Table of Contents

Advertisement

Quick Links

USER'S MANUAL

Thank you very much for purchasing this product.

To ensure correct and safe usage with a full understanding of this product's performance, please be

sure to read through this manual completely and store it in a safe location.

Unauthorized copying or transferral, in whole or in part, of this manual is prohibited.

The contents of this operation manual and the specifications of this product are subject to change

without notice.

The operation manual and the product have been prepared and tested as much as possible. If you

find any misprint or error, please inform us.

Roland DG Corp. assumes no responsibility for any direct or indirect loss or damage which may

occur through use of this product, regardless of any failure to perform on the part of this product.

Roland DG Corp. assumes no responsibility for any direct or indirect loss or damage which may

occur with respect to any article made using this product.

Downloaded From ManualsPrinter.com Manuals

Advertisement

Table of Contents

Summary of Contents for Roland SJ-1045EX

- Page 1 Roland DG Corp. assumes no responsibility for any direct or indirect loss or damage which may occur through use of this product, regardless of any failure to perform on the part of this product.

- Page 2 AVIS Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel brouilleur du Canada. ROLAND DG CORPORATION 1-6-4 Shinmiyakoda, Hamamatsu-shi, Shizuoka-ken, JAPAN 431-2103 MODEL NAME : See the MODEL given on the rating plate.

-

Page 3: Table Of Contents

Contents To Ensure Safe Use ........................4 Pour utiliser en toute sécurité ....................10 Important Notes on Handling and Use ................... 16 Printer unit ..........................16 Ink cartridges ........................16 Chapter 1 Introduction ........................17 1-1 Machine Features ..............................18 1-2 Part Names and Functions .......................... - Page 4 Contents 4-2 Setting the Printing Position and Margins ...................... 65 Shifting the Print-start Position to the Rear ................65 Shifting the Printing Position to the Left ................. 65 Changing the Left and Right Margins ..................66 4-3 Optimizing Printing to Match Media Thickness .................... 68 Adjusting Head Height to Match Media Thickness ..............

- Page 5 6-3 Locations of the Power Rating and Serial Number Labels ..............106 6-4 Specifications ............................... 107 Company names and product names are trademarks or registered trademarks of their respective holders. Copyright © 2005 Roland DG Corporation http://www.rolanddg.com/ Downloaded From ManualsPrinter.com Manuals...

-

Page 6: To Ensure Safe Use

To Ensure Safe Use Improper handling or operation of this machine may result in injury or damage to property. Points which must be observed to prevent such injury or damage are described as follows. WARNING CAUTION About Notices Used for instructions intended to alert the user to the risk of death or se- WARNING vere injury should the unit be used improperly. - Page 7 To Ensure Safe Use Ink, cleaning liquid, and discharged fluid are flammable and toxic This machine weighs 600 kg (1350 lb.). Media weighs 100 kg (220 lb.) Warning Labels Warning labels are affixed to make areas of danger immediately clear. The meanings of these labels are as WARNING WARNING CAUTION...

- Page 8 To Ensure Safe Use Danger of electrical short, shock, electrocution, or fire Danger of fire, burns, or toxic gas emissions This machine carries a high current of a maximum of approximately 10 amperes. This can cause situations WARNING that could not occur with low-power equipment; use caution. This machine has high-temperature Never use media that cannot with- WARNING...

- Page 9 To Ensure Safe Use Ink, cleaning liquid, and discharged fluid are flammable and toxic This machine weighs 600 kg (1350 lb.). Media weighs 100 kg (220 lb.) Warning Labels Warning labels are affixed to make areas of danger immediately clear. The meanings of these labels are as WARNING WARNING CAUTION...

- Page 10 To Ensure Safe Use Danger of electrical short, shock, electrocution, or fire Danger of fire, burns, or toxic gas emissions This machine carries a high current of a maximum of approximately 10 amperes. This can cause situations WARNING that could not occur with low-power equipment; use caution. This machine has high-temperature Never use media that cannot with- WARNING...

- Page 11 To Ensure Safe Use Ink, cleaning liquid, and discharged fluid are flammable and toxic This machine weighs 600 kg (1350 lb.). Media weighs 100 kg (220 lb.) Warning Labels Warning labels are affixed to make areas of danger immediately clear. The meanings of these labels are as WARNING WARNING CAUTION...

