Summary of Contents for ARCA DYNAMIC

- Page 1 Vers. D 10/2011 Labelling machine DYNAMIC User’ s Manual Rev. Description Date New control unit with graphic display 10/2011...

- Page 2 MUD00000 2/28...

- Page 3 Thank you for having chosen a machine manufactured by ARCA Etichette S.p.A.: this equipment has been designed and built using state of the art technologies and procedures in order to guarantee lasting reliability and the maximum safety for its users.

- Page 4 ARCA Etichette S.p.A ARCA Etichette S.p.A does not issue guarantees on the contents of this publication and it (specifically) denies any implicit guarantee, commercial guarantee or its adaptability to any object. Furthermore ARCA Etichette S.p.A reserves the right to revise this publication and modify its contents...

-

Page 5: Table Of Contents

Summary 1.Introduction ....................6 2.General information ..................7 3.Adjustments ....................13 4.Cleaning of the labeller ..................23 5.Labelling machine troubleshooting ..............27 5/28 MUD00000... -

Page 6: Introduction

1.2. Communications with ARCA Etichette S.p.A Customers’ Care Service To solve any problem deriving from the use of the machine, please contact ARCA Etichette S.p.A asking for the Customers Care Service Centre. In order to obtain a quick and accurate solution of the problem, please indicate the following data: - labelling machine model;... -

Page 7: General Information

General information Summary 2.1. Machine description ...................8 2.1.1.Principal functional groups of the labeller ----------------------------------------------------------------- 8 2.2. foreseen use of the labelling machine .............8 2.3.Identification data of the labelling machine ..........9 2.4.Identification data of the control unit ............9 2.5.General safety prescriptions ..............10 2.6.Security systems ..................11 2.7.Glossary .......................11 MUD00000 GB... -

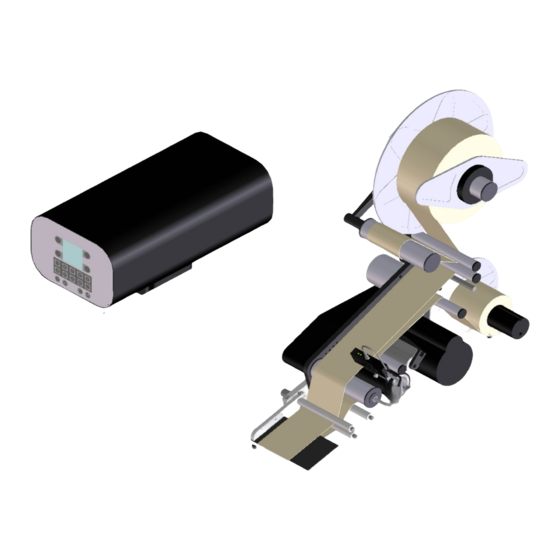

Page 8: Machine Description

The silicon band recovery is carried on by means of the rewinder.. ATTENTION! ARCA Etichette S.p.A. declines any responsibility for damages to persons or things deriving from a wrong use of the machine. Carefully follow the instructions given in this manual for a correct and safe use of the machine. -

Page 9: Identification Data Of The Labelling Machine

S/N: YEAR: YEAR: MADE IN ITALY MADE IN ITALY ARCA ETICHETTE SPA - DIVISIONE SISTEMI ARCA ETICHETTE SPA - DIVISIONE SISTEMI Via Pacinotti - 20010 MARCALLO (MI) - ITALY Via Pacinotti - 20010 MARCALLO (MI) - ITALY ARCA ETICHETTE SPA... -

Page 10: General Safety Prescriptions

2.5. General safety prescriptions THE USE OR MAINTENANCE OF THE MACHINE FROM UNAUTHORISED OR UNTRAINED PEOPLE IS FORBIDDEN. The levels of the operators suggested to carry on specific operations described in the present manual are listed as follows. Then, beside the operation description, the letter is indicated, followed by a number relative to the level corre- sponding to the competence. -

Page 11: Security Systems

DO NOT CHANGE, FOR ANY REASON, THE MACHINE PARTS TO ADAPT NEW DEVICES. IN CASE OF MALFUNCTIONING DUE TO THE INOBSERVANCE OF THE ABOVE-MENTIONED PRESCRIPTIONS, ARCA ETICHETTE S.p.A. DECLINES ALL RESPONSIBILITIES. The machine must be correctly connected, as per diagrams attached to the manual. - Page 12 MUD00000 GB 12/28...

