Table of Contents

Advertisement

Save This Manual

:

For Future Reference

owners

rnanua!

MODEL NO.

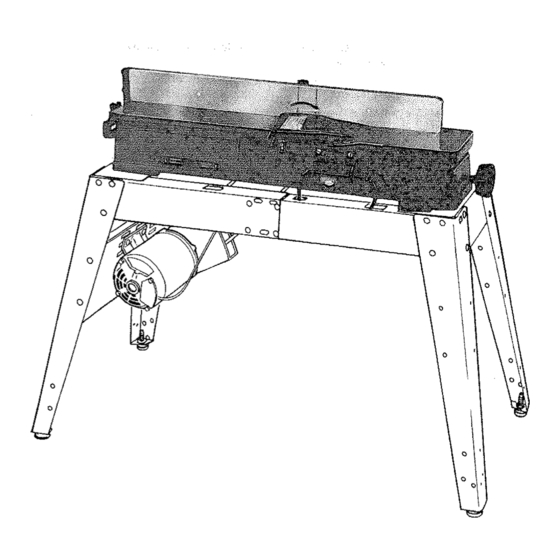

113.206932

JOINTER/PLANER

WITH

LEGS AND MOTOR

113.206891

JOINTERiPLANER

WITH

LEGS AND MOTOR

Serial

Number

Model and serial

number may be found

on a plate attached

to your base.

You should record both

model and serial number

in a safe place for

future use,

CAUTION:

Read ALL

iNSTRUCTiONS

carefully

6-1/8-iNCH

JOINTER-PLANER

® assembly

® operating

• repair parts

Sold

by SEARS,

ROEBUCK

AND

CO.,

Chicago,

_L. 60684

U,S.A.

Part No. 67095

Primed iN US A

Advertisement

Table of Contents

Summary of Contents for Craftsman 113.206891

- Page 1 Save This Manual For Future Reference owners rnanua! MODEL NO. 113.206932 JOINTER/PLANER WITH LEGS AND MOTOR 113.206891 JOINTERiPLANER WITH LEGS AND MOTOR Serial Number Model and serial number may be found on a plate attached to your base. You should record both model and serial number in a safe place for future use,...

- Page 2 eneraisafety instructions for power tooas 1. KNOW YOUR POWER TOOL safety glasses. Also, use face or dust mask if Read and understand the owner's manual and cutting operation is dusty, and ear protectors fabels affixed to the tool Learn its application (plugs or muffs) during...

- Page 3 :: _: _:i ¸¸i ¸¸:¸ii: :: _;: additional safety instructions for jointer-planer Safety is a combination of operator common sense and 9. PROTECTION: EYES; HANDS, FACE, EARS, BODY alertness at all times when the Jointer-Planer is being a. If any part of your jointer is malfunctioning, used.

- Page 4 Assembling Steel Legs ......Sharpening Cutter Blades ....Mounting Jointer-Planer On Recommended GENERAL MAINTENANCE ...... Craftsman Leg Set ......LU BRI CATION ......... i Checking Cutterblades and Screws ....MOTOR MAINTENANCE AND LUBRICATION ..i Mounting Switch. _.;, _._..

- Page 5 MENDED MOTORS ARE DUAL VOLTAGE. It is recommended that you have a qualified electrician replace the TWO prong outlet with a properly grounded THESE CRAFTSMAN MOTORS HAVE BEEN FOUND TO BE ACCEPTABLE FOR USE ON THREE prong outlet. THIS TOOL.

- Page 6 unpaC kingand checking contents : ..TA.LEO LOOSEPARTS No. :, Description ..Qty.: Combination Square A Jointer-Ptaner ......B V-Belt, 1/2 x 52" ......; _l / i•i ii i *C 5/32 Setscrew Wrench ....... *D 1/8 Setscrew Wrench ......1/2"...

- Page 7 unpacking and checking contents TABLE OF LOOSE PARTS The Following Parts Are Included With Models 113.206891 and 113,206932 Item Description Qty. Leg ........B End Stiffener ....... Side Stiffener ......Motor Support ......Motor ........Package of Miscellaneous Small Parts, No, 67035, Consisting of the Following: F Cord Clip ........