-

Page 12: Pour Utiliser En Toute Sécurité

Pour utiliser en toute sécurité La manipulation ou l'utilisation inadéquates de cet appareil peuvent causer des blessures ou des dommages matériels. Les précautions à prendre pour prévenir les blessures ou les dommages sont décrites ci-dessous. Avis sur les avertissements Utilisé pour avertir l'utilisateur d'un risque de décès ou de blessure grave ATTENTION en cas de mauvaise utilisation de l'appareil. - Page 13 Cen- flamme nue. pour éviter les chutes et autres acci- (jusqu'à environ 600 kg (1350 lb.), y compris tre de services Roland DG. L'encre est toxique dents. le support et d'autres éléments); il faut une L'encre et les liquides usés sont toxiques.

- Page 14 Pour utiliser en toute sécurité Risque d'incendie, de brûlures ou d'émissions de gaz toxiques Risque de décharge ou de choc électrique, d'électrocution ou d'incendie ATTENTION Cet appareil transmet une tension élevée (maximum d'environ 10 ampères). Cela peut créer des situa- tions qui ne se produisent pas avec de l'équipement à...

- Page 15 Cen- flamme nue. pour éviter les chutes et autres acci- (jusqu'à environ 600 kg (1350 lb.), y compris tre de services Roland DG. L'encre est toxique dents. le support et d'autres éléments); il faut une L'encre et les liquides usés sont toxiques.

- Page 16 Pour utiliser en toute sécurité Risque d'incendie, de brûlures ou d'émissions de gaz toxiques Risque de décharge ou de choc électrique, d'électrocution ou d'incendie ATTENTION Cet appareil transmet une tension élevée (maximum d'environ 10 ampères). Cela peut créer des situa- tions qui ne se produisent pas avec de l'équipement à...

- Page 17 Cen- flamme nue. pour éviter les chutes et autres acci- (jusqu'à environ 600 kg (1350 lb.), y compris tre de services Roland DG. L'encre est toxique dents. le support et d'autres éléments); il faut une L'encre et les liquides usés sont toxiques.

-

Page 18: Important Notes On Handling And Use

Ink cartridges Ink Cartridges Come in Various Types Use a type that is compatible with the printer. Also, be sure to use only genuine items from Roland DG Corp. Never Subject to Impact or Attempt to Disassemble Never drop or shake forcefully. The impact may rupture the internal pouch and cause the ink to leak. -

Page 19: Chapter 1 Introduction

Chapter 1 Introduction Downloaded From ManualsPrinter.com Manuals... -

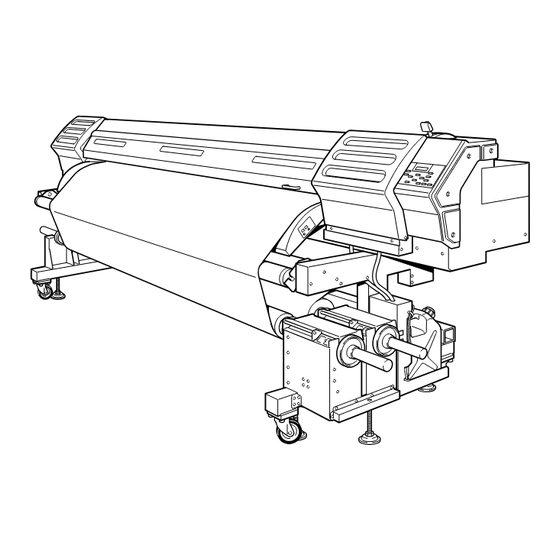

Page 20: Machine Features

1-1 Machine Features This machine is a high-speed, grand-format printer compatible with media having a width of 104 inches. It provides ample image quality for large outdoor signs and the like even in its fastest mode, demonstrating high practicality and productivity. It is provided with the necessary features for high-speed, high-volume printing, including a media feed and take-up systems and media dryer. -

Page 21: Part Names And Functions

1-2 Part Names and Functions Printer Unit and Dryer Front Cover Loading Lever Operation Panel Be sure to close this when you You operate this when you You use this to perform various operations. perform printing. load media. p 21 "Printer Control Panel" Left Side Cover Dryer Right Side Cover... - Page 22 1-2 Part Names and Functions Platen This is the path over which the media passes. A suction Knife Guide fan that keeps the media The media can be cut off from coming loose and a with a straight edge by in- preheater and print heater serting a retractable knife that help fix the ink are...

