Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for 3ntr A4v3

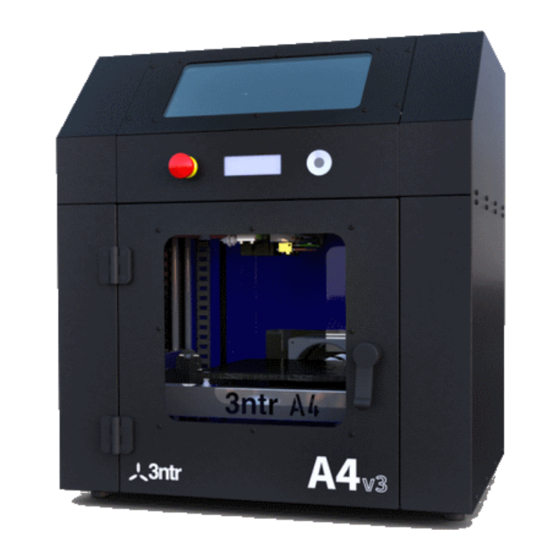

- Page 1 User manual 3d printers A4v3 A2v2 V.201015...

- Page 2 The manual has been prepared trying to list ALL the steps needed to perform each duty: it may look boring, but we invite you to resist and read thoroughly before committing to machine use –...

- Page 3 EC declaration of conformity For the following products: □ A4v2 (3d printer) □ A4v3 (3d printer) □ A2v2 (3d printer) □ A00 (3d printer) □ QT (3d printer) □ F1 (filtering unit) Manufactured by Jdeal-Form srl Via Montegiudeo 9 28047 Oleggio (No)

-

Page 4: Important Safety Advice

Important safety advice Your printer has been built with user safety as main concern, yet it must NOT be used by individuals with reduced mental or physical abilities. This printer is not a toy, is meant to be used by fully responsible and knowledgeable people and printing area must be kept locked in presence of children or people with serious mental problems. -

Page 5: Limited Warranty

LIMITED WARRANTY This Limited Warranty applies to Jdeal-Form products ( 3ntr A4 , 3ntr A2 ) (" Products") sold in the European Union, Iceland , Liechtenstein, Norway and Switzerland after January 1st, 2014. * CAUTION ! As from point (H) of this document, this Limited Warranty does not affect any legal rights under the applicable national law. - Page 6 (G) How to obtain warranty service. To make a claim under this Limited Warranty, please contact your authorized dealer where you purchased the product, or contact Jdeal-Form by e-mail (info@3ntr.net.) (H) Limitations / Warnings. This limited warranty is sole and exclusive remedy by the end-user against Jdeal-Form where permitted by law and subject to paragraph (h).

- Page 7 Unpacking We carefully packaged your printer , to protect it from rough handling usually involved with international freight. Therefore, if despite our efforts, you are being delivered a damaged package you should always refuse delivery or put your remarks on the delivery bill. During unpacking, NEVER use cutters: you risk piercing the packaging, therefore damaging content.

- Page 8 Fig. 2: What's in the box The box shipped inside the printer contains • USB cable AC power cord • 3mm ABS spool • • 3mm HIPS spool • Spare cooling fluid • Hex keys • Filament feeder with PTFE piping •...

- Page 9 Installation Before committing to lifting printer from the shipment pallet, be sure to have the means to lift weights over 30 Kg: • A4 printer: two people will suffice to lift it from ground level to the destination desktop A2 printer: best scenario is using a forklift to bring the pallet+printer at pedestal lever (approx 70cm) then three- •...

- Page 10 A2 printer only: longest pipe is to be placed on feeder #1 (rightmost, when looking on the rear side). Fig. 5: PTFE piping must not touch feeding roller After fitting PTFE piping on each filament feeder, you can mount them on the printer, feeding the piping thru the rear openings, just above each feeder position.

- Page 11 After placing fitting PTFE piping on filament feeder, you can mount feeders on printer, feeding the PTFE piping thru printer opening on the rear, above each feeder position. Each feeder has a “mandatory” position: please refer to fig 7 and 8 for respective printer models. Fig.

- Page 12 When feeders are mounted and wired, you can connect PTFE piping on extruders. Open front panel (to do so, you have to remove four screws using 2.5mm hex key) Fig. 11: Front plate removal Be sure that PTFE piping is untangled. Fig.

