Table of Contents

Advertisement

Advertisement

Table of Contents

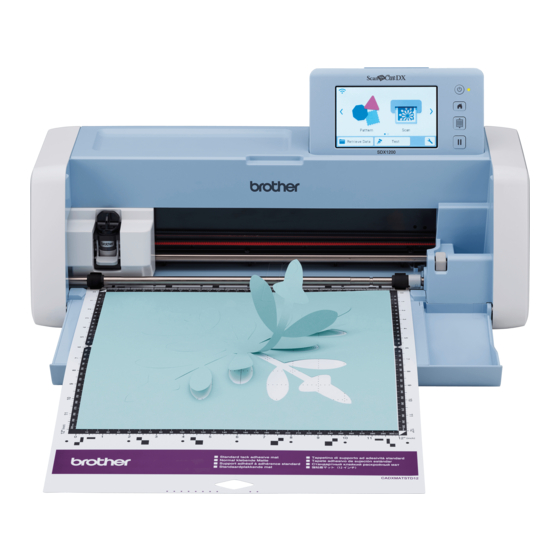

Summary of Contents for Brother ScanNCut DX

- Page 1 Roll Feeder...

-

Page 2: Table Of Contents

CONTENTS Read Before Use ................................. 2 Accessories ........................................2 Operating Precautions ....................................2 Creating Data for the Roll Feeder ..........................3 Activating the Roll Feeder Function ................................3 Creating Data ........................................4 Weeding Box Function ....................................5 Exporting Data as FCM File .................................... 7 Sending Data to the Machine.................................. -

Page 3: Read Before Use

This part is a consumable. When the cutting edge becomes blunt, purchase CADXRFC1 (trimmer blade). Purchase consumables from the authorized retailer where the roll feeder was purchased. Operating Precautions This attachment was specially designed for the ScanNCut DX model. It cannot be used with any model other than the ● ScanNCut DX. -

Page 4: Creating Data For The Roll Feeder

Create data for the roll feeder with CanvasWorkspace (PC Version). CanvasWorkspace (PC Version) (ver. 2.0.0 or later) must be downloaded and installed on your computer. ● (http://s.brother/cuoad/) In order to use CanvasWorkspace, a CanvasWorkspace login ID is required. ● If you do not have a free account, click [Create New Account] in the screen that appears after installation, and then follow the on- screen instructions to create an account. -

Page 5: Creating Data

If necessary, change the height and orientation of the Creating Data artboard. Create data for the roll feeder with CanvasWorkspace. ■ Preparing the Format Start up CanvasWorkspace on a computer. Click (Artboard) on the right side of the screen. a Artboard height b Artboard orientation (Portrait/Landscape) ... -

Page 6: Weeding Box Function

■ Creating Cutting Data Weeding Box Function You can either create original data in CanvasWorkspace or import data, then edit it. For this example, we will create data by editing the pre-installed sample pattern. Weeding is the process of removing the unnecessary parts around a cut pattern to leave the desired parts on the backing Select (Roll Feeder) in the object panel, and then drag... - Page 7 Click (Edit) on the right side of the screen. Select how to specify the size of the weeding box. ■ [Specify the Spacing from the Selected Object] The [Edit] Panel appears in the Control Panel. Specify the values, and then click [OK]. ■...

-

Page 8: Exporting Data As Fcm File

Repeat steps for each object that will be cut Exporting Data as FCM File with a weeding box. The weeding box is created. Save data as an FCM file on a computer or USB flash drive, and then use a USB flash drive to transfer the data to the cutting machine. -

Page 9: Sending Data To The Machine

In CanvasWorkspace, select [Transfer FCM File to Sending Data to the Machine ScanNCut DX via USB Cable…] from the [File] menu. Data opened in CanvasWorkspace can be transferred to a cutting machine as an FCM file (which can be retrieved on the cutting machine). -

Page 10: Installing The Roll Feeder

Installing the Roll Feeder In order to install the roll feeder for cutting, the cutting machine must be prepared, and preparations must be made to install the roll feeder and rolled material onto the machine. Grab the feed roller and feed roller lock dial, and then, Installing the Base Attachment to the Machine while holding the feed roller in place, rotate the feed roller lock dial toward the back to the unlock position... -

Page 11: Installing The Roll Holder

Return the feeder release lever (on the right side of the Installing the Roll Holder machine) to its original position. Place the roll holder down so that its hooks fit into the holes in the front tray cover. a Feeder release lever ... -

Page 12: Checking The End Of The Material

While squeezing the adjustment lever, slide the right Checking the End of the Material guide plate against the roll to correctly align the left edge of the material. Make sure that the end of the material is evenly trimmed to meet all of the following conditions. -

Page 13: Evenly Trimming The End Of The Material

Pull the end of the material until it reaches the guide Evenly Trimming the End of the Material channel. • Check that the side to be cut faces up. Pull the end of the material until it extends past the guide channel. - Page 14 Make sure that the trimmer blade is positioned at the Return the trimmer blade to the right end of the trimmer, right end of the trimmer. and then remove the trimmer. Remove any material that has been trimmed off. a Trimmer blade a Trimmer b Trimmer Memo...

-

Page 15: Feeding The Material

Feeding the Material While keeping the left edge of the material aligned with the rolled material guide, lightly insert the material under the left and right feed rollers. While holding the material inserted under the feed rollers so that the material does not shift, press in the operation panel. -

Page 16: Retrieving Roll Feeder Data On The Machine And Cutting

Retrieving Roll Feeder Data On the Machine and Cutting Retrieve data created in CanvasWorkspace (PC Version) on the cutting machine. From the cutting machine, data cannot be edited, and the scanning functions are not available. Memo Retrieving Data on the Machine •... -

Page 17: Cutting

Confirm the data, and then touch the “OK” key. Cutting Make sure that the auto blade holder has been installed in ● the carriage of the machine. For details on the blade holder that can be used, see “Blades That Can Be Used” on page 36. - Page 18 To perform trial feeding, touch Install the trimmer over the material. • For details, see “Trial Feeding” on page 20. Align the holes in the trimmer with the pins in the base attachment. To change the cutting start position, touch •...