-

Page 23: Printer Control Panel

1-2 Part Names and Functions Printer Control Panel BUSY Light This lights up during printing and other such operations. SETUP Key/Light You press this when you load media. The light Display Screen This displays various set- comes on when media ting menus and other infor- is loaded and the ma- mation. -

Page 24: Media Take-Up And Feed Systems

1-2 Part Names and Functions Media Take-up and Feed Systems AUTO Switch This makes the direction of rotation for take-up and feed during printing change auto- matically. Power Switch This switches take-up and feed MANUAL Switch units on and off. You use this when you want to operate the take-up and feed units manually. -

Page 25: Chapter 2 Operation

Chapter 2 Operation Downloaded From ManualsPrinter.com Manuals... -

Page 26: Switching The Power On And Off

2-1 Switching the Power On and Off Switching the Power On and Off This machine has four power switches. You switch on all four when using the machine. When you finish printing, you turn off switches 2, 3, and 4 as required. You also flip down the loading lever to the rear of the machine. -

Page 27: The Power-Saving Feature

2-1 Switching the Power On and Off The Power-saving Feature This machine is provided with a power-saving feature that switches to a low-power "sleep mode" when a fixed interval passes with no operation. The factory default for the time after which the machine switches to the sleep mode is 30 minutes. -

Page 28: Loading And Cutting Off Media

2-2 Loading and Cutting Off Media How to Load Media WARNING When loading or moving roll media, be sure to use load-handling equipment such as a lifter and carry out operations with care to prevent falls or other accidents. Some roll media may weigh about 100 kg (220 lb.). Attempting manual lifting operations that tax your strength may cause physical injury. - Page 29 2-2 Loading and Cutting Off Media Load the media onto the roll shaft. Media having an outward curl Press in to fit on securely. Press in to fit on securely. Hexagonal wrench Printed surface Hexagonal wrench (large) (large) Roll media End cap Reinforcement pipe End cap...

- Page 30 2-2 Loading and Cutting Off Media Media having an inward curl Press in to fit on securely. Press in to fit on securely. Hexagonal wrench Hexagonal wrench Printed surface (large) (large) Roll media End cap Reinforcement pipe End cap Spacer Roll shaft 110 to 130 mm (4.3 to 5 in.) Adjust the end cap to a position of 110 to 130 mm...

- Page 31 2-2 Loading and Cutting Off Media Mount the roll shaft in the paper pipe. Press in to fit on securely. Press in to fit on securely. Hexagonal wrench Hexagonal wrench Paper pipe (large) (large) End cap End cap Spacer Roll shaft 75 to 100 mm (3 to 4 in.) Adjust the end cap to a position of 75 to 100 mm (3 to 4 in.).

- Page 32 2-2 Loading and Cutting Off Media Mount the media and paper pipe on the take-up and feed units. Switch off the power. Power switch for feed unit Power switch for take-up unit Open the cover. Mount the roll shaft. Roll media Place on the feed unit (interior).

- Page 33 2-2 Loading and Cutting Off Media Pass the media through the printer and adjust the balance weights. Before you pass the media through, move the balance weights to match the width of the media. Tighten When 1220 to 1372 mm (48 to 54 inches) Loosen When 1373 to 2032 mm...

- Page 34 2-2 Loading and Cutting Off Media Adjust the position of the balance weights to match the width of the media. When 1220 to 1372 mm (48 to 54 inches) When 1373 to 1625 mm (54 to 64 inches) When 1626 to 2032 mm (64 to 80 inches) When 2033 to 2641 mm (80 to 104 inches) Tighten Loosen...

- Page 35 2-2 Loading and Cutting Off Media Fasten the media to the paper pipe. Go to the front of the printer. While holding down the media by hand to keep it from slipping out of place, flip the load- ing lever to the rear. Pull the media to a position next to the pa- per pipe.

- Page 36 2-2 Loading and Cutting Off Media While pulling the media to keep it taut, adjust the position of the end of the media. Position so that the end of the media reaches the paper pipe (that is, so that it reaches a position where it can be taped in place).

- Page 37 2-2 Loading and Cutting Off Media Use adhesive tape to fasten the media securely to the paper pipe. Apply the adhesive tape at intervals of about 20 to 30 cm (10 inches). Take-up with outward curl Paper pipe Adhesive tape 20 to 30 cm (approx.

- Page 38 2-2 Loading and Cutting Off Media Set the orientation for automatic feed and automatic take-up. Make the setting for the AUTO switch on the feed unit. Feed side Media having an in- ward curl Media having an out- ward curl Operate the MANUAL switch to take up the media and pull it taut.

- Page 39 2-2 Loading and Cutting Off Media Make the setting for the AUTO switch on the take-up unit. Take-up side Take-up with inward curl Take-up with outward curl Pull back the loading lever to secure the media in place. Chapter 2 Operation Downloaded From ManualsPrinter.com Manuals...

