Worcester Greenstore TC Cylinder 150 litre Installation And Maintenance Instructions Manual

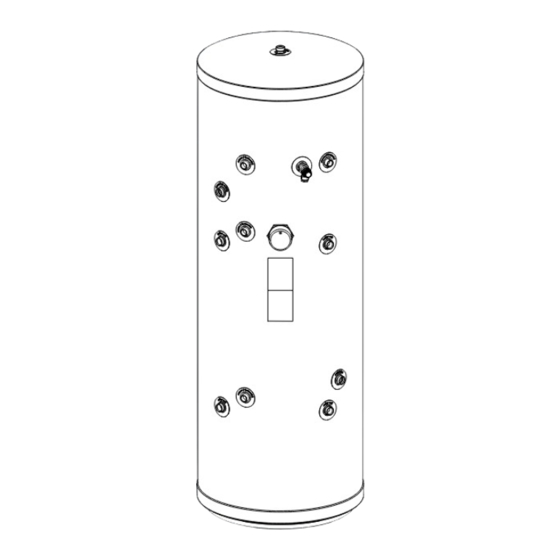

Twin coil indirect unvented hot water cylinder

Hide thumbs

Also See for Greenstore TC Cylinder 150 litre:

Summary of Contents for Worcester Greenstore TC Cylinder 150 litre

- Page 1 Installation and maintenance instructions Twin Coil Indirect Unvented Hot Water Cylinder Greenstore TC Cylinder Series 150/180/210/250/300 litre...

-

Page 2: Table Of Contents

Contents Contents Key to symbols and safety precautions ....3 Spare parts list ........21 Explanation of symbols . -

Page 3: Key To Symbols And Safety Precautions

As a member of the HWA, Worcester adhere to the following statements. ▶ To supply fit for purpose products clearly and honestly described, ▶... -

Page 4: Product Details

Product details Product details Usage These cylinders are designed to accept input from two heat sources, the most common being a solar input supported by a controlled appliance such as a gas or oil boiler. The maximum cylinder heat input must not exceed the following values: Cylinder Max. -

Page 5: Standard Delivery

Product details Standard delivery 6 720 645 525-07.4GX Fig. 1 Twin coil DHW cylinder Temperature and pressure relief valve Immersion heater, 3 kW Tundish Ø 15/22 mm Solar high limit thermostat Cold water inlet control group with anti-vacuum valve 2-port valve Dual cylinder thermostat DHW expansion vessel incorporating fixing bracket [10] Connection set... -

Page 6: Physical And Connection Dimensions

Product details Physical and connection dimensions Fig. 2 Overview of connections Sensor pocket, bottom (internal Ø 20.4 mm) Cylinder flow / return - secondary appliance (Ø 22 mm) Fig. 3 Physical and connection dimensions Sensor pocket, centre (internal Ø 20.4 mm) DHW secondary circulation connection (Ø... - Page 7 Product details clearance dimensions Fig. 4 Recommended minimum wall clearances (all dimensions in mm) 6 720 805 339 (2014/09)

-

Page 8: Specification

Product details Specification Cylinder type Greenstore TC-150 TC-180 TC-210 TC-250 TC-300 WRAS No. 1105064 1105064 1105064 1105064 1105064 WRc No. 15811 15811 15811 15811 15811 General characteristics Dual thermostat setting °C 10/70 10/70 10/70 10/70 10/70 Dual thermostat high limit/Solar high limit thermostat °C Temperature and Pressure relief valve °C... - Page 9 Product details Constant DHW output The constant DHW output shown in the specification refers to the Example: following: With a water/propylene-glycol mixture of 55/45 (frost protection down to approximately – 30 °C), the pressure drop is approximately 1.3 times • Flow temperature 85 °C the value for tap water.

