Table of Contents

Advertisement

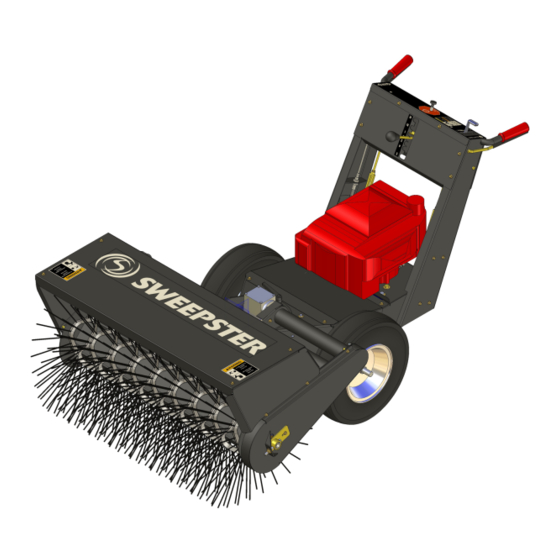

OPERATOR'S AND PARTS MANUAL

Multi-Speed Walk Behind Sweeper

Serial Number: ___________________

Model Number: ___________________

800-456-7100 I www.paladinattachments.com

51-4008

WSP36 Series

2800 N. Zeeb Rd., Dexter, MI. 48130, United States of America Copyright ©

Manual Number: 51-4008

Release Date: February 2015

Serial Number 0807001 and up

Rev. 2

1

Advertisement

Table of Contents

Summary of Contents for Sweepster WSP36 Series

- Page 1 OPERATOR’S AND PARTS MANUAL WSP36 Series Multi-Speed Walk Behind Sweeper Serial Number: ___________________ Manual Number: 51-4008 Release Date: February 2015 Model Number: ___________________ Serial Number 0807001 and up Rev. 2 800-456-7100 I www.paladinattachments.com 2800 N. Zeeb Rd., Dexter, MI. 48130, United States of America Copyright ©...

- Page 2 51-4008...

-

Page 3: Table Of Contents

TABLE OF CONTENTS INTRODUCTION ............................4 SAFETY STATEMENTS ..........................4 GENERAL SAFETY PRECAUTIONS......................5-6 DECALS ...............................7 OPERATION ............................8-11 STORAGE ..............................11 LUBRICATION POINTS ..........................12 MAINTENANCE ............................13-18 MAINTENANCE SCHEDULE ........................13 BRUSH CORE REMOVAL .........................14 BRUSH CORE INSTALLATION .........................14 REPLACING BRUSH SECTIONS ......................15 BRUSH SPEED CHANGE ........................16-17 TRANS AXLE DRIVE BELT REPLACEMENT ....................16 BRUSH DRIVE BELT REPLACEMENT .....................16 ELECTRIC START WIRING ........................18... -

Page 4: Introduction

If you have any questions about information in this CAUTION THIS STATEMENT IS USED manual or need to order parts, please call, write, fax WHERE MINOR INJURY COULD or e-mail SWEEPSTER. RESULT IF THE INSTRUCTIONS ARE NOT FOLLOWED PROPERLY. Sweepster 2800 North Zeeb Road... -

Page 5: General Safety Precautions

GENERAL SAFETY PRECAUTIONS GENERAL SAFETY PRECAUTIONS WARNING PROTECT AGAINST FLYING WARNING READ MANUAL PRIOR TO DEBRIS INSTALL Always wear proper safety glasses, Improper installation, operation, goggles or a face shield when driving or maintenance of this equipment pins in or out or when operation could result in serious injury or causes dust, flying debris, or any other death. - Page 6 GENERAL SAFETY PRECAUTIONS GENERAL SAFETY PRECAUTIONS CONTINUED CONTINUED • Wear safety glasses, protective clothing, and use a sound piece of • Wear the protective clothing cardboard or wood when equipment specified by the tool searching for hydraulic leaks. manufacturer. DO NOT USE YOUR HANDS! SEE ILLUSTRATION.

-

Page 7: Decals

DECALS 50-0726 50-0757 50-0758 Serial Tag Location Item Part Description 50-0726 Decal, Warning, Flying Objects & Entanglement 50-0867 50-0757 Decal, Handle SAFETY DECALS 50-0758 Decal, Shift Pattern 41043 Decal, Warning, Hazardous Dust There are several specific signs on this sweeper. Not Shown: The exact location of the hazards and description of 50-0867... -

Page 8: Operation

OPERATION CAUTION A SWEEPER IS A DEMANDING •Before leaving the operator’s position for any MACHINE. Only fully trained reason, STOP ENGINE. operators or trainee operators under supervision of a fully trained person NOTICE! AVOID TRANSMISSION DAMAGE. should use this machine. Do not shift while in motion. - Page 9 OPERATION Observe wind direction. Sweeping with the wind Operating Tips makes sweeping more effective and helps keep debris off the operator. NOTICE! AVOID SWEEPER DAMAGE. Do not ram into piles The terms swing and angle are used NOTICE! If casters are installed they should interchangeably.