- Page 40 2-2 Loading and Cutting Off Media Install the media clamps. The media clamps are magnetic. Media clamp Line up the hole with the end of the media. How to install correctly Important Notes on the Media Take-up and Feed Systems Never attempt any operation that pulls the media with excessive force, like the ones shown below.

-

Page 41: How To Cut Off Media

2-2 Loading and Cutting Off Media How to Cut Off Media CAUTION The cutter knife used here is sharp and poses a hazard. Carry out operations with caution to avoid injury. Knife guide Cut off the media along the knife guide, using a retractable knife or the like. Chapter 2 Operation Downloaded From ManualsPrinter.com Manuals... -

Page 42: Settings Of Preheater, Print Heater And Dryer

2-3 Settings of Preheater, Print Heater and Dryer What Are the Preheater, Print Heater and Dryer? This machine is equipped with three devices for heating media. You use these mainly to improve ink adhesion and dry the ink. You can adjust the temperature settings to match the type of media and printing speed. Preheater This device warms the media before printing. -

Page 43: Temperature Settings For The Preheater And Print Heater

2-3 Settings of Preheater, Print Heater and Dryer Temperature Settings for the Preheater and Print Heater Procedure Press PRINT to select the preheater or print heater. to make the setting. Preset Actual Press to enable the setting. temp. temp. W 2600 mm Press Press to go back to the original screen. -

Page 44: General Guide For The Preset Temperatures

2-3 Settings of Preheater, Print Heater and Dryer General Guide for the Preset Temperatures The optimal temperature settings vary according to the type of media, differences in the print mode, and other factors. Use the following as a general guide and adjust accordingly. General Guide for Adjustment Preheater Set this to a temperature that is the same as or lower than the temperature of the print heater. -

Page 45: Starting Printing

2-4 Starting Printing Getting Ready to Receive Data from a Computer When you have finished loading media and making the temperature settings for the heating devices, then follow the steps below. This procedure enables the machine to receive data from the computer and perform printing. Procedure Close the front cover. -

Page 46: Printing Tests And Cleaning

2-4 Starting Printing Printing Tests and Cleaning We recommend performing a printing test to check for problems such as dot drop-out before you carry out actual printing. If problems such as dot drop-out are found, clean the print heads. How to Perform a Printing Test Printing test Hold down for one second or longer. -

Page 47: If Ink Runs Out

2-5 If Ink Runs Out Checking for Remaining Ink Procedure Press MENU INK REMAINING Press several times. Press Press Press W 2600 mm Press to go back to the original screen. SETUP SHEET Amount of ink remaining Much Cartridge slot number Little The display shows an approximate guide to the amount of remaining ink, which may differ somewhat from the actual amount remaining. -

Page 48: If Ink Runs Out

2-5 If Ink Runs Out If Ink Runs Out When ink runs out, a warning beep sounds and printing pauses (unless the default settings have been changed). Pull out the empty cartridge and insert a new one. Printing resumes. Procedure The slot number for the empty cartridge flashes. - Page 49 2-5 If Ink Runs Out Important Notes on Replacing Cartridges Be sure to replace with an item of identical type. Never mix items of different types. Never allow the machine to stand with an ink cartridge removed. The print heads may become clogged. Never insert or remove a partially used ink cartridge.

- Page 50 Downloaded From ManualsPrinter.com Manuals...

-

Page 51: Chapter 3 Maintenance And Adjustment

Chapter 3 Maintenance and Adjustment Downloaded From ManualsPrinter.com Manuals... -

Page 52: Daily Care And Maintenance

3-1 Daily Care and Maintenance Disposing of Discharged Ink The drain bottle collects discharged fluid. Dispose of collected material before the bottle becomes full. Switch off the sub power, then remove the bottle, being careful not to spill its contents. Upper limit Discard before this is reached. -

Page 53: Cleaning

3-1 Daily Care and Maintenance Cleaning Pinch rollers Periodically wipe away any grime. Failure to clean prop- erly may result in the trans- fer of grime to the surface of media. Grit rollers Remove buildup of media and other material using a brush. -

Page 54: Care And Maintenance Of The Print Heads

55 "Cleaning the Heads Using the Cleaning Kit" Note: The print heads are components that wear out. Periodic replacement is required, with the frequency of replace- ment depending on use. Purchase them from your authorized Roland DG Corp. dealer or Roland DG Corp. service center. -