- Page 13 Connect the printer using the supplied USB cable. You can connect to your PC or to a printer server. At first we recommend using a PC to better understand basic machine use. Just be sure to route USB cable away from sources of electrical noise (such as power transformers, electric motors, and other high power/high frequency devices) Fig 14: Connect USB cable...

-

Page 14: Using The Printer With Your Computer

Using the printer with your computer We urge you to use a PC at least at the beginning: once you build enough experience then you will be able to switch to more advanced printing methods (SD card, print servers). Therefore you need to physically connect your PC to the printer (supported OS are Windows 7/8, Mac, Linux). Be sure to use the shortest possible USB cable: long cables will pick up electrical noise (= transmission problems = lost prints). - Page 15 Fig. 18: Connection parameters Connector: usually must be left on “Serial connection”. Port: select the port you will use to connect to the printer. The above shown is just an example: according to the periperals connected to your PC (inkjet printer, mouse, webcam, camera, smartphone,...), the printer will be connected to a surely different port number.

- Page 16 Fig. 19: Printer parameters We recommend to set printer defaults as from above figure. You may want to un-check the following options: • Send ETA to printer: this option is sending to the printer the time remaining printing time. It's a useful option, but makes for a slight flickering of the LCD display (when printer updates the time left) that can be disliked by some people.

- Page 17 Fig. 20: Extruder control This tab will let you set the extruder characteristics. You must set the number of extruders available on your printer and each nozzle diameter (standard supply is 0.4mm but other sizes are available). IMPORTANT: be sure to change preset color of each extruder (default is yellow for each one) to get easy preview of the multi-extruder prints !

- Page 18 Fig. 21: Printer shape This tab will let you set you the print area dimensions, using the values as from following table: Xmin Xmax Ymin Ymax Largh. Prof. Alt. A4 (2 ex) 0 A4 (3 ex) 0 Be sure that ALL the Home X/Y/Z settings are set to MIN: failing to do so you could not be able to use your printer!

-

Page 19: Printer Use

Printer use Loading filament Printer need filament: usually you can buy it wound up on plastic spools and loading it on printers takes really few steps. We take the chance to remind you that to get best results you should always stock filaments in a dry place (soaked filament makes for steam during printing process, degrading the quality), away from direct sunlight and heat sources (that speed up polymer... - Page 20 Using a pencil sharpener gets better results. To feed filament: 1. Grab feeding device handle and lock it open using the pivoting ring on the handle 2. Feed the filament into the hole on the lower part of feeding device Fig.

-

Page 21: Filament Removal – Idle Machine

Filament removal – idle machine Filament cannot be removed when machine is “cold”, as it will be melt inside extruder, therefore to remove it you need to follow those easy steps: 1. Set the extruder at 70% of working temperature (usually almost all polymers start softening at 160°-170° C, enough to remove filament) 2. -

Page 22: Changing Filament Type

Changing filament type When dealing with different polymers, procedure is a bit different. Start with a “cold” extruder situation: turn on heating for desired extruder, at about 60-70% of the currently loaded polymer working temperature. Release the feed mechanism and lock it open. Start pulling (not too strong to break it... -

Page 23: Placing Print Tray

Placing print tray Our printers use removable trays: for best results, some care is needed about keeping them clean and intact: for more information revert to maintenance section. To load printing tray into printer, just lean it over the heated print plate: magnets will align and lock automatically. Tray printing surface needs to be clean and free from remains from previous prints: the film coating should be intact, otherwise you should consider applying a new layer. - Page 24 Printing Printing process can be started and managed in three different ways: connected to a PC (using Repetier Host) • ◦ Pros ▪ real time monitoring of temperatures graphs ▪ almost real time visualization of the layer being printed ◦ Cons ▪...

-

Page 25: Print Removal

Print removal When printing process is completed, remove the printing tray and let it cool down. Once printed part is at room temperature, it will be easier to remove from the tray. On thick parts, without fragile zones, hitting the part sideways will pop off the part from the tray. Be very careful when using blades or other sharp tools: you risk damage to part, tray protective film, and even the tray surface ! Each time you remove a print, check the integrity of the protective film and/or airspray (or any other adhesion agent) and... -

Page 26: Extruder Assembling

Extruder assembling As for any maintenance duty, following few key rules will get you a good performing machine: • Keep you work area (were you will be performing extruder assembling) clean: powder, metal shavings, abrasive sand may compromise extruder performance •... -

Page 27: Extruder Change

Extruder change Anytime you need to change the extruder, you must follow this procedure: 1. Perform filament removal procedure 2. Turn OFF all heaters (extruder, plate and chamber) 3. Wait for cooling at room temperature of ALL parts 4. Move the plate at Z>=100, to gain easy access to nozzles 5. - Page 28 much, you could prevent complete rotation of tube adapter during removal 9. Remove (unscrewing) the tube adapter 10. Detach the connector (5): grab the connector body to pull, do NOT pull the cables! 11. Release the locking screw (6) 12. Now all the extruder assy (7) can slide downwards from holding part. 13.