-

Page 19: Trial Cutting

After cutting off the material, confirm the instructions, Trial Cutting and then touch the “OK” key. Perform trial cutting or drawing on the type of material to be used in your project, to check that the desired result can be achieved. - Page 20 (1). In that case, cutting may no longer be performed correctly. Contact Brother Customer Service or Brother authorized service center. Touch to move the test pattern to a different location.

-

Page 21: Trial Feeding

Touch in the test screen to display the settings Trial Feeding screen. Before cutting, you can check if the material can be fed in straight and whether the length of the material is sufficient for the length of the cutting pattern. In order to check that the material can be fed without any problem, do not leave the machine during trial feeding. -

Page 22: Changing The Cutting Start Position

When trial feeding is finished, the following message Changing the Cutting Start Position appears. Touch the “OK” key to return to the previous screen. The cutting start position can be moved up or down (in the feeding direction) to the desired location. To change the cutting start position, touch ... -

Page 23: Continuous Cutting

Touch “Continue to cut”. again to continue cutting. * This depends on the material and operating conditions specified by Brother. ■ Repeatedly Cutting the Same Pattern Touch “Continue to cut”. ... -

Page 24: Removing The Roll Feeder To Feed Using A Mat

Removing the Roll Feeder To Feed Using a Mat The roll feeder must be removed in order to attach material to a mat for cutting. Lift up the base attachment to remove it from the Slide the feed roller from machine. - Page 25 While squeezing the adjustment lever, slide the right Lift up the roll holder to remove the hooks on the roll guide plate. holder from the holes in the front cover. a Hooks on roll holder b Holes in front tray cover Stack the base attachment, roll holder and trimmer to store them.

-

Page 26: Consumables/Maintenance

To purchase parts, contact the retailer where this product was purchased or the nearest Brother authorized service center. For details on optional accessories, refer to the Operation Manual for the cutting machine, or see page 2 in this manual. - Page 27 ■ Installing the Trimmer Blade Fit the tab on the left side onto the rail of the trimmer. Trimmer blade correctly installed Lightly push back on the stopper at the left end of the trimmer. a Tab on trimmer blade b Rail ...

-

Page 28: Cleaning The Trimmer Blade

Cleaning the Trimmer Blade If material debris, lint or dust accumulates inside the trimmer blade, it may no longer cut material. Periodically clean the trimmer blade. Memo • Do not disassemble the trimmer blade. Remove the trimmer blade from the trimmer. •... -

Page 29: Troubleshooting

Troubleshooting If the machine stops operating correctly, check the following possible problems as well as the FAQ on the Brother Solutions Center (http://s.brother/cpoac/) before requesting service. If the problem persists, contact Brother Customer Service or Brother authorized service center. An asterisk (*) listed as a reference page indicates the Operation Manual for the cutting machine. For wireless network troubleshooting, refer to the Wireless Network Setup Guide for the cutting machine. - Page 30 If the blade penetrates the material, faint cut marks may remain on the machine's surface where the blade makes contact (1). Contact Brother Customer Service or Brother The material cannot be cleanly — cut. authorized service center.

-

Page 31: When Material Has Become Jammed In The Machine

When Material Has Become Jammed in the Note Machine • If material gets under the carriage and cannot be removed, make sure that the machine is turned off, remove the holder from the carriage, and then slowly move the Press in the operation panel to turn off the machine. - Page 32 ■ When Jammed Material Cannot Be Removed Cut-off material may not feed out from the back of the machine. Follow the procedure below to remove any jammed material. Note • After cutting off material with the trimmer blade, material being fed out to the back of the machine may be too short and remain in the machine.

-

Page 33: Error Messages

The following table lists some of the messages that may appear while the machine is operating as well as their corresponding solutions. Perform the necessary operation according to the instructions in the message or the solution described here. If the problem persists, contact Brother Customer Service or Brother authorized service center. Cutting Machine Error Messages Error message (cutting machine) Cause/solution The data cannot be read. -

Page 34: Useful Information

The roll feeder is specially designed for the ScanNCut DX. It cannot be used with any model other than the ScanNCut DX. In order to use the roll feeder function, the dedicated application CanvasWorkspace (PC Version) must be installed on your computer and used to edit the pattern. - Page 35 Transfer the cut-out patterns to the After wiping the target surface Finally, peel off only the application application sheet so that they clean, attach the adhesive craft sheet. remain correctly arranged. vinyl cutouts with the application sheet. ( The application sheet (also called a transfer paper or retack sheet) is a low-tack sheet used for attaching the adhesive craft vinyl to the target surface.

-

Page 36: Non-Compatible Material

Non-Compatible Material The following material cannot be used, even if it has backing paper or backing film. The material may separate and cause jamming during cutting. ■ Material whose end curls upward when the roll is loaded with the backing paper or backing film facing down Be sure to check this when using iron-on transfer material. -

Page 37: Sizes Of Rolled Material That Can Be Loaded Into The Roll Feeder

Sizes of Rolled Material That Can Be Loaded Into the Roll Feeder Rolled material of the following sizes can be loaded into the roll feeder. a Material width 305 mm (12") b Roll diameter 39 mm – 115 mm (1.5" – 4.5") c Outer diameter of paper core 42 mm –... - Page 38 English Version A...