Page 55: When Head Cleaning Is Not Effective

3-2 When Head Cleaning Is Not Effective Performing More Powerful Cleaning When the problems such as dot drop-out are not cleared up by the cleaning you perform by pressing (normal cleaning), try the more forceful "medium cleaning" or the even more forceful "powerful cleaning."... -

Page 56: When Powerful Cleaning Is Not Effective

3-1 Daily Care and Maintenance When Powerful Cleaning Is Not Effective If problems such as dot drop-out persist even after you have performed powerful cleaning several times, then use the cleaning kit to clean the heads. Such cleaning can be effective when carried out periodically, according to the frequency of use. -

Page 57: Cleaning The Heads Using The Cleaning Kit

Such cleaning can be effective when carried out periodically, according to the frequency of use. If you use up the cleaning kit, purchase a new one from your authorized Roland DG Corp. dealer or Roland DG Corp. service center. - Page 58 3-3 Cleaning the Heads Using the Cleaning Kit Change to the print-head manual-cleaning mode. Remove any media from the platen and close the front cover. Switch off the sub power. Hold down and switch on the sub power. Press to choose [CLEANING]. MAINTENANCE CLEANING Press...

- Page 59 3-3 Cleaning the Heads Using the Cleaning Kit Clean using the cleaning stick. Be especially careful to clean away any fibrous dust (lint). Clean in the sequence shown in the figure below. Cleaning stick Be sure to clean using one of the included cleaning sticks. Never touch the nozzle surface.

- Page 60 3-3 Cleaning the Heads Using the Cleaning Kit Reattach the side covers and quit the manual cleaning mode. Attach the left and right side covers. Screws Screws Press After the processing to quit the manual cleaning mode ends, the sub power is switched off. Perform a printing test to verify the results of the procedure.

-

Page 61: Replacing Consumable Parts

3-4 Replacing Consumable Parts Replacing the Wipers The wipers are components that you use when cleaning the print heads. When TIME FOR the screen displays a message like the one shown, it means the item needs to be WIPER REPLACE replaced. - Page 62 3-4 Replacing Consumable Parts Replace the wipers. Use the included tweezers. Detach the old wipers. Detach the hook and pull up and out. Insert the new wipers. Felt surface toward the rear Rubber surface toward the front Attach the hook. Hook Reattach the side cover and quit the wiper replacement mode.

-

Page 63: When Not In Use For A Prolonged Period

3-5 When Not in Use for a Prolonged Period Keep Performing Maintenance Switch On the Power Once a Month Switch on the sub power once a month. When you turn on the power, the machine automatically performs some operations such as those to keep the print heads from drying out. Allowing the machine to stand completely unused for a prolonged period may damage the print heads, so be sure to switch on the power to perform these automatic operations. - Page 64 Downloaded From ManualsPrinter.com Manuals...

-

Page 65: Chapter 4 Feature Reference

Chapter 4 Feature Reference Downloaded From ManualsPrinter.com Manuals... -

Page 66: Pausing Or Canceling Printing

4-1 Pausing or Canceling Printing Canceling Printing Before It Finishes Procedure Press Hold down for one second or longer. Stop sending printing data from the computer. Description pauses printing. Pressing a second time here resumes printing, but a horizontal stripe is pro- duced at the location where printing was stopped. -

Page 67: Setting The Printing Position And Margins

4-2 Setting the Printing Position and Margins Shifting the Print-start Position to the Rear Procedure to move the media. Print-start position Description Moving the media using lets you shift the print-start position to the rear. Never use . Doing so may cause the take-up unit to pull the media with undue force, resulting in an error or malfunction. -

Page 68: Changing The Left And Right Margins

4-2 Setting the Printing Position and Margins Changing the Left and Right Margins Procedure Make the setting for the right margin. Press MENU PRINT AREA Press Press twice. RIGHT EDGE to move the heads. Press to enable the setting for the right side. - Page 69 4-2 Setting the Printing Position and Margins Go back to the original screen. If the front cover is open, then close it. Press W 2600mm to go back to the original screen. Description You can perform this operation only when the light is on.

