Table of Contents

Advertisement

Quick Links

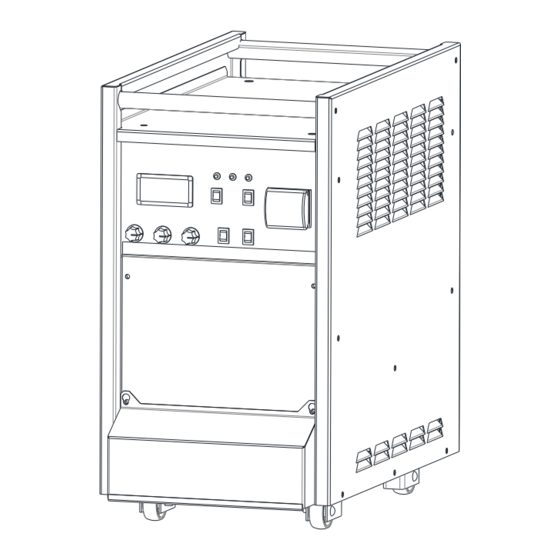

IGBT CONTROLLED DC ARC WELDING MACHINE

●

Thank you for your purchase of Panasonic welding power source.

●

Before operating this product, please read the instructions carefully and save this

manual.

●

SPEC. No.: YD-400AT3HJE

Panasonic Welding Systems (Tangshan) Co., Ltd.

Operating Instructions

Mo d e l No .

YD-400AT

TSM50855

Advertisement

Table of Contents

Summary of Contents for Panasonic YD-400AT

- Page 1 Operating Instructions IGBT CONTROLLED DC ARC WELDING MACHINE YD-400AT Mo d e l No . ● Thank you for your purchase of Panasonic welding power source. ● Before operating this product, please read the instructions carefully and save this manual. ●...

- Page 3 NOTICE: MACHINE EXPORT TO EUROPE This product does not meet the requirements specified in the EC Directives which are the EU safety ordinance. Please bear in mind that this product may not be brought as is into the EU. The same restriction also applies to any country which has signed the EEA accord.

-

Page 4: Table Of Contents

CONTENT S a f e t y P r e c a u t i o n - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1 Important Safety Items---------------------------------------------------------------------- 2 Summarize--------------------------------------------------------------------------------- 5 R at i ng---------------- --------------- -------- --------------- -------- ---------------- - 5... -

Page 6: Safety Precaution

Disclaimer: ◆ Panasonic Welding Systems(Tangshan) Co., Ltd., (hereinafter called “PWST”) and its affiliates (including any subcontractor, sales company or agent) shall not assume or undertake any responsibility or liability of the followings: •Any problem arising out of, or directly or indirectly attributable to,the failure of user to carry out those normal maintenance, normal adjustment and periodical check of this product. -

Page 7: Important Safety Items

2. Important Safety Items Welding power source (10)Perform periodic checks without fail and repair or replace any damaged parts before using the Observe the following instructions to power source. prevent the hazard. Ventilation and protective equipment (1)Never use the welding power source for other Oxygen deficit, fume and gas than welding purpose. - Page 8 performing maintenance work or repair work, provide Installing shielding (curtain etc.) fence or the like around the welding machine so that unauthorized person can not come close carelessly. Arc flash, flying spatter, slugs, and Welding wire noise generated during welding can damage your eyes, skin and hearing.

-

Page 9: Summarize

Notice: In order to get better performance and provide proper maintenance, please follow the below instructions: 1 If welding machine is placed on a slope, a countermeasure should be taken to keep it from falling on one side. 2 The degree of protection is IP21S, appropriate coverage is required in case of rain. 3 When using forklift, please fork welding machine at the side with “Fork”... -

Page 10: Preliminary Arrangements For Operation

Item YD-400AT3HGH YD-400AT3HJE Model Rated input voltage 3—380 (50/60Hz) 3—415 (50/60Hz) Rated input capacity kVA/kW 17.6/16.7 No-load voltage Welding current 20~410 Force current Max. 220 Start current Max. 150 Rated output voltage 36(STICK)/26(SIMPLE TIG) Rated duty cycle Controlled mode IGBT inverter Cooling mode Forced wind cooling —... -

Page 11: Function

Table 5.2 Output current (A) Cable (m) Cable (mm 5. Remark: The length of welding cable=the length of electrode holder+ the length of base metal cable (2) Grounding □ Keep well grounding, would prevent form electric shock and misaction of equipment caused by high- frequency electric wave generated by power source controller. -

Page 12: Connections

2. Power display lamp-------------Will light when turn on the power switch. 3. Welding current adjustor-------Regulates the welding current. 4. Arc force current adjustor------Regulates the arc force current. 5. Arc start current adjustor-------Regulates the arc start current. 6. Warning lamp of over-temperature---Will flicker onece every one second and no output with the abnormal temperature. -

Page 13: Operation

Please connect the output cable (electrode holder) to the end of ORDI. STICK (+), when welding with the ordinary electrode just as Fig.7.1a. Please connect the output cable (electrode holder) to the end of CEL. STICK (+), when welding with the cellulose-coated electrode just as Fig.7.1b. -

Page 14: Caution

1. Electric connection Check the bolts whether fasten and the ill-insulation both in the input side and output side. 2. Is there any hot evidence in the connection between the cables? Make sure that the power source grounding firmly. 3. The inside of the power source If the radiator is covered by a lot of dust, it won’t emit hot unhindered that may be bad for semiconductor or transistor. -

Page 15: Check Points For Abnormal Operation

11. Check points for abnormal operation Table 11.1 Abnormity Cause of warning Countermeasures Power lamp doesn’t light * The shortage of U or V phase in the * Check out the cause of and no output after the power supply the short voltage-phase. -

Page 17: Apart Layout Drawing

13. Apart Layout Drawing... -

Page 18: Parts List

14. Parts List Parts List of YD-400AT3HJE/ YD-400AT3HGH Table 14.1 Q’ty Symbol Part name Code Power Switch NDM1-63C50/3 Power display lamp (green) DB40BG LED(over-temp. warning) DB40BY LED(welding voltage warning) DB40BY Digital meter XL5135V-3T Welding current adjustor TV18Y20FB103FNCB Arc force current adjustor TV18Y20FB103FNCB Arc start current adjustor TV18Y20FB502FNCB... - Page 19 Please be absolutely sure to consult with us before attempting to relocate or resell this product to or in any EU member state or any other country which has signed the EEA accord. Panasonic Welding Systems (Tangshan) Co., Ltd. Add:No.9 Qingnan Road, New & Hi-Tech Development Zone, Tangshan,Hebei, China Post Code:063020 Tel:400-612-5816...