6 (SAME AS 611-616) A AXIS DRIVER CONTROL CABLE - SHIELD +6 (SAME AS 611-616) THREE PHASE POWER TO SPINDLE MOTOR - SHIELD +3 LEG 1 OF 230VAC #14 LEG 2 #14 LEG 3 #14 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 228 POWER ON/OFF CABLE TO FRONT PANEL - SHIELD +4 POWER ON SWITCH LEG 1 (24 VAC) #24 POWER ON SWITCH LEG 2 #24 N.O. POWER OFF SWITCH LEG 1 (24 VAC) #24 POWER OFF SWITCH LEG 2 #24 N.C. 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 229 GENEVA MARK (INPUT 5 TO P6-G) #24 (LATHE PART DOOR) TOOL #1 (INPUT 3 TO P6-E) #24 SHUTTLE IN (INPUT 1 TO P6-C) #24 (LATHE TURRET CLAMPED) SHUTTLE OUT (INPUT 2 TO P6-D) #24 (LATHE TURRET UNCLAMPED) OVERHEAT THERMOSTAT - SHIELD +2 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 230 SPINDLE STATUS SWITCHES SHIELD +6 SIGNAL RETURN (D GROUND) (65) #24 HIGH GEAR (INPUT 6) #24 LOW GEAR (INPUT 7) #24 TOOL UNCLAMPED (INPUT 15) #24 TOOL CLAMPED (INPUT 16) #24 SPINDLE LOCKED (INPUT 17) #24 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 231 Y HOME SWITCH (MOTIF P24-3 TO P5-D) #24 (LATHE TAIL STOCK) Z HOME SWITCH (MOTIF P24-4 TO P5-L) #24 HOME SWITCH RETURN (MOTIF P24-1 TO P5-C) #24 1000 SPINDLE ENCODER CABLE - SHIELD +5 (LATHE TAIL STOCK) 96-8100 1-15-96 HAAS AUTOMATION, INC.

- Page 232 DOOR OPEN RETURN (D GROUND) (65) #24 1060 GROUND FAULT DETECTION SENSE INPUT 1061 + INPUT FROM SENSE RESISTOR 1062 - INPUT FROM SENSE RESISTOR 1070 SKIP INPUT FROM SENSOR - SHIELD +2 1071 LOGIC COMMON 1072 SKIP SIGNAL 1-15-96 96-8100 HAAS AUTOMATION, INC.

- Page 233 VF-S ERIES S E R V I C E M A N U A L ASSEMBLY DRAWINGS CHAPTER 25 ASSEMBLY DRAWINGS 96-8100 1-15-96...

- Page 234 VF-S ERIES TABLE OF CONTENTS S E R V I C E M A N U A L ASSEMBLY DRAWINGS VF -1 BASE 1-15-96 96-8100...

- Page 235 VF-S ERIES S E R V I C E M A N U A L ASSEMBLY DRAWINGS VF -1 COLUMN 96-8100 1-15-96...

- Page 236 VF-S ERIES TABLE OF CONTENTS S E R V I C E M A N U A L ASSEMBLY DRAWINGS VF -1 SADDLE 1-15-96 96-8100...

- Page 237 VF-S ERIES S E R V I C E M A N U A L ASSEMBLY DRAWINGS VF -1 LEADSCREW 96-8100 1-15-96...

- Page 238 VF-S ERIES TABLE OF CONTENTS S E R V I C E M A N U A L ASSEMBLY DRAWINGS VF -3 BASE 1-15-96 96-8100...

- Page 239 VF-S ERIES S E R V I C E M A N U A L ASSEMBLY DRAWINGS VF -3 COLUMN 96-8100 1-15-96...

- Page 240 VF-S ERIES TABLE OF CONTENTS S E R V I C E M A N U A L ASSEMBLY DRAWINGS VF-3 SADDLE 1-15-96 96-8100...

- Page 241 VF-S ERIES S E R V I C E M A N U A L ASSEMBLY DRAWINGS VF -3 LEADSCREW 96-8100 1-15-96...

- Page 242 VF-S ERIES TABLE OF CONTENTS S E R V I C E M A N U A L ASSEMBLY DRAWINGS VF -GEARBOX ASSEMBLY 1-15-96 96-8100...

- Page 243 VF-S ERIES S E R V I C E M A N U A L ASSEMBLY DRAWINGS VF -SERIES SPINDLE 7.5K / 10K VF -O SPINDLE 10K 96-8100 1-15-96...

- Page 244 VF-S ERIES TABLE OF CONTENTS S E R V I C E M A N U A L ASSEMBLY DRAWINGS THROUGH THE SPINDLE COOLANT - TOOL RELEASE PISTON 1-15-96 96-8100...

- Page 245 VF-S ERIES S E R V I C E M A N U A L ASSEMBLY DRAWINGS 96-8100 1-15-96...

- Page 246 VF-S ERIES TABLE OF CONTENTS S E R V I C E M A N U A L ASSEMBLY DRAWINGS DESCRIPTION VF-0/1/2 VF-3/4 VF-6/8 30-3250A Fluid Tank Assy, VF-0/1/2/6 30-3251A Fluid Tank Assy, VF-3/4 30-3170A Hydraulic Cylinder Assy, VF-0/1/2 30-3970A Hydraulic Cylinder Assy, VF-3/4 30-3980A Hydraulic Cylinder Assy, VF-6/8...

Need help?

Do you have a question about the VF-SERIES and is the answer not in the manual?

Questions and answers

I **** selling my VF-7 and would like to get the procedures for getting the machine ready for transport.