-

Page 29: Routine Maintenance

Routine maintenance Filament handling To get good quality prints, you need good quality filaments and you should stock them correctly. Quality The filament must comply with three basic requirements: 1. Polymer quality – composition must be even, without presence of foreign materials 2. -

Page 30: Feeding Roller Cleaning

An alternative method can be tried if nozzle is not completely jammed: 1. Remove filament from the extruder 2. Insert PA6 filament (available on 3ntr web store) whose tip will be appropriately pointed 3. Feed the filament into extruder 4. Heat up the extruder up to 250°C 5. -

Page 31: Fitting The Soft Polymer Feeding Unit (Spfu)

Fitting the soft polymer feeding unit (SPFU) Fig 34: SPFU Used when soft filaments are needed (that are really difficult to use with standard feeders), the SFPU feeder lets you use any elastic filament available for FDM/FFF printers. Here follows the mounting procedure: 1. - Page 32 6. Place the SPFU unit on the extruder #1, plugging the small PTFE part protruding from the unit into the #1 extruder tube adapter 7. Arrange the SPFU routing the extruder cables around it, avoiding any cable pinching or pulling 8.

-

Page 33: Nozzle Z Leveling

Nozzle Z leveling Fig 40: Extruder assembly This procedure is the key to get good printing results. Therefore take your time to perform it correctly, you will be rewarded with consistent printing quality! Before going on, check that all nozzles are clean and free from plastic remains on the tips: to clean them you can warm up all extruders at working temperature with a paper towel (be sure not to leave further paper traces on nozzles!). - Page 34 11. Gently tighten the locking screw(1). Be sure that extruder assy won't freely slide up or down (but yet no excessive torque will be needed to pull it up – DO NOT OVERTIGHTEN) 12. Try to push a bit of A4 copy paper between nozzle and printing plate: paper must not pass 13.

-

Page 35: Xy Nozzle Calibration

! 2. Download (and unzip it in your STL directory) the calibration file: http://3ntr.eu/wp- content/uploads/2015/08/xy_align.zip 3. Import the downloaded files into KISSlicer (use mouse to click on the files while pressing the CTRL key) 4. - Page 36 9. Now, using a small lens, look carefully at the printed part: seek the point where the “align_line” is precisely in the middle of the printed “channel”, both in dX and dY sectors. IF machine is OK, the line should be at the middle of the channels at DX0 and DY0 positions. 10.

- Page 37 Fig. 46: Changed parameters ◦ Now you need to make sure that machine will remember this new setting: send the “M500” command to make the current setup as the default setting. Fig. 47: Storing settings • SOFTWARE (deprecated): faster solution but you will end up with a printer that can't use older gcodes (generated with previous offsets).

-

Page 38: Planned Maintenance

Planned maintenance Here is a list of checks you can commit to every 6-12 months to keep you machine in healthy state. Heat exchanger and liquid reservoir The upper left part of the printer contains the liquid cooling system. Dusty environment may decrease the performances of the heat exchanger (aka: radiator): to avoid problems we recommend to vacuum the air inlets (a household vacuum cleaner will do just fine) just from outside, without the need to remove any machine cover. -

Page 39: Firmware Update

Fig 50: All metrol endstop (top left front door) 44 = A4v3 2ex 441 = A4V3 2ex(ALL METROL ENDSTOPS) 442 = A4v3 2ex HC 4421 = A4v3 2ex HC (ALL METROL endstops) 443 = A4v3 3ex 4432 = A4v3 3ex HC 44321= A4v3 3ex HC (ALL METROL ENDSTOPS) -

Page 40: Firmware Update - Procedure

Firmware update - procedure Download the firmware uploader from our site http://3ntr.eu/wp-content/uploads/2014/08/XLoader.zip Xloader is © Geir Lunde: download it and unzip it on your PC. Now download the latest firmware version for your printer model http://3ntr.eu/?page_id=182 Before committing to firmware upload, be sure that the printer is not connected to any other application running on your PC (I.e..:Repetier Host). -