- Page 8 assembly MOUNTING JOINTER-PLANER i:. From among the loose parts, find the following hard- ware: 4 Carriage Bolts, 5/16-18 x 3/4 3 Hex Head Screws; 5/16-18 x 2 7 Lockwashers, 5/16 in. External Type 7 Washers, 11/32 ID 7 Hex Jam Nuts, 5/16-18 2 Cord Clips LOCK 2.

- Page 9 MOUNTING SW|TCH 2 Lockwashers, External 1/4 1. Locate the following parts: 2 Washers, 17/64 x 1/2 x 1/32 ! On/Off Power Outlet 2. Attach On/Off outlet to infeed table using two tapped holes. 2 Pan Hd. Screws, 1/4-20 x 1/2 IIj!' ILLLjl JI!l...

- Page 10 6. P0sition btherend Of V:Belt ontoCutter head p_iiey..: OPEN ii1111111 iiii iiii II iiiii .lUll eupboth pu eys d 7. Visually fin V-Belt until they are PULLEYS V-BELT perpendicular to the floor by sliding motor sideways ..I-MUST BE STRAIGHT IN-LINE as needed.

- Page 11 WASH ER SLIDING GUARD KNOB (CONCAVE SIDE UP) 6.Attachslidingguardto :10-32xl/4 SCREWS'_ fence with two pan head screws and lockwashers, EXT. TOOTH LOCKWASHERS 7. Place one Sliding Guard Washer, concave side DOWN on support rod. 8. Drop sliding guard onto rod,., place other washer, concave side UP on rod.., screw on Sliding Guard...

- Page 12 : gettmg to know : ..your joi nter-pianer .... g--re:FENCE LOCKS AND STOPS. _The fence can be moved across the J:ointer to take full advantage of the "sharpness" of the blades. The fence should be positioned to the extreme right (toward pulley) but not beyond the end of the blades.

- Page 13 SCALE ADJUSTING Loosen 90 ° stop screw with small screwdriver SCREW and turn knurled sleeve which will cause fence to '_45 _ STOP tilt. Turn sleeve in either ,direction until fence is 45" STOP \ LOCKSCREW square with infeed table, TILT NOTE: If you cannot square fence by turning...

- Page 14 : yourjo" te lane getting:: know:: mn r,p CROWNED CUT i:I_ , I_<_--_-__ ' > _L_ __--_--'-I 5; _ ,.,EEO_=E" MUST,LWAYS BE P ARALLEL.TO THE OUTFEED TABLE..If the : cUt edge or surface of the workpiece CROWNED, it isan indication that the OUTWARD END of the INFEED table is HIGH and must be...

- Page 15 PENCI L e. Insert a pencil in space at end of cutterhead hold cutterguard open. f. Wrap a piece of cardboard around cutterhead protect your fingers and the blades.., secure cardboard with a piece of tape. h. Loosen four lock screws 2 or'3 turns with 1/2 in. wrench.

- Page 16 • " getting to,know your jomter-planer I_'_': ON-OFF SWITCH: it is unlikely that it will be turned "ON" accidentally, when touched or bumped, because of the way it is shaped. Inan emergency, it can be turned "OFF" by striking it with the palm of the hand. The "yellow button"...

- Page 17 MOTOR CORD e. P!ug motor cord into outlet in switch box. OUTLET POWER CORD basic jointer-pUaner operation WARNING: For your own safety, ALWAYS use the hold the cutterhead and can be kicked back toward you, down!push blocks when JOINTING wood that For your own safety, never operate this tool with the fence NARROWER than 3 in..

- Page 18 i ¸¸ • • • basic: omter-planer operatmon, WITH THE GRAIN ROTATION Always feed WITH THE GRAIN whenever possible, if the nature of the workpiece is such that it must be fed AGAINST THE GRAIN, take very light Cuts and feed slowly.

- Page 19 BEVELING Adjust the fence to the desired angle.., tighten fence and guard lock knobs, For pieces of wood 3" or wider hold the board firmty down on both tables and firmly against the fence (as i!lustrated) with your hands on the side and top of the workpiece,.. keep fingers close together.

- Page 20 WEDGE LOCKSCREW._L_ "---'J --.--..,_..,...,,. 7. Remove the six lifter screws. (Two under each blade.) 8. Clean cutterhead, wedges and screws thoroughly with Craftsman Gum and Pitch Remover. also remove the CUTrER HEAD oil from new blades. SETSCREW 9. Replace the six lifter screws and screw them in all the way, but do not tighten.

