Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Mack E7

- Page 1 E7 ENGINE OVERHAUL AUGUST 1997 ENGINE 5-101...

- Page 2 front.fr5 Page 0 Friday, March 17, 2006 11:04 AM Page 0...

- Page 3 Please include a copy of each page in question and mark your comments and suggestions. Name: ________________________________ Phone: (_____) _____-_______ Company: _______________________________________________________ Address: ________________________________________________________ City: _________________________________ State: _______ Zip: _______ Position Title: ____________________________________________________ Thank You For Your Assistance Mack Trucks, Inc. (ATTENTION: RTS STAFF, 6S3) DO NOT STAPLE — USE TRANSPARENT TAPE...

- Page 4 IN THE UNITED STATES BUSINESS REPLY MAIL FIRST CLASS MAIL PERMIT NO. 1602 ALLENTOWN, PA POSTAGE WILL BE PAID BY ADDRESSEE SERVICE PUBLICATIONS (RTS), 6S3 MACK TRUCKS INC WORLD HEADQUARTERS PO BOX M ALLENTOWN PA 18105-9972 FOLD ALONG THIS LINE...

- Page 5 E7 ENGINE OVERHAUL MARCH 2006 2.5M (REP .) © MACK TRUCKS, INC. 1997 AUGUST 1997 10M ENGINE 5-101...

- Page 6 No part of this publication may be reproduced, stored in a retrieval system, or be transmitted in any form by any means including electronic, mechanical, photocopying, recording, or otherwise without prior written permission of Mack Trucks, Inc. Page ii...

-

Page 7: Safety Information

front.fr5 Page iii Friday, March 17, 2006 11:04 AM SAFETY INFORMATION SAFETY INFORMATION Page iii... - Page 8 front.fr5 Page iv Friday, March 17, 2006 11:04 AM SAFETY INFORMATION Advisory Labels Cautionary signal words (Danger-Warning-Caution) may appear in various locations throughout this manual. Information accented by one of these signal words must be observed to minimize the risk of personal injury to service personnel, or the possibility of improper service methods which may damage the vehicle or render it unsafe.

- Page 9 front.fr5 Page v Friday, March 17, 2006 11:04 AM SAFETY INFORMATION Service Procedures and Tool Usage Anyone using a service procedure or tool not recommended in this manual must first satisfy himself thoroughly that neither his safety nor vehicle safety will be jeopardized by the service method he selects. Individuals deviating in any manner from the instructions provided assume all risks of consequential personal injury or damage to equipment involved.

- Page 10 Page vi Friday, March 17, 2006 11:04 AM SAFETY INFORMATION Mack Trucks, Inc. cannot anticipate every Use hoists or jacks to lift or move heavy possible occurrence that may involve a potential objects. hazard. Accidents can be avoided by recognizing...

-

Page 11: Explanation Of Numerical Code

front.fr5 Page vii Friday, March 17, 2006 11:04 AM EXPLANATION OF NUMERICAL CODE EXPLANATION OF NUMERICAL CODE Page vii... -

Page 12: Explanation Of 3-Digit Numerical Code

AND TIRES, DRIVELINE NUMERICAL CODE GROUP 500 — BRAKES, AUXILIARY SYSTEMS The organization of MACK service manuals has been upgraded to standardize manual content GROUP 600 — CAB, TRUCK BODY according to a reference system based on GROUP 700 — ELECTRICAL component identification. -

Page 13: About This Manual

front.fr5 Page ix Friday, March 17, 2006 11:04 AM ABOUT THIS MANUAL ABOUT THIS MANUAL Page ix... - Page 14 It includes brief those that pertain to the E7 engine. The component descriptions and information needed TROUBLESHOOTING section contains to properly service that component.

- Page 15 front.fr5 Page xi Friday, March 17, 2006 11:04 AM TABLE OF CONTENTS TABLE OF CONTENTS Page xi...

-

Page 16: Table Of Contents

front.fr5 Page xii Friday, March 17, 2006 11:04 AM TABLE OF CONTENTS SAFETY INFORMATION ............. iii Advisory Labels. - Page 17 front.fr5 Page xiii Friday, March 17, 2006 11:04 AM TABLE OF CONTENTS [231 PB] FUEL FILTER ADAPTER ASSEMBLY ........4-6 [215 LD] COOLANT CONDITIONER ELEMENT .

- Page 18 [266 KD] DYNATARD ENGINE BRAKE ......... . . 5-51 Dynatard Overload Protection (E7 Engines with Dynatard) ......5-51 Dynatard Overload Protection System .

- Page 19 front.fr5 Page xv Friday, March 17, 2006 11:04 AM TABLE OF CONTENTS Inspection ..............5-56 Assembly .

- Page 20 [211 NB] OIL PAN ............6-46 Description (Isolating Oil Pan Gasket on E7 Engines) ......6-46 Oil Pan Installation .

- Page 21 front.fr5 Page xvii Friday, March 17, 2006 11:04 AM TABLE OF CONTENTS [213 EV] CYLINDER HEADS ........... . 6-51 Description .

- Page 22 E7 Series Engines with Front Timing Indicators ........

- Page 23 200 APPENDIX ..............10-1 E7 ENGINE SERIAL NUMBERS, JACOBS BRAKE APPLICATION ..... . 10-2 E7 LUBRICATION SYSTEM .

- Page 24 front.fr5 Page xx Friday, March 17, 2006 11:04 AM NOTES Page xx...

-

Page 25: 200 General Information

5-101.bk Page 1 Friday, March 17, 2006 11:05 AM 200 GENERAL INFORMATION GENERAL INFORMATION Page 1-1... -

Page 26: Introduction

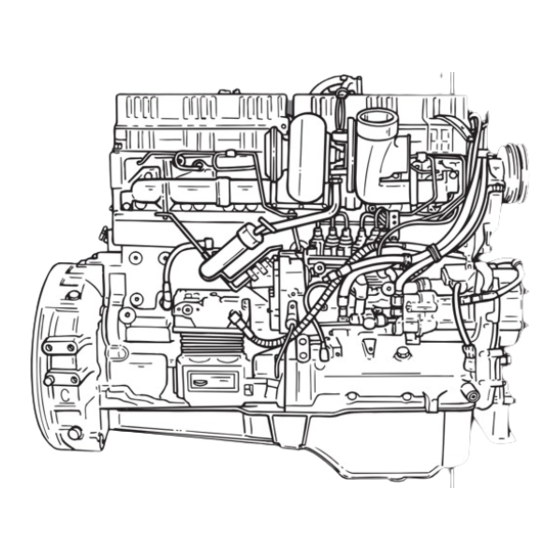

This manual is intended to assist the technician in properly overhauling MACK E7 engines. The manual is divided into nine major sections. Working on the E7 engine is not difficult, but like most present-day precision equipment, it requires proper tools and knowledge. -

Page 27: Engine Model Identification

NO and particulates unique to that engine. Engine Information Plate A given MACK engine may meet federal emission regulations in 49 states (excluding California) or All engines are identified by an engine an engine may meet emission regulations of all information plate located on the front valve cover 50 states (including California). - Page 28 Block seven indicates the initial setting for certified. E7 injection timing. E7 EUP (E-Tech™) engines do not have an Block 5 — Federal Family initial injection timing, as this is controlled electronically. E-Tech™ engines have “NA”...

-

Page 29: Lubricants And Sealants

5-101.bk Page 5 Friday, March 17, 2006 11:05 AM 200 GENERAL INFORMATION LUBRICANTS AND SEALANTS Use only the following recommended sealing All genuine MACK cylinder head gaskets are compounds and lubricants. precoated and do not require any type of sealing compound. Before installing new gaskets, degrease both gasket sealing surfaces to avoid leaks. -

Page 30: Overhaul Part Replacement

5-101.bk Page 6 Friday, March 17, 2006 11:05 AM 200 GENERAL INFORMATION OVERHAUL PART REPLACEMENT Use genuine MACK parts at all times. Parts that are typically replaced during an engine overhaul are listed below: Gaskets and seals Bearings and bushings... -

Page 31: 200 Specifications

5-101.bk Page 1 Friday, March 17, 2006 11:05 AM 200 SPECIFICATIONS SPECIFICATIONS Page 2-1... -

Page 32: Improved Design

Improved Design and a superior engine cooling system. This was all accomplished without a substantial change in Compared to earlier designs, the E7 engines engine weight. include improvements required to accommodate Engine General Specifications Characteristic... - Page 33 Exhaust gas driven, radial flow, engine oil lubricated (Schwitzer or Garrett) Lubrication system Full pressure, wet sump, 33.5 quart (32 L) capacity, 25,000 mile (40,225 km) highway/300 hour stop-and-go change interval, MACK approved EO-L oil. Valve seat inserts Pressed-in cylinder heads (30° inlet seat before November 1996, 20° inlet seat after November 1996, 30°...

-

Page 34: Good Shop Practice - Fasteners

1992 MACK Engine Tune-Up permanent damage to the engine components. Specifications No. 5-304ID92 and V-MAC Metric fasteners are used on the E7 engine with a Service Manual No. 8-201. For information on few exceptions. The exceptions are fasteners... -

Page 35: Fastener Torque

5-101.bk Page 5 Friday, March 17, 2006 11:05 AM 200 SPECIFICATIONS FASTENER TORQUE Proper installation is as important as the selection of the correct fastener. Improperly installing a correct fastener is just as bad as using an Fastener Selection and Installation incorrect one. -

Page 36: Fastener Sizes And Types

5-101.bk Page 6 Friday, March 17, 2006 11:05 AM 200 SPECIFICATIONS Fastener Sizes and Types The pitch of metric fasteners is measured by determining the millimeters per thread. For The first and most important fact that the example, a bolt with 0.8 pitch would have 125 mechanic must know about a fastener is whether complete threads in a 100-millimeter section it is a U.S. -

Page 37: Torque Specifications

5-101.bk Page 7 Friday, March 17, 2006 11:05 AM 200 SPECIFICATIONS TORQUE SPECIFICATIONS This section includes specifications for torquing all critical and standard non-critical fasteners. Torque Specifications for Critical Fasteners Torque Description Lb-Ft N•m Air compressor-to-cylinder block screw Auxiliary driveshaft gear nut (front) 300 dry Auxiliary driveshaft hole cover stud nut Auxiliary driveshaft thrust washer-to-block screw... - Page 38 5-101.bk Page 8 Friday, March 17, 2006 11:05 AM 200 SPECIFICATIONS Torque Specifications for Critical Fasteners (Cont.) Torque Description Lb-Ft N•m Engine turnover bracket screw Exhaust manifold-to-cylinder-head stud nut 10 mm 55 dry 12 mm 65 dry Fan drive pulley to hub Flywheel housing-to-cylinder block screw Flywheel-to-crankshaft screw Fuel filter bracket-to-inlet manifold screw...