-

Page 70: Optimizing Printing To Match Media Thickness

4-3 Optimizing Printing to Match Media Thickness Adjusting Head Height to Match Media Thickness Procedure Press MENU HEAD HEIGHT Press several times. Press HEAD HEIGHT MIDDLE MIDDLE Move the lever. Height-adjustment lever Move firmly, until it stops. High Middle (standard) Low (normally not available for use) W 2600 mm... -

Page 71: Correcting For Misalignment In Bidirectional Printing

4-3 Optimizing Printing to Match Media Thickness Correcting for Misalignment in Bidirectional Printing Procedure Switch off the power to the take-up unit (leaving the feed unit on). Take-up unit Print a test pattern. Press MENU ADJUST BI-DIR Press several times. Press ADJUST BI-DIR TEST PRINT... - Page 72 4-3 Optimizing Printing to Match Media Thickness Enter the correction values that you read. Enter correction values H1 through H6 for each setting number (SETTING NO. 1 through 4), for a total of 24 correction values. Press ADJUST BI-DIR SETTING NO.1 Press to select.

- Page 73 4-3 Optimizing Printing to Match Media Thickness Go back to the original screen. Press W 2600mm Press to go back to the original screen. Description The bidirectional-printing mode (in which the heads perform printing during both their outbound pass and return pass) offers the advantage of being fast, but subtle misalignment occurs between the outbound and return passes.

-

Page 74: Saving Bidirectional Correction Values

4-3 Optimizing Printing to Match Media Thickness Saving Bidirectional Correction Values Procedure Press MENU ADJUST BI-DIR Press several times. Press ADJUST BI-DIR SAVE PRESETTING Press several times. Press SAVE PRESETTING 1 to select a presetting number. Press to save. Press W 2600 mm Press to go back to the original screen. -

Page 75: Performing Feed Correction To Alleviate Horizontal Bands And The Like

4-3 Optimizing Printing to Match Media Thickness Performing Feed Correction to Alleviate Horizontal Bands and the Like Procedure Print a test pattern. Press MENU CALIBRATION Press several times. Press CALIBRATION TEST PRINT Press to start printing. Check the test pattern you printed. Gap present Correct results Overlap... - Page 76 4-3 Optimizing Printing to Match Media Thickness Description The movement transfer of media experiences subtle changes due to the thickness of the media and the tempera- ture of the heating devices. When the movement distance becomes discrepant, horizontal stripes are more likely to occur during printing.

-

Page 77: Accommodating Various Kinds Of Media

4-4 Accommodating Various Kinds of Media Using Transparent Media Procedure Set the media type to "transparent." Press MENU SHEET TYPE Press SHEET TYPE OPAQUE CLEAR to select [CLEAR]. Press to enable the setting. Press W 2600 mm Press to go back to the original screen. SETUP SHEET Use the [PRINT AREA] menu to make the settings for the left and right margins. -

Page 78: Speeding Up Printing For Narrow Media

4-4 Accommodating Various Kinds of Media Description You use this when ink dries poorly even when the dryer is used. Larger values produce progressively slower movement of the media, enabling you to extend the drying time accordingly. Printing time takes correspondingly longer. -

Page 79: Preventing Media From Coming Loose

4-4 Accommodating Various Kinds of Media Preventing Media from Coming Loose Procedure Press MENU VACUUM POWER Press several times. Press VACUUM POWER AUTO to set the value. Press to enable the setting. Press W 2600 mm Press to go back to the original screen. SETUP SHEET Description The platen uses suction to grip the media and keep it stable. - Page 80 4-4 Accommodating Various Kinds of Media Default Setting [PERIODIC CL.]: DISABLE Chapter 4 Feature Reference Downloaded From ManualsPrinter.com Manuals...

-

Page 81: Changing How The Printer Operates

4-5 Changing How the Printer Operates Determining What Happens When Ink Runs Out Procedure Press MENU INK CONTROL Press several times. Press twice. EMPTY MODE STOP CONT. to make the setting. Press to enable the setting. Press W 2600 mm Press to go back to the original screen. -

Page 82: Deactivating The Sleep Mode

4-5 Changing How the Printer Operates Deactivating the Sleep Mode Procedure Press MENU SLEEP Press several times. Press SETTING ENABLE DISABLE Press Press to select [DISABLE]. Press to enable the setting. Press W 2600 mm Press to go back to the original screen. SETUP SHEET Default Setting [SETTING]: ENABLE... -

Page 83: Returning All Settings To Their Initial Values

4-5 Changing How the Printer Operates Returning All Settings to Their Initial Values Procedure Press MENU FACTORY DEFAULT Press several times. Press to execute. Printing a System Report Procedure Press MENU SYSTEM REPORT Press several times. Press to start printing. Press W 2600 mm Press... -