- Page 21 1/8 IN. SETSCREW WRENCH HEAD OF 10. Insert a blade in slot marked 1. ,, so it projects 1/16 in, SQUARE beyond end of the cutterhead. 11, "Insert a wedge next to blade so the flat side of the wedge is against the blade. Push wedge in manualy -do not install two locking setscrews at this time."...

- Page 22 FENCE CUTTER GUARD IN PLACE • • /_• !•: ¸ • :2: Position guard as shown, wtthPIVOT PIN above hole in infeed table: 3. Align SLOT in pin with TANG in spring, and press down, TANG OF SPRING IN CENTER OF 4.

- Page 23 The following parts should be oiled occasionally with SAE No. 20 or No. 30 engine oil. 1. Dovetail spacer and dovetail slide, DOVETAIL 2, Elevating screw (first clean with Craftsman Gum and SPACER AND SLIDE Pitch Remover). ELEVATING SCREW VIEW...

- Page 24 lubrication MOTOR MAINTENANCE AND LUBRICATION NOTE: The speed of this motor can not be regulated or changed. 1. The bearings, in both end shields of the motor, have 4: Every effort should be madeto prevent foreign material been lubricated at the factory with correct lubricant.

- Page 25 TROUBLE SHOOTING -- MOTOR NOTE: Motors used on wood-working tools are particularly susceptible to the accumulation of sawdust and wood chips and should be blown out or "vacuumed" frequently to prevent interterence with normal motor ventilation and proper operation of the centrifugally- operated starting switch, TROUBLE PROBABLE CAUSE...

- Page 26 55 56 FIGURE •...

- Page 27 CRAFTSMAN 6-1/8 INCH JOINTER-PLANER MODELS 113.206801,113.206932 113.206891 Always order by Part Number - Not by Key Number FIGURE 1 -- PARTS LIST Part Part Description Description • ..STD522512 STD512505 "Screw, Pan Hd, 1/4-20 x 1/2 *Screw Mach., 1/4-20 x 1-1/4 Truss Hd.

- Page 28 CRAFTSMAN 6'1/8 INCH JOINTER-PLANER MO D E LS 113.206801,113.206932 AN D 113.206891 FIGURE 2 m LEGS PARTS LiST Part • Description 67033 Stiffener, End 60314 e Screw, Truss Hd 1/4-20 x 5/8 STD55t225 e*Lockwasher, 1/4 External STD541025 e'Nut,...

- Page 29 CRAFTSMAN 6-1/8 INCH JOINTER-PLANER MODELS 113.206801, 113.206932 AND 113.206891 _---_ _- " FIGURE 3 FIGURE 3 -- INFEED TABLE PARTS LIST Part Part Description Description lllll STD561210 *Pin, Cotter, t/8 x 1 21422 Spacer, Dovetail 67015 Guard 21219 Dovetail, Male...

- Page 30 repair parts FIGURE 4 FIGURE 4 -- 21013 FENCE ASSEMBLY PARTS LIST Part Part Description Description ,,,,,,,, STD551210 21013 *Lockwasher, Ext. #10 Fence Assembly STD511102 21440 *Screw, Mach., No. 10-32 x 1/4, Plunger Assembly Pn Hd., Slotted 21430 Pin Assembly, Stop 67009 Guard, Cutter *Screw, Hex Hd., 1/'4-20 x 1-1/4...

- Page 31 CRAFTSMAN 6-1/8 INCH JOINTER-PLANER MODELS 113.206801,113.206932 AND 113.206891 NOTE: ANY ATTEMPT TO REPAIR THIS MOTOR MAY CREATE A HAZARD UNLESS REPAIR IS DONE BY QUALIFIED SERVICE TECHNICIAN. REPAIR SERVICE IS AVA|LABLE AT YOUR NEAREST SEARS STORE. FIGURE 6 -- MOTOR...

- Page 32 owners 6-1/8 raNCH JOUNTER-PLANER manual SERVICE Now that you have purchased your jointer-planer, should need ever exist for repair parts or service, simply contact any Sears Service Center and most Sears, Roebuck and Co. stores. Be sure to provide all pertinent facts when you call MODEL NO.