- Page 10 OPERATION Traveling Around the Work site Heavy Debris 1. Start engine at idle. Travel slowly - 1-2 mph. 2. Select a gear with the appropriate travel speed Sweep a path less than the full width of the for the conditions. sweeper.

-

Page 11: Storage

OPERATION Storage NOTICE! Do not store the sweeper with weight on the brush. Weight will deform the bristles, destroying the sweeping effectiveness. To avoid this problem, place the sweeper on blocks or use storage stands. Do not store polypropylene brushes in direct sunlight. The material can deteriorate and crumble before the bristles are worn out. -

Page 12: Lubrication Points

LUBRICATION POINTS The following grease fittings should be greased NOTICE! NO LUBRICATION IS REQUIRED before each use. See figure for locations. FOR GEARBOX (05-1439) AND TRANSAXLE (05-1423). THESE ARE PRE-LUBRICATED FROM 1. Core bearing (2 fittings) THE FACTORY. DAMAGE WILL (Brush may need to be rotated to align OCCUR AND WILL VOID THE zerk with access hole.) -

Page 13: Maintenance

MAINTENANCE MAINTENANCE SCHEDULE BEFORE AFTER PROCEDURES EACH HOURS HOURS EACH Hardware - Inspect & Tighten Engine & Air Filter - Check & clean if necessary Grease Fittings - See (Lubrication Points) Oil, Engine - Check Level Brush Drive Chain - Adjust & Lubricate V-Belt Inspection Wash Unit - Remove grease and debris Check Battery Connections (Electrolyle... -

Page 14: Brush Core Removal

MAINTENANCE BRUSH CORE INSTALLATION BRUSH CORE REMOVAL 1. Stop engine, push emergency switch and 1. Place core in brush frame. remove spark plug wire. 2. Install chain. 2. Support body in pivot area with a 10 inch minimum support (figure 1). 3. -

Page 15: Replacing Brush Sections

MAINTENANCE REPLACING BRUSH SECTIONS Drive Pins Core 1. Remove core from brush head assembly following brush core removal instructions. Tubes 2. Remove retaining plate from the core assembly. 3. Remove old sections. 4. Install new sections by doing the following: a. -

Page 16: Brush Speed Change

MAINTENANCE BRUSH SPEED CHANGE BRUSH DRIVE BELT REPLACEMENT 1. Stop engine, push emergency switch, remove 1. Stop engine, push emergency switch and spark plug wire. remove spark plug wire. 2. Remove both top and bottom covers. 2. Remove top cover. 3. - Page 17 MAINTENANCE Belt Placement Belt Placement Slow Brush Speed Fast Brush Speed NOT USED UPPER POSITION LOWER POSITION 51-4008...

-

Page 18: Electric Start Wiring

MAINTENANCE Electric Start Wiring BLACK WIRE FROM SWIT PUSH/PULL STOP RED WIRE FROM SWITCH PUSH/PULL STOP BLACK WIRE FROM SWITCH PUSH/PULL STOP Item Part Description 07-0812 Terminal Connector, Q/K, 1/4, Female, 16-14 07-0832 2.5ft Wire, Red, 16ga RED WIRE FROM SWITCH 07-0916 Terminal Ring, #8, 16-14 PUSH/PULL STOP... -

Page 19: Troubleshooting

TROUBLESHOOTING Problem Possible Cause Possible Solution Brush slows or stops when Idler not engaging Adjust turnbuckle sweeping Filter plugging Change or clean air filter Travel speed too fast Travel no more than 5 mph (8 kph) while sweeping (1-3 mph recommended) Trying to sweep too much Make several passes with material at once... -

Page 20: Product Information

PRODUCT INFORMATION Specifications and Model Views without Optional Casters or Hopper 20° 20º 20° A. Overall Height 27.8 inches B. Overall Width at 0° 41.1 inches C. Overall Length at 0° 68.6 inches D. Sweeping Width at 0° 36 inches E. -

Page 21: Bolt Torque Specifications

BOLT TORQUE SPECIFICATIONS 51-4008... -

Page 22: Warranty

WARRANTY Limited Warranty Except for the Excluded Products as described below, all new products are warranted to be free from defects in material and/or workmanship during the Warranty Period, in accordance with and subject to the terms and conditions of this Limited Warranty. Excluded Products. - Page 23 NOTES 51-4008...