Page 84: Changing How The Preheater, Print Heater And Dryer Operate

4-6 Changing How the Preheater, Print Heater and Dryer Operate Switching the Dryer On and Off Procedure Press MENU DRYER Press several times. Press DRYER to make the setting. Press to enable the setting. Press W 2600 mm Press to go back to the original screen. SETUP SHEET Description To operate the dryer, you must switch on both the main power switch for the printer and the main power switch... -

Page 85: Determining How The Preheater, Print Heater, And Dryer Operate

4-6 Changing How the Preheater, Print Heater and Dryer Operate Determining How the Preheater, Print Heater, and Dryer Operate Procedure Press MENU PREHEATING Press several times. Press PREHEATING PREHEAT MENU to make the setting. Press to enable the setting. Press W 2600 mm Press to go back to the original screen. -

Page 86: Recording The Amount Of Remaining Media

4-7 Recording the Amount of Remaining Media Displaying the Amount of Remaining Media on the Screen Procedure Press MENU SHEET REMAIN Press several times. Press SHEET REMAIN SET LENGTH Press to set the amount of media remaining. SET LENGTH 0.0 m 15.0 m Press to enable the setting. -

Page 87: Printing The Amount Of Remaining Media

4-7 Recording the Amount of Remaining Media Description Setting this to [ENABLE] automatically displays [SHEET REMAIN] whenever you change the media and finish setup. This makes it impossible to go on to the next operation unless you redo the setting for the amount remain- ing. -

Page 88: Menu List

4-8 Menu List Main menu Press To the [HEAD CLEANING] menu MENU SHEET TYPE p 75 SHEET TYPE OPAQUE OPAQUE To the [LEFT EDGE] menu To the [CANCEL] menu (*1) PRINT AREA RIGHT EDGE MENU Displayed only when the media p 66 RIGHT EDGE PRINT AREA... - Page 89 4-8 Menu List Continue Continue Continue Continue Continue LOAD PRESETTING 7 LOAD PRESETTING 6 LOAD PRESETTING 5 LOAD PRESETTING 4 LOAD PRESETTING 3 LOAD PRESETTING 2 To the [PRESETTING 1] menu To the [PRESETTING 2] menu ADJUST BI-DIR SAVE SAVE PRESETTING PRESETTING 1 To the [TEST PRINT] menu...

- Page 90 4-8 Menu List Continue To the [SETTING] menu MENU CALIBRATION p 73 CALIBRATION TEST PRINT CALIBRATION SETTING SETTING 0.00% 0.00% To the [TEST PRINT] menu MENU INK CONTROL EMPTY MODE p 79 INK CONTROL EMPTY MODE STOP STOP MENU DRYER p 82 DRYER MENU...

- Page 91 4-8 Menu List Continue MENU p 81 SYSTEM REPORT To "9 to 12" MENU p 45 INK REMAINING To "1 to 8" To the [SET AT LOADING] menu MENU SHEET REMAIN p 84 SHEET REMAIN PRINT MEMO SHEET REMAIN SET LENGTH SET LENGTH 0.0m 0.0m...

-

Page 92: Language And Unit Menu

4-8 Menu List Language and Unit Menu Hold down and switch on the sub power. MENU LANGUAGE p 80 ENGLISH LENGTH UNIT p 80 TEMP. UNIT p 80 ˚C ˚C SETUP SHEET Cleaning and Maintenance Menu Press Hold down for one sec- Hold down and switch on ond or longer. -

Page 93: Chapter 5 What To Do If

Chapter 5 What to Do If Downloaded From ManualsPrinter.com Manuals... -

Page 94: The Machine Doesn't Run

5-1 The Machine Doesn't Run The Printer Unit Doesn't Run Is media loaded correctly? Make sure the media is passed through the guide roller and dancer rollers correctly. Is the power switched on? Switch on the printer's main power, then press the sub power switch and make sure the POWER light comes The Dryer Doesn't Warm Up If the... -

Page 95: Attractive Printing Is Impossible

5-2 Attractive Printing Is Impossible Printed Results Are Coarse or Contain Horizontal Stripes or where it may wobble or experience vibration. Also make sure that the print heads are not exposed to mov- ing air. These factors may lead to missing dots or reduced Do the print heads show dot drop-out? Carry out a printing test and make sure no dot drop-out printing quality. -

Page 96: The Media Becomes Soiled When Printed

5-2 Attractive Printing Is Impossible The Media Becomes Soiled When Printed Do the print heads contact the media? The height of the print heads may be too low. Also, if the media is not loaded and set up correctly, it may wrinkle or come loose and strike the heads. -