-

Page 10: Energy Efficiency

Installation Energy efficiency The following product data comply with the requirements of EU Regulations No. 811/2013 and No. 812/2013 as supplement to the Directive 2010/30/EU. Standing loss (S) Storage volume (V) Storage volume (V) ErP - energy Cylinder description Part number (Watts) (litres) efficiency class... -

Page 11: Solar Connection Diagram

Installation Solar connection diagram 230V AC 230V AC S...solar 6 720 645 525-03.3GX Fig. 8 Pressure reducing valve (G3 kit supplied) Drain valve Solar collector (optional accessory) Greenskies solar package (optional accessory) Circulation pump (heating circuit/cylinder heating) Inlet control set Cold water inlet Expansion vessel (G3 kit supplied) Isolating valve... -

Page 12: Installing The Temperature Sensors

Installation Installing the temperature sensors The temperature sensors and safety equipment are fitted in different locations on the cylinder, subject to system. 6 720 645 525-05.1O Fig. 9 Overview of connections Lower sensor pocket Centre sensor pocket Upper sensor pocket Solar thermal system? System type... -

Page 13: Installation

Installation Installation 3.7.3 Connection on the water side ▶ Install the cold water inlet control group as close as possible to the All hydraulic cylinder connections are suitable for 22 mm cylinder cold water inlet, with the compression fittings supplied. The pipes. -

Page 14: Dhw Expansion Vessel

Installation 3.7.5 DHW expansion vessel Position the inlet control group so that the discharge from both the two safety valves can be joined together via a 15 mm end feed Tee. Connect ▶ Connect the expansion vessel using a rigid pipe connections (e.g.. the Tundish and route the discharge pipe. - Page 15 Installation The table below is based on copper tube. Plastic pipes may be of different bore and resistance. Sizes and maximum lengths of plastic should be calculated using data prepared for the type of pipe being used. Maximum resistance allowed, expressed as a Minimum size of discharge Minimum size of discharge length of straight pipe...

-

Page 16: Electrical Connections

Installation Electrical connections Connecting the indirect controls The indirect thermal controls should be wired into a suitable indirect DANGER: Risk of electric shock! control system to ensure optimum control of the cylinder and boiler. All ▶ Before making any electrical connections, electrical work must conform to current IEE Wiring Regulation disconnect the power supply (230 V AC) to the (BS 3456). - Page 17 Installation 6 720 645 525-10.3GX Fig. 12 Variant dual thermostat wiring: wiring diagram 3 port mid position valve (Y-plan) + 2 port valve G3 protection from excessive solar input. G3 protection from excessive solar input. A solar high limit thermostat will isolate the solar controller and solar pump. Additional wiring for solar pump stations without a gravity break check valve.

- Page 18 Installation Using the Worcester optional Internal Diverter valve • The installation will use the cylinder sensor supplied with the Integral • The high limit thermal cut out of the dual thermostat MUST be wired Diverter Valve kit to control the hot water temperature.

- Page 19 Installation Connecting the immersion heater (Heaters conform to EN60335.2.73) ▶ Ensure the mains voltage corresponds to the voltage rating of the heater as shown on the rating label on the terminal cover. ▶ Only use rigid wires 1.5 mm for main supply. Flexible wire may cause poor electrical connection to AQU-32-3W the heater, resulting in overheat.

-

Page 20: Commissioning

Commissioning Shutting down NOTICE: ▶ When draining either the domestic water system or the cylinder ensure the cold water supply is isolated and that at least two hot water draw off points are opened. One of these hot water draw off points must be the one closest to the cylinder in height terms. -

Page 21: Spare Parts List

& Conditions. To read the full Terms & Conditions please visit us online consumption and extend the heat-up time. at www.worcester-bosch.co.uk/guarantee. The Guarantee Registration form is available on this same page and can be completed and submitted ▶ Subject to the level of scaling, descale the cylinder regularly. - Page 22 MAINS PRESSURE HOT WATER STORAGE SYSTEM COMMISSIONING CHECKLIST This Commissioning Checklist is to be completed in full by the competent person who commissioned the storage system as a means of demonstrating compliance with the appropriate Building Regulations and then handed to the customer to keep for future reference. Failure to install and commission this equipment to the manufacturer’s instructions may invalidate the warranty but does not affect statutory rights.

-

Page 23: Service Record

Service Record It is recommended that your heating system is serviced regularly and that the appropriate Service Interval Record is completed. Service Provider Before completing the appropriate Service Record below, please ensure you have carried out the service as described in the manufacturer’s instructions. - Page 24 0330 123 9119 TRAINING: 0330 123 0166 SALES: 0330 123 9669 Worcester, Bosch Group Cotswold Way, Warndon, Worcester WR4 9SW. Tel. 0330 123 9559 Worcester, Bosch Group is a brand name of Bosch Thermotechnology Ltd. worcester-bosch.co.uk 6 720 805 339...

Need help?

Do you have a question about the Greenstore TC Cylinder 150 litre and is the answer not in the manual?

Questions and answers