- Page 39 5-101.bk Page 9 Friday, March 17, 2006 11:05 AM 200 SPECIFICATIONS Torque Specifications for Critical Fasteners (Cont.) Torque Description Lb-Ft N•m Oil fill hole cover screw Oil filler/tube drain-to-block screw Oil filter bracket-to-cylinder block screw Oil filter valve plunger spring cap Oil pan-to-cylinder block screw Oil pump driven gear retaining nut Oil pump-to-cylinder block mounting screw...

-

Page 40: Torque Specifications For Hose Clamps

5-101.bk Page 10 Friday, March 17, 2006 11:05 AM 200 SPECIFICATIONS Torque Specifications for Critical Fasteners (Cont.) Torque Description Lb-Ft N•m V-MAC components (cont.) Lower support bracket-to-cylinder block capscrews Upper support bracket-to-injection pump capscrews Timing event marker (TEM) V-MAC 7-pin pump connector Bracket-to-block capscrews Hose clamp screw RPM/TDC (engine position) sensor (jam nut) -

Page 41: Torque Specifications For Pipe Plugs

5-101.bk Page 11 Friday, March 17, 2006 11:05 AM 200 SPECIFICATIONS Torque Specifications for Pipe Plugs Torque Pipe Plugs Lb-Ft N•m 1/8 NPT 1/4 NPT 24.4 3/8 NPT 1/2 NPT 3/4 NPT 1 NPT 1-1/2 NPT ® NOTE: All pipe plugs which are not new plugs with preapplied thread sealer must be sealed using Loctite PST pipe thread sealant with Teflon or equivalent. - Page 42 5-101.bk Page 12 Friday, March 17, 2006 11:05 AM 200 SPECIFICATIONS Torque Specifications for Non-Critical Fasteners (Cont.) PROPERTY CLASS 8.8 (Cont.) Tightening Torques Size (mm) Pitch Lb-Ft N•m 3.50 1136 2.00 1250 1695 3.50 1140 1546 3.00 1551 2103 4.00 1465 1986 PROPERTY CLASS 9.8...

- Page 43 5-101.bk Page 13 Friday, March 17, 2006 11:05 AM 200 SPECIFICATIONS Torque Specifications for Non-Critical Fasteners (Cont.) PROPERTY CLASS 10.9 Tightening Torques Size (mm) Pitch Lb-Ft N•m 0.75 1.00 1.00 1.25 1.25 1.50 1.25 1.75 1.50 2.00 1.50 2.00 1.50 2.50 1.50 2.50...

-

Page 44: Fits And Limits

SECT2.FR5 Page 14 Tuesday, March 21, 2006 12:43 PM 200 SPECIFICATIONS FITS AND LIMITS The specifications listed are for new parts. Good judgement, experience and sound shop practice must be used when determining whether to reuse or replace service parts. Fits and Limits Standard Size or Fit Component... - Page 45 SECT2.FR5 Page 15 Tuesday, March 21, 2006 12:43 PM 200 SPECIFICATIONS Fits and Limits (Cont.) Standard Size or Fit Component English Metric CONNECTING ROD (CONT.) Side clearance 0.007–0.014 in. 0.1778–0.3556 mm Twist within 12 inches (30.48 cm) 0.010 in. 0.254 mm Bend within 12 inches (30.48 cm) 0.004 in.

- Page 46 5-101.bk Page 16 Friday, March 17, 2006 11:05 AM 200 SPECIFICATIONS Fits and Limits (Cont.) Standard Size or Fit Component English Metric CYLINDER HEAD (CONT.) Injection nozzle holder insert to bore fit — upper and intermediate 0.001–0.003 in. tight 0.0254–0.0762 mm —...

- Page 47 5-101.bk Page 17 Friday, March 17, 2006 11:05 AM 200 SPECIFICATIONS Fits and Limits (Cont.) Standard Size or Fit Component English Metric FLYWHEEL AND HOUSING Dowel pins Hole in flywheel housing — LH for round pin 0.6259–0.6263 in. 15.8979–15.9080 mm —...

- Page 48 Maximum 0.1143 mm NOTE: Refer to MACK branch or distributor for specifications for piston ring part numbers not listed above. NOTE: For every 0.001 in. (0.0254 mm) increase in gauge diameter, ring gap will increase by 0.003 in. (0.076 mm).

- Page 49 5-101.bk Page 19 Friday, March 17, 2006 11:05 AM 200 SPECIFICATIONS Fits and Limits (Cont.) Standard Size or Fit Component English Metric TURBOCHARGER Model S3B (S4D) Shaft end play 0.003–0.006 in. 0.0762–0.1524 mm Bearing radial check (measured at bearings) 0.018–0.030 in. 0.4572–0.7620 mm (0.018–0.025) in (0.4572–0.6350 mm)

-

Page 50: Metric Mismatch

5-101.bk Page 20 Friday, March 17, 2006 11:05 AM 200 SPECIFICATIONS METRIC MISMATCH Inch Nuts Metric Screws 5-40 M3 x 0.5 1/4-20 M6 x 1.0 *1/4-28 M6 x 1.0 Certain metric/English fastener thread combinations are incompatible and may *5/16-24 *M8 x 1.0 result in mismatch conditions. -

Page 51: Inch Thread Vs. Metric Thread Fastener Combinations Contributing To Assembly Weakness

5-101.bk Page 21 Friday, March 17, 2006 11:05 AM 200 SPECIFICATIONS Inch Thread vs. Metric Thread Incompatible Metric vs. Metric Fastener Combinations Fastener Systems Contributing to Assembly Thread mismatch can also result when combining Weakness fasteners from incompatible metric fastener systems. -

Page 52: Special Tools

5-101.bk Page 22 Friday, March 17, 2006 11:05 AM 200 SPECIFICATIONS SPECIAL TOOLS Special Tool List Tool No. Description Midget Seal Tool 022001 Jacobs Thickness Gauge, 0.060 inch (1.52 mm) 018781 Jacobs Thickness Gauge, 0.080 inch (2.03 mm) 014177 Jacobs Thickness Gauge, 0.085 inch (2.16 mm) 021327 Jacobs Thickness Gauge, 0.100 inch (2.54 mm) 945-6041... - Page 53 5-101.bk Page 23 Friday, March 17, 2006 11:05 AM 200 SPECIFICATIONS Special Tool List (Cont.) Tool No. Description J 37710-A Timing Gear Cover Diamond Dowel Aligner J 37711 Flywheel Housing Diamond Dowel Aligner J 37712 Flywheel Housing/Timing Cover Locating Pin Driver J 37713 Camshaft Bushing Installation Removal Kit (Use with J 21428-01 Kit) J 37715-A...

-

Page 54: V-Mac Tools

5-101.bk Page 24 Friday, March 17, 2006 11:05 AM 200 SPECIFICATIONS Special Tool List (Cont.) Tool No. Description PT6435 Cylinder Liner/Sleeve Puller (lubricate with extreme pressure lubricant J 23444-A) PT6570-11 Dowelout, Extractor (7/16 inch) PT6575 Basic Heavy-Duty Dowelout Kit PT6587 Piston Ring Expander PT7070-A Piston Ring Compressor... -

Page 55: 200 Engine Removal

5-101.bk Page 1 Friday, March 17, 2006 11:05 AM 200 ENGINE REMOVAL ENGINE REMOVAL Page 3-1... -

Page 56: General

5-101.bk Page 2 Friday, March 17, 2006 11:05 AM 200 ENGINE REMOVAL GENERAL Using an appropriate filter wrench, remove the oil filters, fuel filters and coolant Details of the engine removal procedure vary conditioner. from one vehicle to another. This section Loosen clamps that secure the air intake provides general guidelines for removing the tube to the turbocharger and air filter. - Page 57 5-101.bk Page 3 Friday, March 17, 2006 11:05 AM 200 ENGINE REMOVAL 17. Disconnect the heater hoses and A/C 26. Remove the hood rest crossmember(s), if refrigerant lines, if applicable, from applicable. connections at the lower dash panel behind 27. Obtain the appropriate lifting equipment (bar the engine.

- Page 58 5-101.bk Page 4 Friday, March 17, 2006 11:05 AM NOTES Page 3-4...

-

Page 59: 200 Engine Disassembly

5-101.bk Page 1 Friday, March 17, 2006 11:05 AM 200 ENGINE DISASSEMBLY ENGINE DISASSEMBLY Page 4-1... -

Page 60: General

5-101.bk Page 2 Friday, March 17, 2006 11:05 AM 200 ENGINE DISASSEMBLY GENERAL This section includes step-by-step procedures for complete disassembly of the MACK E7 engine upon removal from the vehicle. Major components are removed as assemblies and overhauled in the BENCH PROCEDURES section of this manual. -

Page 61: Mounting Engine In Stand

Make sure to use lifting equipment that is rated at a capacity greater than the weight of the engine. When servicing an E7 engine with an isolating oil pan arrangement, avoid using an engine stand that supports the engine on the oil pan rail while the oil pan is still installed. - Page 62 5-101.bk Page 4 Friday, March 17, 2006 11:05 AM 200 ENGINE DISASSEMBLY 200348a Figure 4-2 — Mount Engine in Stand 1. Adapter plate J 38048 3. Engine stand J 29109 2. Capscrews 4. Capscrew Page 4-4...

