Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Hanbell SAM-285

- Page 1 Operation Manual Oil-Free Scroll Compressor Operation Manual SHANGHAI HANBELL PRECISE MACHINERY CO.,LTD. No.108, Jiangong Rd., Fengjing Area, Jinshan District, Shanghai TEL/FAX : 021-57350280 / 021-51368588 http://www.hanbell.com.cn E-mail: hanbell-sales@hanbell.cn...

- Page 2 12 months after the completion of installation and commissioning at the first job-site or within 15 months from the date of delivery from the Hanbell. However, we will not be responsible if the product does not operate properly for following reasons: ...

- Page 3 Foreword When you compile the operation manual for the equipment with Hanbell scroll air end, all the information and data related to operation safety in this manual shall be fully considered. Please read this manual carefully and make sure fully understand the contents before using the machine.

-

Page 4: Table Of Contents

Operation Manual CONTENT General provisions ............................. 5 Models ..............................5 Identification ............................5 Precautions in using ..........................5 Use the compressor properly ......................7 Sale and after service .......................... 7 2. Safety ................................8 Employee qualification and training ....................8 Safety Instructions .......................... -

Page 5: General Provisions

Operation Manual General Provisions 1.1 Models ; SAM-285, SAM-440, SAM-700 Product coding principles i.e. for SAM -440-08 are as follows: SAM: model series; 440: inlet volume : l/min; 08: discharge pressure: kg/cm^2 The scroll air end rotates counterclockwise from the shaft end direction. - Page 6 Please contact Hanbell for direct drive oil free scroll compressor. The scroll compressor must be installed in the environment which is compatible with the operation...

-

Page 7: Use The Compressor Properly

"technical data". Any other way of usage shall be deemed as improper use. Hanbell shall not be liable for the loss caused by improper use, and those who use the machine shall be responsible for it. -

Page 8: Safety

The company using Hanbell scroll compressor shall explain the scope of responsibility and the ability of employees shall acquired in detail. If the employees do not have the necessary knowledge, corresponding training shall be carried out. - Page 9 It is not allowed to modify and improve the compressor without the authorization of Hanbell. The original spare parts of Hanbell scroll compressor and the parts provided by the dealer authorized by Hanbell can ensure the safety of the scroll air end you purchased.

-

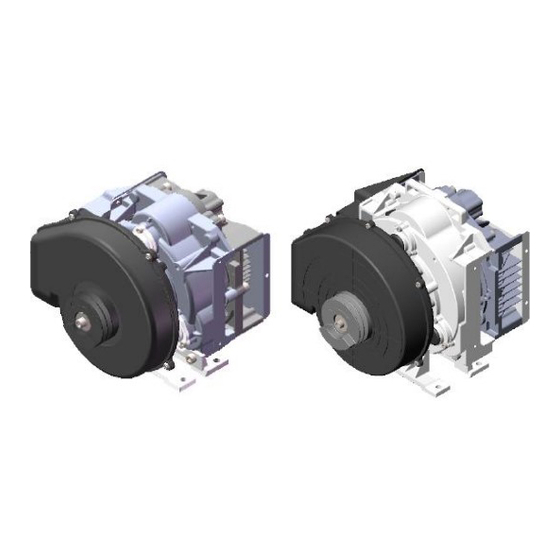

Page 10: Description Of Scroll Compressor And Spare Parts

Operation Manual Description scroll compressor and spare parts 3.1 The Description of scroll compressor Oil free scroll air compressor has lots of excellent technical advantages, such as compact structure, small volume, light weight, low noise, long service life, low vibration value of the whole machine, stable and continuous gas outlet, simple operation, low maintenance cost and so on. -

Page 11: Oil-Free Scroll Air End Technical Data

3.4 Oil-free scroll air end technical data Shaft Rated Exhaust Air displacement Speed Noise Dimensional Weight Power pressure connecting Model level L/min inch r/min dB(A) 2840 SAM-285 PT3/8" 270x300x265 15.5 2400 3050 SAM-440 PT1/2" 347x330x295 19.5 3000 2950 SAM-700 PT3/4" 335x381x357 31.5 2650... -

Page 12: Direction For Installation

Operation Manual Direction for Use Power Supply 1)According to the power and voltage of the machine, suitable power supply shall be provided and the fluctuation of voltage shall not exceed ± 5%, and the three-phase imbalance shall be less than 3%. 2)Use suitable switch and electrical breaker according to the power and voltage of the machine. -

Page 13: Control System

Operation Manual 2)Check whether all pipeline joints, instruments, circuit connection joints, etc. are loose, fallen off or damaged due to transportation, installation, etc. If so, please tighten or replace it; make sure whether the exhaust valve is open. 3)Connect the power line and ground wire, and test whether the voltage and the three-phase power supply is correct. -

Page 14: Maintenance

Operation Manual Maintenance The maintenance person must have certain knowledge of mechanic and electricity and operation skills, and have a certain understanding of air compressors. Carefully read the operation manual before maintenance. 1)Maintenance must be carried out when the machine is stopped, the stop valve is closed and the power supply is off. - Page 15 Operation Manual Maintenance items for scroll air end 1)Check and make sure the maintenance schedule carried out as planned. 2)Carry out daily maintenance. If the current conditions and/or load conditions are harsh, the corresponding maintenance time shall be shortened. 3)Seals do not need to be replaced in early time. Normally they need to be replaced after 3000 hours of 10 bar.g operation.

- Page 16 Operation Manual Working Hours NOTE Working Item 500hrs 2500hrs 5000hrs 10000hrs 15000hrs 20000hrs hours Every Every Every 2 Every 4 Every 6 Every 8 Intervals ● Bearing Grease filling Grease filling per 2500hrs ● ● ● ● ● Tip Seal Check/replace Replace every 2500hrs ○...

-

Page 17: Trouble Shutting

Operation Manual Fault and maintenance ; Fault Case Maintenance 1.No power supply 1.Check power supply 2. Low of voltage 2.Check power supply voltage and motor power 3.Unsuitable dimension and length of 3.Replace wire Fail to start power wire 4.Check the circuit and replace the fuse 4.Fuse broken 5.Exchange the phase 5. - Page 18 Operation Manual a few minutes of operation; b. Check whether the check valve works properly. Open the safety valve for air release, and then check if the valve is installed or set correctly c. Please check to ensure that the air intake system is smooth. If the air intake system is closed, the dynamic and static scroll plates may be damaged during operation, which is not covered by the warranty;...

-

Page 19: Exemption And Statement

Data in this manual are subject to change without notice. Hanbell has the right to change or upgrade the products, and that cannot not be the reason for warranty claim. -

Page 20: Appendix 1 Maintenance And Replacement Diagram For Scroll Compressor

Operation Manual Appendix 1 Maintenance and Replacement Diagram for Scroll Compressor grease filling Tip seal replacement... - Page 21 Operation Manual...

- Page 22 Operation Manual Customer service line:400-770-2158 Tel: 021-5735-0280 Fax: 021-5136-8588 Data in this manual are subject to change without notice.