Page 41: Octoprint Configuration (Print Server)

Octoprint configuration (print server) Connecto to the print server • ◦ mouse and keyboard (USB) ◦ HDMI cable to connect to a TV/monitor ◦ power supply • Turn on print server, after boot enter User: pi Password: raspberry • At system prompt insert startx •... -

Page 42: Info Screen

LCD printer panel The fastest and easiest way to deal with your printer, enabling you to change several key parameter. Here follows a detailed description of each option: be sure to FULLY UNDERSTAND what you are going to do, since you can radically change the way the printer behaves. - Page 43 PREPARE menu Main Auto Home Move Axis Disable stepper Preheat PLA Preheat ABS Preheat GUM Cooldown • Back to main menu • Auto home: bring all axis to zero Move axis: lets you move any axis using the jogwheel • •...

- Page 44 PREHEAT menu (PLA/ABS/GUM) Prepare PLA/ABS/GUM 1 PLA/ABS/GUM 2 PLA/ABS/GUM 3 PLA/ABS/GUM ALL PLA/ABS/GUM BED • Prepare: back to previous menu • 1-2-3: sets the preheating temp for desired nozzle ALL: preheat all the printer heaters • • BED: preheat the printing bed MOVE AXIS menu Prepare Move 10mm (XY)

- Page 45 TEMPERATURE menu Control Nozzle 0 Nozzle 1 Nozzle 2 Nozzle 3 PID-P PID-I PID-D PID-P H1 PID-I H1 PID-D H1 PID-P H2 PID-I H2 PID-D H2 Preheat PLA conf Preheat ABS conf Preheat GUM conf • CONTROL: back to previous menu •...

- Page 46 MOTION menu Control Accel Vxy jerk Vz jerk Vmax X Vmax Y Vmax Z V min Vtrav Min Amax X Amax Y Amax Z A-Travel X step/mm Y step/mm Z step/mm Ve-jerk E0 Vmax E0 Amax E0 A-retract E0 E0steps/mm Ve-jerk E1 Vmax E1 Amax E1...

- Page 47 Troubleshooting Here follow the issues we usually deal with: knowing the answer in advance my save you precious time! #1 – Little or no extrusion • Filament has quality issues (diameter is bigger than 3.1mm or smaller than2.6mm, polymer purity problems, filament is contaminated with powder/dust) Check filament diameter, if needed discard the spool •...

- Page 48 #3 – Part is contaminated by support material / Color separation is not sharp • Extrusion temp is too high When an extruder is deselected, the higher temperature makes for liquid polymer state (aka: oozing) than flows out of nozzle due to gravity. Decrease printing and/or preheating temperature •...

- Page 49 #7 – Temperature readout is high (378°C) even if nozzle is cold Defective thermocouple • Replace heater assembly Bad connector • Replace heater assembly #8 – Printed part has “falling” sides (molten) • Problem with part cooling fan Check fan connection, see If there is anything trapped inside fan. If needed, change fan.

- Page 50 #13 – Sketchy movement, axis doesn't invert direction if needed See #10 • #14 – Filament is stuck into bowden (PTFE pipe feed to extruders) • ANY POLYMER Filament diameter is too big – change spool Excessive pressure on feeding roller: filament is squeezed – relieve pressure •...

-

Page 51: Table Of Contents

Index Congratulations!.........................2 Important safety advice......................4 LIMITED WARRANTY......................5 Unpacking..........................7 Installation.........................9 Using the printer with your computer..................14 Printer use........................19 Loading filament......................19 Filament removal – idle machine...................21 Filament removal – running machine................21 Changing filament type....................22 Placing print tray.......................23 Printing........................24 Print removal......................25 Extruder assembling....................26 Extruder change........................27 Routine maintenance......................29 Filament handling......................29... - Page 52 #3 – Part is contaminated by support material / Color separation is not sharp......48 #4 – Part is bigger / smaller than expected..............48 #5 – Print is not completed..................48 #6 – During homing, axis * doesn't stop and collides............48 #7 – Temperature readout is high (378°C) even if nozzle is cold.........49 #8 –...

Need help?

Do you have a question about the A4v3 and is the answer not in the manual?

Questions and answers