-

Page 63: [271 Cb] Alternator

5-101.bk Page 5 Friday, March 17, 2006 11:05 AM 200 ENGINE DISASSEMBLY [271 CB] ALTERNATOR [215 HB] FAN ASSEMBLY Refer to Figure 4-3. Refer to Figure 4-4. 1. Loosen adjusting capscrew (2) and 1. Loosen eight fan assembly mounting nuts mounting nuts (6). -

Page 64: [231 Pb] Fuel Filter Adapter Assembly

5-101.bk Page 6 Friday, March 17, 2006 11:05 AM 200 ENGINE DISASSEMBLY [231 PB] FUEL FILTER ADAPTER ASSEMBLY Refer to Figure 4-6 1. Disconnect three fuel lines from fittings (2, 3 and 5) on fuel filter adapter assembly (1). Tag and cap all lines. 2. -

Page 65: [215 Ld] Coolant Conditioner Element

5-101.bk Page 7 Friday, March 17, 2006 11:05 AM 200 ENGINE DISASSEMBLY [215 LD] COOLANT Refer to Figure 4-8. CONDITIONER ELEMENT 3. Place a suitable container below the coolant filter area to catch any spilled coolant. Refer to Figure 4-7. 4. -

Page 66: [215 Nu] Thermostat

5-101.bk Page 8 Friday, March 17, 2006 11:05 AM 200 ENGINE DISASSEMBLY [215 NU] THERMOSTAT 2. Loosen two hose clamps (10) on the coupling (12) that connects the oil cooler Refer to Figure 4-8. supply tube (11) to the thermostat housing. 1. -

Page 67: [214 Hd] Air Inlet Manifold

5-101.bk Page 9 Friday, March 17, 2006 11:05 AM 200 ENGINE DISASSEMBLY [214 HD] AIR INLET MANIFOLD [215 NK] COOLANT MANIFOLD Refer to Figure 4-9. Refer to Figure 4-9. 1. Support the air inlet manifold sections and 1. Support the coolant manifold sections and remove 12 capscrews (9) that secure the remove 12 capscrews (5) retaining the manifold sections (6 and 8) to the cylinder... -

Page 68: [215 Dw & 219 Ep] Oil Cooler And Oil Filter Housing Assembly

5-101.bk Page 10 Friday, March 17, 2006 11:05 AM 200 ENGINE DISASSEMBLY [215 DW & 219 EP] OIL COOLER AND OIL FILTER HOUSING ASSEMBLY Unless it is necessary to repair any portion of the oil cooler or oil filter housing, remove the units as Refer to Figure 4-10. -

Page 69: [215 Sw] Water Pump

5-101.bk Page 11 Friday, March 17, 2006 11:05 AM 200 ENGINE DISASSEMBLY [215 SW] WATER PUMP [214 SD] TURBOCHARGER Refer to Figure 4-11. Refer to Figure 4-12. 1. Disconnect coolant return hose to air 1. Remove two capscrews (3) securing compressor (1) at fitting. -

Page 70: [222 Kd] Fuel Nozzle Inlet Tube Assembly

5-101.bk Page 12 Friday, March 17, 2006 11:05 AM 200 ENGINE DISASSEMBLY [222 KD] FUEL NOZZLE INLET 2. Loosen brackets (3 and 5) by removing retaining hardware. TUBE ASSEMBLY 3. Loosen tube sleeve nuts (1) and tube Refer to Figure 4-13. clamping screws at the cylinder heads and remove front (4) and rear (2) tube 1. -

Page 71: [214 Eg] Exhaust Manifold

5-101.bk Page 13 Friday, March 17, 2006 11:05 AM 200 ENGINE DISASSEMBLY [213 JB] VALVE COVER AND Refer to Figure 4-14. RISER 4. If necessary, separate fuel inlet tubes (4) from bracket assembly. Remove nuts (6) from capscrews (1) and remove clamp plate (2), insulators (3) and bracket (5). -

Page 72: [213 Lp, Nv & Lh] Rocker Arm, Valve Yoke And Push Rod

5-101.bk Page 14 Friday, March 17, 2006 11:05 AM 200 ENGINE DISASSEMBLY [213 LP, NV & LH] ROCKER ARM, VALVE YOKE AND PUSH Refer to Figure 4-16. If equipped with a Jake Brake, perform the following: 1. Remove three capscrews (6) from each actuator assembly (15). -

Page 73: [222 Kg] Nozzle Holder

5-101.bk Page 15 Friday, March 17, 2006 11:05 AM 200 ENGINE DISASSEMBLY [222 KG] NOZZLE HOLDER Special Tool Required Injection Nozzle Puller J 37093 After removing the nozzles, it is a good practice to label or tag them for reinstallation into the same cylinders. -

Page 74: [213 Ev] Cylinder Head Assembly Removal

5-101.bk Page 16 Friday, March 17, 2006 11:05 AM 200 ENGINE DISASSEMBLY [213 EV] CYLINDER HEAD ASSEMBLY REMOVAL Cylinder head assemblies are heavy. Lifting a Refer to Figure 4-18. cylinder head requires the help of an assistant or suitable lifting device. Attempting 1. -

Page 75: [212 Rb & Rh] Vibration Damper And Crankshaft Hub

5-101.bk Page 17 Friday, March 17, 2006 11:05 AM 200 ENGINE DISASSEMBLY [212 RB & RH] VIBRATION [261 CK] AIR COMPRESSOR DAMPER AND CRANKSHAFT Refer to Figure 4-20. Disconnect two coolant lines (1 and 4) from the Refer to Figure 4-19. air compressor head (2) at the fittings. - Page 76 5-101.bk Page 18 Friday, March 17, 2006 11:05 AM 200 ENGINE DISASSEMBLY Refer to Figure 4-21. 2. Taking care not to damage or lose the lubrication oil supply tube (2), remove the air 1. Remove three mounting capscrews (5) compressor by pulling it rearward out of the securing air compressor (1) to auxiliary mounting flange.

-

Page 77: [221 Gp] Injection Pump

5-101.bk Page 19 Friday, March 17, 2006 11:05 AM 200 ENGINE DISASSEMBLY [221 GP] INJECTION PUMP Refer to Figure 4-22. 1. Disconnect lubrication supply line (6) at both fittings. Tag and cap fittings. 2. Disconnect fuel lines (1, 3, 4, and 5) at the fittings. -

Page 78: [221 Cd] Econovance

A metal two-piece style drive coupling was Oil pans with isolating gaskets are secured with introduced into production on certified E7 V-MAC nuts and shouldered studs at the timing gear engines built after July 1, 1992 — beginning with cover and flywheel housing. - Page 79 5-101.bk Page 21 Friday, March 17, 2006 11:05 AM 200 ENGINE DISASSEMBLY Figure 4-25 — Oil Pan Bolt Locations 1. Studs and nuts at timing gear cover 3. Shouldered bolts along pan rails 2. Studs and nuts at flywheel housing Page 4-21...

-

Page 80: [219 Mu] Oil Pump

5-101.bk Page 22 Friday, March 17, 2006 11:05 AM 200 ENGINE DISASSEMBLY [219 MU] OIL PUMP Refer to Figure 4-26. If the oil pump must be disassembled for any reason, it will be easier to loosen the housing cover retaining capscrews (2), the screen capscrews (5), the sump capscrews (3), the cover plate capscrews (9), and the relief valve cap (8) while the pump is still secured in position. -

Page 81: [211 Rp] Timing Gear Cover

5-101.bk Page 23 Friday, March 17, 2006 11:05 AM 200 ENGINE DISASSEMBLY [211 RP] TIMING GEAR COVER Do not attempt to remove timing gear cover without removing oil pan. Doing so may result in damage to the isolating oil pan gasket. Refer to Figure 4-27. -

Page 82: [212 Cv] Auxiliary Driveshaft

5-101.bk Page 24 Friday, March 17, 2006 11:05 AM 200 ENGINE DISASSEMBLY [212 CV] AUXILIARY DRIVESHAFT Refer to Figure 4-28. 1. Remove auxiliary driveshaft gear retaining nut (1). 2. Using a hub puller such as J 21834-4A, remove auxiliary driveshaft gear (2) from the splines (5) on the end of shaft. -

Page 83: [212 Np & Lq] Piston And Connecting Rod Assembly

5-101.bk Page 25 Friday, March 17, 2006 11:05 AM 200 ENGINE DISASSEMBLY 4. Taking care not to damage camshaft or bushings, pull camshaft out of the front of the engine. Carefully guide rear of shaft through the journals. If shaft does not come out freely, ensure all valve lifters are clear of camshaft cams and journals. - Page 84 5-101.bk Page 26 Friday, March 17, 2006 11:05 AM 200 ENGINE DISASSEMBLY Refer to Figure 4-32. Refer to Figure 4-33. 3. Using a sharp knife, carefully remove any 4. Rotate crankshaft so that pistons 1 and 6 carbon at the top of the sleeves. Remove are at bottom dead center.

-

Page 85: [212 Uc] Flywheel

5-101.bk Page 27 Friday, March 17, 2006 11:05 AM 200 ENGINE DISASSEMBLY [212 UC] FLYWHEEL Refer to Figure 4-34. 1. With engine stand rotated so that engine is inverted (crankshaft horizontal), loosen all six flywheel retaining capscrews. 2. Remove two of the flywheel retaining capscrews that are opposite each other. -

Page 86: [211 Hd] Flywheel Housing

5-101.bk Page 28 Friday, March 17, 2006 11:05 AM 200 ENGINE DISASSEMBLY [211 HD] FLYWHEEL HOUSING [211 JA] MAIN BEARING CAP Refer to Figure 4-35. 1. Remove eight mounting capscrews (3) from flywheel housing (2). Before removing main bearing caps, ensure they are marked so they can be reinstalled on the 2. - Page 87 5-101.bk Page 29 Friday, March 17, 2006 11:05 AM 200 ENGINE DISASSEMBLY Figure 4-36 — Buttress Capscrew Installation 1. Main bearing cap capscrews 4. Main bearing caps 2. Buttress capscrews, 80 mm 5. Center main bearing cap 3. Buttress capscrews, 110 mm Page 4-29...

-

Page 88: [212 Hp] Crankshaft

5-101.bk Page 30 Friday, March 17, 2006 11:05 AM 200 ENGINE DISASSEMBLY [212 HP] CRANKSHAFT [219 RV] PISTON COOLING SPRAY NOZZLE Refer to Figure 4-37. 1. Using a suitable lifting device, secure a sling or crankshaft support tool around the crankshaft and lifting device hook. -

Page 89: [212 Nc] Cylinder Sleeve

5-101.bk Page 31 Friday, March 17, 2006 11:05 AM 200 ENGINE DISASSEMBLY [212 NC] CYLINDER SLEEVE 6. Remove puller from sleeve. 7. Remove crevice seal (1) from sleeve. Special Tool Required 8. Repeat steps 2 through 7 to remove remaining cylinder sleeves. Cylinder Liner/Sleeve Puller PT6435 Refer to Figures 39 and 40. - Page 90 5-101.bk Page 32 Friday, March 17, 2006 11:05 AM NOTES Page 4-32...