-

Page 13: Adjustments

Adjustments Summary 3.1. Setting the label on the product ...............14 3.2. Micro-switch adjustment ................14 3.3. Photocell adjustment .................15 3.4. Adjustment of the transport roller pressure ..........16 3.5. Adjustment of the mechanical sensor for end of roll ......16 3.6 Label roller replacement ................17 3.7. -

Page 14: Setting The Label On The Product

3.1. Setting the label on the product The machine must be centred on the product to be labelled (according to the needs) both horizontally and vertically, acting on its support. The position adjustment of the labelling machine must be performed according to the kind of application de- vice. -

Page 15: Photocell Adjustment

• should the led fail to switch on, introduce a socket head spanner (2 mm) in the hole of the adjustment device in order to change the pressure of the balancing device which detects the space between labels; • for a further check make the labels go back and forth by hand: the led set on the micro-switch must switch on when it is on the space between two labels, and go off when on a label;... -

Page 16: Adjustment Of The Transport Roller Pressure

3.4. Adjustment of the transport roller pressure In case of wrong feed of the labels (wrong application during the labelling) perform the following indications: • disconnect the power supply and pneumatic if it foresees; • remove the shed (3) loosing the screws; •... -

Page 17: Label Roller Replacement

3.6 Label roller replacement The labels roller must have fit dimensions as described in section 3. To replace the labels roller: unhook the pulling roller; loose the block gear; if it is not finished yet, break the label support silicone band at any point;... -

Page 18: Paper Path

3.7. Paper path To make the labels perform the correct paper path, follow the instructions given: A. unwind the labels coil for at least a meter; B. remove the film from the labels for about 0,5 mt; C. make the paper pass as shown in the figure, it depends if the labelling machine is a left or a right version, paying attention that the labels support silicon band is free of labels after the detaching blade. -

Page 19: Paper Path With "Concorde" Peeler

3.7.2 Paper path with “Concorde” peeler 3.7.3 Paper path with Hot print unit 19/28 MUD00000 GB... -

Page 20: Take Up Roller

3.8 Take up roller To block the paper on the take up roller, follow the indication given: A. insert paper and rotating it by hand for some turns until the paper is blocked; B. rotate the take-up roller by hand up to complete tension of the paper. MUD00000 GB 20/28... - Page 21 Cleaning of the labeller Summary 4.1. Cleaning ......................22 4.1.1. Cleaning of the photocells ------------------------------------------------------------------------------------ 22 4.1.2. Cleaning of the knurled and rubber rollers --------------------------------------------------------------- 23 4.2. Extraordinary maintenance ...............23 21/28 MUD00000...

- Page 22 The labelling machine has been designed and built in order to reduce as much as possible the necessary maintenance and to ensure a correct functioning during the years without problems. ATTENTION! Before performing any maintenance intervention on the machine it is necessary to switch it off and disconnect the electrical supply and possibly also the pneumatic one.

-

Page 23: Cleaning Of The Labeller

4.2. Extraordinary maintenance Any extraordinary maintenance intervention must be performed by authorised personnel only. It is possible to get informations on the authorised personnel calling ARCA ETICHETTE S.p.A. ATTENTION! Any guarantee decays whenever interventions on the machine are performed by non authorised personnel. - Page 24 MUD00000 24/28...

- Page 25 Labelling machine troubleshooting Summary 5.1. Troubleshooting ..................26 25/28 MUD00000...

-

Page 26: Troubleshooting

5.1. Troubleshooting The following table offers you a guide for the most common causes of defects, which can occur on the labelling machines verify on it if the detected defects are included in this table in order to find the possible solutions. Problem Possible cause Solution... -

Page 27: Labelling Machine Troubleshooting

Double label emission optimal adjustment cannot be any adjustment. found Contact ARCA Etichette S.p.a. Missing electrical supply Check the electrical supply The motor does not start Burnt fusers Check the fusers... - Page 28 MUD00000 28/28...

Need help?

Do you have a question about the DYNAMIC and is the answer not in the manual?

Questions and answers