Page 97: The Media Jams

5-3 The Media Jams The Media Jams If an error message is displayed because the media has jammed, immediately correct the problem. Fail- ure to do so may damage the print heads. p 100 [MOTOR ERROR TURN OFF POWER] Is the media warped or wrinkled? Many factors can cause warping or wrinkling. -

Page 98: The Media Cannot Be Taken Up Smoothly

5-4 The Media Cannot Be Taken Up Smoothly The Media Cannot Be Taken Up Smoothly Is media feed unstable? Various factors can make media feed unstable. Refer to the following and correct the problem. p 97 "Media Wrinkles or Shrinks, or Feed Is Un- stable"... -

Page 99: Media Wrinkles Or Shrinks, Or Feed Is Unstable

5-5 Media Wrinkles or Shrinks, or Feed Is Unstable The Media Is Not Straight A variety of problems can occur if the media feed is not smooth. This can cause such problems as poor printing quality, contact with the media by the print heads, misaligned posi- Is the media loaded and set up straight and securely? Feed is not smooth when the media is not straight or tioning, media jams, or poor take-up. -

Page 100: The Print Heads Stopped Moving

If the Heads Still Do Not Move If the heads still do not move, carry out the following emergency response measure, then contact your autho- rized Roland DG Corp. dealer or Roland DG Corp. ser- Make sure the print heads are capped tightly. vice center. -

Page 101: If A Message Appears

5-7 If a Message Appears These are the main messages that appear on the machine's [SET SOL CRT.] Insert the ink cartridge indicated by the flashing num- display to prompt correct operation. They do not indicate ber. This message appears at times such as during car- any error. -

Page 102: If An Error Message Appears

Next, eliminate the cause of the error, then immediately contact your authorized Roland DG Corp. dealer or Ro- switch on the sub power. If the machine is allowed to land DG Corp. service center. - Page 103 5-8 If an Error Message Appears is too low for the media thickness specified on the com- [WRONG CARTRIDGE] puter. The heads move to a location where you can op- erate the height-adjustment lever. Adjust to the displayed A cartridge that cannot be used was installed. height, then press Remove the cartridge to clear the error.

- Page 104 Downloaded From ManualsPrinter.com Manuals...

-

Page 105: Chapter 6 Specifications

Chapter 6 Specifications Downloaded From ManualsPrinter.com Manuals... -

Page 106: Usable Media

6-1 Usable Media Conditions for Usable Media Media width 48 to 104 inches (1220 to 2641 mm) Roll outer diameter ( A) Maximum 250 mm (9.8 inches) Paper pipe (core) inner diameter (B) 3 inches (76.2 mm) Media thickness (C) Maximum 1.0 mm (39 mil) Roll weight Maximum 100 kg (220 lb.) -

Page 107: Printing Area

6-2 Printing Area Printing Area and Margins Media Approx. 1.5 m (5 feet) (*2) Media clamp Media clamp 10 mm (0.4 in.) (*3) 10 mm (0.4 in.) (*3) Printing area Approx. 20 mm Approx. 20 mm (0.8 in.) (*3) (0.8 in.) (*3) Left margin (*1) Right margin (*1) Approx. -

Page 108: Locations Of The Power Rating And Serial Number Labels

6-3 Locations of the Power Rating and Serial Number Labels Serial Number This is required when you seek mainte- nance, servicing, or support. Never peel off the label or let it get dirty. Power Rating Use an electrical outlet that meets the re- quirements for voltage, frequency, and amperage given here. -

Page 109: Specifications

Included items paper pipe, drain bottle, media gauge, media clamps, hexagonal wrenches, cap-unit tool, cleaning kit, cleaning liquid cartridges, soft- ware RIP, Roland-PrintServer CD-ROM, User's Manual, Setup Guide, Roland-PrintServer Network Settings Guide At Roland PET film, print travel: 1 m Temperature: 25°C (77°F), humidity: 50%... - Page 110 Downloaded From ManualsPrinter.com Manuals...

- Page 111 Downloaded From ManualsPrinter.com Manuals...

- Page 112 Downloaded From ManualsPrinter.com Manuals...

- Page 113 Downloaded From ManualsPrinter.com Manuals...

- Page 114 Downloaded From ManualsPrinter.com Manuals...

- Page 115 Downloaded From ManualsPrinter.com Manuals...

- Page 116 R3-070201 Downloaded From ManualsPrinter.com Manuals...

Need help?

Do you have a question about the SJ-1045EX and is the answer not in the manual?

Questions and answers