-

Page 91: 200 Bench Procedures

5-101.bk Page 1 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES BENCH PROCEDURES Page 5-1... -

Page 92: [211 Db] Cylinder Block

5-101.bk Page 2 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES [211 DB] CYLINDER BLOCK Cylinder Sleeve Counterbore Universal dial depth gauge PT5025, with a 3-inch stylus extension PT5052-11, is recommended for measuring the counterbore. SPECIAL TOOLS REQUIRED: Counterbore Tool PT2210 3. - Page 93 5-101.bk Page 3 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES When the entire block must be counterbored, cut It may be necessary to use a flashlight to see the the deepest bores first. This way, the tool can be cutter bit adjusting screw.

- Page 94 5-101.bk Page 4 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES 200328a Figure 5-1 — Counterbore Ledge Tool Installation 1. Cutter plate holder 10. Cutter bit adjuster 2. T-handle 11. Cutter bit 3. Capscrews, M16 x 2 x 90 12.

-

Page 95: [212 Cv] Auxiliary Driveshaft

Refer to Figure 5-2. 6. Follow steps 1 through 5 for the remaining cylinders. Early E7 engine connecting rods were machined to give rod cap bottoms a contoured appearance. Since mid-1992, connecting rod caps have had a flat, machined bottom. The rods are the same in... - Page 96 Refer to Figure 5-3. A redesigned connecting rod assembly with an added alignment sleeve feature was introduced into E7 production engines in April 1995. This connecting rod assembly has two alignment sleeves (3), one sleeve in each capscrew hole of the rod cap (1) to locate and align the cap and rod thrust faces.

-

Page 97: Special Tools Required

It is cost- efficient to replace components when rebuilding. It is essential to closely control the weight of reciprocating parts. MACK E7 connecting rods Always use genuine MACK replacement parts. fall into two weight classes. Prior to mid-1996 production, the weight classes are identified by an “M”... - Page 98 5-101.bk Page 8 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES Refer to Figure 5-5. 3. Position rod assembly in press with piston pin burnishing broach J 37718. Figure 5-4 — Wrist Pin Bushing Removal WRIST PIN BUSHING INSTALLATION Figure 5-5 —...

-

Page 99: [212 Hp] Crankshaft

5-101.bk Page 9 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES important for engine timing. The flywheel is mounted to a flange at rear of crankshaft. Two seals, one at the front and one at the rear, prevent engine lubricating oil from leaking around ends of the crankshaft. -

Page 100: Inspection

90 degrees apart, and record new.) measurements. 6. Check measurements against specifications Effective May 1993, all E7 engine crankshafts are in the FITS AND LIMITS section of this equipped with flywheel-to-crankshaft dowel manual. 183GC238 installed in the rear flange. Prior to this date, only V-MAC engine crankshafts had the 183GC238 dowel. - Page 101 5-101.bk Page 11 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES All new service replacement crankshafts, short Crankshafts used in early mechanically governed blocks or basic engines will have a dowel pin in engines, part No. 4566C5127M, did not have a the crankshaft rear flange.

-

Page 102: [212 Hv] Crankshaft Gear

5-101.bk Page 12 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES [212 HV] Crankshaft Gear INSPECTION Take care not to damage gear teeth while seating gear. After inspecting the crankshaft and determining that it is serviceable, inspect crankshaft gear for 5. -

Page 103: [212 Ub] Flywheel

5-101.bk Page 13 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES CLUTCH PILOT FLYWHEEL FRICTION FACE UNDERCUT 200735a Figure 5-10 — Flywheel Resurfacing [212 UB] FLYWHEEL 1. Inspect the flywheel to determine if it Some machine shop operations can adequately requires resurfacing. -

Page 104: Special Tools Required

New piston rings are designed to further improve oil control, especially relating to particulates control. E7 piston crowns have been modified in the oil control ring groove area. During the second quarter of 1996, the oil drainback holes have been eliminated and replaced by an oil accumulator relief. -

Page 105: Inspection

5-101.bk Page 15 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES Inspection Keystone Ring Groove Check Inspect piston ring grooves, lands, piston skirt Refer to Figure 5-12. and combustion bowl for wear, scuffing, cracks or blow-by. Pistons are NOT repairable. Discard Keystone piston-ring groove gauge J 29510 piston if it is damaged. - Page 106 5-101.bk Page 16 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES For a new ring and piston, oil ring side clearance is 0.0016–0.0030 inch (0.0406–0.0762 mm). For POSITION GAUGE an old ring and piston, the clearance should not IN RING GROOVE exceed 0.0045 inch (0.1143 mm).

-

Page 107: Ring Installation

5-101.bk Page 17 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES Ring Installation Refer to Figure 5-16. 2. Stagger piston rings so that no ring gap is directly over wrist pin bore, and no ring end gaps are aligned over each other. Identification markings on rings should face top of piston. -

Page 108: [213 Ch] Camshaft

Description The piston crown, skirt and rod are marked FRONT. Be sure that rod, piston crown and skirt The gear-driven carbon steel E7 camshaft, with are properly aligned. its large journal bearing diameter of 2.689 inches (68.301 mm), provides excellent bearing unit loading and allows the use of large, durable camshaft lobes. - Page 109 5-101.bk Page 19 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES Make sure there is enough clearance between the end of the camshaft and the floor while removing the gears. Do not let camshaft fall or strike the floor when pressed from the gears. The camshaft can be bent easily, and the bend may go unnoticed.

-

Page 110: Inspection

SECT5.FR5 Page 20 Tuesday, March 21, 2006 12:49 PM 200 BENCH PROCEDURES Inspection Assembly Refer to Figure 5-19. Two methods can be used to assemble camshaft gears on a camshaft. 1. Thoroughly clean camshaft (3). Use the heat method to install new gears on a new camshaft. - Page 111 5-101.bk Page 21 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES 7. Install injection pump driving gear (5) by applying a quick, even pressure until gear bottoms onto camshaft gear. Make sure Wear protective gloves when handling heated camshaft thrust washer holes are accessible gears.

-

Page 112: [213 Ev] Cylinder Heads

(0.076–0.305 mm). Refer to Figure 5-23. 11. Thoroughly clean and degrease injection pump driving gear with a suitable contact The cylinder heads featured on 1991 and later E7 cleaner that dries rapidly and leaves no engines incorporate internal design modifications residue. - Page 113 5-101.bk Page 23 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES 1989/1990 E7 COMBUSTION SYSTEM 6-HOLE NOZZLE ORIGINAL SWIRL TIPS LEVEL 1991 AND LATER E7 COMBUSTION SYSTEM INCREASED SWIRL 8-HOLE VCO LEVEL NOZZLE TIPS 200285a Figure 5-23 — Combustion Chamber Design Refer to Figure 5-24.

-

Page 114: Special Tools Required

5-101.bk Page 24 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES 200284a Figure 5-24 — E7 Cylinder Head Special Tools Required Model MST 50 Universal Spring Tester J 22738-02 Valve Spring Keeper Remover J 29294-B Injection Nozzle Sleeve Extractor J 29880... -

Page 115: [213 Nb] Inlet And Exhaust Valve Removal

[213 NB] Inlet and Exhaust Valve VALVE STEM SEALS Removal Refer to Figure 5-26. A new valve stem seal was introduced into E7 Refer to Figure 5-25. engine production on 11/1/96, beginning with 1. Attach valve spring keeper remover J 29294-B engine serial number 6S2657. - Page 116 5-101.bk Page 26 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES Figure 5-26 — New Valve Stem Seal This new seal is recommended for all E7 engines. Refer to Figure 5-27. The single lip seal has been terminated, and as 4.

-

Page 117: [213 Ex] Cylinder Head Inspection

5-101.bk Page 27 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES When the deck is resurfaced, fire ring groove and valve seat insert dimensions must be reestablished. Correct dimensions are shown in this section. [213 EH] Fire Ring Groove DESCRIPTION Fire ring grooves are located in the machined flat 200483a... - Page 118 5-101.bk Page 28 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES FIRE RING GROOVE CUTTING PROCEDURE Refer to Figure 5-30. 2. Position cylinder head so threaded section Refer to Figure 5-29. of hold-down capscrews can be reached. 1. Place cutter base (1) on cylinder head (2). Install spacer (3), washer (2) and wing Insert hold-down capscrews into appropriate nut (1).

- Page 119 5-101.bk Page 29 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES Refer to Figure 5-31. Refer to Figure 5-32. 3. Place alignment fixture (1) over the cutter base (2) to ensure proper positioning. With fixture in place, tighten wing nuts on hold- The desired finished fire ring groove depth is down capscrews.

-

Page 120: [213 Ep] Valve Guides

5-101.bk Page 30 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES [213 EP] Valve Guides Refer to Figure 5-33. 6. Install a socket (1) and T-handle (2) on INLET AND EXHAUST VALVE GUIDE cutter head (3). Using T-handle, rotate cutter DIMENSIONS head in a clockwise direction only, applying an even downward pressure to cut fire ring... - Page 121 5-101.bk Page 31 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES INSPECTION Refer to Figure 5-36. 3. Use a depth gauge to check valve guide extension. Worn valve guides may result in poor valve-to- seat contact, valve damage or oil consumption. 1.

- Page 122 5-101.bk Page 32 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES Figure 5-38 — Checking Valve Guide Extension Refer to Figure 5-39. 5. Using valve guide reamer J 37481 (1), ream new valve guide (2) to dimension. 200295a Figure 5-37 — Valve Guide Remover J 37482 1.

-

Page 123: [213 Fb] Inlet And Exhaust Valve Seat Inserts

5-101.bk Page 33 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES 6. Thoroughly clean all metal debris from valve guide and surrounding area. 7. Install valves in cylinder head and check for binding, looseness and other conditions that may result in premature valve or valve guide failure. - Page 124 5-101.bk Page 34 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES INSPECTION Visually inspect valve seat inserts for looseness, cracks or other conditions that may result in Collet PT6390-4 is not included in basic kit improper operation. Replace as necessary. PT6391.