-

Page 24: Brush Head Assembly

BRUSH HEAD ASSEMBLY Item Part Qty Description 05-1437 1 Shaft, Drive, Brush Head 05-1439 1 Gearbox, Peerless, Right Angle, 7/8 Shaft 06-0480 1 Sprocket, 40B35, Brush Drive 06-0483 1 Chain, #40, 101 Links, with Master 06-0495 1 Sprocket, 40B13 x 7/8, with Keyway 07-1716 2 Bolt, Carriage, Gr5, 3/8-16 x 1 07-1810 1... -

Page 25: Brush Head Assembly

BRUSH HEAD ASSEMBLY 51-4008... -

Page 26: Body Assembly

BODY ASSEMBLY Item Part Description 06-0009 1 Pulley, Idler, 3 3/4 x 7/8 x 3/8 06-0171 2 Pulley, Idler, 2 x 7/8 x 3/8 06-0477 1 Sprocket, Idler, Chain, #40-14 Tooth, with 3/8 Hole 06-0479 1 Pulley, Brush Drive 06-0482 1 Chain, #40, 74 Pitches, Plus Master 06-0486 1 Pulley, Idler, 3 1/4 x 7/8 x 3/8... - Page 27 BODY ASSEMBLY 51-4008...

-

Page 28: Engine Assembly (Pull Start)

PULL START ENGINE ASSEMBLY Item Part Description 03-9587 1 Engine, Honda, 4.3 HP, GXV160 06-0478 1 Pulley, Engine 07-1255 1 Screw, HHC, Gr8, 3/8-24 x 1 1/4 07-1698 1 Screw, HHC, Gr8, 5/16-18 x 2 07-1718 1 Washer, Lock, Split, Medium, 3/8 07-3273 4 Washer, Lock, Split, Medium, 5/16 07-3275 4... -

Page 29: Caster Assembly

CASTER ASSEMBLY Item Part Qty Description 07-0018 4 Screw, HHC, Gr8, 3/8-16 x 1 07-0253 2 Caster, 5 inch Diameter 07-2952 1 Screw, HFH, CL10.9, M6-1 x 20 07-3273 8 Washer, Lock, Split, Medium, 5/16 07-3275 8 Washer, Flat, Gr8, 5/16 07-3278 8 Nut, Hex, Gr8, 5/16-18 07-3279 8... -

Page 30: Control/Handle Assembly (Pull Start)

PULL START CONTROL / HANDLE ASSEMBLY Item Part Description 07-0140 Washer, Lock, Gr2, #10 07-0141 Nut, Hex, Gr2, 10-24 07-2952 Screw, HFH, CL10.9, M6-1 x 20 07-3617 Nut, Insert, Hex, M6 x 1 07-4039 Nut, Hex, Gr8, 1/4-20 07-4831 Screw, BHC, 10-24UNC, 2B x 3/4 07-6840 Throttle, with Detent and Cable 07-6869... - Page 31 PULL START CONTROL / HANDLE ASSEMBLY USE LOCTITE #243 (BLUE) ON KNOB THREADS. 51-4008...

-

Page 32: Trans Axle Assembly

TRANS AXLE ASSEMBLY Item Part Description 05-0851 Key, Woodruff, 3/16 x 3/4 05-1423 Trans axle, 5 Speed 06-0484 V-Belt, Pulley 06-0494 Pulley, V, 6 1/2 x 3/4RD 07-0145 Nut, Hex, Gr8, 1/4-28 07-1784 Screw, HHC, Gr8, 5/16-18 x 2 1/2 07-2952 Screw, HFH, CL10.9, M6-1 x 20mm 07-3275... -

Page 33: Trans Axle Assembly

TRANS AXLE ASSEMBLY 51-4008... -

Page 34: Control/Handle Assembly (Electric Start)

ELECTRIC START CONTROL / HANDLE ASSEMBLY USE LOCTITE #243 (BLUE) ON KNOB THREADS. 51-4008... - Page 35 ELECTRIC START CONTROL / HANDLE ASSEMBLY Item Part Description 07-0140 Washer, Lock, Gr2, #10 07-0141 Nut, Hex, Gr2, 10-24 07-1305 Switch, Starter, Universal 07-2952 Screw, HFH, CL10.9, M6-1 x 20 07-3617 Nut, Insert, Hex, M6 x 1 07-4039 Nut, Hex, Gr8, 1/4-20 07-4831 Screw, BHC, 10-24UNC, 2B x 3/4 07-6840...

-

Page 36: Engine Assembly (Electric Start)

ELECTRIC START ENGINE ASSEMBLY Item Part Description 03-9632 Engine, Subaru, 5.0 HP, 190cc, Electric Start 06-0512 Pulley, Engine 07-1255 Screw, HHC, Gr8, 3/8-24 x 1 1/4 07-1698 Screw, HHC, Gr8, 5/16-18 x 2 07-1718 Washer, Lock, Split, Medium, 3/8 07-2952 Screw, HFH, CL10.9, M6-1 x 20 07-2956 Nut, Insert, M6 x 1... - Page 37 NOTES 51-4008...

Need help?

Do you have a question about the WSP36 Series and is the answer not in the manual?

Questions and answers