- Page 125 5-101.bk Page 35 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES Refer to Figure 5-42. 4. Grind a groove around inside circumference of valve seat insert. This groove should be 1. Using depth measurement tool (1), measure approximately 0.030 inch (0.762 mm) deep. distance from cylinder head surface (2) to point on insert where groove will be ground.

- Page 126 5-101.bk Page 36 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES VALVE SEAT INSERT COUNTERBORE 2. Check surface finish for smoothness. Check counterbore diameter with an inside Refer to Figure 5-45. diameter micrometer (1). Refer back to specifications listed in Figure 5-45. Valve seat at counterbore depth (3): —...

- Page 127 5-101.bk Page 37 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES If valve seat insert widths exceed specifications when grinding inserts, use a 15-degree angle grinding stone to obtain correct width. Refer to Figure 5-48. 4. After grinding is completed, thoroughly clean valve seat insert.

-

Page 128: [213 Mb] Valve Springs

142.5–157.5 lb. at 1.435 inches (64.6–71.4 kg at 36.4 mm) 3. Thread sleeve puller into end of injection nozzle holder insert. Use slide hammer to Part No. 575GC35 (E7 with Extarder) remove insert. 190–210 lb. at 1.5 inches (86.2–95.3 kg at 38.1 mm) If spring force does not meet specification, discard and install new spring. -

Page 129: [213 Fh] Valve Yoke Guide Pins

5-101.bk Page 39 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES 200306a Figure 5-51 — Injection Nozzle Holder Insert Installation Figure 5-50 — Removing Injection Nozzle Holder Insert 1. Insert 2. Nozzle sleeve installer 1. Slide hammer 2. Sleeve puller J 29880 J 29297 J 2619-01 [213 FH] Valve Yoke Guide Pins... - Page 130 5-101.bk Page 40 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES VALVE YOKE GUIDE PIN REMOVAL VALVE YOKE GUIDE PIN INSTALLATION Refer to Figure 5-52. Refer to Figure 5-53. 1. To remove pin, use valve yoke guide pin If new pin is required, use valve guide pin installer puller kit PT6575 and extractor PT6570-11 J 37809 to drive pin into cylinder head.

-

Page 131: [213 Fp] Cylinder Head Cup Plugs

5-101.bk Page 41 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES [213 FP] Cylinder Head Cup Plugs DESCRIPTION The cylinder head has two different-size cup plugs: 13/16 inch (20.64 mm) and 1-1/16 inch (26.99 mm). CYLINDER HEAD CUP PLUG INSTALLATION 1. -

Page 132: Cylinder Head Pipe Plugs

5-101.bk Page 42 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES Cylinder Head Pipe Plugs Refer to Figure 5-55. 2. Install a 1/8-inch pipe plug in top of rear CYLINDER HEAD PIPE PLUG INSTALLATION cylinder head. 1. Apply dry pipe thread sealant to pipe plug 3. -

Page 133: [213 Nb] Inlet And Exhaust Valves

The valves are also identified by letters The Pyromet exhaust valve cannot be used on “I” (30-degree inlet), “2” (20-degree inlet), E7 engines equipped with a Dynatard € engine “E” (exhaust) or “Y” (Pyromet exhaust), which are brake. The Pyromet exhaust valve head is forged in a slight depression on bottom face of 0.020 inch (0.508 mm) thicker than a... - Page 134 November 1996 which have 20-degree intake valves and seats. These valves and seats replace the 30-degree intake valves and seats in all E7 cylinder heads. The 20-degree valves and seats are 100% interchangeable with the 30-degree valves and seats, provided the seat...

-

Page 135: Inlet And Exhaust Valve Installation

5-101.bk Page 45 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES Inlet and Exhaust Valve Installation Refer to Figures 5-57 and 5-58. The following (Figures 5-57 and 5-58) show a remanufactured cylinder head assembly ID and 20-degree intake valve ID. The inlet and exhaust valve head diameters are nearly the same size. - Page 136 5-101.bk Page 46 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES 1. Lubricate the valve guides and valve stems with engine oil prior to installation. 2. Install valve spring lower washer (Roto-Coil), over valve guide. 3. Lubricate valve stem seals with engine oil and install seals using valve seal installer J 42453.

-

Page 137: [213 Lv] Valve Rocker Arm Shaft

Replace as necessary. Valve Rocker Arm Shaft Assembly Rocker Arms (Except Jacobs Engine Brake) To date, E7 and E7 EUP (E-Tech™) engines use Refer to Figure 5-62. the same rocker arms. Effective second quarter 1997, both models use a newly designed rocker... - Page 138 5-101.bk Page 48 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES 6. Assemble rocker arm retaining (coil) spring 12. Assemble rocker arm retaining (coil) spring (6) on shaft. (6) on shaft. 7. Lubricate exhaust rocker arm (5) and install 13.

-

Page 139: Valve Rocker Arm Shaft Assembly (With Jacobs Engine Brake)

5-101.bk Page 49 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES Figure 5-62 — Valve Rocker Arm Shaft Assembly (Without Engine Brake) 1. Snap ring 7. Locating screw and lock washer 2. Flat spring 8. Bracket with center threaded hole 3. - Page 140 5-101.bk Page 50 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES 4. Thread oil supply screw and O-ring (7) into 10. Place center (second) rocker arm shaft bracket and torque to 5 lb-ft (7 N•m) using bracket (4) and shaft (11) on a flat surface. torque wrench J 24405 or equivalent.

-

Page 141: Dynatard Engine Brake Solenoid

(E7 Engines with Dynatard) Refer to Figure 5-64. 1. On valve rocker arm shaft assemblies E7 engines built after January 1, 1992 and with a Dynatard engine brake, install through mid-year 1993 are equipped with a solenoid mounting adapter seal (O-ring) in Dynatard overload protection system. - Page 142 Dynatard Overload Protection System 16. Install jumper wire No. 41MR21252 to Dynatard injection pump throttle switch. INSTALLATION (E7 MECHANICAL ENGINES) 17. Install fuel injection line L-shaped bracket to stud located on right side of engine block. 1. Remove air cleaner ducting.

-

Page 143: Jacobs€ Engine Brake

The Model 680B Jake Brake engine retarder is a vehicle-slowing device designed and approved for use on MACK E7 engines. Energizing the Jake Brake effectively converts a power- Adjustment (E7 Mechanically producing diesel engine into a power-absorbing Governed Engine with Engine air compressor. -

Page 144: [215 Dw] Oil Cooler Assembly

E7 engines feature a “removable-bundle” type oil cooler. Periodic visual inspection of the oil cooler will indicate condition of gaskets, O-ring and core. -

Page 145: Disassembly

5-101.bk Page 55 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES 23 22 21 200556a Figure 5-67 — Oil Cooler Assembly 1. Gasket 15. Capscrew 2. Coolant outlet end cap 16. Washer 3. O-ring 17. O-ring 4. Mounting flange 18. -

Page 146: Inspection

5-101.bk Page 56 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES Inspection 12. Torque coolant outlet end-cap capscrews to 20 lb-ft (27 N•m) using torque wrench Refer back to Figure 5-67. J 24406 or equivalent. 1. Visually inspect housing (24) for cracks Refer to Figure 5-68. -

Page 147: [215 Sw] Water Pump

5-101.bk Page 57 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES During engine operation, the impeller spins in proportion to engine speed. The spinning impeller blades create a negative pressure (suction) at the When pressure-testing complete oil cooler water pump inlet port and a positive pressure at assembly using an in-line pressure regulator, the outlet port. -

Page 148: Inspection

5-101.bk Page 58 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES 200345a Figure 5-70 — Lubrication Oil Pump 1. Self-locking nut 8. Gasket 2. Washer 9. Inlet flange plate 3. Drive gear 10. Capscrews 4. Housing 11. Plunger 5. Key 12. - Page 149 5-101.bk Page 59 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES 6. Insert pumping gear in housing and check for free play by spinning. If any binding occurs, check housing and gear teeth for burrs, nicks, or other damage. Replace as necessary.

- Page 150 5-101.bk Page 60 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES SIDE CLEARANCE CHECK BACKLASH CHECK Refer to Figure 5-72. Refer to Figure 5-73. 1. Low Limit — Insert a 0.002-inch (0.051 mm) 1. Check backlash between driving gear (3) thickness gauge between side of gears and and driven gear (2) with thickness gauge (1).

-

Page 151: Improved "Fast Ratio" Auxiliary Driveshaft

1.5 fast ratio oil 3. Install a 1.5 fast ratio oil pump driving shaft pump driveshaft gear. gear on an old E7 oil pump. Torque retaining nut to 60 lb-ft (81 N•m). Torque cylinder A noncurrent 1.3 standard ratio E7 oil pump can block mounting screws to 40 lb-ft (54 N•m). -

Page 152: Assembly

5-101.bk Page 62 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES Assembly 7. Install cover (7) on pump and secure with capscrews. Torque to 15 lb-ft (20 N•m). Refer back to Figure 5-70. 8. Install key (5) in driving shaft and gear 1. -

Page 153: Econovance Disassembly

5-101.bk Page 63 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES Econovance Disassembly 3. Remove inner shaft assembly from rear of Econovance housing by manually guiding Refer to Figure 5-75. gear assembly outward. 1. Place scalloped drive hub (5) in a vise 4. -

Page 154: Cleaning And Inspection

5-101.bk Page 64 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES Cleaning and Inspection 1. Thoroughly clean inner sleeve and inner shaft with solvent and dry with compressed air. 2. Inspect inner sleeve and inner shaft for extreme wear, cracks or other damage. Replace as necessary. -

Page 155: Cleaning

5-101.bk Page 65 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES Cleaning Degrease tapered surfaces of injection pump MACK E7 engines equipped with Bosch P7100 camshaft and drive hub with Stoddard No. 303 or Series close-coupled injection pumps require a Loctite 75559, or an equivalent degreasing agent. -

Page 156: Installation Of Drive Hub (V-Mac Engines)

DRIVE COUPLING REMOVAL pump camshaft. A metal two-piece style drive coupling was introduced into production on certified E7 V-MAC engines built after July 1, 1992 — beginning with serial No. 2P and above. When the Celeron drive coupling requires replacement, replace with the two-piece style drive coupling. -

Page 157: [222 Kg] Injector Nozzles

5-101.bk Page 67 Friday, March 17, 2006 11:05 AM 200 BENCH PROCEDURES [222 KG] INJECTOR NOZZLES Nozzle Cleaning 1991 and later MACK E7 engines require When servicing nozzle holder assemblies, different fuel injection nozzles, nozzle holders cleaning of nozzle tips may be necessary. - Page 158 5-101.bk Page 68 Friday, March 17, 2006 11:05 AM NOTES Page 5-68...

-

Page 159: Engine Assembly

5-101.bk Page 1 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY ENGINE ASSEMBLY Page 6-1... -

Page 160: General

GENERAL This section includes step-by-step procedures for Cleaning solvent is flammable and toxic to the complete assembly of the MACK E7 engine. eyes, skin and respiratory tract. Skin and eye Major components that were overhauled in the protection is required. Avoid repeated or BENCH PROCEDURES section of this manual prolonged contact. -

Page 161: Cup Plug Replacement

5-101.bk Page 3 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY 2. Using a wire brush or rotary wheel, remove any rust, corrosion or other debris from the block. If the cylinder block is determined to be 3. Clean all other block surfaces with mineral serviceable after thorough cleaning and spirits or other suitable solvent. -

Page 162: Pipe Plug Replacement

5-101.bk Page 4 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY Pipe Plug Replacement Any rust around a pipe plug is an indication of a leak and the plug should be replaced. REMOVAL 1. Using an appropriate wrench, remove the plug. -

Page 163: [213 Cc] Camshaft Bushings

5-101.bk Page 5 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY [213 CC] Camshaft Bushings 2. Refer to the Fits and Limits chart for camshaft bushing measurement specifications. Check the recorded DESCRIPTION dimensions against the specifications. Lubrication oil is pumped into the cylinder block 3. - Page 164 5-101.bk Page 6 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY INSTALLATION Refer to Figure 6-6. Correct installation of each camshaft bushing is Each camshaft bushing is located at set very important. If a bushing is not properly distances from the thrust washer mounting aligned with both its oil supply and oil feed surface to the forward edge of the bushings.

- Page 165 5-101.bk Page 7 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY Figure 6-7 — Camshaft and Auxiliary Shaft Bushing Alignment Page 6-7...

- Page 166 5-101.bk Page 8 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY Refer to Figure 6-8. 1. Position a replacement bushing (2) against the side of the block at the No. 7 (rear) Refer to Fits and Limits chart for correct bushing bushing bore.

-

Page 167: [212 Cb] Auxiliary Driveshaft Bushing Replacement

5-101.bk Page 9 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY [212 CB] Auxiliary Driveshaft INSTALLATION Bushing Replacement DESCRIPTION Correct installation of auxiliary driveshaft The front and rear auxiliary driveshaft bushings bushings is very important. If bushings are are identical. Engine lubrication oil passing misaligned, lubrication oil will not be allowed to through the No. - Page 168 5-101.bk Page 10 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY 5. Check the bushing surface for burrs caused by installation. Refer to the Fits and Limits chart in this manual for correct bushing ID dimensions. 6. Using an inside micrometer or telescope gauge, measure the ID of the bushing to ensure against using an undersize bushing.

-

Page 169: [212 Nc] Cylinder Sleeve

4. Apply approximately a 1/8-inch (3.18 mm) for satisfactory sleeve life and head gasket seal. bead of RTV silicone (Mack Silastic 342SX32, Dow Corning Silastic RTV732, or The cylinder sleeves are a wet-dry design, made General Electric RTV130) around the of centrifugal cast iron. - Page 170 5-101.bk Page 12 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY Clean any RTV from around the bottom of the cylinder sleeve and the block which may have been pressed between the block and sleeve during installation. 7. After the cylinder sleeve is fully seated, use depth gauge J 26948 or equivalent to check flange height above the deck dimensions.

- Page 171 5-101.bk Page 13 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY Refer to Figure 6-13. HONING THE CYLINDER SLEEVE BORE 8. Using dial bore gauge J 5347-B or equivalent, check the cylinder sleeve for out- of-round and taper limit. Take readings in Engines produced since mid-year 1992 have two directions, 90 degrees apart, at each of finer, more precisely finished cylinder sleeves.

-

Page 172: [219 Rv] Piston Cooling Spray Nozzle

The two-piece piston design uses two types of cooling. A unique splash and forced piston cooling system first appeared on the 1991 E7 engine. Precise targeting of the piston cooling spray provides adequate cooling to the piston crown and fills the four oil reservoirs located in the top of the piston skirt. -

Page 173: Piston Cooling Nozzle Spray Positioning

5-101.bk Page 15 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY Piston Cooling Nozzle Spray Positioning Always replace a badly deformed spray nozzle. Refer to Figure 6-16. Do not attempt to realign it. Precise targeting is necessary to adequately cool the piston crown. The piston cooling oil spray location on the underside of the piston is important;... - Page 174 5-101.bk Page 16 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY Refer to Figure 6-17. 1. Using piston cooling nozzle spray position set J 37721-A (pre-1991) or J 39045 (1991 and later), check the direction of the spray from the nozzles. 2.

-

Page 175: [211 Ha] Cylinder Block Dowel Pins

5-101.bk Page 17 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY [211 HA] CYLINDER BLOCK DOWEL PINS The dowels used for timing gear cover installation Description are similar except for the size. The smaller dowels are used for the timing cover. The larger dowels are used for the flywheel housing. - Page 176 5-101.bk Page 18 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY DIAMOND-SHAPED DOWEL PIN BLADE-TYPE DOWEL PIN INSTALLATION INSTALLATION 1. Position the round end of the blade-type dowel pin into the dowel pin hole in the Refer to Figure 6-19. cylinder block.

-

Page 177: [212 Hp] Crankshaft

5-101.bk Page 19 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY [212 HP] CRANKSHAFT 3. Place the upper half of the bearing insert in the block bore, making sure that the locating tab fits into the notch provided. Installation 4. -

Page 178: [212 Hh] Main Bearing Cap

210 lb-ft (285 N m) using torque wrench J 24407 or equivalent. Unfinished main bearing caps are available for servicing of E7 engines. These are undersize bore bearing caps for service rebore: Use standard thickness thrust washers initially. Cap, Intermediate and Front Main Bearing (Semi-Finished), No. - Page 179 5-101.bk Page 21 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY The thickness of the thrust washers used in the bearing cap must match the thickness of the thrust washers in the block. Be sure to put the bearing surface of the thrust washer against the crankshaft when installing thrust washers.

- Page 180 5-101.bk Page 22 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY Refer to Figure 6-22. 5. Remove capscrews and cap, and check the bearing running clearance. 1. Use Plastigage to check the main bearing clearance. Check each bearing, one at a 6.

-

Page 181: [212 Np & 212 Lp] Pistons And Connecting Rods

Piston Ring Compressor J 23442 or Piston Ring Compressor PT7070-A Description Since 1991, all E7 engines have used a two- piece piston. To ensure a continued high level of piston durability, the piston crown is made of forged steel and the piston skirt is made of cast aluminum. -

Page 182: Installation

200 ENGINE ASSEMBLY Installation Refer to Figure 6-24. MACK E7 6-cylinder engines use a special type 1. Rotate crankshaft so that the journals for the of connecting rod bearing. Each bearing half has No. 1 and No. 6 cylinders are at bottom dead a different thickness. - Page 183 5-101.bk Page 25 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY CHECKING RUNNING CLEARANCE 1. Place a section of Plastigage on the cap bearing and assemble cap to rod. Do not force the piston. This indicates an incorrectly aligned ring. Remove piston, correct 2.

-

Page 184: [211 Hd] Flywheel Housing

Beginning in 1991, flywheel and flywheel housings for E7 engines equipped with standard transmissions incorporate engine timing and engine turnover features. In addition, new procedures and tools were introduced and must be used to ensure optimum performance, engine durability and emission compliance. -

Page 185: Capscrews (Flywheel Housing)

For capscrews should be installed in various flywheel all new-style housings used on the E7 engine, housings. use the following mounting hardware: Refer to Figure 6-26. - Page 186 5-101.bk Page 28 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY Figure 6-26 — Flywheel Housing Bolts Page 6-28...

-

Page 187: Installation

5-101.bk Page 29 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY Installation 4. Apply an even coat of Silastic (approximately a 1/16-inch [2 mm] bead) to 1. Remove the rear crankshaft oil seal from the the flywheel housing mounting surface of the flywheel housing by drilling two 3-mm holes cylinder block. -

Page 188: Runout

5-101.bk Page 30 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY 6. Install the exposed flywheel mounting capscrews and tighten them finger tight. 7. Torque all flywheel housing capscrews to 170 lb-ft (231 N m) using torque wrench J 24407 or equivalent. Refer to Figure 6-30. Figure 6-30 —... -

Page 189: [212 Jh] Crankshaft Wear Ring

5-101.bk Page 31 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY [212 JH] CRANKSHAFT WEAR RING When the service oil seal is to be replaced and the crankshaft flange is worn, the crankshaft can be salvaged by installing a crankshaft wear ring. An oil seal with a larger inside diameter is used with this wear ring. -

Page 190: Wear Ring With Double-Lip Teflon Seal (Automatic Transmission)

5-101.bk Page 32 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY Wear Ring with Double-Lip Teflon 1. Position wear ring in the spring clips of the wear ring installer J 38880 with the arrow Seal (Automatic Transmission) pointing away from the installer tool. The oversize inside diameter lip seal and wear ring are shipped as an assembly, with the seal installed on the wear ring. -

Page 191: [212 Jh] Crankshaft Rear Oil Seal

Viton or Teflon. Viton seals are available with 2. Oil seal an oversized inside diameter and the wear ring is installed in the seal. E7 engines with wet flywheel 3. Using the three guide pins, attach the housings (automatic transmission) use double-lip adapter plate to the crankshaft flange. - Page 192 5-101.bk Page 34 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY 4. Determine the seal and wear ring installation 5. The two installation depths are stamped depth: above two of the guide pin bores of the installation tool press plate. To install the New seal on new crankshaft —...

-

Page 193: Description

5-101.bk Page 35 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY [212 VC] FLYWHEEL (E7 ENGINE WITHOUT POINTER ON TIMING COVER) Description The flywheel has a stamped timing scale of TDC to 45 degrees of engine travel for setting and checking injection pump to engine timing. -

Page 194: Installation

5-101.bk Page 36 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY Installation 4. Torque the capscrews to 185 lb-ft (251 N m), alternating from opposite sides to apply even pressure to the flywheel (use torque wrench J 24407 or equivalent). After resurfacing, any flywheel with drilled balance holes on the clutch side requires rebalancing by a machine shop. -

Page 195: [213 Ch] Camshaft

Description Camshaft Removal/Installation Tool J 41461 Refer to Figure 6-42. Inspection The E7 camshaft design uses large journals to 1. Thoroughly clean the camshaft. decrease bearing loading and to allow for larger, 2. Inspect the camshaft cam lobes. Replace more durable cam lobes. In addition, the profile of... -

Page 196: Installation (Engine In Stand)

5-101.bk Page 38 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY Installation (Engine in Stand) 4. Lubricate the camshaft journals and the camshaft bearing surfaces with clean engine 1. With the cylinder block in the stand, rotate oil. the stand so that the crankcase is upward (engine inverted). -

Page 197: Installation (Engine In Chassis)

5-101.bk Page 39 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY Installation (Engine in Chassis) J 37720-B In order to use the valve lifter tool to hold the valve lifters in position, the cylinder heads must be installed on the engine. Arrange valve lifters so that they can be identified and reinstalled into the same hole from which they came. - Page 198 5-101.bk Page 40 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY 7. Lubricate camshaft journals and camshaft Refer to Figure 6-48. bearing surfaces (in cylinder block) with 9. Secure camshaft captured thrust washer to clean engine oil. the block using the two patch-lock 12-point capscrews (3) and hardened washers.

-

Page 199: [212 Cv] Auxiliary Driveshaft

5-101.bk Page 41 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY [212 CV] AUXILIARY Installation DRIVESHAFT Fast Ratio, 1.5:1, part No. 453GC381M (18 teeth) Standard Ratio, 1.3:1, part No. 453GC379AM (17 teeth) Current production engines (effective February 27, Refer to Figure 6-49. 1992, serial No. -

Page 200: [219 Mu] Oil Pump

5-101.bk Page 42 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY [219 MU] OIL PUMP Refer to Figure 6-50. 3. Install thrust washer (4) and secure it in Description position with the patch-lock capscrews (3) and hardened washers. The oil pump is a gear-type pump. As the pump 4. -

Page 201: Installation

5-101.bk Page 43 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY Installation 2. Secure the pump in position using the mounting capscrews (2). Torque the Refer to Figure 6-51. mounting capscrews to 40 lb-ft (54 N m) using torque wrench J 24407 or equivalent. 1. -

Page 202: [211 Rp] Timing Gear Cover

— Plate, 15 lb-ft (20 N m) For all E7 engines that do not use the front — Sump, 35 lb-ft (47 N m) timing boss, a new timing gear cover (No. -

Page 203: [211 Sb] Timing Gear Cover Seal

2. Position the tool over hub and into the seal opening. Replace the hub if the seal shows signs of wear. Mack Trucks, Inc. does not recommend the use of a service sleeve to repair the crankshaft hub when there is hub damage. When there is damage to the hub, replace it. -

Page 204: [212 Rb] Vibration Damper

[211 NB] OIL PAN Description (Isolating Oil Pan [212 RB] VIBRATION DAMPER Gasket on E7 Engines) Description Reducing oil pan vibration is an important step in reducing engine noise and ensuring oil pan The vibration damper is mounted to the front of... - Page 205 5-101.bk Page 47 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY Other changes include the use of new shouldered reducing the amount of engine vibration oil pan bolts which bottom on the cylinder block transmitted to the pan. rather than the oil pan, and rubber isolators installed between the heads of the pan bolts and The illustration below, Figure 6-54, shows both the oil pan.

- Page 206 5-101.bk Page 48 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY With the new isolating oil pan gasket arrangement, the mounting holes tapped into the cylinder block, timing gear cover, and flywheel The fiber oil pan gasket can be used on engines housing are now 8 mm rather than 10 mm.

- Page 207 The isolating oil pan gasket contains 12 integral locating/retaining cones which lock into holes drilled through the oil pan rails, and two large When servicing an E7 engine with an isolating oil rectangular tabs located directly across from pan arrangement, avoid using an engine stand each other on the inner perimeter of the gasket.

-

Page 208: Oil Pan Installation

CYLINDER BLOCKS the other hand until seated. Continue this procedure for the remaining locating cones. Part numbers for E7 cylinder blocks with 8-mm tapped holes in the pan mounting rail are listed 5. After all cones have been installed, recheck below. -

Page 209: [213 Ev] Cylinder Heads

1994 two standard studs, certified E7-427 and E7-454 engines. This timing No. 107AM5019M, and two flange-head cover is used in conjunction with the isolating oil nuts, No. 191AM2, to attach the oil pan... -

Page 210: Installation

Refer to the TROUBLESHOOTING section for Proper Fire Ring/Cylinder Top Combinations. All MACK head gaskets are precoated and do not require any type of additional sealing compound. 3. Position the completely assembled cylinder heads on the cylinder block. - Page 211 5-101.bk Page 53 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY Several of the head mounting capscrews have Do not install painted capscrews at locations that threaded holes drilled in the heads for bracket- are under the valve cover. mounting purposes.

- Page 212 5-101.bk Page 54 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY Refer to Figure 6-60. 7. Perform the engine run-in procedure, bringing temperatures up to the normal 6. Torque all head mounting capscrews in operating range. three stages to the specified torque. 8.

-

Page 213: [222 Kg] Nozzle Holder Assembly

5-101.bk Page 55 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY [222 KG] NOZZLE HOLDER 2. Lubricate the nozzle holder surface and install O-ring on the nozzle holder. ASSEMBLY 3. Thread injection nozzle puller J 37093 into the top of nozzle holder. Refer to Description Figure 6-62. - Page 214 5-101.bk Page 56 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY 4. Insert nozzle holder in the nozzle holder If the gauge block is too high, it may hole. Be sure to align the locator ball in the indicate that there are two gaskets nozzle holder with the socket in the cylinder installed under the nozzle holder, or the head to ensure inlet tube alignment.

-

Page 215: [213 Lh] Valve Lifter Push Rods

Refer to Figure 6-67. Do not use non-current valve lifter to service current valve lifter. The current E7 valve lifter has no hole in the center of the stem. In conjunction with this Only Dynatard exhaust push rods are not... -

Page 216: Installation

5-101.bk Page 58 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY All E7 production engines starting with serial Refer to Figure 6-68. No. 2X0000 and above, feature valve lifters with 1. Lubricate the yoke guide pins (5) with clean no hole as well as inlet and nonbrake push rods engine oil. -

Page 217: [213 Lp] Rocker Arms

Jacobs engine brake installation. upward in the rocker arms. If extended far below Using a MACK or any other type of screw will rocker arm, the push rods can be bent when result in severe screw wear and engine damage. -

Page 218: Brake Housing Installation

5-101.bk Page 60 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY Brake Housing Installation 2. Check that all push rods are in their sockets and rocker adjusting screws are backed out to prevent piston damage or bent rods. Refer back to Figure 6-70. 3. -

Page 219: [213 Jb] Valve Cover

Cylinder head cover (No. 337GB494M2) used on E7, CH 4 x 2 models with Jake Brake and air conditioning, contacts the air-conditioning expansion valve (mounted on the cab fire wall) during articulation. -

Page 220: [214 Eg] Exhaust Manifold

(103 mm long), each stud requires a spacer. When installing a low-boss exhaust manifold on a pre-1992-1/2 E7 V-MAC engine with injection line brackets fastened to the exhaust manifold, spacer and 113 mm studs are required. - Page 221 5-101.bk Page 63 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY Figure 6-73 — Typical Exhaust Manifold Installation Page 6-63...

-

Page 222: [215 Nk] Coolant Manifold

5-101.bk Page 64 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY [215 NK] COOLANT MANIFOLD 3. Place couple (2) in position on the couple mounting flange. Place two clamps (3) over Inspection the couple. 4. Insert the rear manifold section (4) in the Check the coolant manifold sections for couple. -

Page 223: [261 Ck] Air Compressor

5-101.bk Page 65 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY [261 CK] AIR COMPRESSOR Installation If the oil supply tube is lost, the air compressor will fail from lack of oil. Refer to Figure 6-75. 1. Install a new gasket on the air compressor 3. -

Page 224: [221 Cd] Econovance

5-101.bk Page 66 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY [221 CD] ECONOVANCE [221 GP] FUEL INJECTION PUMP Installation Installation Refer to Figure 6-76. 1. Lubricate with clean engine oil and then This procedure is described and illustrated with install O-ring in groove on front of pump-to-Econovance adapter installed on pump. - Page 225 5-101.bk Page 67 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY 3. Loosen the two upper support bracket-to- fuel injection pump capscrews. 200441a Figure 6-78 — Installing Outer Coupling 200443a Figure 6-80 — Outer Upper Support Capscrew 2. Loosen the three injection pump rear support bracket-to-cylinder block capscrews.

- Page 226 5-101.bk Page 68 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY 5. With the fuel injection pump positioned over 7. Install and torque the remaining fuel the alignment dowels, in one motion, lift the injection pump adapter mounting capscrews rear of the pump and slightly rotate the to 40 lb-ft (54 N m) using torque wrench Econovance hub.

- Page 227 5-101.bk Page 69 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY 9. Torque the three lower support bracket-to- 10. Torque the two upper support bracket-to-fuel cylinder block capscrews to 40 lb-ft injection pump capscrews to 15 lb-ft (54 N m) using torque wrench J 24407 or (20 N m) using torque wrench J 24407 or equivalent.

-

Page 228: [222 Kd] Fuel Nozzle Inlet Tube Assembly

5-101.bk Page 70 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY [222 KD] FUEL NOZZLE INLET 5. Tighten all fuel inlet tube assembly clamping screws to 35 lb-ft (48 N m) torque using TUBE ASSEMBLY torque wrench J 24407 or equivalent. Installation Refer to Figure 6-88. - Page 229 5-101.bk Page 71 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY 200353a Figure 6-88 — Fuel Nozzle Inlet Tube Assembly Installation 1. Nozzle fuel inlet tube and sleeve nut 7. Oil filler feed tube 2. Rear fuel inlet tube assembly 8.

-

Page 230: [214 Sc] Turbocharger

5-101.bk Page 72 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY [214 SC] TURBOCHARGER retaining nuts to 90 lb-in (10 N m) using torque wrench J 5853-C or equivalent. Then make certain that all ducting aligns closely with the Installation (Includes Pre-Lubing turbocharger. -

Page 231: [215 Nu, Ng & Ld] Thermostat, Thermostat Housing, Thermostat Seal And Coolant Conditioner

5-101.bk Page 73 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY [215 NU, NG & LD] THERMOSTAT, THERMOSTAT HOUSING, THERMOSTAT Wherever possible, an arbor press should be used to apply assembly pressure. Do not apply SEAL AND COOLANT hammer blows or uneven pressure directly to CONDITIONER seal surfaces. - Page 232 5-101.bk Page 74 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY Figure 6-90 — Thermostat Housing Installation 1. Capscrew 8. Gasket 2. Coolant conditioner head assembly 9. Coolant manifold 3. Check valve 10. Clamps 4. O-ring 11. Oil cooler supply tube 5.

-

Page 233: [214 Hd] Air Inlet Manifold

5-101.bk Page 75 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY [214 HD] AIR INLET MANIFOLD Refer back to Figure 6-74. 1. Place the front air inlet manifold section (8) into position on the cylinder head and insert the 12-point capscrews (9) and washers. 2. -

Page 234: [215 Sw] Water Pump

5-101.bk Page 76 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY [215 SW] WATER PUMP Installation Refer to Figure 6-92. Water pump-to-housing mounting capscrews should not be lubricated before installation. Instead, apply thread sealing compound to all water pump-to-water pump housing capscrews. Also apply thread sealing compound to water pump housing (pump outlet) to block capscrews. -

Page 235: [215 Dw & 219 Ep] Oil Cooler And Oil Filter Head

5-101.bk Page 77 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY [215 DW & 219 EP] OIL COOLER AND OIL FILTER HEAD Assembling a New Oil Filter Adapter The oil filter head does not come as a complete assembly, so the fittings, nipples, spuds, etc., must be installed before installing the filter head onto the engine. -

Page 236: Installation

5-101.bk Page 78 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY Installation 9. Tighten clamps (3). Torque to 38 lb-in (4.3 N m). Refer to Figure 6-94. 10. Connect Centri-Max™ filter breather hose 1. Lubricate the oil cooler supply tube (5) with (6) to the breather hose fitting (7). - Page 237 5-101.bk Page 79 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY 200654a Figure 6-94 — Oil Cooler and Oil Filter Head Installation 1. Capscrew 8. Oil hose 2. Water pump mounting flange 9. Fitting 3. Clamps 10. Capscrew 4. Coupling 11.

-

Page 238: [271 Cb] Alternator

5-101.bk Page 80 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY [271 CB] ALTERNATOR Fan Belt(s) ADJUSTMENT Installation 1. For consistent measurements, use belt tension gauge tool BT3373-F to check the Refer to Figure 6-95. belt tension. 1. Install the alternator plate (5) and mounting 2. - Page 239 5-101.bk Page 81 Friday, March 17, 2006 11:05 AM 200 ENGINE ASSEMBLY UPPER MOUNTING (TENSION) BOLT TORQUE TO 60–70 LB-FT (81–95 N•m) LOWER MOUNTING BOLTS, TORQUE TO ENGINE 60–70 LB-FT (81–95 N•m) 205234a Figure 6-96 — Engine Belt Arrangement Page 6-81...

- Page 240 5-101.bk Page 82 Friday, March 17, 2006 11:05 AM NOTES Page 6-82...

-

Page 241: Setup And Adjustments

5-101.bk Page 1 Friday, March 17, 2006 11:05 AM 200 SETUP AND ADJUSTMENTS SETUP AND ADJUSTMENTS Page 7-1... -

Page 242: [213 Nb] Valve Yoke And Valve Lash Adjustments (Non-Jake Brake Engine And Dynatard Equipped)

Yoke and valve adjustments are done in two stages on E7 engines. Adjust the yoke clearance Some E7 engines built in early 1995 may be first, then adjust the valve lash. Make sure both equipped with flywheels that have missing or adjustments are done in firing order sequence. -

Page 243: Valve Yoke Adjustment

5-101.bk Page 3 Friday, March 17, 2006 11:05 AM 200 SETUP AND ADJUSTMENTS Valve Yoke Adjustment After verifying that there is a clutch mounting bolt/ bolt hole in line with the TC mark, the next step is to locate the three locations where the valve adjustment marks should be. - Page 244 5-101.bk Page 4 Friday, March 17, 2006 11:05 AM 200 SETUP AND ADJUSTMENTS Figure 7-2 — Flywheel Marks 2. Back off the valve rocker adjusting screws. 3. Loosen the No. 1 cylinder yoke adjusting screw locknuts. 4. Exert moderate force on the yoke by pressing on the rocker arm slipper end.

-

Page 245: Inlet Valve Adjustment

5-101.bk Page 5 Friday, March 17, 2006 11:05 AM 200 SETUP AND ADJUSTMENTS CHECKING YOKE ADJUSTMENT Refer to Figure 7-4. 1. Insert a 0.010-inch (0.254 mm) thickness gauge between the yoke and valve stem, at both the inboard and outboard locations. 2. -

Page 246: Continuation Of Adjustments

TC through 45 degrees of crankshaft rotation for setting and checking pump- to-engine timing. Also, the flywheel has three stamped valve setting locations. E7 engine firing order is 1 - 5 - 3 - 6 - 2 - 4. Page 7-6... -

Page 247: Housing Identification

WEDGE RAMP YOKE ADJUSTING SCREW YOKE E7 engine firing order is 1 - 5 - 3 - 6 - 2 - 4. WEDGE RAMP The Jacobs exhaust valve yoke originally used a valve yoke screw with SAE threads. MACK yokes had metric threads. -

Page 248: Special Tools Required

5-101.bk Page 8 Friday, March 17, 2006 11:05 AM 200 SETUP AND ADJUSTMENTS Special Tools Required CHECKING YOKE ADJUSTMENT 1. To check the yoke adjustment, insert a Jacobs feeler gauges: 0.010-inch (0.254 mm) thickness gauge between the yoke and valve stem, at both 0.060 inch (1.52 mm) No. -

Page 249: Slave Piston, Inlet Valve And Exhaust Valve Lash Adjustments

VALVE aligns with the TC mark on the vibration damper, if equipped). This provides the 30 degrees after TDC relationship for valve lash adjustment necessary with the E7 valve design. Inlet Valve Adjustment Inlet valve lash clearance is 0.016 inch (0.406 mm). -

Page 250: Slave Piston Adjustment

Jacobs feeler gauge. Readjust as necessary. * Refer to 200 APPENDIX (at the back of this manual) for list of selected 1990 E7 engine serial numbers requiring 0.080-inch (2.05 mm) thickness gauge No. 017099 for 1. Loosen the No. 1 cylinder slave piston slave piston adjustment. -

Page 251: Continuation Of Adjustments

2. Adjust the yoke, valves and slave piston lash as previously outlined for the No. 1 cylinder. 200402a Figure 7-12 — Fixed Timing Method E7 engine firing order is 1 - 5 - 3 - 6 - 2 - 4. Make sure key is off. Page 7-11... - Page 252 The engine must be timed during the compression stroke of cylinder No. 1. The injection pump driven gear capscrews on factory-assembled E7 engines come in three different head sizes (15 mm, 16 mm or 17 mm). All four capscrews on a given engine will be the same and the torque is the same for all three head sizes: 40 lb-ft (54 N•m).

-

Page 253: Special Tools Required

5-101.bk Page 13 Friday, March 17, 2006 11:05 AM 200 SETUP AND ADJUSTMENTS Accurately setting the injection pump timing is the Thoroughly clean all residue from the fixed timing best way to ensure optimum fuel economy, port threads (timing access window) before engine durability, and maintain engine exhaust installing tool sensor. - Page 254 5-101.bk Page 14 Friday, March 17, 2006 11:05 AM 200 SETUP AND ADJUSTMENTS 3. Clean the J 37077 tool sensor probe points with compressed air before using. This helps prevent metallic contamination between the sensor probe points. J 37077 200405a Figure 7-17 —...

-

Page 255: Fuel Injection Pump Driven Gear Installation

J 38740 injection pump can be removed from the engine. ENGINE WITH REAR TIMING INDICATOR E7 mechanically governed engines with manual transmissions and all V-MAC engines with 200452a manual and automatic transmissions use the flatback vibration damper with no timing marks. - Page 256 5-101.bk Page 16 Friday, March 17, 2006 11:05 AM 200 SETUP AND ADJUSTMENTS 3. Install two pump drive gear alignment 5. Install two driven gear capscrews in the dowels, J 37085, to ease alignment of drive open holes. Install capscrews snugly to gear to timing gear hub.

- Page 257 5-101.bk Page 17 Friday, March 17, 2006 11:05 AM 200 SETUP AND ADJUSTMENTS J 38740 200458a Figure 7-24 — Rotating Timing Gear Hub Counterclockwise 8. Rotate timing gear hub clockwise until both A and B lamps are lit. There is only a very small band of rotation for which both lamps are lit.

-

Page 258: Checking Pump-To-Engine Timing

5-101.bk Page 18 Friday, March 17, 2006 11:05 AM 200 SETUP AND ADJUSTMENTS Checking Pump-to-Engine Timing Fuel Injection Pump Access Cover Installation To install the fuel injection pump access cover: Using hub bolt to rotate engine backward may 1. Lubricate the access cover O-ring with change bolt torque. -

Page 259: Fuel Injection Pump Pre-Lubrication

5-101.bk Page 19 Friday, March 17, 2006 11:05 AM 200 SETUP AND ADJUSTMENTS 200465a Figure 7-29 — Installing Access Cover Seal Figure 7-31 — P7100 Injection Pump/Mechanical Governor Pre-Lubrication 5. Using Midget sealing tool 814 or equivalent, compress the lead seal. To pre-lubricate the P7100 V-MAC fuel injection pump and governor, remove the timing event 6. -